Professional Documents

Culture Documents

Hermetically Sealed Transformersdc

Hermetically Sealed Transformersdc

Uploaded by

Andreas OktoraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hermetically Sealed Transformersdc

Hermetically Sealed Transformersdc

Uploaded by

Andreas OktoraCopyright:

Available Formats

OIL-IMMERSED

>>>

TRANSFORMERS

BRIEF INTRODUCTION

Varelen Electric Co., Ltd is technological innovation-based enterprise with a long history, owning a

manufacturing base in Changsha, Hunan province, South China.

We specialize in manufacturing various kinds of transformers and substations for mines/residential/factories/

commercial buildings/tunnels power supply, integrated power-driven device, reactors and so on,

We have close cooperation with customers in Spain, Germany, Italy, South Africa, Latin America etc.

With the own brand “ Varelen ” with and the philosophy “Integrate art into product, apply technology to life”, we

are moving towards to be an excellent enterprise.

Varelen Electric Co., Ltd.

Add:Xiaduopu Industry Park, Jinzhou South Road, Ningxiang, Changsha City, Hunan, China.

Zip Code: 410600

Tel: +86 731 8435 1029

Email:sales@varelen.com

Mobil: +86 13873121822

Fax:+86 731 84371029

Http://www.varelen.com

Skype: varelen.cn

>>> PRODUCT OVERVIEW PRODUCTION PROCESS

General Product Features 2

As an ISO9001:2008 certified company, VARELEN offers a complete range of distribution

transformers designed to grant the reliability, durability, and effciency required in utility, industrial The iron core

and commercial applications. Our oil-immersed transformers are manufactured in accordance with Whatever the raw materials, the design, or the production process of the iron

the most demanding industry and international standards. Transformers can be used for indoor or 1

core, Varelen adopts the latest state of technology for it. The silicon steel

outdoor applications and can be provided with off-load tap changer. sheet used is grain-oriented, cold-rolled and insulated on both sides,

guaranteeing low losses and noise and these values are even improved by

Why VARELEN? laser treatment. Numerically controlled cutting machines provide

●+20 years experience R&D team, derived from a 60 years of history transformer factory in for careful treatment in the cutting process in order

Changsha city of China. to avoid mechanical tension in the core and thus

●Various choices for customers base on full range of transformer types. unwanted properties right from the beginning.

4

●Customized transformers with special functions are available. Standard use of step-lap cutting additionally

●Varelen is one of the members who drew up the Chinese National Standard for Explosion-proof reduces the noise, no-load and load losses.

Mobile Substation for Mining.

Main Specifcations: 3

●Transformer type: Oil-immersed type

The winding

●Phases: Three phases Single Phase

The winding as the centerpiece of the transformer must be especially protected

●Capacity: 5kVA-2500kVA, up to 36kV (customization is available, up to 10MVA)

●Frequency: 50/60Hz – both against high electrical stress due to external over voltages and against

●Coolers: corrugated wall or radiator mechanical overloads by short circuits. Varelen transformers are systematically

●Cooling mode: ONAN / ONAF designed to meet these requirements. The windings are made of copper or

●Oil preservation: Hermetically Sealed / Conservator / Free Breathing aluminum. Low-voltage windings are made of strip or flat wire, and the high

●Tap changer: off-load or on-load voltage windings are manufactured from round or profile wire. (“diamond-dotted

●Available fuids: Mineral oil / Dimethyl Silicone / Vegetable Oil paper”) bonds the winding into a compact block while drying and increases the short-

●Winding materials: Aluminum / Copper circuit capacity additionally.

●Low noise solution

●Effcient transformers with reduced losses 5 6

●Advanced equipments

●Packed with of wooden case

●3D package for drawings The Tank

●Standard: IEC60076 Whether during transport or operation –the tank must be absolutely

tight under mechanical stress. Preconditions to achieve this are

Tests constructional experience, the most modern calculation methods

●Insulation resistance and high-quality welding work. Special attention is paid t o

●Resistance for all windings corrosion protection. Pretreatment of the surface is

●Check voltage ratio and vector group processed by phosphating pickling, contributes to

●No load test at rated frequency and rated voltage corrosion protection, just like multi-coating with

●Impedance test preset drying times for each layer. On request,

●Withstand voltage test hot-dip galvanization provides for even better

●Induced over-voltage withstand test protection.

