Professional Documents

Culture Documents

WW 720 PD

WW 720 PD

Uploaded by

pjismannpaucaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

WW 720 PD

WW 720 PD

Uploaded by

pjismannpaucaCopyright:

Available Formats

BERMAD Waterworks

700 Series

Proportional

Pressure Reducing Valve

Model 720-PD

n Long downhill lines

q Serial pressure reduction

q Leakage and burst protection

n High differential pressure systems

q Protection against cavitation damage

q Throttling noise reduction

The Model 720-PD Proportional Pressure Reducing

Valve is a hydraulically operated, diaphragm actuated

control valve that reduces higher upstream pressure

to lower downstream pressure at a fixed ratio.

Features and Benefits Major Additional Features

n Line pressure driven – Independent operation n Solenoid control – 720-PD-55

n Elegant simplicity n Closing & opening speed control – 720-PD-03

o Most cost effective n Emergency pressure reducing valve – 720-PD-59

o Simple to maintain n Pressure Sustaining – 723-PD

o Minimal external accessories

n Variety of reduction ratios – Perfect mission matching See relevant BERMAD publications.

n Built-in check feature – Replacing line sized check valve

n In-line serviceable – Easy maintenance

n Double chamber

o Moderated valve reaction

o Protected diaphragm

n Flexible design – Easy addition of features

n Semi-straight flow – Non-turbulent flow

n Stainless Steel raised seat – Cavitation damage resistant

n Obstacle free, full bore – Uncompromising reliability

n V-Port Throttling Plug – Low flow stability

BERMAD Waterworks

Model 720-PD 700 Series

Operation

The Model 720-PD is a pilotless, double chambered, control valve. The downstream pressure is applied as the closing force

on the top side of both the diaphragm and the seal disk areas. The upstream pressure is applied as the opening force on the

bottom side of the seal disk area.

The net force, resulting from the two opposing dynamic forces acting on the actuator’s diaphragm and seal, determines the

degree to which the valve is open. The valve seeks the point where these forces are equal. As the ratio of the areas of the

seal disk and the diaphragm is constant, the ratio of the upstream and downstream pressures is constant as well.

A rise in downstream pressure causes a momentary increase of the closing force. As a result, the valve throttles closed

reducing downstream pressure according to the constant ratio.

Adding a V-Port Throttling Plug modifies valve ratio by increasing the effective diaphragm area.

When demand is zero, downstream pressure rises in proportion to the ratio, causing the valve to shut off.

Valve Regulates Valve Closed (no system demand)

Reduction Ratios Table

Valve Size 700; 700EN 700ES Notes:

■ Reduction ratio may vary at extreme flow

inch mm Flat-Disc V-Port Flat-Disc V-Port

velocity & upstream pressure.

1.5",2",2.5" 40, 50, 65 3.7 4.0 2.8 3.2

■ Reduction ratios are based on flow

3" 80 2.6 2.9 2.8 3.2

4" 100 2.5 2.8 2.6 2.9 velocity of 2.0-3.0 m/sec ; 6.5-10 ft/sec

5" 125 - - 2.5 2.8 ■ Recommended continuous flow velocity:

6" 150 2.5 2.7 2.5 2.8 0.3-6.0 m/sec ; 1-20 ft/sec

8" 200 2.4 2.6 2.5 2.7 ■ Minimum operating pressure:

10" 250 2.3 2.5 2.4 2.6 0.7 bar ; 10 psi.

