Professional Documents

Culture Documents

Internal Audit Risk Scale and Assessment

Internal Audit Risk Scale and Assessment

Uploaded by

Wasim ArshadOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Internal Audit Risk Scale and Assessment

Internal Audit Risk Scale and Assessment

Uploaded by

Wasim ArshadCopyright:

Available Formats

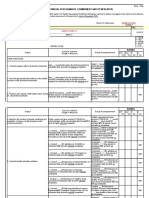

Risk Scale

Revised 12/5/2013

SEVERITY FREQUENCY

1 Fatality A Common Occurance

2 Serious Illness B Known to Occur

3 Product Recall C Could Occur (Probable)

4 Customer Complaint D Not Expected to Occur

5 Insignificant E Practically Impossible

A B C D E

1 1 2 4 7 11

2 3 5 8 12 16

3 6 9 13 17 20

4 10 14 18 21 23

5 15 19 22 24 25

SCORE RISK LEVEL Frequency

1-5 High Weekly

6-9 Major Monthly

10 -15 Moderate Quarterly

16 - 19 Minor 2x/ Year

20 - 25 Low 1x/ Year

**Frequencies determined by risk, may be deviated based on historical evidence**

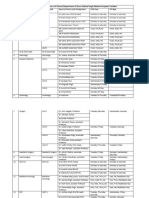

Audit Risk Analysis 2014 Revised 12/5/2013

Risk Analysis

Frequency

Likeliness of Risk Based on Reason for Deviation of

Audit Severity Occurrence Value Risk Audit Frequency Frequency Comments:

Inspections for this program will be

1 GMP - Employee Practices & Hygiene 4 D 21 Yearly Yearly Large Temporary Workforce performed at a minimum weekly

2 GMP - External Grounds 5 D 24 Yearly 2x Year Maintain Facility

3 GMP - Interior Structure 4 C 18 2x Year 2x Year

4 GMP - Equipment 3 D 17 2x Year 2x Year

BRC states a min. of once per month,

5 Zone 1 Audit (open product) 3 D 17 2x Year Monthly Quality concerns only - not food safety South Warehouse and Processing Rooms

