Professional Documents

Culture Documents

VW Scirocco 85-87 EngineServicing

VW Scirocco 85-87 EngineServicing

Uploaded by

Theo Huqueleux0 ratings0% found this document useful (0 votes)

54 views38 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

54 views38 pagesVW Scirocco 85-87 EngineServicing

VW Scirocco 85-87 EngineServicing

Uploaded by

Theo HuqueleuxCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 38

Introduetioy

ENGINE

Contents

1. General Description

ankshaft and Bearings

necting Fiods and Pistons

ylinder Head

niermediate Shaft

ubrication System

Engine

yhnder Head

Intermediate Shaft

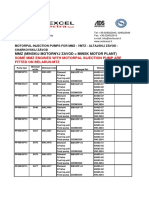

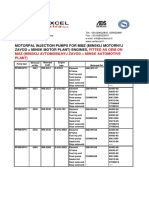

Engive ldentfication Codes and Spoeiications

19 Engine Codes

2, Maintenance

3, Troubleshooting

5.1 Basie Troublashaeting Principles

Smoking

Excassive Oil Consumption

gine Not Rusning,

‘eumption and Low Power

a2

Section 3

Diagnostic Tasting

Compression Test

Wot Compression Test

Leak-dawn Tost

4, Cylinder Head

aa

42

4a

48

46

47

48

49

CCylindar Head Gover and Gasket

Camshaft Drive Bet

Camshatt Oil Seal

Valve Adjustment

(1988-1987 except Scirocco 16V)

Flemoving and Installing Camshatt

Hydraulie Cam Followers.

Checking Hydraulic Cam Followers.

Vaive Stern Oil Seals.

Removing and Installing Gylinder Head,

Disassernbly, Assembly, and Reconditioning

vlinder Head Assembly (B-valve engines)

>ylinder Head Assembly (16-valve engines)

Camshaft and Cam Followers.

Valves and Valve Springs.

Valve Guides

Valve Seats

5, Removing And Installing Engine And Transaxle

Removing

Separating Engine and Trancaxle

intalling,

Aligning Engine and Transaxle Assembly

“

6

w

18

18

20

3-2

ENGINE

6. Cylinder Block And Pistons.

6r

Gylinder Block Oil Seals

Roplacing Front Crankshatt Oil Seal

Replacing Intermediate Shaft O# Seal

Disassembly, Assembly, and Reconditioning

Fistons and Connecting Rods

Piston Rings.

Crankshaft and Intermediate Shatt

Flywheel or Drive Plate

7. Lubrication System:

74

Dynamie OH Pressure Waming System.

‘Checking Low Oil Pressure Warning System

Checking Dynamic Oil Pressure Warning

stem (high tpn}

sling Ol Pressure Switches.

>i Pump

(Ol Spray Nozzles

011 Cooler

8, Technical Data

\

u

i,

v.

v

Tightening Torques

Crankshat, Intermediate Shaft

‘and Crankshatt Bearing Spacifiations

Piston, Piston Ring and Cylinder

Bore Specifications

‘Camshatt, Valve and Cylinder Head

Spocitications

Lubrication Systern Specifications.

28

28

28

20

29

29

a

a

33

38

a4

34

REE

36

26

7

37

a7

38

98

38

eove

rere

Pp.

TABLES

Engine Codes and Specifications

Engine Troubleshooting

Compression Pressure Specifications

Valve Adjusting Dises

(1985-1987, engine code JH only)

Valve Clearance Specifications

(1985-1987, engine code JH only)

Valve Spectications

Minimam Dimensions tor Calculating Valve Seat

Fletacing Dimensions

‘Valve Seat Dimensions (8-valve engines)

\Valve seat dimensions (16-valve engines)

Cylinder and Piston Diameter Spectfcations.

Connecting Rod Specifications

Piston Ring End Gap

Crankshatt Journal Diameter

Piston Ring Side Clearance... 2...

Crankshaft and Cylinder Block Tightening Torques.

Crankshaft and Intermediate Shaft Clearance

ENGINE 3-3

Engine

Introduction

The Cabriolet and Scirocco engines are all four-cylinder, tront-mountad and water-cooled.

‘The cast ron cylinder block supports the crankshattin five main beanngs, The overheadcam-

shaft running in the cylinder head is driven from the crankshaft by a reinforced toothed bet

Displacements 1781 co (109 cu, in.), commonly referred to as 1.8 liters. Horsepower is 24

(SAE nat). The Seirocea 16V engine is also 1.8 IRers, but its cross-flow cylinder head design

and dual overhoadcamehalts with four valves pereykindar (Wa intake andtwo exhauet} raises

rated horsepower to 123 (SAE nat)

The engine is transverse-mounted and inclined toward the rear of the car~a design that

permits alower hoodiine and improves weight cist bution, The engine andiransaxle are sup.

ported as a single unt by a combination of bonded rubber mounts that isolate the drivetrain

and help reduce the transmission of noise and vibration tothe rest ofthe car

The engine's transverse placement takes up less overall space than other designs and

rakes possible a roomier passenger compartment. also concentrates drivetrain weight over

the front driving whee's where i helps improve trection under slippery conditions, Despite a

slight forwardweight bias when thecar is empty, total vehicle weightis distributed about equal-

ly an the front and rear whee\s when the car is loaded. Near-equal weight distribution increas

es stabilty and assures precise handing.

