Professional Documents

Culture Documents

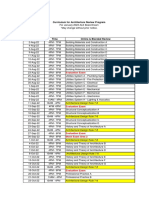

68 36 300-1-SEABC C13 Session 4 Stability 2PerPageColor

68 36 300-1-SEABC C13 Session 4 Stability 2PerPageColor

Uploaded by

elidstone@hotmail.comOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

68 36 300-1-SEABC C13 Session 4 Stability 2PerPageColor

68 36 300-1-SEABC C13 Session 4 Stability 2PerPageColor

Uploaded by

elidstone@hotmail.comCopyright:

Available Formats

1

•1

Session 4

Stability and Other Limit States

SEABC C13

Structural Steel Design

October 5, 2023

Andy Metten, P.Eng, Struct.Eng.

•2

•C13 2022- Session 4 Stability Analysis •1

Couple of Comments on

Assignments

Must be submitted as PDF.

Please don’t submit:

Word files

JPG files

A zipped folder with JPG files!

•3

Make your Life Easier

1) Keep calculations brief.

2) Use tables where possible.

3) Mark up the PDF don’t copy out questions.

(People not doing this often claim assignments

take too long – should be 1-2 hr. max).

•4

•C13 2022- Session 4 Stability Analysis •2

2nd Assignment Solution

• Couple of errors in the solution set.

• Will be reposting the solution.

•5

Aim For Today’s Session

Philosophy of limit states and see how

stability fits in with this philosophy.

Chapter 1 (Limit States Design)

Chapter 2 (Loads)

Chapter 3 (Cantilever beam stability)

Chapter 9 (P-Δ & frame stability)

6

•6

•C13 2022- Session 4 Stability Analysis •3

Roof Beam Problem from

Assignment

Downward Snow

Beam tributary length=10m

Span = 8m

Mf=36.9kN/m*(8m)2 / 8 = 295 kNm Lu=2.0m 7

•7

Downward Snow Strength

Mf=36.9kN/m*(8m)2 / 8 = 295 kNm Lu=2.0m

W 460x52 best

W 410x54 also

works

8

•8

•C13 2022- Session 4 Stability Analysis •4

Roof Beam Problem from

Assignment

Upward Wind

Beam tributary length=10m

Span = 8m

Mf=6.3kN/m*(8m)2 / 8 = 50.4 kNm Lu=8m 9

•9

Upward Wind Strength

Mf=6.3kN/m*(8m)2 / 8 = 50.4 kNm Lu=8m

.

Mr’ at 8m = 63.6kNm* = 71.8 kNm (OK)

.

W410 x 54 and

W460x52 both work

10

•10

•C13 2022- Session 4 Stability Analysis •5

Downward Snow Deflection

W410x54 I=186

8000/23.25 = 344

11

•11

Choose a Beam

Factored Factored Up Deflection

Down Lu=2 Lu=8m

W410x39 Low Strength Low Strength Too Soft

W410x46 Low Strength OK Too Soft

W410x54 OK OK L/344

W410x60 OK OK L/399

W460x52 OK OK L/392

Least weight from above list is W410x60 but

W460x52 would be a better choice. 12

•12

•C13 2022- Session 4 Stability Analysis •6

Unbraced Beams Loaded at Top Flange

Use 1.0L for this:

Use 1.2L for this:

Use 1.4L for this:

•Brace

Pt.

13

L

•13

S16-19 Clause 13.6 5 5 pages of Unbraced Beams

•b) Double

Symmetric Class 3 &

•a) Double Symmetric Class 4

• c) Closed square and round

1&2

• d) Cantilever

•e) Single

Symmetric Class 1

&2&3

•f) Biaxial Bending

•Unbraced beam segments

loaded above shear center

between brace points 14

•14

•C13 2022- Session 4 Stability Analysis •7

•Loaded above shear center

•Loaded between brace points

•Load delivery does not provide lateral restraint

•Load delivery does not provide rotational restraint

•Load applied at level of top flange and not restrained by load:

•Use 𝜔 = 1.0

•Use 1.2 L if simple supported (i.e. M=0 at ends)

•Use 1.4 L other cases (i.e. beam segment with moment at end)

15

•15

For beam with joists attached to deck

What about using formula for

If near center and Mmax ~ Ma ~ Mb ~ Mc

Get:

•𝜔 = =1

•Very important point to note: Joists are attached to

the diaphragm so at each load point the

compression flange of the beam is stabilized. 16

•16

•C13 2022- Session 4 Stability Analysis •8

Unbraced Beams Loaded at Top Flange

(Not attached to a diaphragm)

Use 1.2L for Unsupported Length:

𝜔 =1.0

Brace Pt.

Use1.4L for Unsupported Length

𝜔 =1.0

L

17

•17

Top Flange Restrained Laterally By Diaphragm

Top Flange Loaded By Deck

(Zero moment at ends of beam)

Unsupported Length = 0

𝑈𝑠𝑒 𝑀𝑟

𝐷𝑜𝑛 𝑡 𝑛𝑒𝑒𝑑: 𝜔

18

•18

•C13 2022- Session 4 Stability Analysis •9

Top Flange Restrained Laterally By Diaphragm

Top Flange Loaded Through Joists

(Zero moment at ends of beam)

Unsupported Length = L

𝑈𝑠𝑒 𝑀′ 𝜔 .𝑟

19

If Joist Spaced at 2.5m

•19

Topics for Today

1. Limit states for steel design

2. Philosophy of loads

3. Cantilever beam stability

4. Gerber framing system

5. Stability of individual elements

6. Frame stability

20

•20

•C13 2022- Session 4 Stability Analysis •10

References

CISC Handbook

Clause 9 covers stability of structures and

members

21

•21

References

Roof Framing with Cantilever (Gerber)

Girders and Open Web Steel Joists, Canadian

Institute of Steel Construction, July 1989.

Put out by CISC after Save-On roof

failure – Can only get from AISC

website now

22

•22

•C13 2022- Session 4 Stability Analysis •11

References

Guide to Stability Design Criteria for Metal

Structures (5th Edition) , Theodore Galambos,

John Wiley & Sons, July 1998.

23

•23

There is a 6th edition

Not possible

to figure

from 6th

edition some

of the points

we will

cover from

5th edition.

(C$254.70 from Amazon) 24

•24

•C13 2022- Session 4 Stability Analysis •12

Limit States for Steel

Structures

• Ultimate Limit States

• Serviceability Limit States

25

•25

Ultimate Limit States

• 1) Strength

• 2) Overturning

• 3) Sliding

• 4) Fracture (Fatigue limit state is crack propagation)

26

•26

•C13 2022- Session 4 Stability Analysis •13

Serviceability Limit States

• 1) Deflection

• 2) Vibration

• 3) Permanent deformation

27

•27

Typical Serviceability Check

• Check deflection under variable portion of

load.

– Deflection under live load.

– Deflection under snow load * (SLS=0.9)

Steel Does not creep – we do not include dead load

of structure in our deflection calculations.

(This is not wood or concrete)

28

•28

•C13 2022- Session 4 Stability Analysis •14

Compare to S16-Annex D

Consider “non-permanent” partition loading if

partitions to be added after finishes?

29

•29

Table of recommended maximums based on building type

30

•30

•C13 2022- Session 4 Stability Analysis •15

Non-Industrial Buildings

For the most part limit deflection to L/360.

L/300 will lead to complaints in quality buildings

31

•31

No guidance on combining wind

vertical loading and snow vertical

loading?

Important to do for strength but mostly just

interested in lateral wind deflections.

32

•32

•C13 2022- Session 4 Stability Analysis •16

1995 National Limit States Design

Building Code

Working Stress Design

In 1995 two

ways of

designing one

with “working

stress design”

one limit states

design.

4:15

33

•33

• Eliminated any reference to working stress

Task Force on combinations.

Wind and • They were taken out from:

– NBC 2005

Snow NBC

– NBC 2010

2005 – NBC 2015

34

•34

•C13 2022- Session 4 Stability Analysis •17

NBC 2020 – Lots of New

Material on Serviceability

20 years later

Working stress

load combinations

are back!

35

•35

Serviceability Combination Snow + Wind

Use 1.0S +0.3W

Should use the 0.9 SLS factor for snow

1.0(0.9S) + 0.3W 36

•36

•C13 2022- Session 4 Stability Analysis •18

Serviceability Limit State Protects You

If your design is too bouncy your client will

quickly forget the dollars he saved in

construction costs.

37

•37

Ultimate Limit States

What protects your building from falling down.

• Factored Resistance > Factored Loads

38

•38

•C13 2022- Session 4 Stability Analysis •19

Ultimate Limit States

Factored Resistance >

Factored Loads

Account for variability of

load with load factor.

Account for variability of

resistance with resistance factor.

39

•39

Most Useful for Gravity Load Design

Case Principal Load (2015) Companion Load

(2015)

2 (1.25D or 0.9D) +1.5L 1.0S or 0.4W

3 (1.25D or 0.9D) + 1.5S 1.0L or 0.4W

Will discuss more in a few minutes 40

•40

•C13 2022- Session 4 Stability Analysis •20

Think about the Loads

• Factored Resistance > Factored Loads

99% of your structural 1% of your structural

design effort (to many effort. Often chosen based

significant figures). on historical information

and in some cases may be

varied by 100%

41

•41

Dead Load

• Self weight of structure

• Extra for concrete on deflected structure?

