Professional Documents

Culture Documents

How To Calculate PTH Hole and Pad Diameter Sizes According To IPC-7251, IPC-2222 and IPC-2221 Standards

How To Calculate PTH Hole and Pad Diameter Sizes According To IPC-7251, IPC-2222 and IPC-2221 Standards

Uploaded by

mryalamrbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

How To Calculate PTH Hole and Pad Diameter Sizes According To IPC-7251, IPC-2222 and IPC-2221 Standards

How To Calculate PTH Hole and Pad Diameter Sizes According To IPC-7251, IPC-2222 and IPC-2221 Standards

Uploaded by

mryalamrbCopyright:

Available Formats

Electrical Cables

We are the UK's leading supplier of cables and accessorie

Cleveland Cable Company

Home » Tutorials » IPC Standards » How to calculate PTH hole and pad diameter sizes according to IPC-7251, IPC-2222

and IPC-2221 standards?

How to calculate PTH hole and pad diameter sizes according to IPC-7251, IPC-

2222 and IPC-2221 standards?

This article shows how to calculate PTH (Plated Through-Hole) Hole and Pad Diameter sizes according to IPC-7251, IPC-

2222 and IPC-2221 standards in the following steps:

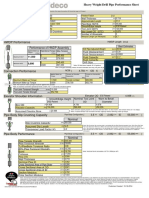

1. Find out the Maximum Lead Diameter

Firstly you should nd out the maximum lead diameter. It is present in the datasheet or package drawing of the

component. The maximum lead diameters for all shape types of holes are shown in the picture 1. Round hole shape is used

for Round PTH Lead. Rectangle hole shape is used for Rectangle PTH Lead. Square hole shape is used for Square PTH Lead.

Picture 1. The Maximum Lead Diameters for Round, Rectangle and Square types of Holes

2. Calculate the Minimum Hole Size

Picture 2. Component Leads and Pad dimensions.

Minimum Hole Size is calculated according to equations below:

Minimum Hole Size = Maximum Lead Diameter + 0.25mm (for Level A of IPC-2222)

Minimum Hole Size = Maximum Lead Diameter + 0.20mm (for Level B of IPC-2222)

Minimum Hole Size = Maximum Lead Diameter + 0.15mm (for Level C of IPC-2222)

3. Calculate the Pad Diameter

After you calculate the Minimum Hole Size, you should know that the Minimum Annular Ring is

0.05mm (50um). According to IPC-2221 the Minimum Fabrication Allowance is 0.6mm for Level A, 0.5mm for Level B and

0.4mm for Level C.

Pad Diameter = Minimum Hole Size + Minimum Annular Ring X 2 + Minimum Fabrication Allowance

Pad Diameter = Minimum Hole Size + 0.1mm + 0.60mm (for Level A of IPC-2221)

Pad Diameter = Minimum Hole Size + 0.1mm + 0.50mm (for Level B of IPC-2221)

Pad Diameter = Minimum Hole Size + 0.1mm + 0.40mm (for Level C of IPC-2221)

Example: Maximum Lead Diameter = 0.55mm

According to Level A Minimum Hole Size = 0.80mm; Pad Diameter = 1.50mm

According to Level B Minimum Hole Size = 0.75mm; Pad Diameter = 1.35mm

According to Level C Minimum Hole Size = 0.70mm; Pad Diameter = 1.20mm

Honda Blade 110 Tem Mới

Ad Tem phong cách, dáng thể thao với Honda

Blade 110 vóc dáng nhỏ gọn pha chút thể thao

Ad

Honda Việt Nam

Xem thêm

IPC-7251 Naming Convention for the Circular and Square Through Hole Pads

C + Pad Diameter + H + Hole Diameter (for the Circular Pad)

S + Pad Diameter + H + Hole Diameter (for the Square Pad)

Example: C150H90

C = Circular Pad

150 = 1.5mm Pad Diameter

H90 = 0.9mm Hole Diameter

Di erences between density levels A, B and C

Levels A, B and C describe the measure of the relative ease of manufacturing.

Density Level A is used for General Design Productibility. It is a Preferred Level. Level A is used for the Low component

density. In this case, footprint geometry is ‘Maximum’. This method is applied to the most robust productibility.

Density Level B is used for Moderate Design Productibility. It is a Standard Level. Level B conditions are suitable for re ow,

wave, drag or dip soldering. In this case, footprint geometry is ‘Median’. This method provides a robust solder attachment

conditions.

Density Level C is used for High Design Productibility. It is a Reduced Level. Level C is used for the High component

density. In this case footprint geometry is ‘Minimum’. This method is applied to a hand-held and portable appliances.

