Professional Documents

Culture Documents

Aluminium 1050

Aluminium 1050

Uploaded by

Sephiwe MafilikaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aluminium 1050

Aluminium 1050

Uploaded by

Sephiwe MafilikaCopyright:

Available Formats

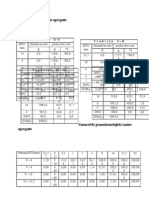

ALUMINIUMS Alloys Pure Aluminium 1050

Chemical composition

% Si Fe Cu Mn Mg Cr Zn Ti Al Others

Minimum

Maximum 0, 25 0, 40 0, 05 0, 05 0, 05 0, 07 0, 05 99, 5 0, 03

International Equivalences

Europe USA Spain France Germany G.B. Italy Sweden Switzerland Japan

E.N. 573 A.A. U.N.E. AFNOR D.I.N. B.S. U.N.I. S.I.S. V.S.M. J.I.S.

EN AW 38.114 A5 A 99.5 4507 A 1050

1,050A 1B 4007 Al 99.5

1050A L-3051 57350 3.0255 9000-P-2 A1x1

Mechanical properties of sheets Standard: EN 485-2 Aluminium EN AW-1050A [Al 99,5]

Nominal Bending radius

Treatment Rm MPa Rp0,2 MPa Min. elongation % a) Hardnes

thickness mm

state Greater s HBS 1)

up to min. max. min. max. A50mm A 180º 90º

than

F 2,5 150,0 65

O/H111 0,2 0,5 65 95 20 20 0t 0t 20

0,5 1,5 65 95 20 22 0t 0t 20

1,5 3,0 65 95 20 26 0t 0t 20

3,0 6,0 65 95 20 29 0,5 t 0,5 t 20

6,0 12,5 65 95 20 35 1,0 t 1,0 t 20

12,5 50,0 95 20 32 20

H14 0,2 0,5 105 145 85 2 1,0 t 0t 34

0,5 1,5 105 145 85 3 1,0 t 0,5 t 34

1,5 3,0 105 145 85 4 1,0 t 1,0 t 34

3,0 6,0 105 145 85 5 1,5 t 34

6,0 12,5 105 145 85 6 2,5 t 34

12,5 25,0 105 145 85 6 34

H16 0,2 0,5 120 160 100 1 0,5 t 39

0,5 1,5 120 160 100 2 1,0 t 39

1,5 4,0 120 160 100 3 1,5 t 39

H18 0,2 0,5 140 120 1 1,0 t 42

0,5 1,5 140 120 2 2,0 t 42

1,5 3,0 140 120 2 3,0 t 42

H24 0,2 0,5 105 145 75 3 1,0 t 0t 33

0,5 1,5 105 145 75 4 1,0 t 0,5 t 33

1,5 3,0 105 145 75 5 1,0 t 1,0 t 33

3,0 6,0 105 145 75 8 1,5 t 1,5 t 33

6,0 12,5 105 145 75 8 2,5 t 33

H26 0,2 0,5 120 160 90 2 0,5 t 38

0,5 1,5 120 160 90 3 1,0 t 38

1,5 4,0 120 160 90 4 1,5 t 38

a) Multiply the coefficient by the sheet thickness

📱:+27766384903 📠:0866053395 📧sepsma@live.com,Physical Address 1176 Rakgogodi Street, Tlhabane 0299

Members: SM Mafilika(founder,CEO) as Best Fleet Trading and Projects CC t/a Gasoilene

page (1)

ALUMINIUMS Alloys Pure Aluminium 1050

Mechanical properties Standard: EN 755-2 Alloy: EN AW-1050A [Al 99,5]

Extruded bar

Treatment Measurements mm Rm MPa Rp0,2 MPa A% A50 mm %

state D1) S2) min. max. min. max. min min.

F4), H112 all all 60 – 20 – 25 23

O, H111 all all 60 95 20 – 25 23

Extruded tube

Measurements Rm MPa Rp0,2 MPa A% A50 mm %

Treatment state 3)

mm e

mín. máx. mín. máx. mín mín.

4)

F , H112 all 60 – 20 – 25 23

O, H111 all 60 95 20 – 25 23

Extruded profile

Estado de Medidas mm Rm MPa Rp0,2 MPa A% A50 mm %

tratamiento e3)

mín. máx. mín. máx. mín mín.

