Professional Documents

Culture Documents

Course Outine (Production Engineering I)

Course Outine (Production Engineering I)

Uploaded by

GetahunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Course Outine (Production Engineering I)

Course Outine (Production Engineering I)

Uploaded by

GetahunCopyright:

Available Formats

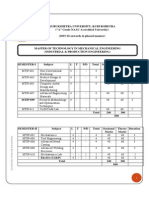

Wolaita Sodo University

CoE, Mechanical Engineering Department

Department of Mechanical Engineering

College of Engineering, Wolaita Sodo University

Course Number Meng 3161

Course Title Production Engineering I

Pre-requisites: Meng 2152 Workshop Technology

Semester:

Status of Course: Compulsory

Degree Program BSc in Mechanical Engineering (Week-end)

Module Manufacturing Engineering

Module

Coordinator

Instructor’s Name Getahun S. Email getahun.sorsa@wsu.edu.et/getahun2445@gmail.com

Office @Material Testing Lab

ECTS Credits 4

Contact Hours Lecture Tutoria Prac./Lab Home study

l

2 3 0 3

Course Objectives The course enables students to understand:

Basic traditional machining processes, their principles, tool geometry, wear of tools,

force and power on traditional machine tools and measures to achieve optimization;

Basic non-traditional machining operation and their principles;

Basic concept of casting process, design of cast, casting defect and their remedies.

Course Description Systematic survey on the most important production processes in the metal-working

industry; Traditional machining processes: Selected process principles, kinematics,

geometry, forces and power, tool wear and tool life, productivity, optimization; Non-

traditional machining processes: Introduction to electric discharge machining, chemical

machining, electrochemical machining, abrasive flow machining, abrasive jet machining,

and ultrasonic machining; Fundamentals of casting processes.

Course Chapters 1. Systematic Surveying of Production Process in Metal Working Industries:

Detail: Classification of manufacturing engineering and process; Break-even analysis.

2. Traditional Machining Processes: Introduction; Selected processes and principles:

Lathe, milling, drilling, grinding, etc.; Kinematics of machine tools: motion of cutter

and tool (cutting speed, feed, metal removal rate, machining time etc.); Geometry

of tools: point and multi tooth cutters (cutters of lathe, milling, etc.); Tool materials;

Force and power; Mechanics of machining; Chip formation; Merchants theory; Tool

wear: causes of wear, types of wear, methods to overcome wear; Tool life: cutting

fluid methods improving tool life, productivity, optimization.

3. Non Traditional Machining Processes: Introduction; Electrical discharge

machining; chemical machining; electrochemical machining; Abrasive flow and

abrasive jet machining; Ultrasonic machining.

4. Fundamental of Casting: Sand casting process (sand casting materials, pattern

making, core making gating system etc.; other method of casting (shell molding,

Wolaita Sodo University

CoE, Mechanical Engineering Department

investment molding, Die casting, centrifugal casting etc.); Defect of casting, Fettling

process.

Teaching and Lectures supported by tutorials,

Learning methods Assignments,

Project Work, and

Industrial visits.

Project Work: Producing different contour on metal cutting machine tools

Assessment/ Assessment/ evaluation & Grading system

evaluation & Assignments and Laboratory 20%,

Grading Systems Mid-semester Examination 30%, and

Final Examination 50%.

Attendance Minimum of 80% attendance during lecture hours;

Requirement: 100% attendance during practical work sessions, except for some unprecedented

mishaps; and

Presence during industrial visit/visits.

Literature: Textbook:

1. Schey, John H., Introduction to Manufacturing Processes, 3rd ed. 1999

2. Groover, M. P. (2017). Shaping Processes for Plastics: Injection Molding.

Fundamentals of Modern Manufacturing: Materials, Processes and Systems,

287.