Share: LinkedIn | Google+ | Facebook | Twitter

Instrumentation Connectors Solar Cable, Solar Test_Point_TE_RCU…

Cables Interconnects Panel Wire -

Photovoltaic Wire

Manufacturer

Ad Cleveland Cable Company pcb-3d.com Ad leadergroup-cn.com pcb-3d.com

Excellent PCB Free How to calculate PTH Degson_DG301-5.0-…

manufacturer hole and pad diameter

sizes according to

IPC-7251, IPC-2222…

Ad POE-PCBA pcb-3d.com pcb-3d.com pcb-3d.com

Tutorials in the category: IPC Standards

How to calculate PTH hole and pad diameter sizes according to IPC-7251, IPC-2222 and IPC-2221 standards?

IPC-7251 Naming Convention for Through-Hole 3D Models and Footprints

IPC-7351B Naming Convention for Surface Mount Device 3D Models and Footprints

IPC-7X51 Naming Convention for Connectors and Mechanical Components

Naming Convention for Non Standard Surface Mount Device 3D Models and Footprints

Noel đỉnh sắm TV QLED lớn

Sales đỉnh mùa Giáng Sinh giảm 40% TV QLED tặng kèm Loa

Tháp ấn tượng

Samsung Vietnam Mở

Copyright © 2010-2020 / All Rights Reserved PCB 3D

You might also like

- Basic Stress Calculation 30-Aug-2016Document80 pagesBasic Stress Calculation 30-Aug-2016anandmoon273100% (3)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- 2010 ProlineUK CatalogueDocument84 pages2010 ProlineUK Cataloguealtaaraf_prolineuk50% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Centrifuga Iec Medispin Manual Instrucciones y ServicioDocument17 pagesCentrifuga Iec Medispin Manual Instrucciones y ServicioDiana PedrozaNo ratings yet

- CBR600F Diagrama ElectricoDocument1 pageCBR600F Diagrama ElectricoanxonyNo ratings yet

- E Catalogue 19 SEPDocument37 pagesE Catalogue 19 SEPVũ Minh TuấnNo ratings yet

- HSNL EngDocument54 pagesHSNL Engwebhareggebru06No ratings yet

- KDL 32 P 3550Document53 pagesKDL 32 P 3550Инж. Хранимир БешковNo ratings yet

- Continental Device India Limited: An IS/ISO 9002 and IECQ Certified ManufacturerDocument6 pagesContinental Device India Limited: An IS/ISO 9002 and IECQ Certified Manufacturermestre_giovasNo ratings yet

- JVC DR-MV1S VCR-DVDDocument75 pagesJVC DR-MV1S VCR-DVDCaptain444100% (1)

- IT3401C Codeur RotatifDocument4 pagesIT3401C Codeur RotatifDejuan HuffNo ratings yet

- Features: LM317 3-Terminal Adjustable RegulatorDocument18 pagesFeatures: LM317 3-Terminal Adjustable Regulatorpvm_manuNo ratings yet

- STR KM7500Document80 pagesSTR KM7500Betania100% (1)

- MITER BEND Formula To Calculate Length Angle of Cut Weight and Cut-Back of The Miters With PDFiftypeoDocument9 pagesMITER BEND Formula To Calculate Length Angle of Cut Weight and Cut-Back of The Miters With PDFiftypeoamlanfacebookNo ratings yet

- Diagrama de Blu-Ray Sony HBD-E370Document114 pagesDiagrama de Blu-Ray Sony HBD-E370Antonio ChavezNo ratings yet

- Hdi Presentation 110913Document58 pagesHdi Presentation 110913jawsmNo ratings yet

- Supplement To Turning Tools and Rotating Tools CataloguesDocument243 pagesSupplement To Turning Tools and Rotating Tools Cataloguessaotinhyeu307783No ratings yet

- Sony hcd-dx375 SM (ET)Document104 pagesSony hcd-dx375 SM (ET)Kevin RafuseNo ratings yet

- BXCD1734 - Revb BXCD1734 DatasheetDocument9 pagesBXCD1734 - Revb BXCD1734 Datasheetmeows21No ratings yet

- BMD Plug Gauges: Technical GuideDocument52 pagesBMD Plug Gauges: Technical Guidekunalkp88No ratings yet

- Catalog For Bearing DesignDocument70 pagesCatalog For Bearing DesignHameer ReddyNo ratings yet

- HCD Cpx11 SMDocument78 pagesHCD Cpx11 SMNelu FnNo ratings yet

- YD109Document10 pagesYD109soimosNo ratings yet

- Mtech Engineering: SupplyDocument4 pagesMtech Engineering: Supplyz018125No ratings yet