6 Zone 2 Audit (product areas- not open) 4 C 18 2x Year 2x Year Fillers, Downline, Material staging

7 Zone 3 Audit (auxiliary areas) 4 D 21 Yearly Yearly Warehouse, outside perimeter

For GMP purposes, This is a BRC

Sanitary Operations - Product Flow (Rec, fundamental, Frequent new

8 Blend, fill, pack ship) 4 D 21 Yearly 2x Year equipment/HACCP changes

4 parts: Filler, Downline and Processor

Sanitation validation; Master Sanitation

Schedule, CIP Concentrations, Times, and

Temps, Visual Checks. Quarterly inspections

may be a combination of audits and self-

9 Sanitation Program 3 D 17 2x Year 2x Year assessments

Quarterly surverys and review of trend

Based on past history, reports; annual overview audit of entire

10 Pest Management 4 D 21 Yearly Quarterly recommendation of BRC program

11 Warehouse, Shipping and Receiving 4 D 21 Yearly Yearly Include inventory checks

12 Utilities, Water & Air 4 D 21 Yearly Yearly

13 Good Lab Practices - Micro Testing 4 E 23 Yearly Yearly Does not directly affect food safety

14 Maintenance, PMP 3 D 17 2x Year 2x Year

Not expected to occur based on robust

allergen program; Quarterly inspections

may be a combination of audits and self-

15 Allergen Control 2 D 12 Quarterly Quarterly assessments.

Environmental Monitoring and Product

16 Inspection, Testing & Fill Weights 4 D 21 Yearly Yearly 5.5.1.1

Yearly/ Prior to ANY High Acid

changes which may Includes HACCP Flow Diagram and Flow

17 HACCP Validation and Verification 3 E 20 Yearly affect food safety Charts

Inspections: Zone 1 - Quarterly; Zone 2 - 2x

18 Glass and Brittle Plastic 4 D 21 Yearly Yearly Year; Zone 3 - Yearly

4.9 To include non-food grade chemicals,

MSDS, segregation and storage, training of

19 Chemical and Foreign Material Control 4 D 21 Yearly Yearly personnel, review of GMP audits and G&BP

Daily inspections and validation of food

security programs. Quarterly audits may be

a combination of audits and self-

20 Food Security 1 E 11 Quarterly Quarterly assessments

Control of Non-Conforming Product and

21 Raw Materials 3 D 17 2x Year 2x Year Hold Program

22 Customer Complaints and Customer Service 4 D 21 Yearly Yearly

Raw Material Management and Incoming

23 Material Inspection 3 D 17 2x Year 2x Year

24 Specification Compliance 4 D 21 Yearly Yearly

25 Calibration 4 D 21 Yearly Yearly Inspected quarterly

26 Rework 4 D 21 Yearly Yearly

Mass Balance check required every 6

27 Identity Preserved (Kosher and Organic) 3 D 17 2x Year 2x Year months by BRC

28 Vendor/Contractor Management 5 E 25 Yearly Yearly

Includes Training, Personal Hygiene,

Medical Screening, and Protective Clothing/

Aspects of this program are audited/

29 Personnel 4 D 21 Yearly Yearly reviewed with other programs as well

A Mock Recall will also be performed

30 Traceability and Recall 2 E 16 2x Year 2x Year minimally twice a year

31 Control of Operations 2 E 16 2x Year 2x Year Systems review of Process Control

OTHER BRC FUNDAMENTAL AUDITS

Or as necessary, or upon any changes

Senior Management Commitment N/A N/A N/A N/A Yearly that affect the scope of the program KPI Review, Objective Action Plan

Or as necessary, or upon any changes Review of document for accuracy, review of

Document Review N/A N/A N/A N/A Yearly that affect the scope of the program records for current revisions

Or as necessary, or upon any changes

Corrective Actions N/A N/A N/A N/A Yearly that affect the scope of the program Review of effectiveness

Or as necessary, or upon any changes

External and Internal Audits Review N/A N/A N/A N/A Yearly that affect the scope of the program Audit close outs, on-time performance

You might also like

- ASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal HygieneDocument5 pagesASEAN TMHS GMP Training Chapter 4 Annex 1 SOP On Personal Hygienesunny mgxNo ratings yet

- Access Control To GMP AreaDocument4 pagesAccess Control To GMP AreaNishit SuvaNo ratings yet

- Raw Material SupplierDocument9 pagesRaw Material SuppliersutharitesshNo ratings yet

- Platinium Marine Products SDN BHD Hazard Analysis and Critical Control Point (Haccp) Manual Title Section: Process Flow ChartDocument7 pagesPlatinium Marine Products SDN BHD Hazard Analysis and Critical Control Point (Haccp) Manual Title Section: Process Flow ChartHas platiniumNo ratings yet

- Aka GMP Audit FormDocument8 pagesAka GMP Audit FormAlpian BosixNo ratings yet

- Procedure FOR Handling of Complaints and Appeals: Nabh-Proc - C&ADocument8 pagesProcedure FOR Handling of Complaints and Appeals: Nabh-Proc - C&APranav KumarNo ratings yet

- SCF 07 Quality ManagementDocument48 pagesSCF 07 Quality ManagementGyorgy LukacsNo ratings yet

- MD-QMS ObjectivesDocument1 pageMD-QMS Objectivessfda.badrmedicalNo ratings yet

- Organization Structure: L L M L L MDocument9 pagesOrganization Structure: L L M L L MNasef Mohd0% (1)

- SOP On Handling of Critical and Non-Critical DeviationsDocument6 pagesSOP On Handling of Critical and Non-Critical DeviationsRajnish PatilNo ratings yet

- SOP-PC-02 V3.4 Supplier Selection and EvaluationDocument2 pagesSOP-PC-02 V3.4 Supplier Selection and EvaluationPhilNo ratings yet

- SOP For Rawmaterial SievingDocument2 pagesSOP For Rawmaterial SievingarunNo ratings yet

- Change Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-XxxDocument7 pagesChange Control Report: X Pharmaceutical Manufacturing Company Quality Assurance Department Ref. SOP No.: Sop-Xxxrouss1906No ratings yet

- Document Change Request FormDocument2 pagesDocument Change Request FormOlexei SmartNo ratings yet

- Annexure-2 Market Complaint FormDocument2 pagesAnnexure-2 Market Complaint FormSagar ChavanNo ratings yet

- Iso22000 - Internal Audit ChecklistDocument2 pagesIso22000 - Internal Audit ChecklistGidion Jeffri PoerbaNo ratings yet

- SOP For Sampling of Packing MaterialDocument3 pagesSOP For Sampling of Packing MaterialSolomonNo ratings yet

- Tracebility Processrecall ProceduresDocument5 pagesTracebility Processrecall ProceduresRyan100% (1)