References:

1. Beddoes J., Principles of Metal Manufacturing processes, John

Wiles & Sons Inc. New York, 1999

2. Rao P.N., Manufacturing Technology, second edition, Tata McGraw Hill

Publishing Company Limited, New Delhi, 1998

3. Krara, Steve, Macahine Tool and Manuafacturing Technology, 1997.

You might also like

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Prof Ethics QuizDocument30 pagesProf Ethics QuizChirag ShahNo ratings yet

- Metal Cutting and Tool DesignDocument3 pagesMetal Cutting and Tool DesignHemanth YadaNo ratings yet

- Books Mechanical EngineeringDocument19 pagesBooks Mechanical Engineeringnavaneeth32450% (8)

- Fielders PurlinsGirts ManualDocument104 pagesFielders PurlinsGirts ManualthailanNo ratings yet

- MEng3181-Manufacturing Engineering I-Course Outline - 103309Document2 pagesMEng3181-Manufacturing Engineering I-Course Outline - 103309Yonael MezmureNo ratings yet

- MME310: Manufacturing Technology-II: Department of Mechanical Mechatronics Engineering The LNM IIT, JaipurDocument2 pagesMME310: Manufacturing Technology-II: Department of Mechanical Mechatronics Engineering The LNM IIT, Jaipurraghav dhamaniNo ratings yet

- Manufacturing Processes UTA026Document9 pagesManufacturing Processes UTA026Tania CENo ratings yet

- PMC ModuleDocument91 pagesPMC ModuleAbdi ZerihunNo ratings yet

- Metal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyDocument4 pagesMetal Processing Technology (Meng 5324) : Ambo University Institute of TechnologyFikadu EshetuNo ratings yet

- Manufacturing Tech SyllDocument4 pagesManufacturing Tech SyllJagjit SinghNo ratings yet

- Manufacturing Engineering IDocument4 pagesManufacturing Engineering Iahmish kabbaxe100% (1)

- Subject Production Techology SyllabusDocument3 pagesSubject Production Techology SyllabusbmdbmdbmdNo ratings yet

- Course Outline MPIDocument2 pagesCourse Outline MPIgirma workuNo ratings yet

- Manufacturing Process 4 PDFDocument2 pagesManufacturing Process 4 PDFVijayalaxmi MudhigondaNo ratings yet

- r05010302 Engineering MechanicsDocument39 pagesr05010302 Engineering Mechanicsdassault megecNo ratings yet

- Manufacturing Engineering 2 Course OutlineDocument1 pageManufacturing Engineering 2 Course OutlineLayike AlemayehuNo ratings yet

- Certificate: Stani Memorial College of Engineering & Technology PHAGI, JAIPUR-303005 Department of Computer EngineeringDocument22 pagesCertificate: Stani Memorial College of Engineering & Technology PHAGI, JAIPUR-303005 Department of Computer EngineeringAmit Choudhary0% (2)

- Course Outline MFG IIDocument2 pagesCourse Outline MFG IIAbrham ChanieNo ratings yet

- PP Syllabus (R2019)Document3 pagesPP Syllabus (R2019)shaikh javedNo ratings yet

- MCE 538 enDocument1 pageMCE 538 enاحمدالاغبريNo ratings yet

- 5 MPDocument3 pages5 MPASIST MechNo ratings yet

- Credits Total Marks: Sathyabama Institute of Science and TechnologyDocument1 pageCredits Total Marks: Sathyabama Institute of Science and TechnologyGiridharan RuNo ratings yet

- Machining Science: Prof. Sounak Kumar Choudhury Type of Course: Course Duration: Exam Date: 29 Mar 2020Document1 pageMachining Science: Prof. Sounak Kumar Choudhury Type of Course: Course Duration: Exam Date: 29 Mar 2020Abhishek kumarNo ratings yet

- Machining Science: Jigs & FixturesDocument15 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- RTM Nagpur University Syllabus (Theory)Document5 pagesRTM Nagpur University Syllabus (Theory)Milind KshirsagarNo ratings yet

- Machining Science: Jigs & FixturesDocument77 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- RTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TDocument27 pagesRTM Nagpur University Mechanical Engineering Machining Processes Syllabus (Theory) Course code-BEME401TxaloliNo ratings yet

- Manufacturing ProcessDocument3 pagesManufacturing ProcessSatyam PatelNo ratings yet

- 01 C18 - ME2302 Introduction To Materials Science and Manufacturing EngineeringDocument2 pages01 C18 - ME2302 Introduction To Materials Science and Manufacturing EngineeringVidura PrasadNo ratings yet

- Manufacturing and Materials SyllabusDocument3 pagesManufacturing and Materials SyllabusAstroNirav SavaliyaNo ratings yet

