Professional Documents

Culture Documents

Lecture 1 - Student Version

Lecture 1 - Student Version

Uploaded by

MYLENE BUENOOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lecture 1 - Student Version

Lecture 1 - Student Version

Uploaded by

MYLENE BUENOCopyright:

Available Formats

Malampaya Offshore JG Summit Petrochemical Group

Pilipinas Shell Petroleum Corporation

First Gen Corporation

ICE 410 ADVANCED CONTROL SYSTEM DPSC

Control Room – Operator Work Stations

ICE 410 ADVANCED CONTROL SYSTEM DPSC

Control Room – System Cabinet

ICE 410 ADVANCED CONTROL SYSTEM DPSC

DCS Graphics

ICE 410 ADVANCED CONTROL SYSTEM DPSC

DCS Graphics DCS Function Block Program

ICE 410 ADVANCED CONTROL SYSTEM DPSC

INDUSTRIAL PROCESSES

CONTINUOUS

DISCRETE

BATCH

Continuous production is called a continuous

process because the materials, either dry bulk or

fluids that are being processed are continuously in

motion, undergoing chemical reactions or subject

to mechanical or heat treatment.

Continuous usually means operating 24 hours per

day, seven days per week with infrequent

maintenance shutdowns, such as semi-annual or

annual. Some chemical plants can operate for

more than one to two years without a shutdown.

Blast furnaces can run from four to ten years

without stopping.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

INDUSTRIAL PROCESSES

CONTINUOUS

DISCRETE

BATCH

Discrete manufacturing is the production of distinct items. Automobiles, furniture, toys, smartphones,

and aeroplanes are examples of discrete manufacturing products. The resulting products are easily

identifiable and differ greatly from process manufacturing where the products are undifferentiated, for

example oil, natural gas and salt.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

INDUSTRIAL PROCESSES

CONTINUOUS

DISCRETE

BATCH

Batch production is a method

whereby a group of identical

products are produced

simultaneously (rather than one at a

time). It is up to the manufacturer to

decide how big the batch will be,

and how often these batches will be

made.

Each batch goes through the

separate stages of the

manufacturing process together.

Meaning that another batch can’t

begin a stage, if the previous one is

still within that part of the cycle.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

PROCESS VARIABLES

PRESSURE

TEMPERATURE

FLOW

LEVEL

ANALYSIS

Measurement of process variables is essential in control systems to controlling a process. The value of

the process variable is continuously monitored so that control may be exerted. Four commonly

measured variables that affect chemical and physical processes are: pressure, temperature, level and

flow but there are in fact a large number of measurement quantities which for international purposes use

the International System of Units (SI)

ICE 410 ADVANCED CONTROL SYSTEM DPSC

CONTROL LOOP ELEMENTS

SENSING

TRANSMITTING

CONTROLLING

FINAL CONTROLLING

A sensing element/sensor is a device that performs the initial measurement and energy conversion of a

process variable into analogous electrical or pneumatic information.

A transmitting element/transmitter is a device that converts a reading from a sensing element into a standard

signal and transmit that signal to a controller/controlling element.

A controlling element/controller is a device that receives data from a transmitter, compares that data to a

programmed set point and if necessary signals the final controlling element to take corrective action.

A final controlling element is the part of the control system that exerts a direct influence on the process. It is

the device that provides those required changes in the process variable to bring it to the set point.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

CONTROL LOOP SIGNALS

ANALOG

DIGITAL

The analog signals were used in many systems to produce signals to carry information. These

signals are continuous in both values and time. The use of analog signals has been declined with

the arrival of digital signals. In short, to understand analog signals – all signals that are natural or

come naturally are analog signals.

Unlike analog signals, digital signals are not continuous, but signals are discrete in value and time.

These signals are represented by binary numbers and consist of different voltage values.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

CONTROL LOOP CLASSIFICATION

OPEN LOOP

CLOSED LOOP

A control system in which the control action is totally independent of the output of the system then it is

called an open-loop control system. A manual control system is also an open-loop control system.

Control systems in which the output has an effect on the input quantity in such a manner that the input

quantity will adjust itself based on the output generated is called a closed-loop control system.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

CONTROL LOOP PARAMETERS

PROCESS VALUE (PV)

SET POINT (SP)

MANIPULATED VALUE (MV)

A process value is the current measured value of a particular part of a process which is being

monitored or controlled. An example of this would be the temperature of a furnace.

A setpoint is the desired or target value for an essential variable, or process value of a system.

Departure of such a variable from its setpoint is one basis for error controlled regulation using

negative feedback for automatic control.