4)

F , H112 all 60 – 20 – 25 23

1) D = Diameter of circular section bars.

2) S = Distance between faces for square-section and hexagonal bars, thickness for rectangular section bars.

3) e = Wall thickness.

4) Treatment state "F": the values of the characteristics are indicated merely for the sake of information.

Physical properties

Modulus of Specific Melting Linear expansion Thermal Electrical Electrical

Dissolution

elasticity weight temperature coefficient conductivity resistivity at conductivity%

potential V

N/mm2 g/cm3 ºC 1/106K W/mK 20ºC - cm IACS

69.000 2,70 646-657 23,5 229 2,9 59,5 -0,84

Technological suitabilities

State

Welding Natural behaviour Anodized Mechanization State F

H14

Under flame MB In a rural environment MB For protection MB Chip fragmentation M M

At the arc under MB In an industrial B

argon gas environment Decorative B Surface gloss R R

Owing to electrical In a marine

MB B Hard anodized MB

resistance environment

Brazed MB In sea water B

State H-

Stamping State 0

14

State H-18 Coating

Owing to expansion MB B M Lacquered MB

Deep stamping MB B M Galvanized B

Electroless nickel B

Thermal treatments Products Observations and applications

Forging temperature interval: 350º - Wire rods, extruded Excellent corrosion-proofing and conformability. Good

500ºC profiles, tubes, electrical and thermal conductivity. Typical

Total annealing: 340ºC sheets, plates. applications: tanks and boilers, roofs and rooftops,

Partial annealing: 240ºC chemical industry, food equipment and containers,

deformable tubes for pharmaceutical containers,

condenser blades, nuclear applications, rivets etc.

📱:+27766384903 📠:0866053395 📧sepsma@live.com,Physical Address 1176 Rakgogodi Street, Tlhabane 0299

Members: SM Mafilika(founder,CEO) as Best Fleet Trading and Projects CC t/a Gasoilene page (2)

You might also like

- Gasoilene MANDATE LetterDocument1 pageGasoilene MANDATE LetterSephiwe Mafilika100% (1)

- Cambridge O Level: Physics 3174/12Document16 pagesCambridge O Level: Physics 3174/12Nathan MwansaNo ratings yet

- A Student's Guide To Dimensional Analysis PDFDocument222 pagesA Student's Guide To Dimensional Analysis PDFMalvado Aun Mas Malvado100% (5)

- (MOD) 01 Measurement of Physical Quantities PDFDocument6 pages(MOD) 01 Measurement of Physical Quantities PDFPatrick VerroyaNo ratings yet

- Sabater Fundimol Catalog p22 23Document2 pagesSabater Fundimol Catalog p22 23Pep VasilevaNo ratings yet

- Sabater-Fundimol Catalog p32-33 PDFDocument2 pagesSabater-Fundimol Catalog p32-33 PDFSağlam RasimNo ratings yet

- ALUMINIUM ALLOYS For Electrical ApplicationsDocument1 pageALUMINIUM ALLOYS For Electrical Applicationstwo travellerNo ratings yet

- 07 10 2019 Lamifil Aluminium Alloys For Electrical ApplicationsDocument1 page07 10 2019 Lamifil Aluminium Alloys For Electrical ApplicationscantigiNo ratings yet

- NR216Document4 pagesNR216shahbazNo ratings yet

- Pump Head CalculationDocument3 pagesPump Head CalculationSkylink Estimation TeamNo ratings yet

- 3 C ExcelDocument1 page3 C ExcelFederica CortegosoNo ratings yet

- U (10 - 3 VB) /SB VB (Q T2) /T3Document18 pagesU (10 - 3 VB) /SB VB (Q T2) /T3Dipo A SantikoNo ratings yet

- Alfani Mahmudah m0318009 Uas No2Document3 pagesAlfani Mahmudah m0318009 Uas No2Alfani MahmudahNo ratings yet

- Cycloidal Follower Displacement: Theta (Deg)Document24 pagesCycloidal Follower Displacement: Theta (Deg)navdinNo ratings yet

- Anexo #8 Tabla de Valores Sistema de Rciadores ZoonosisDocument23 pagesAnexo #8 Tabla de Valores Sistema de Rciadores ZoonosisAndres Felipe LopezNo ratings yet

- Tarjetas de Cubicacion - S. R. Esp..Document3 pagesTarjetas de Cubicacion - S. R. Esp..az75207663No ratings yet