Tha information in this section ofthe ranual is intended both as a guide to Cabriolet and

jcroceo owners andas.a reference or professional mechanics, Some of the procedures and

‘epairs described require special equipment and some prior knowledge of general engine re-

pair and assembly practices. If you tack the skil, tools, or a suitablo workplace for servicing

‘orrepairing the engine, we suggest you leave these repairsta.an authorized Volkswagen deal-

er oF other qualified automotive repairshop, We especially urge youto consul your authorized

Volkswagen dealer before beginning any repairs on aca that may be covered wholly ori part

by any of tha extensive warranties issued by Volkswagen United States, Inc

3-4 ENGINE

1, GENERAL DESCRIPTION

The inline fourcylinder overhead cam engine is water

cooled and transmits power through a piston-driven rank:

shaft. Tho oyinder block is made of cast iron with integral

ylinders completely exposed on all sides to the coolant that

circulates through the water jacket. A separate cast aluminum

alloy cylinder head contains the beltcriven camshaft and the

lente valve tain. A cutaway view ofthe engine appears in Fig

Fig. 14

4.1 Engine Components

Crankshaft and Bearings

Tre fly counterweighted crankshaft rotates in ve replace

able spli-shell main baarings. A 6-piece center main bearing

upper shel, lower shel, and four thrust bearings) controls

-nkshalt ena thrust. Flexible lip seals, prossedt into light alloy

Seal carriers, are used at both ends ofthe crankshalt to prevent

i oakage,

Connecting Rods and Pistons

shel be

1 1048s are sloe! forgings, Replaceable spit

rags are used at the crankshaft end and lead-bnanze

‘boated steel bushings a the pision pin end. The pistons are of

the three-ring type with two upper compression rings. ard a

‘ower one-piece ol scraver ring, FulHloating piston pins are

folained a each end by cirelps

Cylinder Head

“The cylinder head is an aluminum alloy casting. The over:

head camshaft bearing surtaces andthe bores fr the cam foi

lowers (valve liters) are machined directly into the cylinder

head casting, The valve guides are press-fit and replaceable,

Valve Train

The single averhoad camshaltis dren from the crankshalt

by atoothed, steel-reintorced belt. The cam|abes and bucks

style camn followers directly actuate the intake and the exhaust

valves, Valvecloarance is adjusted by iting the cam fallowers,

with shims of different sizes. Starting with the 1988 model

year, 8-valve engines have hydraulic cam followers, These

Use engine oll pressure to maintain cotract valve clearances

Intake and exhaust valves are equipped with dual valve

springs and both upper and lower spring seats,

Intermediate Shaft

The intermediate shaft, turning in the cylinder black, is

Yocated above and paralle to the eranksha. tis driven at halt

‘crankshaft speed by the camshaft drive bet, nd in turn aves,

the ol pump and the ignition distibutor shaft

Lubrication System

A gear-type oll pump driven by the intermediate shatt draws

‘8 through a strainer inthe bottom of the ol pan and forces it

through a spin-on replaceable filer and into the engine's oi

passages. A pressure relief valve Irnits the pressure in the,

system, and after bypass valve assures lubrication oven the

fiter is plugged. An oll cooler is attached to the fiter housing,

Engine coolant circulales through the ol cooler to help rod:

‘rate il emperature. In addition to a warning system for low oil,

pressure, a more sensitive dynamic oil pressure warning sys

tem operates at elevated engine rpm,

1.2 16-valve Engine

The 16-vale engine is a highly developed version of the

basic 1.8 iter engino, sharing most of is major design feetures

‘There are several differences. in the cylinder head as well as,

cther elated systems, which distinguish the 16-valve version

Cylinder Block

The cylinder block used for the 16-valve engine has several

‘modifications io help make it more sultabie tothe higher power

‘pu. pray in the lubrication system. The passageways

Cconneeting the crankcase and the upper cylinder heaa are

larger, to alow better ventiation and oll return, and an addi:

ticnal cil passage in the block suppies of toa sores of spray

nozzles, one below each oyinder. Ato pressure above 3.8 bar

{50 ps). the nozzles open and smal streams of al are sprayed

at the underside of each piston to provide adeltional cookin

The cytincer block casting is also modified to accept a larger

crankcase breather

Pistons

‘The 1évalvo engine, because ofits diferent cylinder head

design and vaive arrangement, uses a diferent piston than the

cher 1.8 Iter engines to achieve me necessary combination of

‘compression ratio and valve clearance,

Cylinder Head

The cylinder head is. of course, tha 16-valve engine's major

departure fromm Volkswagon $ oth 1.8 ier engines. ts cross:

flow design festures four valves per cylinder, versus the usual

‘wo, oporatod by two overhead camsnatts. The result is more

efficient ai flow into anc out of the combustion chernbers, and

fn engine with greater efficiency and power over a wace rpm

range!