12" 300 2.2 2.4 2.3 2.5

14" 350 2.2 2.4 - -

16" 400 2.2 2.3 2.2 2.4

18" 450 2.2 2.3 - -

20" 500 2.2 2.3 2.2 2.3

Pilot System Specifications

Standard Materials:

Tubing & Fittings:

Stainless Steel 316 or Copper & Brass

Accessories:

Stainless Steel 316 or Brass

BERMAD Waterworks

Model 720-PD 700 Series

Typical Applications

There are two major applications for the Model 720-PD Proportional Pressure Reducing Valve:

n Long downhill lines:

o Systems A1 and A2 prevent the downhill line from exceeding its pressure rating.

n High differential pressure systems:

o System B reduces cavitation damage and noise level by distributing the load of the high differential pressure.

o System C illustrates protecting a circulation valve from high differential pressure and resultant severe cavitation.

o System D shows protecting a level control valve from high differential pressure.

Typical Installations

Downhill Serial Pressure Reducing System High Differential Pressure Reducing System

A1 A2 B

Relief Valve

Relief Valve Model 73Q

Model 73Q Relief Valve

Model 73Q

Strainer

Model 70F Proportional

Strainer Pressure Reducing

Model 70F Proportional Pressure Valve Model 720-PD Pressure Reducing

Reducing Valve Valve Model 720

Model 720-PD

High Differential Pressure Circulation System High Differential Pressure Level Control System

C Pump Control D

Valve Model 740

Proportional

Pressure Reducing

Valve Model 720-PD

Pressure Sustaining Valve

Model 730 Proportional Pressure

(used as circulation valve) Reducing Valve Level Control

Model 720-PD Valve Model 750

BERMAD Waterworks

700 Series

Technical Data Differential Pressure Calculation

Size Range: DN40-900 ; 11/2–36” Q

ΔP =( )

2

End Connections (Pressure Ratings):

(Kv;Cv)

Flanged: ISO PN16, PN25 (ANSI Class 150, 300)

Threaded: BSP or NPT ΔP = Differential Pressure for fully open valve (bar; psi)

Others: Available on request Q = Flow rate (m3/h; gpm)

Valve Patterns: “Y” (globe) & angle, globe (DN600-900 ; 24”-36”) Kv = Metric system - valve flow coefficient

Working Temperature: Water up to 80°C ; 180°F (flow in m3/h at 1 bar ΔP with 15°C water)

Standard Materials:

Cv = US system - Valve flow coefficient

Body & Actuator: Ductile Iron

(flow in gpm at 1 psi ΔP with 60°F water)

Internals: Stainless Steel, Bronze & coated Steel

Diaphragm: Synthetic Rubber Nylon fabric-reinforced Cv = 1.155 Kv

Seals: Synthetic Rubber

Coating: Fusion Bonded Epoxy, RAL 5005 (Blue) approved for

drinking water or Electrostatic Polyester Powder

Flow Data & Dimensions Table

DN / Size 40 1.5” 50 2” 65 2.5” 80 3” 100 4” 150 6” 200 8” 250 10” 300 12” 350 14” 400 16” 450 18” 500 20”

Kv / Cv - Flat 54 62 57 66 60 69 65 75 145 167 395 456 610 705 905 1,045 1,520 1,756 - - 2,250 2,599 - - 4,070 4,701

700ES

Flow Data

Kv / Cv - V-Port 46 53 48 56 51 59 55 64 123 142 336 388 519 599 769 888 1,292 1,492 - - 1,913 2,209 - - 3,460 3,996

Kv / Cv - “Y” Flat 42 49 50 58 55 64 115 133 200 230 460 530 815 940 1,250 1,440 1,850 2,140 1,990 2,300 3,310 3,820 3,430 3,960 3,550 4,100

700EN

700 &

Kv / Cv - “Y” V-Port 36 41 43 49 47 54 98 113 170 200 391 450 693 800 1,063 1,230 1,573 1,820 1,692 1,950 2,814 3,250 2,916 3,370 3,018 3,490

L (mm / inch) 230 9.1 230 9.1 290 11.4 310 12.2 350 13.8 480 18.9 600 23.6 730 28.7 850 33.5 - - 1,100 43.3 - - 1,250 49.2