- Lect 1Document16 pagesLect 1ravish kumarNo ratings yet

- Machining Science: Jigs & FixturesDocument26 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Me785 - Machining and Forming - Lab ManualDocument28 pagesMe785 - Machining and Forming - Lab Manualemily clarkeNo ratings yet

- Bmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lDocument3 pagesBmee304l Metal-Forming-And-Machining TH 1.0 67 Bmee304lKrijayNo ratings yet

- Production Processes and MetrologyDocument3 pagesProduction Processes and MetrologymaheshNo ratings yet

- Modern Manufacturing ProcessesDocument3 pagesModern Manufacturing ProcessesAmaniNo ratings yet

- MAKAUT Manufacturing Processes SyllabusDocument2 pagesMAKAUT Manufacturing Processes SyllabusRTET Plagiarism CheckNo ratings yet

- Course Outline MEFB213Document10 pagesCourse Outline MEFB213lucasNo ratings yet

- Introduction, Press & MachiningDocument327 pagesIntroduction, Press & MachiningLucky DagaNo ratings yet

- B Tech Mechanical Engineering 6thDocument17 pagesB Tech Mechanical Engineering 6thprakashkumarsenNo ratings yet

- Gujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909Document3 pagesGujarat Technological University: Mechanical Engineering (19) SUBJECT CODE: 2161909ShahinNo ratings yet

- Machining Science: Jigs & FixturesDocument29 pagesMachining Science: Jigs & FixturesChidu KNo ratings yet

- Ali Ubaid-284951-CDocument42 pagesAli Ubaid-284951-CDei mosNo ratings yet

- PH.D Programme: Teaching Schedule & Study SchemeDocument3 pagesPH.D Programme: Teaching Schedule & Study SchemeGursharanSinghGandhiNo ratings yet

- PP-I Syllabus (SH2019)Document2 pagesPP-I Syllabus (SH2019)Vishwa RohindNo ratings yet

- B.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesDocument1 pageB.SC. Mechanical Engineering Course Skeleton Manufacturing Processes Muhammad Amjad 2010 3 Sept. 2011-Jan. 2012 3 1 Books and ReferencesAmin FarukiNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Single Point Cutting ToolDocument22 pagesSingle Point Cutting ToolMeer UmarNo ratings yet

- Syllabus NON-TRADITIONAL MACHININGDocument1 pageSyllabus NON-TRADITIONAL MACHININGranjithkrajNo ratings yet

- Basics of Metal Cutting 1Document70 pagesBasics of Metal Cutting 1Saideep GhimireNo ratings yet

- Tool EngineeringDocument3 pagesTool EngineeringAmirDeshmukhNo ratings yet

- FMP-611, 3 (2-1) Manufacturing and Reverse EngineeringDocument10 pagesFMP-611, 3 (2-1) Manufacturing and Reverse EngineeringMuhammad IrfanNo ratings yet

- Manufacturing ProcessDocument3 pagesManufacturing ProcessReham EltuhamyNo ratings yet

- Fdocuments - in Swami Ramanand Teerth Marathwada Ramanand Teerth Marathwada University DesignDocument52 pagesFdocuments - in Swami Ramanand Teerth Marathwada Ramanand Teerth Marathwada University DesignPankaj AghavNo ratings yet

- ME572-Progress Report - AfifDocument28 pagesME572-Progress Report - AfifMrk KhanNo ratings yet

- MCMT SyllabusDocument3 pagesMCMT SyllabusshahazadNo ratings yet

- MCE 331 Syllabus V2.1Document3 pagesMCE 331 Syllabus V2.1Najmul Puda PappadamNo ratings yet

- Course Outline For Metal Forming, Welding and Casting Laboratory PracticeDocument1 pageCourse Outline For Metal Forming, Welding and Casting Laboratory Practicebirhanubic23No ratings yet

- Rajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringDocument49 pagesRajiv Gandhi Proudyogiki Vishwavidyalaya, Bhopal Diploma in Automobile EngineeringAbhi SharmaNo ratings yet

- L0 MEC205 Zero Lecture UpdatedDocument42 pagesL0 MEC205 Zero Lecture UpdatedJames PrakashNo ratings yet