• Partition load.

• Partition load not supposed to include:

– Mechanical / Electrical components

– Architectural finishes

42

•42

•C13 2022- Session 4 Stability Analysis •21

New for NBC 2020

If the building has earth and plants, we Line at right

are required to consider the earth and = new

plants as part of dead load.

43

•43

Partition Load 1kPa?

• Steel stud wall with gyproc both sides =

0.25 kPa per square meter of wall.

2.4m

2.4m 2.4m Create a whole

nest of 2.4m x

2.4m x 3m high

2.4m

rooms

• Partition weight = 2.4m x 2 x 3.0m *0.25

kPa / (2.4m x 2.4m) = 0.625 kPa

44

•44

•C13 2022- Session 4 Stability Analysis •22

New In NBC 2020

If partitions shown (e.g. school) then can use

calculated weight. If not shown (e.g. office

building) assume 1.0 kPa. 45

•45

Dead Load

Clause 7.1.1 requires the dead load to include

the “additional weight of concrete and

finishes resulting from deflections of

supporting members”

46

•46

•C13 2022- Session 4 Stability Analysis •23

Dead Load Counteracting

• All non-seismic combinations replace

1.25D with 0.9D

• Ignore partition load if relieving load

• Commentary E for the structural

commentaries says do not do skip dead

loading on floors.

47

•47

No Skip Dead Load

1.25Dead or 0.9 Dead

1.25Dead

0.9Dead 0.9Dead

48

•48

•C13 2022- Session 4 Stability Analysis •24

What do load factors cover:

• Minor Overload due to magnitude of load.

• Minor Overload due to distribution of load.

• Minor round-off in calculation

49

•49

What Load Factors Don’t cover:

• Gross errors in calculation

• Loads of excessively higher than designed

for.

• Deficiencies in the material

50

•50

•C13 2022- Session 4 Stability Analysis •25

The Load Factors Don’t cover this:

51

•51

Surrealism

René Magritte

L'Anniversaire,

1959

An architect would say it is surrealism because the bolder

obviously does not fit in the room while a structural

engineer says it is surrealism because of the discontinuity

between the load and the resistance of the floor.

52

•52

•C13 2022- Session 4 Stability Analysis •26

Where do Load Factors &

Combinations come from:

• National Building Code sets load

combination factors.

• Same for all materials.

• Extensive probability studies

53

•53

NBCC 2020 Load Cases

•Companion Action approach

Case Principal Load Companion Load

1 1.4D

2 (1.25D or 0.9D)+1.5L 1.0S or 0.4W

3 (1.25D or 0.9D)+1.5S 1.0L or 0.4W

4 (1.25D or 0.9D)+1.4W 0.5L or 0.5S

5 1.0D + 1.0E 0.5L or 0.25S

54

•54

•C13 2022- Session 4 Stability Analysis •27

Load Combination Results

Case Principal Load Companion Load

2 (1.25D or 0.9D)+1.5L 1.0S or 0.4W

• 1.25D + 1.5L

• 1.25D + 1.5L + 1.0S

• 1.25D + 1.5L + 0.4W

• 0.9D + 1.5L

• 0.9D + 1.5L + 1.0S

• 0.9D + 1.5L + 0.4W

55

•55

Load Combination Results

Case Principal Load Companion Load

3 (1.25D or 0.9D)+1.5S 1.0L or 0.4W

• 1.25D + 1.5S Similar to Case 2 but

with snow governing

• 1.25D + 1.5S + 1.0L

• 1.25D + 1.5S + 0.4W Last week’s roof

• 0.9D + 1.5S design load #1

• 0.9D + 1.5S + 1.0L

• 0.9D + 1.5S + 0.4W

56

•56

•C13 2022- Session 4 Stability Analysis •28

Load Combination Results

Case Principal Load Companion Load

4 (1.25D or 0.9D)+1.4W 0.5L or 0.5S

• 1.25D + 1.4W Similar to Case 2 but

with snow governing

• 1.25D + 1.4W + 0.5L

• 1.25D + 1.4W + 0.5S Last week’s roof

• 0.9D + 1.4W design load #2

• 0.9D + 1.4W + 0.5L

• 0.9D + 1.4W + 0.5S

57

•57

Get lots of Load Combinations

• Need to only work with those that govern.

• Can dump all into computer or can think

• If looking at downward load on simple span

roof beam:

•1.25D + 1.5S + 0.4W Consider this

•0.9D + 1.5S + 0.4W Don’t bother

with this

(Looking for maximum down load and 1.25D on a

simple span beam is always worse than 0.9D) 58

•58

•C13 2022- Session 4 Stability Analysis •29

Load Cases to Ignore

• 1995 code used to say:

• “If it can be shown by engineering principles, or if

it is know from experience, that neglect of some or

all of the effects due to T does not affect the

structural safety and serviceability, they need not

be considered in the calculations”

(This no longer in Code)

59

•59

Live Load

• Not always easy to decide what is

appropriate loading.

• Building Code Table 4.1.6.3 gives loading

for various occupancies.

•60

•C13 2022- Session 4 Stability Analysis •30

Imagine designing a University

Lecture Classroom / Theater

Somewhere on this spectrum

•61

•62

•C13 2022- Session 4 Stability Analysis •31

Assembly Areas - Option a

• Classrooms or Courtrooms with or without

fixed seats:

• Live load = 2.4 kPa

•63

Assembly Areas Option b

• Portions of assembly areas with or without fixed

seats that have backs for the following use:

– Lecture Halls

– Live load = 2.4 kPa.

•64

•C13 2022- Session 4 Stability Analysis •32

Loading Choices for a University Theatre:

Assembly Auditoria 4.8 kPa

Lecture halls without

4.8 kPa

fixed seats with backs:

Classroom with or

2.4 kPa

without fixed seats

Lecture hall with fixed

2.4 kPa

seats with backs

100% difference in loading and not clear which to

choose

•65

Weight of People

Regulated Weight of US Airline Passengers

Including worn clothing and carry- on Baggage

Males Summer 200 lbs 0.88 kN

Males Winter 205 lbs 0.91 kN

Females Summer 179 lbs 0.80 kN

Females Winter 184 lbs 0.82 kN

4:30

•66

•C13 2022- Session 4 Stability Analysis •33

Loading Typical University Lecture

Theatre Estimate:

• Room say 10m x 15m = 150 sq. m.

• 75 people at 1kN each = 75kN

• 50 sets of hand luggage at 0.025kN (5 lb) each

=2kN

• 75 chairs and part desk at 0.2kN each = 15kN

• Total Wt = 75kN + 2 kN + 15 kN = 92 kN

• Loading = 92 kN / 150 sq. m = 0.6 kPa

•67

More than one occupancy

• Building Code clause 4.1.5.8 “Where an

area of floor or roof is intended or 2 or more

occupancies at different times, the value to

used from Table 4.1.5.3 shall be the greatest

value for any of the occupancies served”

68

•68

•C13 2022- Session 4 Stability Analysis •34

Very Crowded Conditions

(Before Social Distancing)

• Want a space of at least 3’ x 3’

• Average individual weight say 175 Lbs

• Gives 19 Psf = 0.9 kPa

• Many occupancy loads are derived from

historical precedent and what works from

serviceability requirements rather than

strength requirements.

69

•69

So Why Design for 4.8kPa

(100 Psf?)

Loads in Code “Historical” have been found to

work well in past.

• Not a lot of failures.

• Good “feel” – if design for 1 kPa very bouncy

• Works for most construction equipment.

• If something goes wrong you want to have

designed to the Code.

• If you design within the Code very, very good

chance nothing will go wrong. 70

•70

•C13 2022- Session 4 Stability Analysis •35

Why we

design

stairs for

4.8kPa

71

•71

However Some Loads Not Conservative

Mechanical areas are often much heavier loaded than the Code

would suggest

Work out

loads from

Equipment

Lists 72

•72

•C13 2022- Session 4 Stability Analysis •36

Another Load that is Often

Unconservative

Offices above first story at 2.4 kPa is usually very insufficient for

most normal office with file storage.

Rolling file

storage can

get to 16 kPa

73

•73

What the Code is Saying is Both of These

Should be Designed for Same Loading:

Office Above Ground: 2.4 kPa School Classroom: 2.4 kPa

As a responsible engineer you need to think about the loads and design in

for the expected loads – client very upset if they can’t use building for its

intended use.

Structure does not know what it was “supposed

to be designed for” only what the actual load is. 74

•74

•C13 2022- Session 4 Stability Analysis •37

Loads from Environmental

Forces

• Earthquake

• Snow

• Wind

• Temperature

• Foundation Settlement

75

•75

Loads from Environmental

Forces

• Earthquake

• Snow

• Wind

• Temperature

• Foundation Settlement

76

•76

•C13 2022- Session 4 Stability Analysis •38

Snow Load

• Based on 1/50 year return period

• 2% chance of being exceeded in one year.