PN16; 25

W (mm / inch) 150 5.9 165 6.5 185 7.3 200 7.9 235 9.3 300 11.8 360 14.2 425 16.7 530 20.9 - - 626 24.6 - - 838 33

700-ES

h (mm / inch) 80 3.1 90 3.5 100 3.9 105 4.1 125 4.9 155 6.1 190 7.5 220 8.7 250 9.8 - - 320 12.6 - - 385 15.2

H (mm / inch) 240 9.4 250 9.8 250 9.8 260 10.2 320 12.6 420 16.5 510 20.1 605 23.8 725 28.5 - - 895 35.2 - - 1,185 46.7

Weight (Kg/lb) 10 22 10.8 23.8 13.2 29 15 33 26 57.2 55 121 95 209 148 326 255 561 - - 437 960 - - 1,061 2,334

L (mm / inch) - - - - - - 310 12.2 350 13.8 480 18.9 600 23.6 730 28.7 850 33.5 - - - - - - - -

PN16; 25

W (mm / inch) - - - - - - 200 7.9 235 9.3 320 12.6 390 15.4 480 18.9 550 21.7 - - - - - - - -

700-EN

h (mm / inch) - - - - - - 100 3.9 118 4.6 150 5.9 180 7.1 213 8.4 243 9.6 - - - - - - - -

H (mm / inch) - - - - - - 305 12 369 14.5 500 19.7 592 23.3 733 28.9 841 33.1 - - - - - - - -

Weight (Kg/lb) - - - - - - 21 46.2 31 68.2 70 154 115 253 198 436 337 741 - - - - - - - -

L (mm / inch) 205 8.1 210 8.3 222 8.7 250 9.8 320 12.6 415 16.3 500 19.7 605 23.8 725 28.5 733 28.9 990 39 1,000 39.4 1,100 43.3

“Y” PN16

Class 150

W (mm / inch) 155 6.1 165 6.5 178 7 200 7.9 223 8.8 320 12.6 390 15.4 480 18.9 550 21.7 550 21.7 740 29.1 740 29.1 740 29.1

h (mm / inch) 78 3.1 83 3.3 95 3.7 100 3.9 115 4.5 143 5.6 172 6.8 204 8 242 9.5 268 10.6 300 11.8 319 12.6 358 14.1

H (mm / inch) 239 9.4 244 9.6 257 10.1 305 12 366 14.4 492 19.4 584 23 724 28.5 840 33.1 866 34.1 1,108 43.6 1,127 44.4 1,167 45.9

700 Flanged

Weight (Kg/lb) 9.1 20 10.6 23 13 29 22 49 37 82 75 165 125 276 217 478 370 816 381 840 846 1,865 945 2,083 962 2,121

L (mm / inch) 205 8.1 210 8.3 222 8.7 264 10.4 335 13.2 433 17 524 20.6 637 25.1 762 30 767 30.2 1,024 40.3 1,030 40.6 1,136 44.7

Class 300

“Y” PN25

W (mm / inch) 155 6.1 165 6.5 185 7.3 207 8.1 250 9.8 320 12.6 390 15.4 480 18.9 550 21.7 570 22.4 740 29.1 740 29.1 750 29.5

h (mm / inch) 78 3.1 83 3.3 95 3.7 105 4.1 127 5 159 6.3 191 7.5 223 8.8 261 10.3 295 11.6 325 12.8 357 14.1 389 15.3

H (mm / inch) 239 9.4 244 9.6 257 10.1 314 12.4 378 14.9 508 20 602 23.7 742 29.2 859 33.8 893 35.2 1,133 44.6 1,165 45.9 1,197 47.1

Weight (Kg/lb) 10 22 12.2 27 15 33 25 55 43 95 85 187 146 322 245 540 410 904 434 957 900 1984 967 2,132 986 2,174