●Partial discharge measurement

●Oil leakage test

You might also like

- P&ID Fire FightingDocument1 pageP&ID Fire FightingAndreas OktoraNo ratings yet

- Toroidal Transformers For Universal Application: NuvotemDocument16 pagesToroidal Transformers For Universal Application: NuvotemFidel Segundo Fernandez HuertaNo ratings yet

- 09hermetically Sealed OilDocument2 pages09hermetically Sealed OiljuliancansenNo ratings yet

- Magna Plus Generators Brochure PDFDocument6 pagesMagna Plus Generators Brochure PDFPaul Peraza0% (1)

- SVEL - Cast Resin Dry-Type Transformers (Catalogue) - 2017 - 02Document28 pagesSVEL - Cast Resin Dry-Type Transformers (Catalogue) - 2017 - 02Levi Franco CarvalhoNo ratings yet

- Ortea Transformer CatalogDocument20 pagesOrtea Transformer CatalogKeyur PandyaNo ratings yet

- Salient Features of Ahpfc PanelDocument4 pagesSalient Features of Ahpfc PanelYusuffNo ratings yet

- Dry-Type Transformers For Railways Brochure A4 - vFINALDocument18 pagesDry-Type Transformers For Railways Brochure A4 - vFINALYusuke Okudaira100% (1)

- Distribuion TransformerDocument10 pagesDistribuion Transformertalha0703097No ratings yet

- Ve 24 Vacuum Circuit BreakersDocument9 pagesVe 24 Vacuum Circuit Breakersharihoed.s7201801No ratings yet

- Electrical Equipment Joint Stock Company: Powered by QualityDocument16 pagesElectrical Equipment Joint Stock Company: Powered by QualityLUATNo ratings yet

- Transformer Solutions From Schneider ElectricDocument18 pagesTransformer Solutions From Schneider ElectricÖmer AlanNo ratings yet

- HHV12 PrimeDocument9 pagesHHV12 Primesandesh shahaneNo ratings yet

- WL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationDocument42 pagesWL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/Applicationdoso_995125293No ratings yet

- Two-Circuit Limit SwitchDocument43 pagesTwo-Circuit Limit SwitchViet NguyenNo ratings yet

- WL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationDocument9 pagesWL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationHamzaBelhakiNo ratings yet

- 0 - AlkargoPoTrans (Referencia)Document12 pages0 - AlkargoPoTrans (Referencia)glenysyaNo ratings yet

- E2.2 Transformador 500vaDocument8 pagesE2.2 Transformador 500vaAdrian Romero RomeroNo ratings yet

- Cat VM1 (EN) M 1VCP000157-compressed CompressedDocument68 pagesCat VM1 (EN) M 1VCP000157-compressed CompressedJorge GranadosNo ratings yet

- Medium Voltage Vacuum Circuit Breakers With Magnetic Drive 12... 24 KV - 630... 4000 A - 16... 50 KaDocument68 pagesMedium Voltage Vacuum Circuit Breakers With Magnetic Drive 12... 24 KV - 630... 4000 A - 16... 50 KaAhmed ElsawyNo ratings yet

- WL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationDocument43 pagesWL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationKibria SiddiqueNo ratings yet

- WL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationDocument44 pagesWL/WLM: Wide Range of Two-Circuit Switches Select One For The Operating Environment/ApplicationMarco TàiNo ratings yet

- DISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFDocument16 pagesDISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFedmarrobNo ratings yet

- Transformer BrochureDocument20 pagesTransformer BrochureJ Naveen KumarNo ratings yet

- PowerPartners OverheadDocument19 pagesPowerPartners OverheadShung Tak ChanNo ratings yet

- RetrieveDocument2 pagesRetrievePhạm Hồng ViệtNo ratings yet

- Product Catalog - Distribution TransformersDocument12 pagesProduct Catalog - Distribution Transformerspt epjNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Transformer BrochureDocument6 pagesTransformer Brochuresunil patelNo ratings yet

- W Series Data Sheet 125, 250 Watt AC-DC and DC-DC DIN-Rail Mount ConvertersDocument28 pagesW Series Data Sheet 125, 250 Watt AC-DC and DC-DC DIN-Rail Mount ConvertersTommy DwiNo ratings yet

- Series: Technical FeaturesDocument5 pagesSeries: Technical Featuresarturo velazcoNo ratings yet

- Monolite SLADocument5 pagesMonolite SLAPhilip WalkerNo ratings yet

- Catalog Appleton WSR Interlocked Receptacle Cover en Us 178392Document3 pagesCatalog Appleton WSR Interlocked Receptacle Cover en Us 178392Eecol phone ParedesNo ratings yet

- Automotive Catalog 9 - 20Document20 pagesAutomotive Catalog 9 - 20Germain CruzzNo ratings yet

- SS Outdoor Vacuum Circuit BreakerDocument2 pagesSS Outdoor Vacuum Circuit Breakersandesh shahaneNo ratings yet

- MICRO SWITCH™ Basic Switches Line Guide - 004649-8-ENDocument7 pagesMICRO SWITCH™ Basic Switches Line Guide - 004649-8-ENaqilNo ratings yet