• Does not include global warming effects

Life Of Building Probability of

Exceedence

50 Years 64%

75 Years 78%

100 Years 87%

77

•77

Snow Load

• Authority having jurisdiction sets values

• Vancouver Snow load Ss=1.8 Sr=0.2

• Granville and 41st Ss=1.9 Sr=0.3

•Granville and

•Vancouver 41st

Except

Granville and

41st

78

•78

•C13 2022- Session 4 Stability Analysis •39

Load Factor taking account?

• Vancouver Snow load Ss=1.8 Sr=0.2

• Granville and 41st Ss=1.9 Sr=0.3

• 1.8(0.8) + 0.2 = 1.64 kPa

• 1.9(0.8) + 0.3 = 1.82 kPa

• 1.82 / 1.64 = 1.10

79

•79

Can Get Sharp Changes in Snow

Load at boundaries

• Vancouver Snow • Burnaby Snow

Ss=1.8 Sr=0.2 Ss=2.9 Sr=0.7

(Based on snow at SFU)

80

•80

•C13 2022- Session 4 Stability Analysis •40

Only one of these is the “real” load

• This roof to be • This roof to be

designed for designed for

S=0.8(1.8)+0.2= S=0.8(2.9)+0.7=

1.64 kPa 3.02 kPa

81

•81

One option

• Get Environment Canada to do site specific

snow load. ($100).

• Can save $ Thousands in construction costs.

82

•82

•C13 2022- Session 4 Stability Analysis •41

Snow Roof collapses Europe 2004-2006

Poland: Jan 2, 2006 Moscow: Feb 23, 2006

German Ice Rink Jan 3, 2006 Moscow: Swimming Pool Feb 2004 83

All Photos: BBC Website

•83

Earthquake Since NBCC 2005

• Probability of being exceeded = 2% in 50

years

• Based on 1/2500 years return period

• Importance factor for schools and post

disaster buildings.

84

•84

•C13 2022- Session 4 Stability Analysis •42

Magnitude 7 event is similar to

Haiti where 250,000 killed

More than 10 events of magnitude 6.0 to

7.3 have occurred within 260 kM of

Vancouver since 1800.

Potential is that the smaller

frequent scattered events could

be up to magnitude 7.3.

•85

•85

Unintentional

Creation of seismic

events

86

•86

•C13 2022- Session 4 Stability Analysis •43

Seismic Risk For Fort Nelson is

rated as Low

• (But based on data that does not include “fracking”)

• If you are working on a project in Fort Nelson

would you consider higher earthquakes???

Currently there are several projects planned in the

area including a gas plant of approximate cost

$800Million - $1Billion 87

•87

Seismic Risk Based on Past Events

• What if we are doing something that

appears to increase the risk?

88

•88

•C13 2022- Session 4 Stability Analysis •44

Fracking and Seismic

Present thought from seismologists:

• Overall risk does not increase but may get

earlier release of smaller events.

• Use values from Code for your design.

89

•89

Wind Loads

• NBCC 1965-1995

• q10 for deflection

• q10 for cladding strength

• q30 or q100 for strength of structure

• NBCC 2005 – 20??

• q50 for everything

– Iw wind importance factor

90

•90

•C13 2022- Session 4 Stability Analysis •45

Wind Effects in Permanent Structures Often

Expressed First in Non-Structural Items

• Windstorm Calgary Nov 27,

2011 (During Grey Cup being

held in Vancouver)

91

•91

Wind Load

• Takes complex problem and condenses with

charts.

Load factors give designer

confidence 92

•92

•C13 2022- Session 4 Stability Analysis •46

Please Don’t Say

“The Code specified load is the largest that

can ever occur”

Most Loads are Limited only by

what the Code feels is appropriate

93

•93

Wind pressure q

Probability of Probability of Probability of

Probability of

being being being

being exceeded in

exceeded per exceeded in exceeded in 75

100 years

year 50 years years

q10 10.0% 99.5% 100.0% 100.0%

q30 3.3% 81.6% 92.1% 96.6%

q50 2.0% 63.6% 78.0% 86.7%

q100 1.0% 39.5% 52.9% 63.4%

94

•94

•C13 2022- Session 4 Stability Analysis •47

Seismic Vs Wind Load

• Wind load has load factor (1.4).

• Seismic load factor 1 and then design load

reduced by RdRo

Life Of Building Wind Probability of Seismic

Exceeding listed value Probability of

Exceedence

50 Years 64% 2%

75 Years 78% 3%

100 Years 87% 4%

95

•95

Actual Wind Probability

• Q=1/2 ρ V2 = 1/2 (0.0012929)V2 (NBCC Appendix C)

• Q50=0.45 kPa V=26.4 m/sec

• Apply Load factor of 1.4 for wind

• What is return for Sqrt(1.4)* 26.4m/sec)= 31.2m/sec

Appendix C NBCC:

Get Return Period = 650 years

Less than seismic = 2,475 years 96

•96

•C13 2022- Session 4 Stability Analysis •48

Ponding Loads On Roof

Design for 1 day rain on roof or 30mm above

scuppers whichever is less.

97

•97

Temperature Loads

• Not much guidance in code.

• Depends on differential between erected

and in place

• Often ignored

98

•98

•C13 2022- Session 4 Stability Analysis •49

Settlement Loads

• No problem if entire building settles.

• Stresses depend on differential settlement

• Soils consultant provides differential values

• Often ignored unless on very soft soil

4:45

99

•99

Settlement Effects on Rigid

Construction

• Entire frame settling as a unit has not effect

on structural stresses.

100

•100

•C13 2022- Session 4 Stability Analysis •50

Settlement Effects on rigid

construction

• Rotation of entire frame as a unit has not

effect on structural stresses.

101

•101

Settlement Effects on Rigid

construction

• Settlement that distorts frame will result in

stresses

102

•102

•C13 2022- Session 4 Stability Analysis •51

Even differential settlement often

not a problem in steel structures

due to simple span construction.

•No Added stress in simple

span beams

•Column

Settles

103

•103

Conversion of Settlement Data to

Structural Forces

104

•104

•C13 2022- Session 4 Stability Analysis •52

NBC 2020 Combinations

T is not shown 105

•105

T in NBCC 2020

• If T affects structural safety add in with

load factor of 1.25

• Don’t combine with seismic loads.

106

•106

•C13 2022- Session 4 Stability Analysis •53

Load Distribution

• For snow: Building Code clause 4.1.6.3

requires for roofs of less than 15 degree

slope consider:

• 1) Full snow everywhere.

• 2) Full snow or half snow as produces worst

effect.

50% 100% 50%

107

•107

Even if were doing half snow

would still put on Load factor of

1.5 throughout

50% 100% 50% Service

Apply load Factor = 1.5

75% 150% 75% Factored

108

•108

•C13 2022- Session 4 Stability Analysis •54

Load Distribution

• For Live Load: Building Code clause

4.1.5.3 requires us to consider:

• 1) Full live everywhere.

• 2) Full live only on those parts which

produce the worst effect. (no live

elsewhere)

0% 100% 0%

109

•109

What about loads not in Code?

Roof failures from volcanic ash.

In Canada would be hard to justify to your client that

you were increasing your structure cost to

accommodate volcanic ash (might not be so hard in

Tonga). 110

•110

•C13 2022- Session 4 Stability Analysis •55

Loads – Please take this away

• We spend vastly more time in analysing the

building than we do in computing the loads.

• Occupancy loads are based on historical

design methods.

• Environmental design loads have great

probability of being exceeded during life of

structure.

• Effects of load change with distribution

111

•111

Resistance Factors

• Resistance factors for items with greatest

uncertainty have lowest numbers.

112

•112

•C13 2022- Session 4 Stability Analysis •56

• Resistance (Ø) factor for steel = 0.9

• Exceptions:

Item Symbol Value

Reinforcing Steel Ør 0.85

Bolts Øb 0.80

Shear Connectors ØSC 0.80

Beam web bearing interior Øbi 0.80

Beam web bearing exterior Øbe 0.75

Bearing of bolts on steel Øbr 0.75

Weld metal Øw 0.67

Anchor rods Øar 0.67

Concrete Øc 0.65

113

•113

Stability of Individual Members

• Two options:

• S16 Clause 9.2.6 – Detailed analysis.

• S16 Clause 9.2.5 – Simplified method brace

for 2% of force in compression flange or

chord at point of support.

114

•114

•C13 2022- Session 4 Stability Analysis •57

Stability

• Members in compression loose capacity as

the distance between support points

increases

115

•115

Stability of Individual Members

• Stabilize compression flange to prevent

lateral torsional buckling by attaching to

diaphragm. .

116

•116

•C13 2022- Session 4 Stability Analysis •58

S16 Detailed method

* o b * C f

Pb

L

• Requires an understanding of initial

imperfections.

117

•117

* o b * C f

P

Items in Equation b L

• Pb= Force in the brace

• 0 = Initial misalignment, taken as tolerance

for sweep or camber. The variation in

straightness for W sections with flanges

greater than 150mm is L / 1000.

• b = 0

118

•118

•C13 2022- Session 4 Stability Analysis •59

Items in * o b * C f

Pb

Equation L

Number of brace Beta

Points

1 2

2 3

3 3.41

4 3.63

Greater than 4 4

• Cf = Force in column or compression force

being braced.