- Course OverviewDocument14 pagesCourse OverviewVinayaka G PNo ratings yet

- Advanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingFrom EverandAdvanced Noncontact Cutting and Joining Technologies: Micro- and Nano-manufacturingNo ratings yet

- Group For AssignmentDocument1 pageGroup For AssignmentGetahunNo ratings yet

- Project Two. Process Financial Transactions and Prepare Financial The Accounts in The Ledger ofDocument11 pagesProject Two. Process Financial Transactions and Prepare Financial The Accounts in The Ledger ofGetahunNo ratings yet

- Course Plan FormatDocument6 pagesCourse Plan FormatGetahunNo ratings yet

- AssignmentDocument2 pagesAssignmentGetahunNo ratings yet

- Worksheet For Chapter 05Document4 pagesWorksheet For Chapter 05GetahunNo ratings yet

- WSU Sponsorship 2Document1 pageWSU Sponsorship 2Getahun100% (1)

- የጋራ ቅጥርና አስተዳደርDocument15 pagesየጋራ ቅጥርና አስተዳደርGetahunNo ratings yet

- Worksheet For ChapterDocument17 pagesWorksheet For ChapterGetahunNo ratings yet

- Quiz 2Document1 pageQuiz 2GetahunNo ratings yet

- What Is An ElectionDocument3 pagesWhat Is An ElectionGetahunNo ratings yet

- Tsinukal BezabihDocument101 pagesTsinukal BezabihGetahunNo ratings yet

- Course Outline & Class Ground RulesDocument8 pagesCourse Outline & Class Ground RulesGetahunNo ratings yet

- Individual Assignment - IDocument3 pagesIndividual Assignment - IGetahunNo ratings yet

- Getahun Sorsa TitlesDocument8 pagesGetahun Sorsa TitlesGetahun100% (1)

- Fastest: The City Road in The WorldDocument35 pagesFastest: The City Road in The WorldGetahunNo ratings yet

- A Continuous Improvement Journey in The Higher Education SectorDocument9 pagesA Continuous Improvement Journey in The Higher Education SectorGetahunNo ratings yet

- Cobblestones Are Creating Jobs and Empowering Ethiopia's Urban Poor - Cities AllianceDocument1 pageCobblestones Are Creating Jobs and Empowering Ethiopia's Urban Poor - Cities AllianceGetahunNo ratings yet

- Design and Manufacturing of Cobble StoneDocument18 pagesDesign and Manufacturing of Cobble StoneGetahunNo ratings yet

- Research Article: In-Depth Analysis and Defect Reduction For Ethiopian Cotton Spinning Industry Based On TQM ApproachDocument8 pagesResearch Article: In-Depth Analysis and Defect Reduction For Ethiopian Cotton Spinning Industry Based On TQM ApproachGetahunNo ratings yet

- Manufacturing Process Improvements Using Value Adding Process Point Approach: A Case StudyDocument20 pagesManufacturing Process Improvements Using Value Adding Process Point Approach: A Case StudyGetahunNo ratings yet

- Francisco Delgado - ResumoDocument10 pagesFrancisco Delgado - ResumoGetahunNo ratings yet

- Six Sigma: Quality Processing Through Statistical AnalysisDocument4 pagesSix Sigma: Quality Processing Through Statistical AnalysisGetahunNo ratings yet

- Kaizen Approach For Enhancing Quality Management Practices in HeisDocument10 pagesKaizen Approach For Enhancing Quality Management Practices in HeisGetahunNo ratings yet

- Journal of Cleaner Production: Carlos Cuviella-Su Arez, Antonio Colmenar-Santos, David Borge-Diez, Africa L Opez-ReyDocument17 pagesJournal of Cleaner Production: Carlos Cuviella-Su Arez, Antonio Colmenar-Santos, David Borge-Diez, Africa L Opez-ReyGetahunNo ratings yet

- Primavera Basic Course ContentsDocument6 pagesPrimavera Basic Course ContentstiktokNo ratings yet

- Ssangyong Actyon P1684 Engine Trouble Code - Ssangyong Actyon P1684 OBD-II Diagnostic Powertrain (P) Trouble Code For Ssangyong ActyonDocument2 pagesSsangyong Actyon P1684 Engine Trouble Code - Ssangyong Actyon P1684 OBD-II Diagnostic Powertrain (P) Trouble Code For Ssangyong ActyonMiguel CofreNo ratings yet