L (mm / inch) 155 6.1 155 6.1 212 8.3 250 9.8

Class 150; 300

“Y” PN16; 25

W (mm / inch) 122 4.8 122 4.8 122 4.8 163 6.4 Specify when ordering:

h (mm / inch) 40 1.6 40 1.6 48 1.9 56 2.2

H (mm / inch) 201 7.9 202 8 209 8.2 264 10.4 n Size

700 Threaded

H

Weight (Kg/lb) 5.5 12 5.5 12 8 18 17 37 n Main model

W

L (mm / inch) - - 121 4.8 140 5.5 159 6.3 h n Additional features

Angle PN16; 25

Class 150; 300

W (mm / inch) - - 122 4.8 122 4.8 163 6.4

L n Pattern

R (mm / inch) - - 40 1.6 48 1.9 55 2.2

h (mm / inch) - - 83 3.3 102 4 115 4.5 n Body material

H (mm / inch) - - 225 8.9 242 9.5 294 11.6 n End connection

Weight (Kg/lb) - - 5.5 12 7 15 15 33 n Coating

n Voltage & main valve position

DN / Size 600 24" 700 28" 750 30" 800 32" 900 36"

n Tubing & Fittings materials

L (mm / inch) 1,450 57.1 1,650 65 1,750 68.9 1,850 72.8 1,850 72.8

Operational data (according to model)

Globe PN16

n

Class 150

W (mm / inch) 1,250 49.2 1,250 49.2 1,250 49.2 1,250 49.2 1,250 49.2 H

h (mm / inch) 470 18.5 490 19.3 520 20.5 553 21.8 600 23.6

n Pressure data

h

H (mm / inch) 1,965 77.4 1,985 78.1 2,015 79.3 2,048 80.6 2,095 82.5 n Flow data

L

Weight (Kg/lb) 3,250 7,150 3,700 8,140 3,900 8,580 4,100 9,020 4,250 9,350 n Reservoir level data

L (mm / inch) 1,500 59.1 1,650 65 1,750 68.9 1,850 72.8 1,850 72.8 n Settings

Globe PN25

Class 300

W (mm / inch) 1,250 49.2 1,250 49.2 1,250 49.2 1,250 49.2 1,250 49.2

h (mm / inch) 470 18.5 490 19.3 520 20.5 553 21.8 600 23.6 W

* Use Bermad’s Waterworks

H (mm / inch) 1,965 77.4 1,985 78.1 2,015 79.3 2,048 80.6 2,095 82.5

Ordering Guide

Weight (Kg/lb) 3,500 7,700 3,700 8,140 3,900 8,580 4,100 9,020 4,250 9.370

info@bermad.com • www.bermad.com

The information herein is subject to change without notice. BERMAD shall not be held liable for

any errors. All rights reserved. © Copyright by BERMAD. PC7WE20-PD 08

You might also like

- Control Valve V91Document18 pagesControl Valve V91vency100% (1)

- Hydromatik Uchida Rexroth A7V PumpDocument6 pagesHydromatik Uchida Rexroth A7V Pumppedro 1100% (1)

- Prince Valves PDFDocument82 pagesPrince Valves PDFMauricio Ariel H. OrellanaNo ratings yet

- HM15013EDocument10 pagesHM15013EYoni EhmNo ratings yet

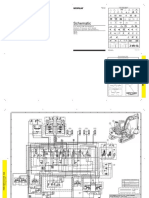

- 312 BL Diagrama HidraulicoDocument2 pages312 BL Diagrama Hidraulicoesmeralda67% (3)

- Flow Control PDFDocument4 pagesFlow Control PDFachmadinNo ratings yet

- WW 723 PDFDocument4 pagesWW 723 PDFAlexander Fuentes100% (1)

- Waterworks: 700 SIGMA SeriesDocument2 pagesWaterworks: 700 SIGMA SeriesRuben SoteloNo ratings yet

- Bermad: Pressure Sustaining and Reducing ValveDocument4 pagesBermad: Pressure Sustaining and Reducing Valveagieyogaswara100% (1)