- Worksheet in RC Retaining WallDocument1 pageWorksheet in RC Retaining WallteweldeNo ratings yet

- K91.31 Fig T302-M3 B302-S13 en FinalDocument1 pageK91.31 Fig T302-M3 B302-S13 en FinaladrianioantomaNo ratings yet

- Certificado Calibracion Meghometro Megabras 2 - 2018Document6 pagesCertificado Calibracion Meghometro Megabras 2 - 2018pasco pasco0% (1)

- Friction Connected ParticlesDocument44 pagesFriction Connected ParticlesHadi MirzaNo ratings yet

- Catalog Goodyear For TruckDocument2 pagesCatalog Goodyear For Truckcv majujayautama100% (1)

- WWW WWW WWW WWW: CitatuneDocument6 pagesWWW WWW WWW WWW: CitatuneRudi HariantoNo ratings yet

- Mezclas de MaterialesDocument8 pagesMezclas de MaterialesAlejandro LopezNo ratings yet

- SKFDocument4 pagesSKFDouglasNo ratings yet

- Universidad Nacional Del Santa: Facultad de IngenieríaDocument7 pagesUniversidad Nacional Del Santa: Facultad de IngenieríaMiguel CruzNo ratings yet

- Air Fuses: In-Line Excess Flow Shut-Off ValvesDocument3 pagesAir Fuses: In-Line Excess Flow Shut-Off ValvesAttila VáczNo ratings yet

- University: Bangladesh and Eleclrical !NDDocument10 pagesUniversity: Bangladesh and Eleclrical !NDM.g. Rahman MunnaNo ratings yet

- En 10025-2-2004 BS HotRolledProductDocument7 pagesEn 10025-2-2004 BS HotRolledProductChrill DsilvaNo ratings yet

- Simplex MaxiDocument2 pagesSimplex MaxiJane RicoNo ratings yet

- Lab 1 CalculationDocument4 pagesLab 1 CalculationClinton NdhlovuNo ratings yet

- Rplot PDFDocument1 pageRplot PDFOmar Alejandro RamírezNo ratings yet

- Diagrama Cengel Apuntes Transferencia de CalorDocument4 pagesDiagrama Cengel Apuntes Transferencia de CalorJuanita López SánchezNo ratings yet

- Extracto Norma ASTM A792Document2 pagesExtracto Norma ASTM A792Christian Latorre VielmaNo ratings yet

- 0805SMD010 HitanoDocument9 pages0805SMD010 Hitanoemail emailNo ratings yet

- Acos Ferramenta Ligados Astm A 681Document2 pagesAcos Ferramenta Ligados Astm A 681Wenderson SouzaNo ratings yet

- Programming ComputerDocument13 pagesProgramming ComputerEsterlytalbgNo ratings yet

- Tabela Tubos HidráulicosDocument1 pageTabela Tubos HidráulicosJPJFNo ratings yet

- Kurva Kesetimbangan Uap Cair RDocument6 pagesKurva Kesetimbangan Uap Cair RWanda YunitaNo ratings yet

- En 10025-2 ExtractDocument1 pageEn 10025-2 Extractpalani.djpNo ratings yet

- Planilla de Hierros Sala Profesores MC Tipo No. Dimensiones A B C D (M) Cadena de Amarre Ø (MM)Document2 pagesPlanilla de Hierros Sala Profesores MC Tipo No. Dimensiones A B C D (M) Cadena de Amarre Ø (MM)Lenny Viteri EnriquezNo ratings yet

- 4499 32a1b AtomizingsteampressurecontrollerDocument1 page4499 32a1b Atomizingsteampressurecontrollerakcaglayan09No ratings yet

- Dados Ivo TebuloDocument3 pagesDados Ivo TebuloIvo Dias TebuloNo ratings yet

- AAG Tolerances GBDocument2 pagesAAG Tolerances GBJayantNo ratings yet

- Thermanit Weldingfillermetalsforpowerplantengineering1Document18 pagesThermanit Weldingfillermetalsforpowerplantengineering1DarioNo ratings yet

- Caracteristica TécnicaDocument8 pagesCaracteristica TécnicaAnderson De Souza JesusNo ratings yet

- EJERCICIO 13 Tratamiento de DatosDocument10 pagesEJERCICIO 13 Tratamiento de DatosVALENTINA ROMERO CUBIDESNo ratings yet