‘The oylinder head is an aluminum atoy casting with sintered

steel vaive seals. The press-fit valve guides are replaceable,

lis the bearing Surfaces for the dual camshafts and the bores

for the cam followers are machined directly into the cylinder

head casting. Fig. 1-2 shows the 16 valve cytnder head and is

four-valve combuston chambers

Zs |

cead

Ae

Valve Train

‘The camshafts are diven by the crankshaft via a single

toothed, steel-reintoroed belt. The bel rves a single sprocket

atiached to the exhaust carnshal. The exhaust camshaft in tur

‘drives the intake camshaft through a roller chain and sprockets

al the other end of the cylinder head. The orve belt and

sprockes, although similar to those of the other 4.8 iter en

gines, are modified fo handio tho extra loads of the 16 vave

valve train Fig 1-3 shows the orientation of the camshafts and

‘dive mechanisms in the assembled cylinder head, The cam

lobes oparate the intake and exhaust valves directly through

hydraulic cam followers which use engine oi, supplied under

pressure by the lubrication system, to maintain correct valve

Clearances. A sprayet assembly, sinar to that used fo coo!

the pistons, is used in the cylinder head to prevent of from

ENGINE 3-5

raining out of the supply gallery for the cam tollowers. Soci

Lunlled exhaust valves aid heat transfer and reduce valve seat

temperature. Dual valve springs and both upper and lower

‘spring seals are used on the intake and exhaust valves.

Fig. 1-9, ive cylinder heat

Intermediate Shaft

‘The ignition distributor on the 16-valva engine is drivan si

recy by the exhaust camshaft. The intermediate shat, which

drives only the oil pump, is driven at 60% of crankshatt speed

by the camehatt etive bal,

1.3 Engine Identification Codes and Specifications

Ditlerent versions ofthe basic four-cylinder angine are used

inthe oars cavared by this manual, Velkswagan uses a unique

engine code to identity each vorsion and to distinguish be-

‘ween ther diferent pansand specications. The engine cade

is the single most important piace of information fer you to

knowabout your engine. Throughoutthis manual, where

lent procedures oF specications may apply the engina codes:

are used to dently the correct information for each engine.

Finding Engine Codes

The engine code can be viewed in the engine compart

rant. The code, JH for example, appears at the baginning of

the engine number. The number ie stamped on a flat area of

the top of the engine block, just below the lower edge of the

sylinder head, between cylinders No, 3 and No. 4, The engine

number stamnpis shown n Fig. 1-4, Table lists Cabriolet and

Scirocco engine cades, application information, and major

engine specications,

3-6 ENGINE

2. MAINTENANCE

Volkswagen specifies the maintenance steps below, to be

ied outat specific time and mileage intervals, Anumber in,

bold ype indieates that the procedure is in this cection, under

that numbered heading, Soe LUBRICATION AND MAINTE

NANCE for athorlsted tems, and or the prescribed intervals.

1. Checking engine oil level

2. Changing engine il and oil iter

3. Replacing spark plugs

4. Chacking engine compression pressure, 3.2

5, Adjusting valve clearance (with mechanical cam

followers, 1985-1987 8-valve engine only). 4.4

6. Replacing cylinder head cover gasket (only with

valve adjustinent listed above). 4.1

3. TROUBLESHOOTING

The princips of internal combustion can be very complex,

butthe basic engine functions are pretty simple. The potential

for problems is fimited

Wear is the main cause of any problem in an engine that

15 normal use and receives proper maintenance. Wear at

the abilty ofthe pistons, piston rings and valves to seal

‘combustion chambers-—to create and maintain compres:

Wear increases clearances between movingparts. Final

‘wear affects the components that keep the crankshaft and

s,vaive train and ignition properly timed.

ist

his troublashooting section deals with the basic engine

tigate an engine oll pressure warning, orto

hoot the lubrication systam, see 7. Lubrication Sys-

temin this section, To troubleshoot other, more general pr.

° ferns with engine cooting or the way the engine starts or runs,

| stoke ‘nm (in) ‘see COOLING SYSTEM. FUEL SYSTEM and IGNITION,

| Number of

| einer

f

[Bore sam

3.1 Basic Troubleshooting Principles

To isolate and identiy engine problems, always begin with

ccaratul observation ofthe symptoms. Some importantthingsto

look ior are:

How quickly did the problem develop? Problems that oceu

‘suddenly are probably caused by a failure thal can be correct

edby some sort of repair. Aproblemthat has developed grad.

ually, especialy aftar years and many tens of thousands of

miles, is mote ikely brought onby wear. ft may meanthat more

comprehensive overhaul works required,

pian change with engine speed? if 20, the

st likely an engine problem, Noises which re

only ina certain pm range suggest a vibration

ses of athersymptoms that vary with the speed af

thecarare more ikely causedby problems somewhere else in

the dewetrain or running gear.

Is the symptom load dependent? Forces at work inside a

‘unning engine vary as the demand for power varies. Symp-

toms which are more severe during hard accaleration indicate

‘certain kinds of problems, Symptoms which are more apparent

‘ano Joad or high vacuuny (example: coasting at high 1pm)

point to other problesns. Note that higher engine loads also

affect ne tue! and jgntion systems, which may be responsible

for high-toadt performance problers,

's the symptom temperature dependent? Does t only occur

when the engine is cold? Does it change as the engine warms

up? How? Metal parts expand and contract with changes in

femporature. Clearances change, Oi viscosity ane! cooking

system pressure change. in troubleshooting symptoms which

‘change as the engine gets warm, look far an engine cha

teristic that changes with temperature.