• L = Length between bracing points.

119

•119

Example for a 10m long W 530x66 beam what is the

brace force required if it is braced at third points.

• Axial force in brace = ?

120

•120

•C13 2022- Session 4 Stability Analysis •60

Example for a 10m long W 530x66 beam what is the

brace force required if it is braced at third points.

• Compression force in flange =

164mm*11.4mm*350,000*0.9 *10-6 = 589 kN121

•121

Example for a 10m long W 530x66 beam what is the

brace force required if it is braced at third points.

• Braced at third points: Kb = * o b * C f

Pb

L

( 3.0) * (0.010m 0.010m) * (Cf 589KN)

10.6KN

(L 10m / 3 3.33m)

10.6 kN / 589 kN = 1.8% of compression

flange force

122

•122

•C13 2022- Session 4 Stability Analysis •61

SIMPLIFYIED METHOD

Example for a 10m long W 530x66 beam what is the

minimum brace force it is braced at third points.

• Simplified method – use 2% force

• Compression force in flange =

164mm*11.4mm*350,000*0.9 *10-6 = 589 kN

Pb 0.02 * 589 kN 11.8kN

Round to 12 kN

123

•123

Make sure bracing strong enough

Also need load path to solid resistance if tie all

members together will buckle same direction.

124

•124

•C13 2022- Session 4 Stability Analysis •62

Members Stabilized by Metal

Deck

Clause 9.2.7 requires that beams stabilized by

a slab or deck shall be stabilized by a force

equal to 5% of the flange force distributed

over the length of the beam.

125

•125

Structural

Design of

the Gerber

Girder

Cantilever

System

(Filling the knowledge gap)

126

•126

•C13 2022- Session 4 Stability Analysis •63

Gerber Framing System

Very common steel roof framing system especially for retail and

warehouse use.

1

2

7

•127

Just What is Gerber Framing?

• Gottfried Heinrich Gerber invented the

Gerber Girder System in the 19th century.

128

•128

•C13 2022- Session 4 Stability Analysis •64

Was Originally Used in Bridge

Construction

Quebec Bridge (you might be wearing part of the

predecessors of this bridge)

129

•129

Advantages

• Drop in beam can be smaller than if standard

framing

• Cantilever moment reduces moment on interior

span

• Interior span deflections reduced by continuity.

130

•130

•C13 2022- Session 4 Stability Analysis •65

Disadvantages

• Takes more analysis to design

• Need to consider stability of system.

131

•131

Gerber Framing and Stability Case Study:

Save-On Foods at Station Square / Metrotown

132

•132

•C13 2022- Session 4 Stability Analysis •66

Save-On / Station Square

Roof Collapse

(Burnaby BC)

At 9:00 AM on the morning of April 23,

1988, customers were let into the store as

part of a grand opening sale for senior

citizens. Within 15 minutes of the opening

the roof had collapsed.

https://en.wikipedia.org/wiki/Station_Square_coll

apse

5:00

133

•133

Collapse was on a Saturday

Morning – Papers on Sunday

Morning had figures showing what

went wrong.

Province Newspaper Day following the roof

collapse.

134

•134

•C13 2022- Session 4 Stability Analysis •67

Collapse Resulted in Detailed

Inquiry

Figures from: Commissioner Inquiry, Station Square Development, Burnaby, British Columbia. Report of the Commissioner Inquiry,

Station Square Development, Burnaby, British Columbia Inquiry Commissioner: Dan I. Closkey.

135

•135

There Have Been Other Halifax March 2015 in

“White Jean” Snowstorm

Similar Failures:

Texas

• Source: https://csengineermag.com/gerber-girders-from-

forensic-investigation-to-repairs/

Photos and text: Michel Comeau, M.Sc., P.Eng.

Campbell Comeau Engineering Limited (Halifax) 136

•136

•C13 2022- Session 4 Stability Analysis •68

These Three Failures All Show the Same Beam

– Column Issue:

Gerber Beam “rolls over” and web buckles at point of column

support

137

•137

A Quick Review of Stability

Stability – Point #1

Slender members in tension don’t buckle –

Slender members in compression will buckle

Tension

Compression

138

•138

•C13 2022- Session 4 Stability Analysis •69

Stability - Point #1 Result

If you brace the tension flange you don’t do much to

help the compression flange).

Unsupported top

flange in compression

and wants to buckle

Brace to bottom flange

(in tension) does not

help brace compression

flange

139

•139

140

Gerber System –

Unfortunately only some

of the brace points go to

compression flange

Top Flange Tension = Green

Bottom Flange

Compression = Red

140

•140

•C13 2022- Session 4 Stability Analysis •70

Stability Point #2: Unsupported Length

• Members in compression rapidly loose capacity as the

distance between support points increases

141

•141

Stability – Point #3

• Point #3– Unsupported length of member can be greater

than the length of the member!

Cantilever Length

Effective unbraced

length of cantilever

can exceed length of

cantilever

142

142

•142

•C13 2022- Session 4 Stability Analysis •71

Stability – Point #4

Inflection points are not necessarily points of

lateral support

Inflection points

can move and are

not points of lateral

support

143

•143

Stability Point #5

Bracing one element in compression to a similar

element in compression just makes both buckle the

same way but does not help prevent the buckling

occurring.

144

•144

•C13 2022- Session 4 Stability Analysis •72

Stability Point #6

P P

’

The force required to stabilize a compression

element is not large (~2% of compression force)

but you need to provide the load path.

(A small brace does a lot of stabilizing but no

2% P’

brace does not help you).

P P

’

145

•145

Beams Only partly restrained by diaphragm

Shear connections at

end not connected to

web not top flange of

beam

Drop in beam from Gerber framing system. Restrained only at locations shown. (Only place

it’s connected to anything so only hope of possible stability)

146

146

•146

•C13 2022- Session 4 Stability Analysis •73

Cantilever Beam Stability

Clause 13.6(d)

For cantilever beams, a rational

method of analysis taking

• Cantilever beams can buckle if not account the lateral support

controlled conditions at the support and tip

of the cantilever should be used.

147

•147

Effective

Unsupported

Length of

Cantilever

1989 CISC

publication

148

148

•148

•C13 2022- Session 4 Stability Analysis •74

A Beautiful Beam Column Intersection

1) Joist Connects top of

column to diaphragm.

2) Vertical stiffener in

beam at column location

3) Bottom Chord extension

on joist at column

Has the three things we are looking for at the column

149

•149

What K to use? (Zero Top Flange Load)

(100% of load through connection plate)

K=1.0

100% of cantilever load through shear tap no top flange load.

150

•150

•C13 2022- Session 4 Stability Analysis •75

What K to

use?

K=1.5 to 2.5

151

•151

What K to

use?

K=1.5 to 2.5

K=1.0

152

•152

•C13 2022- Session 4 Stability Analysis •76

Philosophy

• Stability should not be a numbers issue.

• Provide positive stability where required.

• Some engineers like to use a minimum K of 1.5 on cantilevers

• Use higher than K=1.5 where appropriate

My take: Go with the

most conservative

value of the K

provided by the

guides.

K=2.5

153

•153

Stability is Like Playing Hockey

The other team has the puck

in your endzone and is trying

to score– you want to get

that puck away from the net.

154

•154

•C13 2022- Session 4 Stability Analysis •77

Two Cases Where Getting High k

1) Evaluating Existing building without sufficient

stability helpers. Go with high k so that don’t get

false sense of security.

2) Designing New building – Add sufficient stability

helpers to get your k down.

155

•155

How to Design A Gerber System

1) Establish the Geometry and

loading

2m

12m 12m

156

•156

•C13 2022- Session 4 Stability Analysis •78

Design the drop in span

Design as any other roof beam:

a) Factored down load Factored (dead + Snow + wind down)

b) Factored up load Factored (Dead – wind uplift)

c) Check Serviceability

157

•157

Consider

Pattern

Loading

Building Code clause 4.1.6.3 requires that we examine two load cases:

1. Full snow load everywhere with appropriate factors applied.

2. Use Ca=1.0 everywhere, use pattern loading of 100% and 50%

snow load to give the most unfavourable loading condition.

158

•158

•C13 2022- Session 4 Stability Analysis •79

Top Flange

Tension = Green

Bottom Flange

Compression = Red

159

•159

Station Square – Beam that

Failed Almost all in Negative

bending

160

•160

•C13 2022- Session 4 Stability Analysis •80

Gerber System – Design Back Span

• Check interior span – inflection point is not a brace point!

• Consider different load cases

• Take account of the stability

161

•161

Gerber System Design

Final Step – Make the Details Happy

Checklist:

Bottom Chord Joist Extension YES

Vertical Stiffener YES

Joist support to top flange at cantilever tip YES

“Intellectuals solve

problems, geniuses prevent

them.” Albert Einstein

162

•162

•C13 2022- Session 4 Stability Analysis •81

Gerber System – What Matters #1

Provide positive bracing at column (top and bottom flange)

BAD GERBER GOOD GERBER

163

•163

Gerber System – What Matters #2

Provide Web Stiffener at column

Web Stiffener

BAD GERBER GOOD GERBER

164

•164

•C13 2022- Session 4 Stability Analysis •82

The Web Stiffener is Really Important

No web stiffener is an issue with all of these failures.