- WW 720 SIGMA EN ES Product Page 2017Document2 pagesWW 720 SIGMA EN ES Product Page 2017amsyong loeNo ratings yet

- Bermad: Level Control and Pressure Sustaining ValveDocument4 pagesBermad: Level Control and Pressure Sustaining ValveMaryoly BlancoNo ratings yet

- Bermad: Pressure Reducing and Sustaining ValveDocument4 pagesBermad: Pressure Reducing and Sustaining ValvePerlita M. A SebastianNo ratings yet

- Bermad: High Pressure, Pressure Reducing ValveDocument4 pagesBermad: High Pressure, Pressure Reducing ValveviqibagasNo ratings yet

- WW 770-U - FCVDocument4 pagesWW 770-U - FCVMohamed MansoorNo ratings yet

- Bermad: Flow Control ValveDocument4 pagesBermad: Flow Control ValveLLOYD ANDREW CORPUZNo ratings yet

- Sostenedora Presion BERMADDocument6 pagesSostenedora Presion BERMADguzman_10No ratings yet

- Pressure Reducing Valve: Model: 47-02Document2 pagesPressure Reducing Valve: Model: 47-02Phong Duong100% (1)

- Folder - VaLvulaDocument2 pagesFolder - VaLvulaVinger Mann Comercio e Serviços LtdaNo ratings yet

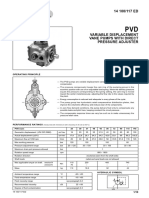

- PVS Series NachiDocument19 pagesPVS Series NachiDian Pramadi100% (1)

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 pagesRate of Flow and Fuel Shut Off Valve: Modelanon_867776278No ratings yet

- WW 430 2013Document4 pagesWW 430 2013ClaudiaHernandezMesaNo ratings yet

- WW Ordering Guide 700 SeriesDocument4 pagesWW Ordering Guide 700 SeriesagieyogaswaraNo ratings yet

- PDF 24Document4 pagesPDF 24hn20002001No ratings yet

- IR-WW 73Q Product-Page EnglishDocument4 pagesIR-WW 73Q Product-Page EnglishTriyono GunturNo ratings yet

- Unloader Valve (Discharging) : Technical ManualDocument4 pagesUnloader Valve (Discharging) : Technical ManualUmar OmarNo ratings yet

- 3-Way Vale 15mm-50mm SizeDocument18 pages3-Way Vale 15mm-50mm Sizesantosh yadavNo ratings yet

- Catalogo Bombas NachiDocument57 pagesCatalogo Bombas NachiCesar Muñoz OssesNo ratings yet

- V DireccionalesDocument70 pagesV DireccionalesFabian CampañaNo ratings yet

- Bomba Paul 50 NGDocument4 pagesBomba Paul 50 NGLucía Salazar de TeránNo ratings yet

- Main Pump PDFDocument36 pagesMain Pump PDFElia MekdadNo ratings yet

- dv700 en 1113Document8 pagesdv700 en 1113ElivarjaoNo ratings yet

- Brodie Valv dsbv89Document4 pagesBrodie Valv dsbv89Helver PachónNo ratings yet

- Hydraulic Swivel Clamps, Double Action: Screw-In Version Operating Pressure Max. 250 BarDocument8 pagesHydraulic Swivel Clamps, Double Action: Screw-In Version Operating Pressure Max. 250 BardmalfazNo ratings yet

- CV300 2Document13 pagesCV300 2Achariya ParpromNo ratings yet

- Releif Valve 3k 6-010-1Document2 pagesReleif Valve 3k 6-010-1francis_15inNo ratings yet

- Pressure-Reducing Valve, Pilot-Controlled Type VDM: Product DocumentationDocument15 pagesPressure-Reducing Valve, Pilot-Controlled Type VDM: Product DocumentationY.EbadiNo ratings yet

- Flow Control ValvesDocument28 pagesFlow Control ValvesPaul WoodwardNo ratings yet