The paragraphs which follow describe particular types of

problems and some of the basic troubleshooting principles

associated with them, Table b lists symptoms of problems

‘commonly associated with engine trouble, thelr probable

causes, and suggested corrective actions. The numbers in

bold type in the Corective action column refer to numbered

headings in this section where the suggested repairs are de:

senbed,

Noise

Inordertorun reably and smoothly under harsh conditions,

the intemal engine parts are manufactured to procise dimen

Sons, assembled wath precision clearances petween moving

pars, and lubricated by a pressurized oiling system,

Most unidentified ongine noises resuk from clearances

\whion have become too lange due to worn or faled parts, lack

‘of adequate lubrication. or bath. The importance of lubrication

cannot be over.emphasized. For best resus, troubleshooting

‘engine noises should only be done when the of and fiker have

bbeon recently changed and the ol level is correct.

High-pitched metalic tapping noises are caused by rela

tively small lightweight parts and are most likely an indication

of excessive clearances in tho valve train, Valve tain noise

accompanied by burning ol (lue-gray smoke in the exhaust)

particulary at startup or when decolerating from high rpm, ts

an indication of worn valve guides which can only be remedied

by overhaul or replacement of the eyinder head. In a high-

mileage engine, a light metalic rate or chatter under acceler

ation, accompanied by increased oil consumption and smok:

ing, may indicate severely worn or broken piston rings. Since

this clagnosis means overhaul cr replacement of the engine,

the problem should be further investigated with a compression

cr cylinder leakage test. See 32 Diagnostic Testing,

Deep. metalic knocking sounds are caused by excessive

Clearances betwoon heavier components. Closer analysis of

the noise wit often help identity the problem, Piston slap,

ENGINE 3-7

caused by excessive piston skit to cylinder wall clearance, is,

worse when the engine is cold and may be accompanied by

increased oil consumption and reduced compression due to

accelerated piston ring wear. A double Kaock, most pro

‘nounced atidle or iow load, is due to excessive clearance at the

piston pin and upper connecting rod bushing,

Crankshatt bearing problems produce a deep, hollow knack

‘hal is worst when the engine is warm, A noise that is very

[pronounced under load, pethaps louder during the transition,

‘tom aoceleration to coasting, is most likely caused by a dam-

aged connecting rod bearing, Crankshaft main bearings pro-

duce a lower, dull knock, An intermittent knock, indicating

excessive crankshatt end play, may be most apparent when

depressing o* releasing the clutch, These problems seldom

‘occur as isolated failures. They are almost always an indication

fof the overall engine conditon which can only be properly

‘cowected by complete engine overhaul or replacement

Fumbiing or groaning from the engine compartment may

ot indicate engine problems at al, bul rather & worn bearing

for bushing in an engine-drven accessory. They include the

coolant pump. alternator. and may include a power steering,

[pump and air conditioning compressor. The air conditioning,

‘compressor is equipped with an electricaly-switched clutch

type pulley, so.a bad compressor will only be noisy when the ai

conditioning is on. To check other accessories, run the engine

briefly wth the drive bet disconnected and see ifthe naise has

stopped. Once the drive belt's moved, tuming the pulley anc,

shall by hand inay also reveal a bad bearing or bushing, A

property functioning accessory should tum smooth.

Fluid Leaks

Fluid leaking from and around the engine is most likely

tether ol, coolant, or brake fluid. Look for wet spots on the

engine to help pinpoint the source. tt may be helpfulto start by

leaning the suspected area,

“The most ikely Sources of engine o leaks are the oil iter

‘gasket. the crankcase oil seals, the cylinder head cover gas

kets, or the oll pan gaskets. See 6. Cylinder Block and Pis-

tons for more information on the gaskets and seals.

“The power steering system is another possible source of oil

leaks near the engine. For repairs to the power steering Sys

tom, see SUSPENSION AND STEERING.

Coolants a mixture of water and antifreeze, yellow green in

color or perhans brown if the cooling system is corroded. A.

pressure test of the cooking system isthe best way to discover,

{ang pinpoint leaks, See COOLING SYSTEM,

Brake fuid is clear, perhaps shightly purple, and a litle

slippery. Look for wat spots around the master cylinder oF

brake ines, Especially check the fleble hoses near tho wheels.

‘See BRAKES for repair information,

3-8 ENGINE

‘Smoking

“Smoke which is visible under the hood willbe eithor blue:

‘gray smoke from burning oil, or white steam from the cooling

system. Both symptoms indicate a leak. Soe Fluid Leaks

above,

‘Smoke in the exhaust indicates something getting into the

combustion chamber and being burned which does not be-

jong there, The colar of the smoke identifies the contaminant

Blue-gray smoke is ror ol, Ol smoke, probably accompa:

ied by inereased oil consumption and oll residue on spark

plugs, ndicates that engine olis getting past piston rings, ave

guices, the cyinder head gasket, or some coinbination of the

three, Us jprossion fest for diagnosis. See 3.2 Diagnos-

tic Testing. Compression pressures in an older engine which

fae aver, but below specifications, point to piston ring and

fylncer wall wear and the need for engine overhaul or replace:

ment. Ifthe smoking is mest obvious under high engine vac

tuum, such as while coasting at high rpm, and compression

pressures aro within specsfations, leaking valve guide ol seals

‘orvalve guides aro a probable cause. See 4, Cylinder Head for

«epair informatio,

(OW) smoke oF steam appeanng suddenty in the exaust,

‘along with low compression pressure in one cylinder or two

adjoning cylinders, is very probably due to a failed oyfinder

head gasket. Look also for coolant loss, olin the radiator, or

‘water in the oll whlch turns the cit an opaque, creamy brawn)

See 4.8 Removing and Installing Cylinder Head for ropair

procedures

Black smoke is caused by the engine getting too much fue.