- Industrial VisitDocument20 pagesIndustrial VisitKanchan kumarNo ratings yet

- LS Transfomer 225kva-2500kvaDocument20 pagesLS Transfomer 225kva-2500kvasonech khorngNo ratings yet

- WL Ds e 18 1 csm582-2308360Document44 pagesWL Ds e 18 1 csm582-2308360Brion Bara IndonesiaNo ratings yet

- Inductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVDocument6 pagesInductive Voltage Transformers Serie UEV, UEX, UEZ 123 To 765 KVOscar Francisco Astudillo Paillamilla100% (1)

- SEVA PDFDocument31 pagesSEVA PDFMohammed NawazNo ratings yet

- Eaton Ulusoy HMH Switchgear Catalog Ca022025 en UsDocument16 pagesEaton Ulusoy HMH Switchgear Catalog Ca022025 en UsNayely CarrascoNo ratings yet

- Catalogue AMTED399086EN (Web)Document180 pagesCatalogue AMTED399086EN (Web)joseNo ratings yet

- GNB Absolyte OverviewDocument4 pagesGNB Absolyte OverviewHani Samir ShaabanNo ratings yet

- Circuit ProtectionDocument8 pagesCircuit ProtectionAris SalongaNo ratings yet

- Crabtree Wiring AccessoriesDocument408 pagesCrabtree Wiring AccessoriesRonie PaduaNo ratings yet

- Vacuum Circuit Breakers: For Generator Switching ApplicationsDocument12 pagesVacuum Circuit Breakers: For Generator Switching Applicationsabut tirtaNo ratings yet

- Ds Bps K PFC Melcher Series-1665524Document29 pagesDs Bps K PFC Melcher Series-1665524toxicelNo ratings yet

- Actuator Brochure MOTOCONDocument16 pagesActuator Brochure MOTOCONAniket PatilNo ratings yet

- Gas Insulation TransformerDocument16 pagesGas Insulation TransformerEnrique Medina CalvilloNo ratings yet

- Distribution Transformers BrochureDocument12 pagesDistribution Transformers BrochureaboobakerNo ratings yet

- Corona & Plasma: For ExtrusionDocument8 pagesCorona & Plasma: For ExtrusionHuy Tuan QuachNo ratings yet

- Data Sheet Ramsey Pro Line EmeaDocument5 pagesData Sheet Ramsey Pro Line Emeadekyun49No ratings yet

- Powerfullstop Katalog 2017 02Document18 pagesPowerfullstop Katalog 2017 02PredragPeđaMarkovićNo ratings yet

- WL Two-Circuit & WLM Long-Life Two-Circuit Limit SwitchDocument40 pagesWL Two-Circuit & WLM Long-Life Two-Circuit Limit SwitchMuhamad PriyatnaNo ratings yet

- (LV SWGR) Susol - Ul - Catalog - en - 202005 May 21, 2020v1.0Document32 pages(LV SWGR) Susol - Ul - Catalog - en - 202005 May 21, 2020v1.0Truong HungNo ratings yet

- MELODY-Oil Immersed Transf.Document4 pagesMELODY-Oil Immersed Transf.Ahmet TosunNo ratings yet

- Megger Impulse GeneratorsDocument4 pagesMegger Impulse GeneratorsFire NowNo ratings yet

- History and Emerging of The Industry: Industrial Training at Industry PremisesDocument21 pagesHistory and Emerging of The Industry: Industrial Training at Industry PremisesDharam PatelNo ratings yet

- Analog Dialogue Volume 46, Number 1: Analog Dialogue, #5From EverandAnalog Dialogue Volume 46, Number 1: Analog Dialogue, #5Rating: 5 out of 5 stars5/5 (1)

- 1.p-Synchronizing Asbuilt +modifikasi ModelDocument34 pages1.p-Synchronizing Asbuilt +modifikasi ModelAndreas OktoraNo ratings yet

- 7.DB-25 Sheet 2Document1 page7.DB-25 Sheet 2Andreas OktoraNo ratings yet

- Report Foam Analyis PT Surya SegaraDocument1 pageReport Foam Analyis PT Surya SegaraAndreas OktoraNo ratings yet

- UNDERGROUND POWER & TELECOM - AsbuiltDocument1 pageUNDERGROUND POWER & TELECOM - AsbuiltAndreas OktoraNo ratings yet

- Cek List Motor Base Oil PumpDocument1 pageCek List Motor Base Oil PumpAndreas OktoraNo ratings yet

- Solo Run Motor Base OilDocument1 pageSolo Run Motor Base OilAndreas OktoraNo ratings yet

- Base Oil Pump SchematicDocument1 pageBase Oil Pump SchematicAndreas OktoraNo ratings yet

- Pe Ea002i DWG 00 e 004 9Document1 pagePe Ea002i DWG 00 e 004 9Andreas OktoraNo ratings yet

