Professional Documents

Culture Documents

Pre - Installation Check List of kfm-106mc High Speed

Pre - Installation Check List of kfm-106mc High Speed

Uploaded by

Gopinath Kulkarni0 ratings0% found this document useful (0 votes)

3 views1 pageThis document is a pre-installation checklist for a KFM-106MC high speed machine being installed at AJANTA PRINT ARTS in Navi Mumbai. It lists technical details of the machine like dimensions, weight, power requirements, and consumables needed. It also notes that an operator familiar with lamination processes will be required, and the tentative installation and training schedule is 3 and 4 days respectively. Customer signatures are required to acknowledge the checklist.

Original Description:

KFM106

Original Title

Pre- Installation Check list of kfm-106mc high speed

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document is a pre-installation checklist for a KFM-106MC high speed machine being installed at AJANTA PRINT ARTS in Navi Mumbai. It lists technical details of the machine like dimensions, weight, power requirements, and consumables needed. It also notes that an operator familiar with lamination processes will be required, and the tentative installation and training schedule is 3 and 4 days respectively. Customer signatures are required to acknowledge the checklist.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

3 views1 pagePre - Installation Check List of kfm-106mc High Speed

Pre - Installation Check List of kfm-106mc High Speed

Uploaded by

Gopinath KulkarniThis document is a pre-installation checklist for a KFM-106MC high speed machine being installed at AJANTA PRINT ARTS in Navi Mumbai. It lists technical details of the machine like dimensions, weight, power requirements, and consumables needed. It also notes that an operator familiar with lamination processes will be required, and the tentative installation and training schedule is 3 and 4 days respectively. Customer signatures are required to acknowledge the checklist.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

A-11, Naraina Industrial Area, Phase I,

New Delhi – 110 028, India.

Phone: +91 (0) 11 41043410 / 11

e-mail: sales@amplegraphics.in

CIN: U29199DL2000PTC104497

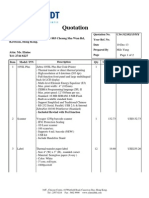

PRE INSTALLATION CHECK LIST

Machine Name KFM-106MC - HIGH SPEED

Customer Name AJANTA PRINT ARTS

Installation Adress B-24, TTC INDUSTRIAL AREA,MIDC,AIROLI, NAVI MUMBAI - 400708

Contact Person for Installation

Name Parag Lagoo Contact number 9960443044

Expected machine arrival date at Customer Premises

Machine Size L 11.2 W 2.1 H 2.9

Machine Weight 10500 KG IN 40 HQ CONATINER CONTAINS S BOXES

Recomonded Floor Area L 13.7 W 4.9 H 3.2

Need Er. Support for Unloading YES/ NO

TOTAL CONNECTED LOAD 78KW

Power Requirment 380 VOLTS/3 PHASE/50 HZ STABLIZED POWER

If Customer put Separate Servo

Stablizer IF DEDICATED THAN IT MUST BE 125KVA WITH OUT PUT OF 380 VOLTS

Air Requirment 6-8 AIR BARPRESSURE DRY AIR-21 CFM

Ducting YES AT 2 POINT, LAMINATION HOST AND HOT KIFE UNIT

Earthing Recomonded Dedicated Earting Maxinum voltage 1.5 VOLT

MCCB 125 Ampere with Mounting Box

Cable 1.95 SQ mm Armoured Cable with Thimble ( as pwr distance from Main Panel to Servo )

2. 35 SQ mm Green Wire Earthing Cable With Thimble

Heat Transfer Oil 50 Ltr Heat Transfer Oil ( Recomonded Shell S2 )

Glue Any Standard Company High Speed Dry Lamination Adhesive

Film As per your Job Metpet / BOPP/ Gloss/Matt

Paper As per your Job Requirment

1 Operator and Assistant ( Operator Must be aware about Lamintaion Process and Auto Feeder

Operator )

Tentative Desired Engineer

Deputation date for Installation

Note:- Customer has to arrange accomodation and food for 2 person during Installation and Training

Tentative Installation need 3 days and Training 4 days.

Signature Engineer Customer Signature

You might also like

- TPB 10en101 PDFDocument5 pagesTPB 10en101 PDFJoseph BoshehNo ratings yet

- 2 SdsillerDocument21 pages2 SdsillerBagas Maulana SNo ratings yet

- 13 Structured Cabling - Scope of WorkDocument3 pages13 Structured Cabling - Scope of Workmichael jamesNo ratings yet

- Method Statement - 115kV 100 MVA Transformer InstallationDocument75 pagesMethod Statement - 115kV 100 MVA Transformer Installationessam khalilNo ratings yet

- AMBPL Busduct SpecsDocument5 pagesAMBPL Busduct SpecsPrasadNo ratings yet

- Tvi Reasource Dev Phils. Inc at 400 Kva - Dca-400spkiiDocument3 pagesTvi Reasource Dev Phils. Inc at 400 Kva - Dca-400spkiiFedilino P. FornollesNo ratings yet