165

•165

Gerber System – What Matters #3

• Provide bracing at cantilever tip

BAD GERBER GOOD GERBER

5:15

5 166

•166

•C13 2022- Session 4 Stability Analysis •83

Gerber System – What Matters:

#4 Do Analysis with appropriate pattern Loading

167

•167

Gerber System – What Matters #5

• Check cantilever span using appropriate k.

168

•168

•C13 2022- Session 4 Stability Analysis •84

Gerber System – What Matters #6

• Check interior span – inflection point is not a brace point!

Interior Beam Moment

400

Factored Moment

200

Distance

(KNm)

0 Min

11

Max

-200

-400

Distance Along Beam

Watch out for Negative moment across full back-span

169

•169

Hopefully The Forgoing Gives An

Indication of How to Design

Gerber Framing

But put yourself in 1988.

170

•170

•C13 2022- Session 4 Stability Analysis •85

Put Yourself in the

Designer’s Shoes in 1988:

You are a young EIT recently graduated. You are working in a busy

structural engineering office. You have been given the job of

designing a roof system for a supermarket.

You are going to design a Gerber System roof

(because that is what everybody does)

Gerber Framing and cantilever beam stability has not been

discussed in your university classes.

Nobody has trained you how to do these designs.

171

•171

S16-M78 (Before Station Square)

No special flags for cantilever beams & no

mention of Gerber Framing using this edition of the

standard it would not have been unreasonable to

assume a cantilever beam is just like any other

unbraced beam.

172

•172

•C13 2022- Session 4 Stability Analysis •86

Clause 13.6 Covers Bending Resistance of Unsupported Beams

Clause 13.6(d)

Use rational analysis:

You are not quite sure what this is all about so you

go look in the references to try to find out. Not

much on Gerber framing published.

173

•173

What Does Your Design Look Like?

Would you know to:

• Add a vertical stiffener at the column?

• Consider the stability of the cantilever and use the correct unbraced length?

• Consider the stability of the backspan and figure the unbraced length?

174

•174

•C13 2022- Session 4 Stability Analysis •87

Now Put Yourself in 2017

• You are on the S16 Committee

• There are no specific Gerber Clauses in S16

• This is “the most common roof framing system” in

North America.

175

•175

Should you add Gerber Framing requirements to S16?

1. Do Nothing – keep status quo – (everyone should now

Options :

about this by now anyway)

Trouble is Gerber Framing is not being taught in school and

the engineers who have the knowledge are retiring or worse.

176

•176

•C13 2022- Session 4 Stability Analysis •88

Should you add Gerber Framing requirements to S16?

Options

2) Provide

: methods of analysis and formulas in Code.

Trouble is Gerber Framing does not have good closed form

solutions that could appear in Code.

177

•177

Should you add Gerber Framing requirements to S16?

3) Provide warnings in Code and more guidance in commentary.

Options:

At least this gives a warning and the S16-19 commentary

(Available only in the CISC Handbook 12th edition) has a full

page on Gerber Construction.

Only 12th edition has commentary

for Gerber Framing

178

•178

•C13 2022- Session 4 Stability Analysis •89

Solution – Add Clauses that Flag the Issue

S16-19:

179

•179

a) Look After the

Cantilever

(a) the stability and strength of the Gerber beam accounting

for the effect of rotational restraint at the column; rotational

restraint in the cantilevered span; relative lengths of cantilever

and back-span; and portion of load that is applied to the top

flange of the cantilever

180

180

•180

•C13 2022- Session 4 Stability Analysis •90

b) Look after the Web at the column

(b) the stability and strength of the web of the Gerber beam

at the column including the effect of stabilizing connections

to the bottom and top flanges and the presence of a

vertical stiffener

181

•181

c) Look After the Backspan

c)The stability and strength of the back-span of the Gerber beam

taking account of support conditions at bottom and top flange

and the shape of the moment diagram taking account of full and

partial loading.

182

•182

•C13 2022- Session 4 Stability Analysis •91

Why Not a Closed Form Solution?

Lots of debate about what formulas / methods to use.

Not everyone agrees with the methods presented today.

Hard to find a better solution that can be used reasonably in a design situation.

183

•183

Back to Save-On Foods:

Issues During Construction

During construction there were concerns about the structure.

Excessive deflection

Very “lively” / “bouncy” structure.

Reviewed by two consultants and found OK by using

higher strength from mill certificates.

184

•184

•C13 2022- Session 4 Stability Analysis •92

The Problem with Mill Certificates

Beam resistance formulas based on Specified Yield for grade of steel.

Formulas expect mill certificates to be higher than specified strength.

Due to residual stresses – test results will vary depending on where you

take test sample.

185

•185

How S16 covers (now)

Not allowed to use mill certificates to increase capacity of beam.

186

•186

•C13 2022- Session 4 Stability Analysis •93

Result of Failure: Inquiry to the Roof Collapse

The provincial government

convened a Commissioner

Inquiry (Closkey Inquiry) to

look at causes of failure and

try to prevent occurring again.

After the failure & inquiry there

were several changes in the

structural design industry in

British Columbia and Canada.

187

•187

Inquiry Results: Load Calculation Errors

Enquiry finds several issues with the calculation of loads.

Loads had increased as design proceeded (concrete topping

increased, heavy concrete sidewalk added). Lighter weight option for

sidewalk not used by contractor.

Changes in loads not reflected in the design.

188

•188

•C13 2022- Session 4 Stability Analysis •94

Inquiry Results Resistance

Inquiry finds lots of issues with the beam resistance calculations

Concentrated Research on Gerber Framing and Engineer Education

Unfortunately, much of this has faded away.

189

•189

Concerns About Consulting Industry

Practice

Fast-tracking – creates more chance for error.

Bidding for professional services, and

Fragmentation of contractual responsibility.

There were desires to have minimum fees so that professionals were chosen on

merit and service rather than fee driven. This desire still remains.

190

•190

•C13 2022- Session 4 Stability Analysis •95

Increased

Emphasis on

Checking

Concept reviews now a

mandatory part of

design.

Much more emphasis on

checking what has been

produced.

191

•191

Increased Experience Required for Structural

Engineers

Minimum years of experience to get a P.Eng. In BC raised from 2 years to 4 Years.

Increased emphasis in BC on getting additional education and mentoring during your EIT period.

Struct.Eng. Program introduced in BC requiring 10 years experience and exams to achieve.

Mandatory continuing education.

192

192

•192

•C13 2022- Session 4 Stability Analysis •96

Struct.Eng.

Higher designation than P.Eng. Required for

structural engineers for public buildings.

• Ten years of experience minimum.

• Write exams

• Continuing education requirement.

193

•193

Continuing Education For Structural Engineers

Codes change – how to keep current?

Subjects such as Seismic & Gerber design not taught in engineering schools.

Methods of analysis and design change.

Continuing education program started with evening courses for structural engineers.

SEABC Courses continue to this day.

194

•194

•C13 2022- Session 4 Stability Analysis •97

Another Issue

Treatment of bolted joist connections

Can the bolt holes lead to fracture in

tension zone?

(Apparently in Quebec have to bolt all joists in

place (“it’s the law”))

195

•195

Montreal Failure

Photos courtesy: Elie Chakieh, P.Eng, ing., M.Eng. BDS Director of Engineering & Expertise

E.E.Chakieh Consultants Montreal, QC

196

•196

•C13 2022- Session 4 Stability Analysis •98

Effect of Bolt Holes to Secure Joists

197

17mm holes for

5/8” bolts to

secure joists

Simple Span Beam (Tension at

bottom Compression at top))

• Above from shop drawing on one of our

jobs bolting can happen in BC.

197

•197

First Question:

Do the bolt holes reduce the capacity at the critical section?

(Are we taking away moment capacity at the critical section?)

What S16-19 says:

If bolt hole in compression No worries as long as stuffed standard bolt

hole.

If bolt in tension Max 15% of flange permitted.

198

•198

•C13 2022- Session 4 Stability Analysis •99

Typical Simple Span Beam

199

17mm holes for

5/8” bolts to

secure joists

Simple Span Beam

(Tension at bottom

Compression at top)

• Bolt in compression so no worries

199

5:30

•199

How About our Gerber System?

Joist Connection

in Tension Zone

• To take away only 15%

• 5/8” bolt: 17mm hole 2 bolts need a 226mm flange

• ¾” bolt: 22mm hole 2 bolts need a 293mm flange

200

•200

•C13 2022- Session 4 Stability Analysis •100

Say Have Gerber Girder W530x74

• Flange width = 166mm (Flange thickness = 13.6mm)

• Shop drawings come back with 2 – 5/8” bolts (2x17mm

holes)

Flange reduction = 2*17mm / 166mm = 20%

(Does not work by 14.1.2)

Flange Gross Area = ØAgFy= 0.9*166*13.6*350/1000 = 711 kN

Flange Net Area = ØuAnFu

0.75*(166-2(17))*13.6*450/1000 = 605 kN

(The 15% is generous at 15% you still get net section failure)

(Get net section failure) 201

•201

For 15% flange Reduction with 2 bolt holes:

Min Flange Width

Hole Size

for 2 bolts

½” Bolt 14mm 186mm

5/8” Bolt 17mm 226mm

Often “most efficient” beams have

skinny flanges: ¾” Bolt 22mm 293mm

W610x82 bf=178mm By S16-19 can’t even

use ½” bolt in these

W530x74 bf=166mm

W530x66 bf=165mm

202

•202

•C13 2022- Session 4 Stability Analysis •101

Next Question:

If the bolt holes do reduce the capacity who should fix

the issue?