- 4499 13a1b Fueloiltemperaturecontroller0Document1 page4499 13a1b Fueloiltemperaturecontroller0akcaglayan09No ratings yet

- Ajuste A Ecuaciones Lineales en ExcelDocument6 pagesAjuste A Ecuaciones Lineales en ExcelJesús HernándezNo ratings yet

- Gradiva ProgramDocument7 pagesGradiva Programapi-3841190No ratings yet

- Capacidad de Carga (General)Document68 pagesCapacidad de Carga (General)leoNo ratings yet

- DIN 2093 UNI 8737 Molle A TazzaDocument6 pagesDIN 2093 UNI 8737 Molle A TazzaRoby MastreNo ratings yet

- Tarjetas de Cubicacion MilagrosaDocument6 pagesTarjetas de Cubicacion Milagrosaaz75207663No ratings yet

- CPCL Turbine ReportDocument25 pagesCPCL Turbine ReportRajesh GoladaNo ratings yet

- How To Condition A New Capillary GC Column - BGBDocument4 pagesHow To Condition A New Capillary GC Column - BGBr.rezaei7521No ratings yet

- Ic 269Document5 pagesIc 269Poonam SahniNo ratings yet

- EN 10213 Material SpecificationsDocument1 pageEN 10213 Material Specifications김창배No ratings yet

- Separators-Parameter ListDocument3 pagesSeparators-Parameter ListJezrell JaravataNo ratings yet

- Mechanical Properties of Aluminium AlloysDocument2 pagesMechanical Properties of Aluminium AlloysHytech Pvt. Ltd.No ratings yet

- Thomas Slope Method: Time DaysDocument9 pagesThomas Slope Method: Time DaysAnantha SinghNo ratings yet

- Analysis and Simulation of Signal Filters: X(S) As+B Y(s) S S+CS+DDocument31 pagesAnalysis and Simulation of Signal Filters: X(S) As+B Y(s) S S+CS+DFelix Pinto MacedoNo ratings yet

- MRU - (X Vs T)Document1 pageMRU - (X Vs T)Räqüël Päücärä KäsäsNo ratings yet

- Chemical Composition of 1/3/5/6 Series AluminumDocument1 pageChemical Composition of 1/3/5/6 Series Aluminummukmin nbperkasaNo ratings yet

- Bar Bending Schedule: MLA QuartersDocument2 pagesBar Bending Schedule: MLA QuartersGurram Lakshmi NavakanthNo ratings yet

- Shippingterms and AbbreviationsDocument38 pagesShippingterms and AbbreviationsFyzelvee EscanerNo ratings yet

- PS - Corn Oill - v01Document3 pagesPS - Corn Oill - v01Sephiwe MafilikaNo ratings yet

- EOI - Gardening and Landscaping Business Training and Incubation Programme 24.06.2024Document2 pagesEOI - Gardening and Landscaping Business Training and Incubation Programme 24.06.2024Sephiwe MafilikaNo ratings yet

- Icpo 200.000Document5 pagesIcpo 200.000Sephiwe MafilikaNo ratings yet

- AccessrightsguideDocument15 pagesAccessrightsguideSephiwe MafilikaNo ratings yet

- FVTR Flyer FIA Internal Diesel Injector DepositsDocument2 pagesFVTR Flyer FIA Internal Diesel Injector DepositsSephiwe MafilikaNo ratings yet

- The Rights of A Third Party Beneficiary of A Bill of Lading To ADocument14 pagesThe Rights of A Third Party Beneficiary of A Bill of Lading To ASephiwe MafilikaNo ratings yet

- SP Chrome Ore Specs.Document5 pagesSP Chrome Ore Specs.Sephiwe MafilikaNo ratings yet

- SGS OGC SAT Example EN 202001Document25 pagesSGS OGC SAT Example EN 202001Sephiwe MafilikaNo ratings yet

- RMI Membership Certificates SAVABA Ramcom Truck Load Bodies Pty LTD 1Document1 pageRMI Membership Certificates SAVABA Ramcom Truck Load Bodies Pty LTD 1Sephiwe MafilikaNo ratings yet

- EN590 10ppm SPECIFICATIONS PEGASUS OILDocument1 pageEN590 10ppm SPECIFICATIONS PEGASUS OILSephiwe Mafilika100% (1)