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNo ratings yet

- Pipeline Coatings PDFDocument29 pagesPipeline Coatings PDFAsimNo ratings yet

- Amphenol Connex Broadcast SolutionsDocument20 pagesAmphenol Connex Broadcast SolutionsAmphenolConnexNo ratings yet

- 1108PCDFCADocument56 pages1108PCDFCAulicitos100% (1)

- BPE Catalog 2022Document48 pagesBPE Catalog 2022debulusNo ratings yet

- Fibre Optic Connectors PenetratorsDocument17 pagesFibre Optic Connectors PenetratorsquanNo ratings yet

- 3051CDocument5 pages3051CAntonio FloresNo ratings yet

- What Is PCB Current Calculator, Its Importance, and How To UseDocument13 pagesWhat Is PCB Current Calculator, Its Importance, and How To UsejackNo ratings yet

- CV9202H A39Document49 pagesCV9202H A39Zoi LleshiNo ratings yet

- Industrial Rugged Metal Optical Encoder: Page 1 of 7Document7 pagesIndustrial Rugged Metal Optical Encoder: Page 1 of 7tiagogrilo100% (1)

- Mitsubishi Xd221u SeDocument70 pagesMitsubishi Xd221u SeCiborgSeptiembreNo ratings yet

- Product:: SAFE-T-Line® Red 2 X 1.5 mm2 LPCBDocument2 pagesProduct:: SAFE-T-Line® Red 2 X 1.5 mm2 LPCByanuar tinoNo ratings yet

- HC4000 ManualDocument66 pagesHC4000 ManualJim HarmkeNo ratings yet

- DJB Brochure 2017 V37Document36 pagesDJB Brochure 2017 V37Nirmalya DasguptaNo ratings yet

- Material Submittal-P6 Abha - SCSDocument131 pagesMaterial Submittal-P6 Abha - SCShabeebmudassir7677No ratings yet

- WhiteLED, 0.2mm., 8layer PDFDocument3 pagesWhiteLED, 0.2mm., 8layer PDFJeang NitisupornratNo ratings yet

- Sony hcd-hpz7 hpz9 Ver-1.1 PDFDocument112 pagesSony hcd-hpz7 hpz9 Ver-1.1 PDFperro sNo ratings yet

- What Is New in IPC 7351C - 7351004Document27 pagesWhat Is New in IPC 7351C - 7351004jagadees21No ratings yet

- Technical Specification For Perforated DIN RAILDocument9 pagesTechnical Specification For Perforated DIN RAILFrancis SonkengNo ratings yet

- G-FIRE Figure 730 Mechanical Tees and Crosses Threaded and Grooved Outlets - TFP1860 - 08 - 2022Document11 pagesG-FIRE Figure 730 Mechanical Tees and Crosses Threaded and Grooved Outlets - TFP1860 - 08 - 2022Leila DinizNo ratings yet

- B.cable Glands TCF. 15-7-23Document83 pagesB.cable Glands TCF. 15-7-23BirjuAJotwaniNo ratings yet

- JVC gr-d750 gr-d770 gr-d771 gr-d775 gr-d790 gr-d796 Uc Us SM PDFDocument64 pagesJVC gr-d750 gr-d770 gr-d771 gr-d775 gr-d790 gr-d796 Uc Us SM PDFguanteNo ratings yet

- Figure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingDocument4 pagesFigure 740 GRINNELL Rapid Installation Pivot-Bolt (GRIP) Rigid CouplingСергей КолесниковNo ratings yet

- 79001FS TechdataDocument2 pages79001FS TechdataMohammed SalahNo ratings yet

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаNo ratings yet

- JVC Gr-D720ex, D725eg, D740ex, D760ex, D770exDocument64 pagesJVC Gr-D720ex, D725eg, D740ex, D760ex, D770exOleg OlegerNo ratings yet

- LCD Repair Bonding MachineDocument9 pagesLCD Repair Bonding Machineassurant laudoNo ratings yet

- James Walker o Ring GuideDocument32 pagesJames Walker o Ring Guidecvishwas1159No ratings yet

- 2183R TechdataDocument2 pages2183R TechdataNelson NeriNo ratings yet

- Sil9287bcnu Hdmi SonyDocument8 pagesSil9287bcnu Hdmi SonyEmilio PinatoNo ratings yet

- Model 626B03 Low Frequency Industrial ICP® Accelerometer Installation and Operating ManualDocument19 pagesModel 626B03 Low Frequency Industrial ICP® Accelerometer Installation and Operating ManualFBNo ratings yet

- WWW Online Iso Calculator Com Online Bolt Torque CalculatorDocument6 pagesWWW Online Iso Calculator Com Online Bolt Torque CalculatormashudiNo ratings yet