• A) Engineer should have oversized beam based on assuming bolts.

• B) Detailer should tell fabricator to add extra plates to help beam.

• C) Joist supplier should just use welded connections.

My Take: Design engineer using Gerber System should account for

possibility of bolt holes for joist fastening and state maximum size of

bolt holes that can be used without adding reinforcing on drawing.

203

•203

Second Way: Select Beam With Sufficient

Capacity Such that Net Section works

Looking for 368kNm at the column – tension in top flange

Beam Mr Mr’ Flange Max bolt Size for

Lu=4.0m Width 15% flange W460x74

(mm)

bf=190

W610x82 683 kNm 443kNm 178 <1/2”

tf=14.5

W530x74 562 kNm 357kNm 166 <1/2”

d=457

W460x74 469 kNm 379kNm 190 ½”

W360x91 522 kNm 513 kNm 254 5/8”

Web moment resistance adds: Try: W460 with two 1/2” bolts

ØFyZ=0.9(345MPa)(412)= 128kNm

Flange Net Area = ØuAnFu

0.75*(190-2(14))*14.5*450/1000 = 793 kN

Mr~793kN*(.457-0.0145) + 128kNm = 350 kNm + 128kNm = 478kNm

(Net Section Mr slightly greater than gross section - OK)

204

(Should say on drawings “Maximum ½” diameter bolt for fastening joists”)

•204

•C13 2022- Session 4 Stability Analysis •102

Bolt Holes in Gerber Beam Flanges

• Bolt holes in tension zone do make a difference

• Can govern design if think of allowing for bolts

• In example better solution choose a beam not in the bold

sections – wider flange is better – gives more stability and

better option for bolts.

• State on drawings maximum bolt size permitted.

Best option

Maximum Joist fastening Bolt = ½”

205

•205

What’s Happening to Gerber System Now

• Included in S16-19 which is being used more as projects move to NBC 2020.

• University of Alberta Testing Program.

• Talks on Gerber Framing such as this.

• Both UBC and BCIT teach Gerber system in their undergrad steel course.

• Textbooks cover Gerber framing

All of today’s session covered in

this book (except the bolt bit)

206

•206

•C13 2022- Session 4 Stability Analysis •103

University of Alberta Steel Centre

Doing Extensive Study on Gerber Design

Advisory Committee Members:

Charles Albert, Elie Chakieh, Hesham Essa, Michael Holleran, Mark Lasby, Andy

Metten, Samuel Richard, Elie Saint-Onge, Michael Samuels, Logan Callele and Alfred

Wong

•207

•207

Structural

Design of

the Gerber

Girder

Cantilever

System

(Filling the knowledge gap)

208

•208

•C13 2022- Session 4 Stability Analysis •104

Sample Problem – Two

Span Beam With Cantilever

Numbers covered in Structural

Steel for Canadian Buildings

For talk let’s cover principals

209

•209

What We Want to Do:

1. Determine loads using appropriate pattern

loading

2. Check cantilever using appropriate unsupported

length and consideration of lateral buckling.

3. Check backspan using appropriate unsupported

length.

4. Check support at column – add vertical stiffener.

5. Check Serviceability.

210

•210

•C13 2022- Session 4 Stability Analysis •105

Find K for

Cantilever

• Restrained top &

bottom at root.

• Restrained at top at tip

• Loads from top flange

211

•211

Six Load Cases to Consider

Case Live Load Dead Load

#1 Live Load both Spans 1.25 D

#2 Live Load Cantilever Only 1.25D

#3 Live load Interior Span Only 1.25D

#4 Live Load both Spans 0.9D

#5 Live Load Cantilever Only 0.9D

#6 Live load Interior Span Only 0.9D

212

•212

•C13 2022- Session 4 Stability Analysis •106

Resulting Moment Curves

213

•213

Next:

1. Check cantilever using appropriate unsupported

length and consideration of lateral buckling.

2. Check backspan using appropriate unsupported

length.

3. Check support at column – add vertical stiffener.

4. Check Serviceability.

Won’t go through numbers here but

this is where you find this.

214

•214

•C13 2022- Session 4 Stability Analysis •107

P-Delta Effects

• An issue in flexible structures

especially those that are moment frames

or cantilevered structures

215

•215

P-Delta – Axial load offset from

base

Vertical load

results in lateral

movement

216

•216

•C13 2022- Session 4 Stability Analysis •108

Sometimes you

want the P-Delta

Artist: Liz Magor

look Foundry: Steve Harman

217

•217

P-Delta Effects

V * H 3 6 KN * (5m) 3

0.083m

3 * EI 3 * 200 *15.1

M =V*H + P* Δ = (6kN * 5m) + (25 kN * 0.083m)

= 30 kNm + 2.08 kNm = 32.1 kNm 218

•218

•C13 2022- Session 4 Stability Analysis •109

Use Clause 8.6.1 as an amplification factor for

multiplying the results of a first order analysis to

obtain the second order results.

1

U2

C f f

1

V f h

1

U2 1.07

25KN * 0.083m

1

6 KN * 5m

Mf=Mfy + U2 Mft = 30 kNm + 1.07*(2.08 kNm) = 32.2 kNm

(OK less than Mr of 74.7 kNm) 219

•219

P-Delta By Computer:

Delta = (0.083 * 1.074) = .089 (PFrame gives 90.3mm)

M= 30 kNm +1.07(25kN*.083m) = 32.23 kNm

(PFrame gives 32.3 kNm 220

•220

•C13 2022- Session 4 Stability Analysis •110

Overly flexible problems –

Beware of U2 > 1.4

1

U2

C f f

1

V f h

1

U2 2.239

200 KN * 0.083m

1

6 KN * 5m

221

•221

Notional Loads - 8.7.2

The translational load effects produced by notional lateral

loads, applied at each story, equal to 0.005 times the

factored gravity loads contributed by that storey, shall be

added to the sway effects for all load combinations.

•Factored D+L

0.005 * Factored

Gravity Load

222

•222

•C13 2022- Session 4 Stability Analysis •111

Moment Frames – Get load at

each floor to start P-Delta Load

0.005 * Factored

Gravity Load Roof

0.005 * Factored

Gravity Load level 2

223

•223

Calculate the Notional Loads Under

Factored Dead + Live + Snow

Snow = 0.0 kPa

Dead = 4.7kPa

Live = 4.8 kPa

224

•224

•C13 2022- Session 4 Stability Analysis •112

Calculate the Notional Loads - Roof

Under Factored Dead and Live & Companion Snow

13kN Snow = 1.7 kPa

? Dead = 1.6kPa

Live = 1.0 kPa

Total Notional Load on roof level:

= 0.005(1.25(Dead) + 1.5(Live) + 1.0(Snow))

= 0.005(1.25(1.6kPa) + 1.5(1.0kPa) + 1.0(1.7kPa)) * (22.5m x 45m) = 26.3kN

As a uniformly distributed load = 26.3kN/45m = 0.59kN/m

225

•225

Calculate the Notional Loads - Floor

Under Factored Dead and Live & Companion Snow

13kN Snow = 0.0 kPa

33kN Dead = 4.7 kPa

Live = 4.8 kPa

Snow = 0.0 kPa

Dead = 4.7kPa

Live = 4.8 kPa

Total Notional Load on Floor level:

= 0.005(1.25(Dead) + 1.5(Live) + 1.0(Snow))

= 0.005(1.25(4.7kPa) + 1.5(4.8kPa) + 1.0(0.0kPa)) * (22.5m x 45m) = 66.0kN

As a uniformly distributed load = 66kN/45m = 1.47kN/m

226

•226

•C13 2022- Session 4 Stability Analysis •113

Notional Loads Must be

Considered With All Load Cases

1.25D+1.5L + 1.0S

13kN

33kN

1.25D+1.5L + 1.0S

227

•227

Overall Frame Stability

Design for local buckling of individual

members may not insure stability of overall

frame.

Differs from P-Delta analysis in that it is

not necessary to laterally displace the

structure to get a buckling failure.

228

•228

•C13 2022- Session 4 Stability Analysis •114

Overall Frame Stability

2 ( EI )

Pcrit

( KL) 2

2 ( 200 * 15.1)

298KN

(2.0 * 5m) 2

229

•229

Computer Buckling Analysis

Results for first

buckling mode.

Buckling Force =

200 kN * 1.49935

= 299.9 kN

Compares well

with 298 kN

found by hand

analysis.