- SOP For Change ControlDocument10 pagesSOP For Change Controlisrael afolayan mayomiNo ratings yet

- SOP For IQADocument25 pagesSOP For IQAMuhammad As'adNo ratings yet

- Annual Product Review (APR) Product Quality Review (PQR)Document34 pagesAnnual Product Review (APR) Product Quality Review (PQR)Sundar GanesanNo ratings yet

- Haccp PlanDocument1 pageHaccp Planjlordmercader100% (1)

- Issuance of DocumentsDocument2 pagesIssuance of DocumentsAshok KumarNo ratings yet

- Sop For in - Process Fill Weight DeterminationDocument1 pageSop For in - Process Fill Weight DeterminationPrince MoniNo ratings yet

- G.2 Allergen Validation RecordDocument1 pageG.2 Allergen Validation RecordBibekNo ratings yet

- Sterille Production AreaDocument12 pagesSterille Production AreaNavdeep ChaudharyNo ratings yet

- Ludhiana Flour & General Mills Private Limited: M L SOPDocument3 pagesLudhiana Flour & General Mills Private Limited: M L SOPMilan BankNo ratings yet

- GPM Guideline Inspect EngDocument96 pagesGPM Guideline Inspect EngDilawar BakhtNo ratings yet

- QSP Control of Documented InformationDocument2 pagesQSP Control of Documented InformationtriveshNo ratings yet

- 09 GMP SOP 08 Quality Control LaboratoryDocument5 pages09 GMP SOP 08 Quality Control Laboratorykishan chiraniaNo ratings yet

- SOP For Sampling of Finished ProductDocument3 pagesSOP For Sampling of Finished ProductSolomonNo ratings yet

- Syarikat Kejora Sdn. BHD: Document Title Traceability/Recall Inspection Record Reference No. SKSB/P06/REC/002Document1 pageSyarikat Kejora Sdn. BHD: Document Title Traceability/Recall Inspection Record Reference No. SKSB/P06/REC/002misz_rubyNo ratings yet

- BP 2 5 2 Vs FM Verification ScheduleDocument6 pagesBP 2 5 2 Vs FM Verification Schedulealias brownNo ratings yet

- Preventive Maintenance PlanDocument7 pagesPreventive Maintenance PlanCuyapo Infirmary Lying-In HospitalNo ratings yet

- SOP For Handling and Control For Prohibited ItemsDocument4 pagesSOP For Handling and Control For Prohibited ItemsSolomon GamanuelNo ratings yet

- QP-72-03 Customer CommunicationDocument3 pagesQP-72-03 Customer CommunicationSamsudin Ahmad0% (1)

- 32 Prepare FP Specification 032Document2 pages32 Prepare FP Specification 032ASHOK KUMAR LENKANo ratings yet

- Corrective & Preventive Action Report SA8000:2014: Rajda Industries & Exports Pvt. LTDDocument2 pagesCorrective & Preventive Action Report SA8000:2014: Rajda Industries & Exports Pvt. LTDAVISEK GHOSHNo ratings yet

- MPVC FSSC Management Review Meeting-2023-01Document1 pageMPVC FSSC Management Review Meeting-2023-01swapon kumar shillNo ratings yet

- Vendor/ Supplier QuestionnaireDocument3 pagesVendor/ Supplier QuestionnaireThanh NguyễnNo ratings yet

- 10.2 Management Review Control Procedure (AT-HSSE-P-10-02V0-2022) - ReleaseDocument6 pages10.2 Management Review Control Procedure (AT-HSSE-P-10-02V0-2022) - ReleaseGeyko RuslanNo ratings yet

- SOP For Destruction of Control Samples (Raw Material and Finished Product)Document3 pagesSOP For Destruction of Control Samples (Raw Material and Finished Product)Solomon100% (1)

- Methodology For Determination of Hazard Controls CCP S and OPRP SDocument4 pagesMethodology For Determination of Hazard Controls CCP S and OPRP SRosinanteNo ratings yet

- SOP065RMSD - 04 Raw Material Specification Development FormDocument4 pagesSOP065RMSD - 04 Raw Material Specification Development FormGrace ChenNo ratings yet

- Change Control Form RevisedDocument5 pagesChange Control Form RevisedMusyoka UrbanusNo ratings yet

- Ludhiana Flour & General Mills Private Limited: Annexures of Haccp SystemDocument2 pagesLudhiana Flour & General Mills Private Limited: Annexures of Haccp SystemMilan BankNo ratings yet