FUEL SYSTEM for more troublesnocting information,

Excessive Oil Consumption

Some oil consumption is normal and incieates healthy flow

‘and cistributon ofthe vital lubricant in the engine, This is why

cil lavel must be checked, and occasionally corrected, be-

‘ween oil changes. Aside from leaks, increased oil consumo:

tion wall usually be accompanied by some smoking, however,

slight, and the causes of excessive ol consumption are the

same as those for oil smake in the exhaust. As with smoking

ssymploms, gradual increases are caused by worn piston ings,

andior valve quides. Sudden high olf consumption suggests,

broken rings or a failed cylinder head gasket. Sea Smoking

above for more troubleshaoting information

Poor Fuel Consumption and Low Power

Poor fuel consumption and low power can, of course, sug

gest problems with the fuel or ignition systems, particularly on

2 lowileage engine, On an engine wath high mileage, su

fering the effects of wear, low compression may be the cause.

Normal wear of the vats, piston rings, and cylinder wal

decreases their ability to seal. The intake and compression of

the aivfuol mature bacomes legs efficient, and the engine has,

to work harder, using more fuel, to produce the same amount

(of power. Engine condition can be evaluated with a compres:

Sion test, See 3.2 Diagnostic Testing,

Engine Not Running

[An engine problem which affects timing may prevent the

engine from starting or cunning. The camshaft dive belt and

‘sprockets are responsible for ming the actions of the valves,

land the igniton system relative to the pistons and crankshaft

‘A.wom belt and sprockets may jump teeth throwing off al the

tengine’s timing functions, and stit appear to be perfectly nor

mal. To check camshaft and ignition timing, see 4.2 Camshaft

Drive Belt and IGNITION, Other troubleshooting information

{or an engine which fas to start can be found in ELECTRICAL,

‘SYSTEM, FUEL SYSTEM, and IGNITION,

Table b. Engine Troubleshooting

Probable cause

‘Symptom

+ Pinging ot ating | a. grain un

31 100 tar advanced

wad, | Fue! does nat meet manotactre's

oetane raquremerts

accnerating, ees

Sapecay rom ow | SO a

Sree tigeanue | d. Spark pags damages or rong heat

pre ignition |: Rirhus micro too fear

2. Sereaching or ‘a Loose, won, oF cemaged

| © saucaing noise

L Inajeates Sipping

bs. Excessive bet loads duo to lace

‘ongine ivan comport

2.Se0

4. Replace spark plugs. Sao IGNITION

Corrective action

‘8. Cone ignition ining, See WENITION

'. Sutch to nigher octane tue. S28 FUEL SYSTEM for ful octane

rearomert

‘COOLING SYSTEM

0, Soo FUEL SYSTEM

Inspect, replace, or tighten Bol), Se LUBRICATION AND

MAINTENANCE

‘Locale ans eoplac fatoc component. 3.2

‘continued on next page

3-9

ENGINE

Table b. Engine Troubleshooting (continued)

Probable cause

8, Cosirt pare

bb. Atenator

© Power stesing pump

| 4. Camshat crive net tensioner beating

[Rr conetoning compressor

3. Growing or

raebing, varies with |

‘engine tpoy a

bearing or bushing

irean engine-srvan

}

| a Low o pressure and dotectve

tapong nose wares | * warn Wy creut

Srey with €OIPE | vate ash aut of achustent

spew ou preszure | © (1965 7987, engee code)

amestes ©. Deloctve cam talower(s)

4. Light metatie

5. Light reali krack

varies racy with

engine speed. OF

pressure waning

Faght ting or Ray

"ritag my be

‘most noticeable ater |

fare stops or during |

here cemerng) "| ¢ Insutient of pressure

Incas lack of

Sufeent of supply

Low of eve

| Resticted tay) ol ter

Faking wave sono so

| er ae ee

Shue gray hast

smoke oly sare

plugs incites ol

buming in

ombusion chamber |

eho yay stoke

ancior white Steam

esha

|. Failed cyinaer head gasket (probably

‘oennpianied by low camoression

Feacings} See 32

| Warged or cracker eykader neat

(probably accomparied by low

Compression readings). See 32

|: Grackea eyinder block

8. Back exaust | a Rich alge mieure

smoke I

9. Engine uns badly, | a, Span phug wes istated incomecty|

ops and backines | incorrect vale ding

10. Engine wil aot start Fallet ignition system

orn Ser" | Bron cme ve bok

arate engine

Mee |e incaret camsnat rng dot

jumped bolt or neomect asst

«Worn or broken pistons or piston sngs

Corrective action

2. See COOLING SYSTEM

bo. Soo ELECTRICAL SYSTEM

| 6 See SUSPENSION AND STEERING

4. Roslace bob ensioner. 2

| «©. Replace cormpressor

|

|

|

|

‘8. Check oi pressure ander waming systom. 7.