230

•230

•C13 2022- Session 4 Stability Analysis •115

Ultimate Limit States - Fatigue

• NBCC / BCBC Clause 4.1.3.3

• “A building and its structural components

shall be checked for serviceability limit

states as defined in Clause 4.1.3.1(1)(a) and

fatigue under the effect of the specified

loads as required in the standards described

in Section 4.3.”

231

•231

Building Code Clause 4.3 –

Material Standards

• 4.3.1 Wood 086.1 No fatigue

• 4.3.2 Masonry S304 No fatigue

• 4.3.3 Concrete A23.3 No Fatigue

• 4.3.4 Steel S16-14 Clause 26

5:45 232

•232

•C13 2022- Session 4 Stability Analysis •116

S16 – Clause 26

• Clause 26.1

• “The life of the structure shall be taken as

50 years unless otherwise stated.”

• Clause 26.3.5

• Generally ignore fatigue if number of cycles

is less than 20,000.

233

•233

20,000 in 50 years

• The number of “stress cycles” per day must

average

20,000Cycles

1.1Cycles / day

50Years * 364 Days

234

•234

•C13 2022- Session 4 Stability Analysis •117

Clause 26.1

• “Members subjected to fatigue loading shall

be designed, detailed, and fabricated so as

to minimize stress concentrations and

abrupt changes in cross section”

235

•235

Fatigue Requirements

• Number of Cycles

• Significant Stress Range

• Stress range includes tension (not an issue

for compression only)

• For most buildings both are considered low

and fatigue is ignored.

• Fatigue is an issue in industrial buildings

with crane rails and in bridge design.

236

•236

•C13 2022- Session 4 Stability Analysis •118

Bridge Cable Fatigue Testing

ALRT Bridge (Skybridge)

237

•237

Ultimate Limit State-Overturning

• Generally an issue with the support of

lateral elements

• Clause 6.3.2 tells you take care of the

situation.

238

•238

•C13 2022- Session 4 Stability Analysis •119

Geotechnical Issue

239

•239

Ultimate Limit State-Sliding

• Generally an issue with the support of

lateral elements (eg: Cantilever retaining

walls).

• Nothing in the steel code

240

•240

•C13 2022- Session 4 Stability Analysis •120

Serviceability Limit States -

Deflection

• Worked out using service live load only.

• No dead load included.

• Use S16 Annex D to find “acceptable”

values.

241

•241

Serviceability Limit States -

Vibration

• Long span, light structures affected.

• Clause 6.3.3 refers to dynamic loading

• S16-14 - Annex E gives reference to use for

calculation and guide.

• See discussion from Session 2

242

•242

•C13 2022- Session 4 Stability Analysis •121

Serviceability Limit States -

Permanent Deformation

• Used to be covered directly in Code

• Composite beams that are unshored during

construction must not have stresses that

exceed Fy.

• Slip critical joints to be proportioned to

carry loads without slipping.

• Generally trying to keep beams below Fy

under “normal” circumstances

• No longer covered as separate issue.

243

•243

•CISC Publication – Free Download 244

•244

•C13 2022- Session 4 Stability Analysis •122

Caracas October 2004 –

Uncontrolled fire steel high-rise

No Total Collapse

245

•245

Fire Effects

•Reduction in strength 50% at 600oC

•Reduction in stiffness 70% at 600oC

•Increased elongation

246

•246

•C13 2022- Session 4 Stability Analysis •123

Fire Protection

•Active:

•Sprinklers

•Fire Department

•Passive:

•Spray Fire proofing

•Thickness of concrete topping on deck

•Non-combustible construction

247

•247

Occupied Floors usually need to be

fire rated – unoccupied roofs don’t

•Columns and beams

of Unoccupied roof

unrated

•Columns and beams

of Occupied Floor

Fire rated 248

•248

•C13 2022- Session 4 Stability Analysis •124

Roof beam –

needs to be fire

rated if supporting

occupied floor

Floor will need to

be fire rated

249

•249

Fire aspects from designer’s

standpoint

•Some fire assemblies

use 115mm reinforced •Design load

topping on deck rather implications

than fire proofing deck

= 2 hour rating

•115mm

250

•250

•C13 2022- Session 4 Stability Analysis •125

Fire aspects from designer’s

standpoint

•Some fire assemblies •Structural size

require minimum M/D implications

ratios for beams and

columns.

SI (kg /m / m) Imperial (Lb/ft/in)

Designation

Beam Column Beam Column

W200

x42 47.6 40.0 0.813 0.683

x36 41.4 34.8 0707 0.594 251

•251

Column mass may have to

accommodate rating

Minimum wall thickness of HSS 127x127 steel column to satisfy the

fire resistance rating of

Fire Proofing Minimum 1 Hour Fire 2 Hour Fire

Thickness of Resistance Resistance

Type X Gyproc Rating Rating

1 layer 5/8” 15.9mm HSS 127X127 x Not Possible

Type X 8.0

2 layer 5/8” 31.8mm HSS HSS

Type X 127x127x4.8 127x127x13

252

•252

•C13 2022- Session 4 Stability Analysis •126

Intumescent Paint – exposed steel

that needs fire rating

•It is not uncommon

for fires to start in

buildings due to

welding

253

•253

Thank you for being here

Next Week– Deck Design

Next week almost all from

Chapter 7

254

•254

•C13 2022- Session 4 Stability Analysis •127

You might also like

- Concrete Design Handbook 4th EditionDocument134 pagesConcrete Design Handbook 4th Editionelidstone@hotmail.com67% (6)

- Concrete Design Handbook 4th EditionDocument134 pagesConcrete Design Handbook 4th Editionelidstone@hotmail.com67% (6)

- C4-1 Lecture 1 - Intro Lecture Big PictureDocument67 pagesC4-1 Lecture 1 - Intro Lecture Big Pictureelidstone@hotmail.comNo ratings yet

- Concrete Design Handbook 4th Edition SeminarDocument44 pagesConcrete Design Handbook 4th Edition Seminarelidstone@hotmail.com100% (1)

- A Guide For Designing With Standing Seam Roof PanelsDocument78 pagesA Guide For Designing With Standing Seam Roof Panelselidstone@hotmail.comNo ratings yet

- Seismic Design Manual PDFDocument881 pagesSeismic Design Manual PDFelidstone@hotmail.comNo ratings yet

- MAK BOQ Modular KitchenDocument9 pagesMAK BOQ Modular KitchenSuhail AhmedNo ratings yet

- Composite Engineering Show 12 11 14Document22 pagesComposite Engineering Show 12 11 14AliNo ratings yet

- Ch9 Design of Beam ColumnDocument11 pagesCh9 Design of Beam ColumnZeyad Abd elrazekNo ratings yet

- RC1 - Chapter 4Document57 pagesRC1 - Chapter 4Khoi DuongNo ratings yet

- Handout-Appendix DDocument102 pagesHandout-Appendix DNaqib NaeemiNo ratings yet

- Chapter 2 - Section ClassificationDocument32 pagesChapter 2 - Section ClassificationMADHURJO MEHENAZ A20EA3003No ratings yet

- CVE4002 Lecture 04 SlidesDocument58 pagesCVE4002 Lecture 04 SlidesKeith YangNo ratings yet

- MODULE No. 3 Two Way SlabDocument29 pagesMODULE No. 3 Two Way SlabCedric EnticoNo ratings yet

- C2 1) StrainDocument3 pagesC2 1) Strainbce23090017No ratings yet

- Laterally LoadDocument92 pagesLaterally LoadMadhusudan MadhuNo ratings yet

- Design of Box CulvertDocument66 pagesDesign of Box CulvertMd Ghani HaiderNo ratings yet

- CE302 - Beams - Design of PurlinsDocument4 pagesCE302 - Beams - Design of PurlinsCE20B1024 SRIBALANNo ratings yet

- Masonry Design ASDvsSD PDFDocument47 pagesMasonry Design ASDvsSD PDFAnonymous 1BdR0EQgbuNo ratings yet

- Peter GroupDocument28 pagesPeter GroupSamuel WoldeNo ratings yet

- CIVL5277 Lecture 9 - Design of Bending MembersDocument78 pagesCIVL5277 Lecture 9 - Design of Bending Membersjihe0020No ratings yet

- CE 415 4 Analysis and Design of Beam For ShearDocument57 pagesCE 415 4 Analysis and Design of Beam For ShearLhee Ann GarboNo ratings yet

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDocument21 pagesStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNo ratings yet

- Session 2 - Des BullDocument59 pagesSession 2 - Des BullCyril Jean-BaptisteNo ratings yet

- 1E5 APL1 Glass Structures VUDocument10 pages1E5 APL1 Glass Structures VUAnonymous AV90SAXa5VNo ratings yet

- Ce 401 Structural Design Lecture 1: Steel Connections-Bolted ConnectionsDocument22 pagesCe 401 Structural Design Lecture 1: Steel Connections-Bolted ConnectionsIsrael PopeNo ratings yet

- Tilt Up DesignDocument27 pagesTilt Up DesigntwinniesNo ratings yet

- Steel Frame Design Manual: Italian NTC 2008Document99 pagesSteel Frame Design Manual: Italian NTC 2008Angel VargasNo ratings yet