- Ho So San Pham CODDocument14 pagesHo So San Pham CODwebhareggebru06No ratings yet

- Engineering Service Revenues World Summary: Market Values & Financials by CountryFrom EverandEngineering Service Revenues World Summary: Market Values & Financials by CountryNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Solder SkipsDocument5 pagesSolder SkipsmryalamrbNo ratings yet

- AppNote REDCUBE TerminalsDocument14 pagesAppNote REDCUBE TerminalsmryalamrbNo ratings yet

- File TypesDocument2 pagesFile TypesmryalamrbNo ratings yet

- DS CR 5000 Board Designer en v2Document2 pagesDS CR 5000 Board Designer en v2mryalamrbNo ratings yet

- Goulds Pumps: WE SeriesDocument4 pagesGoulds Pumps: WE SeriesJorge ManobandaNo ratings yet

- Kit 1575822922941Document857 pagesKit 1575822922941Md DanishNo ratings yet

- PT1 2 JustinDocument5 pagesPT1 2 JustinAnnissa PacaldoNo ratings yet

- 002 Quotation RavichandraDocument2 pages002 Quotation RavichandraBABA SIDNo ratings yet

- I 3-P D, U T: UtomaticrelaytestsetDocument4 pagesI 3-P D, U T: UtomaticrelaytestsetCARLOS LÓPEZNo ratings yet

- Parts and Functions of MotherboardDocument4 pagesParts and Functions of MotherboardJimmySyNo ratings yet

- 5 - Power TweaksDocument9 pages5 - Power TweaksLucas100% (1)

- Tweeter Replacement Instructions: 600 SeriesDocument1 pageTweeter Replacement Instructions: 600 SeriesGilbertoNo ratings yet

- Catalogo de Producto Oddysey PDFDocument148 pagesCatalogo de Producto Oddysey PDFhector martinez100% (1)

- Smi Low Pressure: Digital / Analog SensorDocument15 pagesSmi Low Pressure: Digital / Analog SensorhajaNo ratings yet

- Cat C32: Diesel Generator SetsDocument6 pagesCat C32: Diesel Generator Setsavinash_1229No ratings yet

- Yuyao Hilite Electric Co.,Ltd: CE23, Far East Industrial Park, Yuyao City 315400, Zhejiang Prov., ChinaDocument153 pagesYuyao Hilite Electric Co.,Ltd: CE23, Far East Industrial Park, Yuyao City 315400, Zhejiang Prov., ChinaEnrico BertoliniNo ratings yet

- HYUNDAI Tucson Plug-In Hybrid 2024Document98 pagesHYUNDAI Tucson Plug-In Hybrid 2024buleu_alexandruNo ratings yet

- Dim520dk UmDocument24 pagesDim520dk UmMaherNo ratings yet

- IFU Hawk 766 Exhaust Gas AnalyzerDocument8 pagesIFU Hawk 766 Exhaust Gas AnalyzerAndrew MarkNo ratings yet

- Wba3d31070j549204-Bimmer Work PDFDocument4 pagesWba3d31070j549204-Bimmer Work PDFStevan AritonovicNo ratings yet

- WOB Solar Power Product Solutions Guide BrochureDocument21 pagesWOB Solar Power Product Solutions Guide Brochurevineets058No ratings yet

- W342 E1 11+CS CJ CP+ReferenceManualDocument277 pagesW342 E1 11+CS CJ CP+ReferenceManualRyan Yudha AdhityaNo ratings yet

- SpicerDocument3 pagesSpicerBrayan Mejia AlvarezNo ratings yet

- Manual Book DSP-37-55 (V) A (W) (R) NDocument156 pagesManual Book DSP-37-55 (V) A (W) (R) NAgeng A. PooNo ratings yet

- RAB Chiller SipatexDocument4 pagesRAB Chiller Sipatexoki100% (1)

- Catalogo Paleta RotatoriaDocument8 pagesCatalogo Paleta RotatoriaRafael Jose Tasco ZabaletaNo ratings yet

- ) 1972 GE SCR Manual 5ed PDFDocument712 pages) 1972 GE SCR Manual 5ed PDFabrap_dNo ratings yet

- HeliCoil Plus All Tools MetricDocument16 pagesHeliCoil Plus All Tools MetricdesignNo ratings yet

- Crane N RiggingDocument34 pagesCrane N RiggingRajuNo ratings yet

- Job - Hazard AnalysisDocument2 pagesJob - Hazard AnalysisJenny Matic MendozaNo ratings yet

- NGR Technical InformationDocument6 pagesNGR Technical InformationPrabakar PNo ratings yet

- Belt DrivesDocument3 pagesBelt DrivesBibek DevNo ratings yet