The manipulated value is the parameter that is adjusted to bring the process back to the desired

setpoint.

ICE 410 ADVANCED CONTROL SYSTEM DPSC

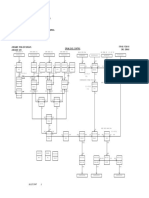

To HP Flar

SP = MV: HC

50% 01 PV: 45%

SP: 60 m3/s Header

MV: 40%

FIC FY

ZT ZI 01 01

01 01 MV: 40% <

PV: 50 m3/s

SP: 5 bar PIC PV-01

01B

FT

PIC

SP: 4 bar MV: 30% 01

01A

Gas/LiquidHV-01

From Inlet Separation PV: 3 bar PT FV-01

01 Gas

Process: Separation of To Inlet Co

Gas and Liquid

Process Variables:

Level of Liquid in D01 D01 LT

PV: 45%

LIC SP: 50%

Pressure of Gas in D01 01 01

Flow of Gas exiting D01

MV: 40%

Valve (HV01) opening Liquid

To Condens

Separator

LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

To HP Flar

SP = MV: HC

50% 01 PV: 45%

SP: 60 m3/s Header

MV: 40%

FIC FY

ZT ZI 01 01

01 01 MV: 40%

PV: 50 m3/s <

SP: 5 bar PIC PV-01

01B

FT

PIC

SP: 4 bar 01A MV: 30% 01

HV-01

Gas/Liquid

From Inlet Separation PV: 3 bar PT FV-01

01 Gas

Sensing/Transmitting To Inlet Co

Elements:

LT01

PT01

PV: 45%

FT01 D01 LT LIC SP: 50%

01 01

ZT01

MV: 40%

Controlling Elements:

LIC01 Liquid

PIC01A/B To Condens

FIC01 Separator

FY01 LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

To HP Flar

SP = MV: HC

50% 01 PV: 45%

SP: 60 m3/s Header

MV: 40%

FIC FY

ZT ZI 01 01

01 01 MV: 40%

PV: 50 m3/s <

SP: 5 bar PIC PV-01

01B

FT

PIC

SP: 4 bar 01A MV: 30% 01

HV-01

Gas/Liquid

From Inlet Separation PV: 3 bar PT FV-01

01 Gas

Sensing/Transmitting To Inlet Co

Elements:

LT01

PT01

PV: 45%

FT01 D01 LT LIC SP: 50%

01 01

ZT01

MV: 40%

Controlling Elements:

LIC01 Liquid

PIC01A/B To Condens

FIC01 Separator

FY01 LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

To HP Flar

SP = MV: HC

50% 01 PV: 45%

SP: 60 m3/s Header

MV: 40%

FIC FY

ZT ZI 01 01

01 01 MV: 40% <

PV: 50 m3/s

SP: 5 bar PIC PV-01

01B

FT

PIC

SP: 4 bar MV: 30% 01

01A

HV-01

Gas/Liquid

From Inlet Separation PV: 3 bar PT FV-01

01 Gas

Final Controlling Elements: To Inlet Cooler

HV01

LV01

PV01

PV: 45%

FV01 D01 LT LIC SP: 50%

01 01

Signals:

MV: 40%

Analog - 4-20 mA, 3-15 psi

Liquid

To Condens

Separator

LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

To HP Flar

SP = MV: HC

50% 01 PV: 45%

SP: 60 m3/s Header

MV: 40%

FIC FY

ZT ZI Loop P01B 01 01

01 01 MV: 40%

PV: 50 m3/s <

SP: 5 bar PIC PV-01

01B

Loop Z01 PIC

FT

SP: 4 bar 01A MV: 30% 01

HV-01

Loop H01

Gas/Liquid

From Inlet Separation PV: 3 bar PT Loop P01A/F01 FV-01

01 Gas

Classification: To Inlet Co

Open Loop - H01, Z01

Closed Loop PV: 45%

L01 - Simple PID D01 LT LIC SP: 50%

01 01

P01B - Simple PID

P01A/F01 - Override Loop L01 MV: 40%

Liquid

To Condens

Separator

LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

HC

Re

SP = MV: SP: 60 m3/s

50%

01 PV: 45%

MV: 40% To

FIC FY

ZT

01

ZI

01

01 01 He

MV: 40% <

SP: 4 bar PIC PV-01 PV: 50 m3/s

01B

FT

PIC

SP: 4 bar 01A MV: 30% 01

HV-01

Gas/Liquid

From Inlet Separation PV: 3 bar PT

01

FV-01

Gas

Parameters: To Inlet

PV

SP D01 LT PV: 45% LIC SP: 50%

01 01

MV MV: 40%

Liquid

To Condens

Separator

LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

To HP Flar

SP = MV: HC

50% 01 PV: 45%

SP: 60 m3/s Header

MV: 40%

FIC FY

ZT ZI 01 01

01 01 MV: 40% <

PV: 50 m3/s

SP: 5 bar PIC PV-01

01B

FT

PIC

SP: 4 bar MV: 30% 01

01A

HV-01

Gas/Liquid

From Inlet Separation PV: 3 bar PT FV-01

01 Gas

Activity 1 To Inlet Co

Find, explain a process with a

Control System and identify

the following:

PV: 45%

1. Process Variables D01 LT LIC SP: 50%

01 01

2. Loop Elements (Sensing,

Transmitting, Controlling, MV: 40%

Final Controlling)

3. Signals (Analog/Digital) Liquid

4. Parameters (PV, SP, MV) To Condens

5. Loop Classification Separator

(Open, Closed) LV-01

ICE 410 ADVANCED CONTROL SYSTEM DPSC

You might also like

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 4 out of 5 stars4/5 (4)

- " Control Laboratory " Experiment: Flow Control Date: 19-10-2015Document16 pages" Control Laboratory " Experiment: Flow Control Date: 19-10-2015mohammed kadhimNo ratings yet

- Software Project Management: Pert/CpmDocument14 pagesSoftware Project Management: Pert/CpmHemant SinghNo ratings yet

- Automation Process ControlDocument39 pagesAutomation Process ControlAbdurabu AL-MontaserNo ratings yet

- Inst PrabhaDocument29 pagesInst Prabharaj guptaNo ratings yet

- Evaporative Emission Control PressureDocument5 pagesEvaporative Emission Control PressureDaniel Mamani ParedezNo ratings yet

- TL - 07 - 07-12 Microlink 3 Service BullitinDocument8 pagesTL - 07 - 07-12 Microlink 3 Service BullitinCristobal MartinezNo ratings yet

- MC90 Appendix B Actuators and ControllersDocument10 pagesMC90 Appendix B Actuators and ControllersMobin GhariNo ratings yet

- Auto Control Loops in Thermal Power Plant: Sith - Ananda KumarDocument37 pagesAuto Control Loops in Thermal Power Plant: Sith - Ananda KumarVignesh RajanNo ratings yet

- FlowCon DPCV BrochureDocument4 pagesFlowCon DPCV BrochureDenon EvonNo ratings yet

- PCBL-CPP/FCS0101/DR0065.edf: Job Name: PCBL-CGP Durgapu Job Code: Ce15 STN No: Fcs0101 DRG: DR0065Document1 pagePCBL-CPP/FCS0101/DR0065.edf: Job Name: PCBL-CGP Durgapu Job Code: Ce15 STN No: Fcs0101 DRG: DR0065Purnima GunturuNo ratings yet

- 奉申自控15版英文样本Document154 pages奉申自控15版英文样本VCON GLOBALNo ratings yet

- Typical Controls Report For FS5002 MKIIDocument13 pagesTypical Controls Report For FS5002 MKIIchdiNo ratings yet

- Flash Code C7Document6 pagesFlash Code C7hanumkiyamaNo ratings yet

- Centum VP 5 Eng Control PgmsglobalDocument36 pagesCentum VP 5 Eng Control PgmsglobalfaqdaniNo ratings yet

- 233 - Instrument Symbology & P&IDDocument22 pages233 - Instrument Symbology & P&IDLuqman Saputra100% (1)

- Additions, Revisions, or Updates: Subject DateDocument7 pagesAdditions, Revisions, or Updates: Subject DateEduardo Aguirre GarciaNo ratings yet

- Process DescriptionDocument6 pagesProcess DescriptionrssmartinvestNo ratings yet

- Integrated Startup Procedure1Document8 pagesIntegrated Startup Procedure1moturuappalasreenuNo ratings yet

- Adcatraining Control Valve 5 Rev 01Document36 pagesAdcatraining Control Valve 5 Rev 01Fendy ShirahNo ratings yet

- Preliminary - MITTEN HPU Only Rev DDocument120 pagesPreliminary - MITTEN HPU Only Rev DFabyano BrittoNo ratings yet

- HSC 19 01 030E - Optidist - 7Document9 pagesHSC 19 01 030E - Optidist - 7Geyser Anderson Corales CeronNo ratings yet

- Air Conditioning System For Medical SpacesDocument16 pagesAir Conditioning System For Medical SpacesMatias Sandoval AlarconNo ratings yet

- Tutorial Aspen DynamicsDocument20 pagesTutorial Aspen DynamicsRobbie_LOCO100% (2)