1 Adjust valve ash, 4.4

‘6. Chock com tolowers and replace as equa. 46

‘a Check ang covect of ove. Soe LUBRICATION AND

MAINTENANCE

|b. Gung engi nd er See LUBRICATION AND

sennifenace

6. Check of pressure. 7.

a. Rplace valve stam ol seals. 4.7

|b. Overhaul or replace eyinder head.

6. Overhaul or replace engine

a. Replace cise Head gasket 4.8

bs Recurtace o replace cylinder hed gasket. 48

‘9, Sop FUEL SYSTEM

2. nla wires comeaty. Soe IGNITION

'B Chock camsnat drive alt ant camehat timing. 4:2

Soe IGNITION

|. Chock cam sprocket olaion as engine tums over. instal

‘camshaf ave nel ae necessay 42

1. Check camshaft timing, Replace belt and sprockets ae nacessary

alist bo tension 4.2 |

|

|

t

|.

3.2 Diagnostic Testing

‘The tests thal foflow can be used to help isolate engine

problems, to better understand a problem belo staring ox:

pensive repairs, or just to periodically check engine conctton,

Compression Test

A test of compression pressures in the individual cylinders

‘wil tel alot about the consiton ofthe engine without the need

for taking for taking it apart, The testi relatively simple and

Fequires a compression toster, a spark plug wrench, a sora:

rive, and a jumper ware to d'sable the igniton system,

3-10 ENGINE

The battery and starter must be capable of turning the

engine at normal cranking speed to achieve meaningful re

sulls. The area around the spark plugs should be clean, to

{avoid getting debris inside the engine when they are removed.

Because engine temperature may affoct compression, the most

accurate results are obtained when the engine is at normal

operating temperature

‘To test compression:

4, With the ignition off, disconnect the coil wie from the

Cconter ofthe distributor cap (leinal 4) and connectit to

{ground on the engine block using a jumper wire, This ts

to disable the secondary citcut ofthe ignition system,

2. Disconnect one end of the duct between the air How

vensor and the throttle bocy to disable the fue injection

system,

8. Remove the spark plug wires Irom the spark plugs. Use

care 10 pull on oth the wire and the boot atthe same

time to avoid damage to the connectors. Label the wires

‘sothat they can be reattached te the correct spark plugs.

4. Remove the spark plugs and set them aside, in order

Corresponding to the cylinders from which they sere

removed.

5. Thread the compression tester into the first cylinder’'s

‘spark plug hole, just tight enough to seal around the

park plug hole. Use care not to damage the seal on the

gauge line,

6. With the transmission in neuiral and the throttle held wide

‘open, crank the engine with the starter. The gauge

‘eading should increase with each engine revolution.

‘Continue cranking unt the gauge reading stops increas:

Ing (about 4 to 5 revolutions). Record the highest value

inaicated by the gauge

Release the pressure, either with the gauge valve or by

slowly removing the gauge, allowing the pressure to

bleed off while threading it out of the sper plug hole,

8 Repeat the test for each of the ether cylinders. Record

the data and compare with table c

‘Table c. Compression Pressure Specifications

Engine code

oH “] 2H, PL

‘Compression

pressure ~ psi (ty

awengines

aria

20) | 00-130)

198 7B)

a0

‘Weare

‘maximum aiference

batwoen eyindors

HG

9. Reinstalthe spark plugs ane the spark plug wires in their

‘original focatons. Reinstal the air duct. Reconnect the

call wie.

Low compression is evidence of poosy seated combustion

chambers. The characteristics ofthe test results help isolate the.

‘cause oF causes. Generally, compression pressures which are

relatively even but below acceptable specifications indicate

worn piston rings andior eylinder walls. Low but erate values,

tend to indicate valve leakage, Dramatic differences, such as

‘acceptable values in some cylinders and very low values in one.

fr two cylinders are the sign of a localized failure, probably of

fa head gasket, There are twa more tests which can further

‘sofate the problem

Wet Compression Test

‘To analyze poor compression and further identify the source

of the leakage, repeat the compression test, this time with

about tablespoon of ol squirted into each cylinder. The ol wil

temporanly help seal between the piston rings and the cylinder

wall practically eéminating teakage past the rings for a short

‘ime. If this test yields higher compression readings than the

‘ry” compression test, the difference can be attributed to

Jeakage botwoon the piston rings and cylinder wals, due either

{© woar or fo broken piston rings. Litte or ne change in com:

pression readings indicates other leakage, probably trom the

valves ora failed cylinder head gasket

Leak-down Test

The most conclusive diagnosis of low compression symp-

toms requires a leak down test. Using a special tester and a

supply of compressed air, each cylinder is pressurized. The

rate at which the air leaks out of the cylinder, as well as the

‘sound of the air escaping, can more accurately pinpoint the

magnitude and source of the leakage. Any engine compres:

sion diagnosis which wil require major disassembly should test

be confined by the more accurate laak-cown test, Because

the test requires special equipment and experience, it may be

desirable to have i performed by a Volkswagen dealer or other

‘quail repair shoo.