- Gate Valve Die-Forged: Pressure Seal BonnetDocument8 pagesGate Valve Die-Forged: Pressure Seal Bonnetedark2009No ratings yet

- Modelo FP420-00Document4 pagesModelo FP420-00Valdimar CorreiaNo ratings yet

- Bermad: Booster Pump Control and Pressure Sustaining ValveDocument4 pagesBermad: Booster Pump Control and Pressure Sustaining ValveLeo NovoxNo ratings yet

- 4 Water FloodDocument6 pages4 Water FloodEduardoWire100% (1)

- Cartridge Pressure Switch Type ACB and CCB: Data SheetDocument12 pagesCartridge Pressure Switch Type ACB and CCB: Data Sheetlazar.bulovanNo ratings yet

- FDV-R-RN2 Ds 01Document4 pagesFDV-R-RN2 Ds 01Lucas Procópio SouzaNo ratings yet

- Catalogos BombasDocument12 pagesCatalogos BombasJose NavarreteNo ratings yet

- Oil Pump Type Aj Gear Sizes 4-6: ApplicationsDocument2 pagesOil Pump Type Aj Gear Sizes 4-6: Applicationsr_cristiNo ratings yet

- Relief Valve 5k 6-015-1Document2 pagesRelief Valve 5k 6-015-1francis_15inNo ratings yet

- CSA Direct Acting Valves 8.2017Document42 pagesCSA Direct Acting Valves 8.2017dalla nabilNo ratings yet

- Ktm512 en MainDocument12 pagesKtm512 en MainFilip SerafimovNo ratings yet

- Operating Principle: PVD Sizes 25 30 37 48 45 56 72 90 115 145Document10 pagesOperating Principle: PVD Sizes 25 30 37 48 45 56 72 90 115 145ahmedNo ratings yet

- 30 PR (D) PDFDocument1 page30 PR (D) PDFhoussem houssemNo ratings yet

- Submersible Water PumpDocument72 pagesSubmersible Water Pumpjohn dimailigNo ratings yet

- WW 450 65 2023Document4 pagesWW 450 65 2023Marcel TatebeNo ratings yet

- Model 210 Digital Electro-Hydraulic Set StopDocument4 pagesModel 210 Digital Electro-Hydraulic Set StopykozeNo ratings yet

- Control Valve: Sizing GuideDocument13 pagesControl Valve: Sizing GuideJOSE MARTIN MORA RIVEROSNo ratings yet

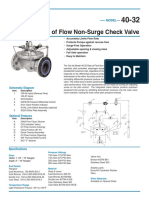

- Rate of Flow Non-Surge Check Valve: ModelDocument2 pagesRate of Flow Non-Surge Check Valve: ModelAndrzej BąkałaNo ratings yet

- Safety Shutdown Valve SSV Control System BrochureDocument12 pagesSafety Shutdown Valve SSV Control System BrochureWellington Barbalho100% (1)

- Air Filter + Regulator + LubricatorDocument12 pagesAir Filter + Regulator + LubricatorSunil ChandrawanshiNo ratings yet

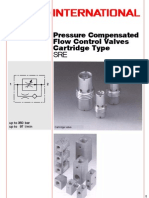

- Flow Control Valves Pressure Compensated Cartridge TypeDocument6 pagesFlow Control Valves Pressure Compensated Cartridge TypevrgohilNo ratings yet

- Bermad: Level Control ValveDocument4 pagesBermad: Level Control ValveSupolNo ratings yet

- Bermad 710 Solenoid Data SheetDocument4 pagesBermad 710 Solenoid Data Sheetdianne fabillonNo ratings yet

- Modern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlFrom EverandModern Borehole Analytics: Annular Flow, Hole Cleaning, and Pressure ControlNo ratings yet