- Summary Power CableDocument1 pageSummary Power CableAndreas OktoraNo ratings yet

- Cable Low Voltage Specification PDFDocument12 pagesCable Low Voltage Specification PDFAndreas OktoraNo ratings yet

- Einstein S Letter To RooseveltDocument2 pagesEinstein S Letter To RooseveltFlávio FilhoNo ratings yet

- Uc Davis Thesis FormatDocument7 pagesUc Davis Thesis Formatmonicaturnercolumbia100% (1)

- Application of Tensors in Special Relativity: 4.1 The Energy - Momentum TensorDocument9 pagesApplication of Tensors in Special Relativity: 4.1 The Energy - Momentum TensorPrince N XabaNo ratings yet

- Procedimiento de Reemplazo de CojinetesDocument32 pagesProcedimiento de Reemplazo de CojinetesJavier Hector CayaNo ratings yet

- Making Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintDocument11 pagesMaking Conductive Ink Using Old Batteries, Pencil Lead, and Activated Charcoal With Glue and PaintGuian EitoNo ratings yet

- C-218052-Dimas Pramuja-Jurnal MRS 2Document27 pagesC-218052-Dimas Pramuja-Jurnal MRS 2Dimas PramujaNo ratings yet

- IDC Unit-5Document13 pagesIDC Unit-5Gaurav SinghNo ratings yet

- Boost Glide and WaveriderDocument24 pagesBoost Glide and Waveriderbring it onNo ratings yet

- Concrete Embedment Strain Gauges: 4200 SeriesDocument2 pagesConcrete Embedment Strain Gauges: 4200 SeriesJosé GomesNo ratings yet

- Lktyr235a01 PH I Adv 1Document28 pagesLktyr235a01 PH I Adv 1Atharva GuptaNo ratings yet

- Optical Signal ProcessingDocument38 pagesOptical Signal Processingsujay pujariNo ratings yet

- Xu 2010Document10 pagesXu 2010VICTOR MANUEL URIBE CORDOVANo ratings yet

- Berekening Van Een CirkelsegmentDocument2 pagesBerekening Van Een Cirkelsegmentuser 54No ratings yet

- 24 Organic Review 2023Document37 pages24 Organic Review 2023Elyssa En YingNo ratings yet

- Aptitude Day5Document45 pagesAptitude Day5Sachindra ManeNo ratings yet

- States of Matter Solved QuestionsDocument18 pagesStates of Matter Solved QuestionsAryan SaxenaNo ratings yet

- Answer Solution NEET-2023 (Code-F2) FinalDocument76 pagesAnswer Solution NEET-2023 (Code-F2) Finaldhanan7aysatNo ratings yet

- Thomas Benette Glass PQDocument36 pagesThomas Benette Glass PQeromax1No ratings yet

- Data SheetDocument4 pagesData SheetRachel FloresNo ratings yet

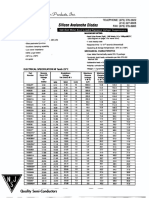

- 1N56 Series: Silicon Avalanche DiodesDocument2 pages1N56 Series: Silicon Avalanche DiodesabolfazlNo ratings yet

- Cis515 13 sl1 C PDFDocument68 pagesCis515 13 sl1 C PDFMathSpaceNo ratings yet

- Electroosmosis Technology For Soil Remediation - Laboratory Result, Field Trial, and Economic ModelingDocument11 pagesElectroosmosis Technology For Soil Remediation - Laboratory Result, Field Trial, and Economic ModelingLydia DarmiyantiNo ratings yet

- Paper 4 NewDocument4 pagesPaper 4 NewDimansa HettiarachchiNo ratings yet

- Aks 4100 - 4100u PDFDocument20 pagesAks 4100 - 4100u PDFmahmoud4871No ratings yet

- 055 - Anti-Lock Brake System - ABS Solenoid Relay CircuitDocument5 pages055 - Anti-Lock Brake System - ABS Solenoid Relay CircuitDesron SamuelNo ratings yet

- Impact of Mass and Deformation On The Gearbox of Large Wind TurbinesDocument134 pagesImpact of Mass and Deformation On The Gearbox of Large Wind TurbinesTarek MagdyNo ratings yet

- XYZ 1010 ManualDocument149 pagesXYZ 1010 ManualmjNo ratings yet

- Comparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CalDocument22 pagesComparison of Polytropic and Isentropic Efficiency of Natural Gas Compressor Calculated Using Aspen HYSYS & Using Manual CaljrfmlNo ratings yet

- Ccna 3Document64 pagesCcna 3lynjazmin abalusNo ratings yet

- EDITED STE Electronics Q1M6 ApoderadoCorazon SMNHSDocument29 pagesEDITED STE Electronics Q1M6 ApoderadoCorazon SMNHSwetlog lolololim100% (1)