4. CYLINDER HEAD

The cylinder head can be removed from the engine for

repairs without frst removing the engine from the car, and

many cylinder head repairs can be accamplished without re

moving the cylinder head from the engine, The cylinder head

cover gasket, the camshat(s). the camshaft drive belt, the

camshaft ol seal, the valve guide oil seals, and the cam follow:

fers ave al accessible wih the cyinder head installed

Reconditioning the cylinder head is nol overly complicated,

‘but requires time and an exteneive tool selection. tf good:

‘machine shop services are not avalable in your area, or time is,

2 factor, installation of a remanufactured cylinder head is an

alternative. Remanufactured cylinder heads are avaiable trom

fan authorized Volkswagen dealer.

4.1 Cylinder Head Cover and Gasket

Gaskets that have ben compressed will naver seal as well

if used a socond time. They should be replaced any time the

‘caver is removed, Any sign of ail leakage around or below the

over ie also cause to replace the gaskets, The 8-valve en:

gines use a two-piece gasket set. Notice that the halt-round,

Plug at the back ofthe headis also an important seal, The two-

pisca gasket set for 16-valve engines has built-in plugs,

To remove and install cylinder head cover and gaskets

1ove the eight 10 mm nuts and the eeintoreing

sts.

2. Remove the secket-head flanged nut remthe camshaft

sive belt upper cover.

8, Lift off

camshat

e cylinder head cover and its gasket. Raise the

t drive belt upper cover slightly for clearance. i

the gasket is stuck to the cylinder head, use a gasket

removing tool to separate the gasket from the head,

‘Remove the sealing plug from the rear of the cylinder

head and remove the semi-circular gasket piece from

inside the front of the cover.

caunion —

Femnove lf f the old gasket Work ears it

tho gasket is stuck Damage to ater surace

‘nif ease leaks Only use a gasket remover teal

dasignad for the purpose.

4, Installtionis the reverse of removal, Make sure the tabs

‘onthe semi-circular piece carrectly mate the sats on the

gasket to ensure a good seal. Torque the eight nuts and

the socket head flanged nut to 10 Nm (87 in, fo).

‘To remove and install cylinder head cover and gasket

(16-valve engines)

4. Remove the spark plug wire connectors, Remove the

intake airboot fromthe throtla housing and remave the

small rubber hose between the intake air boot and the

idle air vale.

Disconnect the electrical connector far the charcoal

‘canister control valve, and the large vacuurn hase from

the back of the upper intake manda.

8, Ramova the support bot from the back ofthe upper in

taka manifold, then remova the five nuts and washers

that join the upper intake manifold te the fower intako

rmanifole

4, Retate the upper manifold up end away trom the en:

gine, Remove and label electrical connections or vacu

Lum hoses as required. Then secure the manifold out of

the way

ENGINE 3-11

5, Remove the two inner bolts and the six outer bolts trom

the cover, and lit the cover from the cylinder head.

necessary, use a soft hammer to loosen the cover. Re:

‘move the center gasket from the cylinder head or the

cauTion —

Remove all of the old gasket Work carctuly

tho gasket fe stuck. Damage to oither surface

if cause leaks. Only use a gasket romover feo!

designed for the purposo.

6. Installation isthe reverse of removal. Torque the eight

cover bolts to 10 Nm (87 in. to). Torque the five mani

fold nuts and the manifold support bot to 20 Nm (15 f

|b). Torque the support bolt last.

42 Camshaft Drive Belt

‘The camshaft drive belt and its related parts are shown ia

Fig. 4-1. The bettisinstalled forthe lie ofthe engine, However,

te guard against unexpected failure the publisher recom

mend periodic inspection ofthe belt, as well as the additional

precaution of belt replacement at 60,000 to 75,000 miles

(86,0000 120,000 km) or every 4to 5 yaars,

Removal of hebetis the best way to performathorough in-

spection. For PL (16-vale) engines, a special wrench is re-

quired to adjust the camshaft dive belt tensioner. On all,

engines, the dive belt can be replaced without removing the

drive belt sprockets

Whenever tho dive baits installod, the camshaft and intet~

rmeciate shattiming must be adjusted

To remove and inspect camshatt drive belt:

§, Remeve the nut and the socket-head shouldered nut

securing the upper camshaft drive belt cover, and re-

move the cover.

2, Loasen the coolant pump pulley bolts, and remove the

\Vpelis as described in LUBRICATION AND MAINTE.

NANCE. Remove the coolant pump pulley.

3, Using @ socket wrench on the crankshatt vibration

damper bol, rotate tha engine by hand to set the No. 1

piston at Top Dead Center (TDC), and remove the vi

bration damper from the crankshaft

cauTion —

Fotating the crankshaft or the camshat wit the

hve Bott romeved may cause inerforonee

tnbich ean damage pistons and valvos.

4. Remove the nuts and bolt that hold the lower camshatt

civa belt cover to the coclant pump and to the front of

the engine, and remove the lower cover.