- Sauer Danfoss PVE-series 4Document52 pagesSauer Danfoss PVE-series 4aaa100% (1)

- Process Control Fundamentals - ADDDocument115 pagesProcess Control Fundamentals - ADDAsif100% (2)

- EhtcDocument38 pagesEhtcPardeepChahal100% (1)

- Diagnostic Trouble Codes (DTC) : DTC P0712 Transmission Fluid Temperature Sensor Circuit Low Input (High Temperature)Document4 pagesDiagnostic Trouble Codes (DTC) : DTC P0712 Transmission Fluid Temperature Sensor Circuit Low Input (High Temperature)luis eduardo corzo enriquezNo ratings yet

- HPFANGX DatasheetDocument9 pagesHPFANGX DatasheetParedão FrankensteinNo ratings yet

- Liquid Level Controller - Water Level Controller - Level Controller - GIC IndiaDocument5 pagesLiquid Level Controller - Water Level Controller - Level Controller - GIC IndiaPrasadPurohitNo ratings yet

- EH4500-2 Hoist RevOct05Document61 pagesEH4500-2 Hoist RevOct05FAF majorNo ratings yet

- Pve and PVHC For PVG 32, PVG 100 and PVG 120: Service ManualDocument16 pagesPve and PVHC For PVG 32, PVG 100 and PVG 120: Service Manualphankhoa83-1No ratings yet

- Piping and Instrumentation Diagram (P&Id) : By: Rod Mhark C. Carcuevas BSEE V-3Document34 pagesPiping and Instrumentation Diagram (P&Id) : By: Rod Mhark C. Carcuevas BSEE V-3Anthony SamonteNo ratings yet

- Control and Instrumentation of Chemical ProcessesDocument38 pagesControl and Instrumentation of Chemical ProcessesdioniewilsonatyahooNo ratings yet

- FlowCon Application GuideDocument62 pagesFlowCon Application Guidenobita3No ratings yet

- Dynamics Quick Guide BetaDocument15 pagesDynamics Quick Guide BetaCHANADASNo ratings yet

- R59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMDocument22 pagesR59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMRamon Bochaca SandiumengeNo ratings yet

- Cupiagua CPF Time Delayed Overcurrent: Function Test CertificateDocument2 pagesCupiagua CPF Time Delayed Overcurrent: Function Test CertificatesushantNo ratings yet

- Noja PowerDocument2 pagesNoja PowerDanilo Lizama Da SilvaNo ratings yet

- SCC201 ServiceDocument48 pagesSCC201 ServiceMarin Octavian MihailNo ratings yet

- Over Current Protection IC: General DescriptionDocument11 pagesOver Current Protection IC: General DescriptioniammiaNo ratings yet

- Real Time Monitor Wa470 480Document7 pagesReal Time Monitor Wa470 480João MariaNo ratings yet

- Basics of - PID ControlersDocument26 pagesBasics of - PID ControlersNair67udayNo ratings yet

- General Description Features: 2A Step Down DC To DC ConverterDocument9 pagesGeneral Description Features: 2A Step Down DC To DC ConverterEmanuel CarageaNo ratings yet

- Service Quick Help Tablet enDocument133 pagesService Quick Help Tablet enpinticaniulian9042100% (1)

- Eaton IFPM 32 (4038D English)Document4 pagesEaton IFPM 32 (4038D English)ibrahem fawzy (اعرف اكثـــــر)No ratings yet

- 01 15 FCU-Kit Brotec EN Rev01Document14 pages01 15 FCU-Kit Brotec EN Rev01Lucian BaraganNo ratings yet

- Basic InstrumentationDocument29 pagesBasic InstrumentationDineshKumarNo ratings yet

- Procédure de Test FABIAN EVO-TS-AA-03e - TI - 7250 - Rev04-2017 PDFDocument22 pagesProcédure de Test FABIAN EVO-TS-AA-03e - TI - 7250 - Rev04-2017 PDFDorian BuissonNo ratings yet

- CatalogueDocument29 pagesCatalogueAnonymous CPmZqMNo ratings yet

- Control Valve: Mr. Mouto YDocument86 pagesControl Valve: Mr. Mouto YDuong NguyenNo ratings yet

- Rexroth AA4VGDocument64 pagesRexroth AA4VGSedin MurtićNo ratings yet

- Part 4 Hydraulic Control Principle and ParametersDocument22 pagesPart 4 Hydraulic Control Principle and ParametersrohanNo ratings yet

- Valve Technology: - by Fabian C. GonzalezDocument106 pagesValve Technology: - by Fabian C. GonzalezNyoman RakaNo ratings yet