- Department: M.R. & Quality Control Document Title: Control of Non-Conforming ProductDocument3 pagesDepartment: M.R. & Quality Control Document Title: Control of Non-Conforming ProductJamil VoraNo ratings yet

- Production Record TemplateDocument4 pagesProduction Record Templatenurul wahyuniNo ratings yet

- Purpose:: Validation Type: In-House Validation Critical Limit: AbsenceDocument1 pagePurpose:: Validation Type: In-House Validation Critical Limit: AbsenceMilan BankNo ratings yet

- Contamination Control StrategyDocument13 pagesContamination Control Strategyisrael afolayan mayomiNo ratings yet

- Approved External Providers ListDocument2 pagesApproved External Providers ListMuhammad BabarNo ratings yet

- Capa and Change ManagementDocument2 pagesCapa and Change ManagementEldaniz HasanovNo ratings yet

- Report - In-Plant TrainingDocument79 pagesReport - In-Plant TrainingShubh DarjiNo ratings yet

- 2 Food Loss and WasteDocument61 pages2 Food Loss and Wastemarani.1952816No ratings yet

- Fifo ProcedureDocument2 pagesFifo ProcedureHaseem Ali100% (1)

- Procedure For Emergency PreparenessDocument4 pagesProcedure For Emergency PreparenessNaizil KareemNo ratings yet

- Job Description: Position: Class: Departament: División: Report To: Manager: General DescriptionDocument3 pagesJob Description: Position: Class: Departament: División: Report To: Manager: General DescriptionRubenCastilloOlguinNo ratings yet

- SOP For Product RecallDocument26 pagesSOP For Product Recallmonumj143100% (1)

- Procedure For Supplires EvaluationDocument3 pagesProcedure For Supplires EvaluationQA Lepl100% (1)

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- New Microsoft Word DocumentDocument5 pagesNew Microsoft Word DocumentWasim ArshadNo ratings yet

- New ProgrammingDocument1 pageNew ProgrammingWasim ArshadNo ratings yet

- HACCP Validation Checklist Annual ReassementDocument2 pagesHACCP Validation Checklist Annual ReassementWasim ArshadNo ratings yet

- Food Fraud Chat RoughDocument15 pagesFood Fraud Chat RoughWasim ArshadNo ratings yet

- ImplementationDocument4 pagesImplementationWasim ArshadNo ratings yet

- New 1 BookDocument1 pageNew 1 BookWasim ArshadNo ratings yet

- Internal Audit FindingDocument2 pagesInternal Audit FindingWasim ArshadNo ratings yet

- Mind AddressDocument2 pagesMind AddressWasim ArshadNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentWasim ArshadNo ratings yet

- Condenser, 30-4-15Document3 pagesCondenser, 30-4-15Wasim ArshadNo ratings yet

- New Microsoft Word DocumentDocument1 pageNew Microsoft Word DocumentWasim ArshadNo ratings yet

- Rotary ScreeDocument1 pageRotary ScreeWasim ArshadNo ratings yet

- Cond PumpDocument1 pageCond PumpWasim ArshadNo ratings yet

- Connecting RodDocument1 pageConnecting RodWasim ArshadNo ratings yet

- Boiler 80Document18 pagesBoiler 80Wasim ArshadNo ratings yet

- Air HeaterDocument1 pageAir HeaterWasim ArshadNo ratings yet

- Chain For ElevatorsDocument1 pageChain For ElevatorsWasim ArshadNo ratings yet

- BoilerDocument2 pagesBoilerWasim ArshadNo ratings yet

- Chemical Dosing PumpDocument1 pageChemical Dosing PumpWasim ArshadNo ratings yet

- BoardsDocument1 pageBoardsWasim ArshadNo ratings yet

- AIDocument1 pageAIWasim ArshadNo ratings yet

- SLP Cfy Cover LetterDocument7 pagesSLP Cfy Cover Letterafmrpaxgfqdkor100% (1)

- Mindfulness: The Big IdeasDocument6 pagesMindfulness: The Big IdeasLuis AndradeNo ratings yet

- The Pathophysiology and Genetics of OCDDocument12 pagesThe Pathophysiology and Genetics of OCDCrescent FangNo ratings yet

- ACTIVITY Psychological First Aid PFADocument25 pagesACTIVITY Psychological First Aid PFAChristine DianeNo ratings yet