- Steel Frame Design Manual: Italian NTC 2008Document96 pagesSteel Frame Design Manual: Italian NTC 2008Haytham ZaghloulNo ratings yet

- Lecture 1 (Introduction)Document43 pagesLecture 1 (Introduction)hakim baharomNo ratings yet

- Chapter Two-2-Deflection & End Block PDFDocument28 pagesChapter Two-2-Deflection & End Block PDFAmirul Asyhraf ArsadNo ratings yet

- Course Title: Mechanics of Materials Course Code: MM-205 Year: S.EDocument14 pagesCourse Title: Mechanics of Materials Course Code: MM-205 Year: S.ESahar Batool QaziNo ratings yet

- Matter of Long-Term Deflection Control in TCVNDocument21 pagesMatter of Long-Term Deflection Control in TCVNHoang Duc LocNo ratings yet

- Cold-Formed Steel Structures To The AISI Specification (Civil and Environmental Engineering) by Gregory J. Hancock, Thomas Murray, Duane S. EllifritDocument411 pagesCold-Formed Steel Structures To The AISI Specification (Civil and Environmental Engineering) by Gregory J. Hancock, Thomas Murray, Duane S. EllifritDhiraj Roka100% (1)

- RNL 10 Falling Object Protective Structure Testing SandvikDocument6 pagesRNL 10 Falling Object Protective Structure Testing SandvikAnonymous d23gWCRQNo ratings yet

- Chapter 1 - Introduction To Steel DesignDocument53 pagesChapter 1 - Introduction To Steel DesignMADHURJO MEHENAZ A20EA3003No ratings yet

- Update1 Iith SsDocument14 pagesUpdate1 Iith SsSatyajit PatilNo ratings yet

- Spring2022 PRE5322 Topic5 FramesDocument19 pagesSpring2022 PRE5322 Topic5 Framesmohammed hamdyNo ratings yet

- 2244-Pipe Lifting StandDocument16 pages2244-Pipe Lifting StandSreejith SureshNo ratings yet

- Steel 5 - Custom Girders 1Document60 pagesSteel 5 - Custom Girders 1Neon LalNo ratings yet

- MOW 312 - Semester Test 2 (2021) MemoDocument6 pagesMOW 312 - Semester Test 2 (2021) MemoWillem van der WaltNo ratings yet

- RC1 Chapter 5Document40 pagesRC1 Chapter 5Khoi DuongNo ratings yet

- Plate Girders: Sequence of Fabrication of Plate GirderDocument16 pagesPlate Girders: Sequence of Fabrication of Plate Girderraunak upadhyayaNo ratings yet

- Design of Cantilever Retaining WallDocument3 pagesDesign of Cantilever Retaining WallanjuajeshNo ratings yet

- Ad and Disad of FRP-1Document3 pagesAd and Disad of FRP-1Rishika DixitNo ratings yet

- Final - PTPresentation - 060525Document50 pagesFinal - PTPresentation - 060525Tran VietcuongNo ratings yet

- Project: Client: Engineer: Remarks:: SteelmanDocument5 pagesProject: Client: Engineer: Remarks:: SteelmanDaniel RabascallNo ratings yet

- Discussion 4 - Waveguide Modes ContdDocument22 pagesDiscussion 4 - Waveguide Modes ContdLudwing BoltzmannNo ratings yet

- Puentes Basado en Desplazamiento 5Document43 pagesPuentes Basado en Desplazamiento 5Juan David CarvajalNo ratings yet

- MagNet - Tutorials PDFDocument220 pagesMagNet - Tutorials PDFbasamvenkatNo ratings yet

- TRM ISB Request Minimum Input Data - Template - v.1Document14 pagesTRM ISB Request Minimum Input Data - Template - v.1Hemang KhandelwalNo ratings yet

- Draft Report PDFDocument10 pagesDraft Report PDFSupun Aravinda JayawardhaneNo ratings yet

- Structural Analysis 7 Edition in SI Units: Displacement Method of Analysis: Moment DistributionDocument47 pagesStructural Analysis 7 Edition in SI Units: Displacement Method of Analysis: Moment DistributionAbdul Wali KhanNo ratings yet

- CHAP 12 Displacement Method of Analysis - Moment DistributionDocument47 pagesCHAP 12 Displacement Method of Analysis - Moment DistributionWilliam FaustinNo ratings yet

- S5403 Nelson InoueDocument36 pagesS5403 Nelson InoueDanielNo ratings yet

- FmsdownloadDocument7 pagesFmsdownloadRichard PekitpekitNo ratings yet

- r0 5x2 Boxpipe f2000 18d Renewsys Staad Analysis ReportDocument39 pagesr0 5x2 Boxpipe f2000 18d Renewsys Staad Analysis ReportMohammed Moin MotalaNo ratings yet

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDocument23 pagesStructural Steelwork Eurocodes: Development of A Trans-National ApproachxangNo ratings yet

- Designing A Concrete Beam: Icon LegendDocument5 pagesDesigning A Concrete Beam: Icon LegendNitish TakalkarNo ratings yet

- Designofdisturbedregions 1Document30 pagesDesignofdisturbedregions 1Bhaskar BongaralaNo ratings yet

- 1 Reinforced Concrete T Girder Bridge - Indian CodeDocument60 pages1 Reinforced Concrete T Girder Bridge - Indian CodeSandipan Dhar100% (1)

- Structural Steelwork Eurocodes: Development of A Trans-National ApproachDocument25 pagesStructural Steelwork Eurocodes: Development of A Trans-National ApproachAmey GudigarNo ratings yet

- Design of CorbelDocument32 pagesDesign of CorbelSathish Kumar Civil100% (1)

- SH San 609 MSC FEM TutorialsDocument93 pagesSH San 609 MSC FEM TutorialsXabier ZarrandicoecheaNo ratings yet

- Prestresses Concrete Beam StrengtheningDocument9 pagesPrestresses Concrete Beam StrengtheningAnhera enterpriseNo ratings yet

- Mechanics of Optimal Structural Design: Minimum Weight StructuresFrom EverandMechanics of Optimal Structural Design: Minimum Weight StructuresNo ratings yet

- Wave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsFrom EverandWave Propagation: From Electrons to Photonic Crystals and Left-Handed MaterialsNo ratings yet

- 72 - 36 - 316-1-2024 E11 Lecture 6 FEP 20240211Document67 pages72 - 36 - 316-1-2024 E11 Lecture 6 FEP 20240211elidstone@hotmail.comNo ratings yet

- 68 36 301-1-SEABC C13 2023 Session 5 Decks 2PerPage ColorDocument131 pages68 36 301-1-SEABC C13 2023 Session 5 Decks 2PerPage Colorelidstone@hotmail.comNo ratings yet

- 68 36 302-2-SEABC C13 2023 Session6 Axially Loaded Members 2PerPageColorDocument130 pages68 36 302-2-SEABC C13 2023 Session6 Axially Loaded Members 2PerPageColorelidstone@hotmail.comNo ratings yet

- 50 1 323-1-Base Isolation and Dampers 2022Document121 pages50 1 323-1-Base Isolation and Dampers 2022elidstone@hotmail.comNo ratings yet

- 72 - 36 - 315-2 E11 2024 Lecture 5 WindDocument88 pages72 - 36 - 315-2 E11 2024 Lecture 5 Windelidstone@hotmail.comNo ratings yet

- 72 - 36 - 318-1-2024 E11 Lecture 7 FEP 2023Document69 pages72 - 36 - 318-1-2024 E11 Lecture 7 FEP 2023elidstone@hotmail.comNo ratings yet

- 51 - 1 - 302-1-Csep E21 Lecture 4 EfmDocument57 pages51 - 1 - 302-1-Csep E21 Lecture 4 Efmelidstone@hotmail.comNo ratings yet

- 68 36 299-1-SEABC C13 2023 Session3 UnbracedBeams Roof Beams 2PerPageColorDocument119 pages68 36 299-1-SEABC C13 2023 Session3 UnbracedBeams Roof Beams 2PerPageColorelidstone@hotmail.comNo ratings yet

- C4-1 Lecture 5 - Dynamic Response of BuildingsDocument75 pagesC4-1 Lecture 5 - Dynamic Response of Buildingselidstone@hotmail.comNo ratings yet

- 2020 National Building Code of Canada Seismic Hazard MapsDocument12 pages2020 National Building Code of Canada Seismic Hazard Mapselidstone@hotmail.comNo ratings yet

- 51 - 1 - 301-1-Csep E21 Lecture 3 EfmDocument65 pages51 - 1 - 301-1-Csep E21 Lecture 3 Efmelidstone@hotmail.comNo ratings yet

- Expanding Wood Use Towards 2025Document44 pagesExpanding Wood Use Towards 2025elidstone@hotmail.comNo ratings yet

- Deaggregation of NBCC 2015 Seismic Hazard For Selected Canadian CitiesDocument9 pagesDeaggregation of NBCC 2015 Seismic Hazard For Selected Canadian Citieselidstone@hotmail.comNo ratings yet

- C4-1 Lecture 4 - Earthquake HazardsDocument102 pagesC4-1 Lecture 4 - Earthquake Hazardselidstone@hotmail.comNo ratings yet