- Diagnostic Trouble Codes (DTC) : DTC P0711 Transmission Fluid Temperature Sensor Circuit PerformanceDocument4 pagesDiagnostic Trouble Codes (DTC) : DTC P0711 Transmission Fluid Temperature Sensor Circuit Performanceluis eduardo corzo enriquezNo ratings yet

- 2010 Pressure Control CatalogDocument20 pages2010 Pressure Control CatalogjondesousaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Chapter 4Document34 pagesChapter 4Sayed NagyNo ratings yet

- Homework 1 SolutionDocument5 pagesHomework 1 SolutionMrinmoy SahaNo ratings yet

- Ques STDocument19 pagesQues STLakshmi ZaharaNo ratings yet

- Value Engineering at XeroxDocument23 pagesValue Engineering at XeroxKenneth Z. PenianoNo ratings yet

- Chapter 15: Thermochemistry Key Notes: Fundamentals Aspects Thermochemistry Is AnDocument11 pagesChapter 15: Thermochemistry Key Notes: Fundamentals Aspects Thermochemistry Is AnSarthakNo ratings yet

- Welding SPCDocument3 pagesWelding SPCnineapril82100% (1)

- Data Curation and ManagementDocument24 pagesData Curation and ManagementMohammed SeidNo ratings yet

- Traffic Sign Detection Using Convolutional Neural NetworksDocument7 pagesTraffic Sign Detection Using Convolutional Neural NetworksIJRASETPublicationsNo ratings yet

- System Development Life Cycle (SDLC)Document44 pagesSystem Development Life Cycle (SDLC)adeo paleviNo ratings yet

- MECH 3340 Chapter 7.1Document26 pagesMECH 3340 Chapter 7.1ZarikhNo ratings yet

- Fuzzy Control Distillation ColumnDocument5 pagesFuzzy Control Distillation ColumnhardmanpersonNo ratings yet

- Polyphase DecompositionDocument29 pagesPolyphase Decompositionjw_lee_an1906No ratings yet

- Farjadian - A Resilient Shared Control Architecture For Flight ControlDocument8 pagesFarjadian - A Resilient Shared Control Architecture For Flight ControlISSSTNetworkNo ratings yet

- Introduction To Software Testing: Engr. Anees Ur RahmanDocument27 pagesIntroduction To Software Testing: Engr. Anees Ur RahmanMuhammad NaeemNo ratings yet

- LinearTI Dynamic Systems PDFDocument439 pagesLinearTI Dynamic Systems PDFmaurizio.desio4992No ratings yet

- Corollary of 2nd Law of ThermodynamicsDocument8 pagesCorollary of 2nd Law of ThermodynamicsHusnain A Ali75% (4)

- Unit 1 Requirement Analysis: Unit 1 Software Project ManagementDocument10 pagesUnit 1 Requirement Analysis: Unit 1 Software Project Managementvvv1991No ratings yet

- TestDocument4 pagesTest阿聯 シNo ratings yet

- SE-Unit-2-Agile DevelopmentDocument20 pagesSE-Unit-2-Agile Developmentits9918kNo ratings yet

- Linear EqualizerDocument39 pagesLinear EqualizerVicky PatelNo ratings yet

- Adaptive Input - Output Linearizing Control of Induction Motors PDFDocument14 pagesAdaptive Input - Output Linearizing Control of Induction Motors PDFJorge LavínNo ratings yet

- Lee Et Al-1998-AIChE JournalDocument10 pagesLee Et Al-1998-AIChE JournalNoUrElhOdaNo ratings yet

- DTEE-504: Diploma (EE) (Fifth Semester) Examination, 2019Document4 pagesDTEE-504: Diploma (EE) (Fifth Semester) Examination, 2019YouTube officialNo ratings yet

- Jenis Bisnis Logistik-2 - NewDocument38 pagesJenis Bisnis Logistik-2 - NewMutiara IndahNo ratings yet

- CHATGPTDocument1 pageCHATGPTInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Critical Path Method (CPM) : Purpose of PERT AnalysisDocument3 pagesCritical Path Method (CPM) : Purpose of PERT AnalysisWicklife OtienoNo ratings yet

- SamplingDocument13 pagesSamplingravikumar rayalaNo ratings yet

- Master Thesis Neural NetworkDocument4 pagesMaster Thesis Neural Networktonichristensenaurora100% (1)

- CS507 Quiz 1 File by Tanveer Online Academy-2Document4 pagesCS507 Quiz 1 File by Tanveer Online Academy-2Ishmal Rizwan100% (1)