- Bilal Ahmad Khan CVDocument2 pagesBilal Ahmad Khan CVfr.faisal8265No ratings yet

- Werner Erhard S Est Training in The PrisonsDocument8 pagesWerner Erhard S Est Training in The PrisonsMauroVentolaNo ratings yet

- Project ReportDocument27 pagesProject Reportniladri mondalNo ratings yet

- Ribo Fact Sheet - NewDocument1 pageRibo Fact Sheet - Newmahmoud redaNo ratings yet

- An Appraisal On Occlusal Philosophies in Full-Mouth Rehabilitation A Literature ReviewDocument4 pagesAn Appraisal On Occlusal Philosophies in Full-Mouth Rehabilitation A Literature ReviewaggrolNo ratings yet

- Swimming Pools and Spa Pools: Standard For The Operation ofDocument40 pagesSwimming Pools and Spa Pools: Standard For The Operation ofakramNo ratings yet

- Stresses and Challenges For New Graduates in HospitalsDocument6 pagesStresses and Challenges For New Graduates in HospitalskitsilNo ratings yet

- 1 PBDocument8 pages1 PBJauharotun NisaNo ratings yet

- Firefly Prime Mobile AppDocument7 pagesFirefly Prime Mobile Appmukh bhaNo ratings yet

- NewDocument17 pagesNewMadhu BalaNo ratings yet

- Social Awareness QuestionnaireDocument13 pagesSocial Awareness QuestionnaireBenjar FerandezNo ratings yet

- Soal Inggris - 2Document6 pagesSoal Inggris - 2vivitrisami05No ratings yet

- Passenger Locator Form: Non-Red ListDocument4 pagesPassenger Locator Form: Non-Red ListSamadrukNo ratings yet

- Cowan 1999Document20 pagesCowan 1999ggggggggggg32No ratings yet

- Closed PTW AuditDocument1 pageClosed PTW Auditf.BNo ratings yet

- Disorders of The Digestive SystemDocument108 pagesDisorders of The Digestive SystemNina Lao CamamaNo ratings yet

- Chun-Hung Chen Kun-Cheng ChouDocument38 pagesChun-Hung Chen Kun-Cheng ChoutwnationNo ratings yet

- Department of Labor: Bct-Fy01Document101 pagesDepartment of Labor: Bct-Fy01USA_DepartmentOfLabor100% (1)

- Individual Performance Commitment and Review (Ipcr) : Name of Employee: Approved By: Date Date FiledDocument12 pagesIndividual Performance Commitment and Review (Ipcr) : Name of Employee: Approved By: Date Date FiledTiffanny Diane Agbayani RuedasNo ratings yet

- Main AmbaniDocument28 pagesMain AmbaniankursagarNo ratings yet

- ANALISIS PENERAPAN SISTEM LOCKOUTTAGOUT (LOTO) PADA BAGIAN OPERASI DAN PEMELIHARAAN DI PT. X TANJUNG EMAS KOTA SEMARANG (Berdasarkan Standar OSHA 29 CFR Part 1910.147 Dan Part 1910.333) PDFDocument11 pagesANALISIS PENERAPAN SISTEM LOCKOUTTAGOUT (LOTO) PADA BAGIAN OPERASI DAN PEMELIHARAAN DI PT. X TANJUNG EMAS KOTA SEMARANG (Berdasarkan Standar OSHA 29 CFR Part 1910.147 Dan Part 1910.333) PDFAfif Fayadh VictoryNo ratings yet

- Punctate: NumberDocument6 pagesPunctate: NumberMuhamad Chairul SyahNo ratings yet

- Written Report Abnormal PsychologyDocument23 pagesWritten Report Abnormal PsychologyCy Esquibel LingaNo ratings yet

- OPD and OT Days of Doctors of Clinical Department of Guru Gobind Singh Medical HospitalDocument4 pagesOPD and OT Days of Doctors of Clinical Department of Guru Gobind Singh Medical HospitalBohar singh Brar BrarNo ratings yet

- Post Partum Psychosis Nursing Diagnosis: Aurelio, Lyca Mae MDocument3 pagesPost Partum Psychosis Nursing Diagnosis: Aurelio, Lyca Mae MLyca Mae AurelioNo ratings yet

- 3) Z. 10.1016@j.jcrc.2020.06.005 (Alexis Tabah)Document18 pages3) Z. 10.1016@j.jcrc.2020.06.005 (Alexis Tabah)Mastifa HanasitaNo ratings yet