- Waterpipe v1Document25 pagesWaterpipe v1idigitiNo ratings yet

- Component Operation: Section 3Document82 pagesComponent Operation: Section 3Tú Xuân LươngNo ratings yet

- Emergency IsolationDocument2 pagesEmergency Isolationkrbabu1969No ratings yet

- Section 35 - Hydraulic System - Chapter 9Document46 pagesSection 35 - Hydraulic System - Chapter 9Cristian SterieNo ratings yet

- FS 02 (1) ModelDocument1 pageFS 02 (1) ModelEngr.Muhammad ObaidullahNo ratings yet

- (Centrifugal Pump Calculation For DM PW Water To R-401Document20 pages(Centrifugal Pump Calculation For DM PW Water To R-401Ashish PawarNo ratings yet

- Valves Objective QuestionsDocument4 pagesValves Objective QuestionszhangyiliNo ratings yet

- Moteur - MA - USDocument24 pagesMoteur - MA - USGERALD SIMONNo ratings yet

- Pump and Line CalcDocument1 pagePump and Line CalcEsapermana RiyanNo ratings yet

- Triple Duty ValveDocument4 pagesTriple Duty ValveDIL DILDARNo ratings yet

- BE Specs VG1000 M9000 TableDocument3 pagesBE Specs VG1000 M9000 TableKumar sssssNo ratings yet

- 8009 PDFDocument42 pages8009 PDFlungu mihaiNo ratings yet

- Accumulators - Epe: Fluid AccessoriesDocument9 pagesAccumulators - Epe: Fluid AccessoriesTHEMBANo ratings yet

- S770 Hyd Std-Op V-1604Document2 pagesS770 Hyd Std-Op V-1604Teknik MakinaNo ratings yet

- P04T0235 / POM: Avora Black-1Ö089BDocument2 pagesP04T0235 / POM: Avora Black-1Ö089BHeike BaumannNo ratings yet

- Skip Handling: TP501 Festo DidacticDocument7 pagesSkip Handling: TP501 Festo DidacticHossam AbdelhameedNo ratings yet

- UPDA Mech - Pumps - NFPA - General Question-Session 3 PDFDocument60 pagesUPDA Mech - Pumps - NFPA - General Question-Session 3 PDFSuresh SubbarayanNo ratings yet

- Plano Hidraulico 24M UENR2143UENR2143-03 - SISDocument4 pagesPlano Hidraulico 24M UENR2143UENR2143-03 - SISFredy Manrique AstoNo ratings yet

- SPDIDocument501 pagesSPDIEugene Odullada MangaringNo ratings yet

- Series 40 M44 MPV044D and MPT044D Parts ManualDocument144 pagesSeries 40 M44 MPV044D and MPT044D Parts ManualSzilárd SNo ratings yet

- Sprinkler Design Training Manual-Pg6Document20 pagesSprinkler Design Training Manual-Pg6Mark CendanaNo ratings yet

- 3 Pipe Sizing 2013 3Document34 pages3 Pipe Sizing 2013 3siva anand100% (1)

- Deluge Valve 6inDocument8 pagesDeluge Valve 6inJojo Abordo FernandezNo ratings yet

- Homework Prop Drawing 2010-2011Document4 pagesHomework Prop Drawing 2010-2011bongoyozoNo ratings yet

- Allvalves Price List 2017 Knife Gate Valves Rev 1Document10 pagesAllvalves Price List 2017 Knife Gate Valves Rev 1shomadeNo ratings yet

- Pump Selection Condensate Pump: Deaerator Pressure With 10% Allowance Assuming Piping Pressure DropDocument3 pagesPump Selection Condensate Pump: Deaerator Pressure With 10% Allowance Assuming Piping Pressure DropJom BonhayagNo ratings yet

- Excavator: - Flow Rate - Pressure Adjustment (+/-5 Bar)Document7 pagesExcavator: - Flow Rate - Pressure Adjustment (+/-5 Bar)zero cloud100% (1)