- CERTIFICATE OF PRODUCT QUALITY JET A - 1 Gasoilene 2000,000BBL-1Document2 pagesCERTIFICATE OF PRODUCT QUALITY JET A - 1 Gasoilene 2000,000BBL-1Sephiwe MafilikaNo ratings yet

- Bridgeit WashingtonDocument27 pagesBridgeit WashingtonSephiwe MafilikaNo ratings yet

- Draft Contract For ALUMINUM INGOTSDocument3 pagesDraft Contract For ALUMINUM INGOTSSephiwe MafilikaNo ratings yet

- Beware 10082020 4Document2 pagesBeware 10082020 4Sephiwe MafilikaNo ratings yet

- Commercial Invoice 1Document1 pageCommercial Invoice 1Sephiwe MafilikaNo ratings yet

- Psychrometric ChartDocument1 pagePsychrometric ChartDejan DosljakNo ratings yet

- CH Sample Paper 4 UnsolvedDocument10 pagesCH Sample Paper 4 UnsolvedMeruthulaNo ratings yet

- Orthodontic WiresDocument35 pagesOrthodontic WiresSadhu Abhijeet100% (1)

- Space Lattice Basis Crystal StructureDocument6 pagesSpace Lattice Basis Crystal StructureMainzaNo ratings yet

- ProblemDocument7 pagesProblemMary Claire NevalgaNo ratings yet

- DG - 1411114236 - 3plastic Part Design GuidelinesDocument38 pagesDG - 1411114236 - 3plastic Part Design GuidelinesK S RANJITH ランジットNo ratings yet

- The Solar System SHSDocument28 pagesThe Solar System SHSVJ MendozaNo ratings yet

- Structural Analysis Problems and Solutio PDFDocument22 pagesStructural Analysis Problems and Solutio PDFjay balagotNo ratings yet

- Ana GeoDocument2 pagesAna GeoJasi AhahaNo ratings yet

- Aeronautical Engineering SyllabusDocument103 pagesAeronautical Engineering Syllabusmurjass85No ratings yet

- Susol VCB E 1405Document220 pagesSusol VCB E 1405tawanda1984No ratings yet

- Imat Equation + Formula SheetDocument6 pagesImat Equation + Formula SheetNhi NguyenNo ratings yet

- Admmodule Stem Gp12n-Id-30Document23 pagesAdmmodule Stem Gp12n-Id-30Yasser MacknoNo ratings yet

- Pump FundamentalsDocument14 pagesPump FundamentalsJithin Rajan JosephNo ratings yet

- HUeLLER-HILLE NBH170-4 BJ1998 EN V1Document17 pagesHUeLLER-HILLE NBH170-4 BJ1998 EN V1aldacirjoe8360No ratings yet

- Module 3 - Circuit AnalysisDocument4 pagesModule 3 - Circuit AnalysisJinalyn NacuspagNo ratings yet

- High Voltage Engineering: Unit-I Electric Field StressesDocument9 pagesHigh Voltage Engineering: Unit-I Electric Field StressesmaheshNo ratings yet

- Virtual WorkDocument21 pagesVirtual WorkNIKHIL GOYALNo ratings yet

- Cse N13 February2019 PDFDocument152 pagesCse N13 February2019 PDFDaniel MargineanNo ratings yet

- VFD-EL-W Series: Delta Sensorless Vector Control Compact DriveDocument12 pagesVFD-EL-W Series: Delta Sensorless Vector Control Compact Drivedaniel serafimNo ratings yet

- Jumo Midas S05: OEM Pressure Transmitter - UniversalDocument11 pagesJumo Midas S05: OEM Pressure Transmitter - Universalsandeep varma penumatshaNo ratings yet

- Textil LAB Testing - Gihan RanganaDocument11 pagesTextil LAB Testing - Gihan RanganaGihan RanganaNo ratings yet

- Relationship Between Density and Moisture ContentDocument2 pagesRelationship Between Density and Moisture ContentivanNo ratings yet

- Principles Remote Sensing PDFDocument540 pagesPrinciples Remote Sensing PDFHay Day RNo ratings yet

- Experiment No.2Document10 pagesExperiment No.2Pankaj GargNo ratings yet

- TUNNELLINGDocument14 pagesTUNNELLINGkumarmanojod010215No ratings yet

- 200 20 Pi DTS 00008Document72 pages200 20 Pi DTS 00008ritesh142No ratings yet