ENGINE

Fig. 4-1. Canishat crise bot ard cove

5 camshaft crive belt tensioner locknut to 18

it tension. Then remove the drive belt by work:

ng of the sprockets,

6. Inspect the tensioner bearing and the bat. Spin the bear

ing t

tory

eck that runs srnoathly. Inspect tho ckive belt

jamage such as exposedthreads and missing

teoth. Damaged camponents should be replaced,

Nore —

Fale of tha seatod tenstonar boating

sibilly, On a high-mileage engine, «

placing he tenaicner when replacing the bel.

To install and adjust camshatt drive belt

1. Use 2 socket on the cantar bolt to rotate the camshaft

sprocket by hand until the timing marks are aligned

The camshaft timing marks for PL (16-valve) engines

fre shown in Fig. 4-2, The camshatt timing marks for

the Bvalve angines are shown in Fig.

af

; |

|

| |

\

SE rte | |

| centana et \\ |

ete ener—! | \

seroatetoen——} |

Pete

Fig. 42 Gamshatt

with cyinder head

fn PL (16a engine

om et an of i.

Fig. 4-3, rv bos pina mark area for eametat ad

nteracate aig an waive engines.

2, Loosely installthe camshatt drive bel over the crankshaft

andintermediate shett sprockets. Then temporary install

the exarkshaft vibration damper onto the crankshaft

4. Rotate the crankshaft and the intermediate shaft by

hand unti the timing marks line up. The crankshaft and

the intermeciate shatt timing marks for 8-valve engines

fare shown above in Fig. 4-3. The crankshaft timing

‘marks for PL (1B-valve) engines are shown in Fig, 4-4

note —

On A.valve engines oni, the intermediate shaft

‘ining we icused becatee it rvs the igniten

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- FR CHAMPION85139064 Spark Plug Trouble Tracer 420x594 LRDocument1 pageFR CHAMPION85139064 Spark Plug Trouble Tracer 420x594 LRTheo HuqueleuxNo ratings yet

- Vue en Coupe Piston de Tête Hydraulique VADocument6 pagesVue en Coupe Piston de Tête Hydraulique VATheo HuqueleuxNo ratings yet

- Vue en Coupe Piston de Pompe Injection en LigneDocument1 pageVue en Coupe Piston de Pompe Injection en LigneTheo HuqueleuxNo ratings yet

- 10EXSOVDocument5 pages10EXSOVTheo HuqueleuxNo ratings yet

- Fuel InjectorDocument1 pageFuel InjectorTheo HuqueleuxNo ratings yet

- Type de Connecteur LucasDocument1 pageType de Connecteur LucasTheo HuqueleuxNo ratings yet

- Liste de PièceDocument1 pageListe de PièceTheo HuqueleuxNo ratings yet

- Imt Catalog 2016Document8 pagesImt Catalog 2016Theo HuqueleuxNo ratings yet

- Process Sur VéhiculeDocument5 pagesProcess Sur VéhiculeTheo HuqueleuxNo ratings yet

- Eclate 729030-51380 3tne88-B1Document2 pagesEclate 729030-51380 3tne88-B1Theo HuqueleuxNo ratings yet

- 10X9903113EXDocument1 page10X9903113EXTheo HuqueleuxNo ratings yet

- 10TATRADocument3 pages10TATRATheo HuqueleuxNo ratings yet

- SSP 246 Distribution VariableDocument30 pagesSSP 246 Distribution VariableTheo Huqueleux100% (1)

- 10DEUTZ914SOLENOIDSDocument1 page10DEUTZ914SOLENOIDSTheo HuqueleuxNo ratings yet

- Eclate 719520-51100 2tne68-ErDocument10 pagesEclate 719520-51100 2tne68-ErTheo HuqueleuxNo ratings yet

- Injecteurs TNVDocument3 pagesInjecteurs TNVTheo HuqueleuxNo ratings yet

- 10MAZDocument3 pages10MAZTheo HuqueleuxNo ratings yet

- Eclate 729948-51330Document10 pagesEclate 729948-51330Theo HuqueleuxNo ratings yet

- Calage Pompe Injection MPDocument9 pagesCalage Pompe Injection MPTheo HuqueleuxNo ratings yet

- 728890-51350 3ym20Document7 pages728890-51350 3ym20Theo HuqueleuxNo ratings yet

- Eclate 129970-51000Document6 pagesEclate 129970-51000Theo HuqueleuxNo ratings yet

- Reglage 729430-51480 4tne88-EhysDocument1 pageReglage 729430-51480 4tne88-EhysTheo HuqueleuxNo ratings yet

- Eclate 729430-51480 4tne88-E..Document8 pagesEclate 729430-51480 4tne88-E..Theo HuqueleuxNo ratings yet

- Programme Général LMC 2022Document1 pageProgramme Général LMC 2022Theo HuqueleuxNo ratings yet

- Gedore France Compendium 2021Document460 pagesGedore France Compendium 2021Theo HuqueleuxNo ratings yet

- 2QM20HDocument74 pages2QM20HTheo HuqueleuxNo ratings yet

- Boites 944Document3 pagesBoites 944Theo HuqueleuxNo ratings yet

- Boites 924Document1 pageBoites 924Theo HuqueleuxNo ratings yet