- Overview of API Pipeline Valve Specifications 6D and 6DSS: 23 - 24 April 2013Document3 pagesOverview of API Pipeline Valve Specifications 6D and 6DSS: 23 - 24 April 2013IrudhayarajAnthonySamyNo ratings yet

- Is 800 2007 PDFDocument158 pagesIs 800 2007 PDFvineets058No ratings yet

- Exchange Admin-Engineer ResponsibilitiesDocument2 pagesExchange Admin-Engineer ResponsibilitiesJJ JJNo ratings yet

- Calendar of Events - CSEDocument1 pageCalendar of Events - CSESIETDOCNo ratings yet

- PGP Glimpses Summer Placements 2022Document24 pagesPGP Glimpses Summer Placements 2022gaurav rajNo ratings yet

- Ched-Marina Moa PDFDocument45 pagesChed-Marina Moa PDFChes Vergara100% (1)

- 12.08.22 - The Seismic Behaviour of Buildings Erected in Solid Timber Construction - Report (English)Document124 pages12.08.22 - The Seismic Behaviour of Buildings Erected in Solid Timber Construction - Report (English)Sharonda CastilloNo ratings yet

- Sri Vidya College of Engineering & Technology Course Material (Lecture Notes)Document36 pagesSri Vidya College of Engineering & Technology Course Material (Lecture Notes)Ruqaiya KhanamNo ratings yet

- R ResultDocument44 pagesR ResultMahesh Babu MahiNo ratings yet

- Final A-315 B Arch SteelDocument2 pagesFinal A-315 B Arch SteelSanjay TiwariNo ratings yet

- The Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestDocument5 pagesThe Experimental Study of Eccentric Loadingfor Piled Raft Foundations Settling On Slope CrestInnovative Research PublicationsNo ratings yet

- ACADEMIC TRANSCRIPT (Undergraduate) : National University of Sciences and TechnologyDocument1 pageACADEMIC TRANSCRIPT (Undergraduate) : National University of Sciences and TechnologyMuhammad Hashim KhanNo ratings yet

- Structural Theories & Application: Building Structural System (Timber)Document18 pagesStructural Theories & Application: Building Structural System (Timber)scegtsNo ratings yet

- B4 3-R3Document28 pagesB4 3-R3api-3782519No ratings yet

- 016&017 - Hearing Record - 2 February 2016Document13 pages016&017 - Hearing Record - 2 February 2016Cam MargrettNo ratings yet

- Fiberstruct Deflection ImpactDocument2 pagesFiberstruct Deflection Impactnicholas_j_vaughanNo ratings yet

- Scope of Services To Be Dispensed by Consulting Civil-Structural EngineersDocument2 pagesScope of Services To Be Dispensed by Consulting Civil-Structural EngineersVeenoyNo ratings yet

- Switch Gear and Proctection: Subject Code: A70231 Regulations: R15 - Jntuh Class: IV Year B.Tech EEE I SemesterDocument21 pagesSwitch Gear and Proctection: Subject Code: A70231 Regulations: R15 - Jntuh Class: IV Year B.Tech EEE I SemestervenkatNo ratings yet

- Drum Level Control (Descon)Document17 pagesDrum Level Control (Descon)Adeel Ahmed100% (1)

- 14.gi Conduit BecDocument4 pages14.gi Conduit BeckailasamvvNo ratings yet

- Panel Builder - Mar 2018Document228 pagesPanel Builder - Mar 2018setyawanNo ratings yet

- NTPC Ad2013Document4 pagesNTPC Ad2013knsaravanaNo ratings yet

- Analysis of Methodologies For The Evaluation of Power Outage Costs PDFDocument5 pagesAnalysis of Methodologies For The Evaluation of Power Outage Costs PDFHachimenum AmadiNo ratings yet

- Syllabus System Analysis&DesignDocument2 pagesSyllabus System Analysis&DesignczhanyNo ratings yet

- Bs-En 1993-1-9 - 2005Document35 pagesBs-En 1993-1-9 - 2005Martijn OttenNo ratings yet