- Nec Tokin Oe128 DatasheetDocument2 pagesNec Tokin Oe128 DatasheetAfwan Al Fauzan Assalafy100% (3)

- StatementDocument83 pagesStatementkinautica kinauticaNo ratings yet

- Cylinder ReportDocument2 pagesCylinder ReportShiju TajNo ratings yet

- RosemountDocument24 pagesRosemountVirgilio VillonNo ratings yet

- SR - DSTE/TPJ, S&T Branch. Southern Railway Trichy Division. Trichy, TamilnaduDocument9 pagesSR - DSTE/TPJ, S&T Branch. Southern Railway Trichy Division. Trichy, TamilnadurajasankarNo ratings yet

- VRV/VRF System Tender DocumentDocument7 pagesVRV/VRF System Tender Documentdheerajdorlikar0% (1)

- Fantech SelectionDocument5 pagesFantech SelectionOanh NguyenNo ratings yet

- Auto Shrink MCDocument4 pagesAuto Shrink MCMadanKarkiNo ratings yet

- ACO Haustechnik: Muli-Max - F Prefabricated Wastewater Pump StationDocument60 pagesACO Haustechnik: Muli-Max - F Prefabricated Wastewater Pump StationPetre DragomirNo ratings yet

- FFU PasportDocument2 pagesFFU Pasportzivkovic brankoNo ratings yet

- FAX2000L: Operator's ManualDocument194 pagesFAX2000L: Operator's Manualhans_johns1No ratings yet

- (C30) Technical Specification - ENDocument14 pages(C30) Technical Specification - ENhicham1963No ratings yet

- Catalogues: Rabigh II Project Interconnecting Package (UO1)Document206 pagesCatalogues: Rabigh II Project Interconnecting Package (UO1)dodonggNo ratings yet

- MQ SP M 4039Document6 pagesMQ SP M 4039jaseel k0% (1)

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiNo ratings yet

- APFC Panel 23.06.23Document11 pagesAPFC Panel 23.06.23rambhool singh ChohanNo ratings yet

- Motherboard 945gz7mcDocument29 pagesMotherboard 945gz7mcBlacky OzzyNo ratings yet

- TFM-138B: VHF/FM Airborne Transceiver (S/N's 1500 Onwards Use F14 Software and Up)Document48 pagesTFM-138B: VHF/FM Airborne Transceiver (S/N's 1500 Onwards Use F14 Software and Up)staedtlerpNo ratings yet

- Quotation - FOILEX REWT-4060-1300 - Mono Layer Blown Film line-TIBAPLAST-Tunisia-TCO20SAM10597 - 0Document23 pagesQuotation - FOILEX REWT-4060-1300 - Mono Layer Blown Film line-TIBAPLAST-Tunisia-TCO20SAM10597 - 0Mohamed ZakiNo ratings yet

- Technical Queries PoweQ-02 IRAN TRANSFODocument3 pagesTechnical Queries PoweQ-02 IRAN TRANSFO54045114No ratings yet

- A307 0515 98 Enq Rev0Document167 pagesA307 0515 98 Enq Rev0Balamurugan ArumugamNo ratings yet

- Wave TrapDocument31 pagesWave TrapVelu Samy100% (1)

- MR 71-2018 Tender Document Master 23 March 2018Document1,001 pagesMR 71-2018 Tender Document Master 23 March 2018Ronish ChandraNo ratings yet

- 1Kw Hybrid Solar System Smart SolarDocument12 pages1Kw Hybrid Solar System Smart SolarST Home Appliance RepairsNo ratings yet

- TDFM 9300Document39 pagesTDFM 9300Jeane MarquesNo ratings yet

- TNB O&m Rev 003Document7 pagesTNB O&m Rev 003Azwan AwalludinNo ratings yet

- Reply of Pre-Bid QueryDocument1 pageReply of Pre-Bid QueryPiyush OjhaNo ratings yet

- DN 60778 PDFDocument4 pagesDN 60778 PDFAeshna VidereNo ratings yet

- NEC TOKIN 0E128 OE128 Proadlizer CapacitorsDocument2 pagesNEC TOKIN 0E128 OE128 Proadlizer CapacitorsJana JrabNo ratings yet

- SFT3508F IPTV Gateway User's ManualDocument19 pagesSFT3508F IPTV Gateway User's Manualgiovani echegarayNo ratings yet

- 9.construction Safety Health ProgramDocument23 pages9.construction Safety Health ProgramJohn Rex ErandioNo ratings yet

- 51 105 PVC Dual Pipe - 20 50Document9 pages51 105 PVC Dual Pipe - 20 50Ankit PrajapatiNo ratings yet

- TK 7102H (Sup)Document25 pagesTK 7102H (Sup)Julio Cesar QuintelaNo ratings yet

- Fan FantechDocument6 pagesFan FantechjatakompNo ratings yet

- ScheduleDocument131 pagesScheduleAnonymous bqTQaq0gDNo ratings yet

- SOP For Microwave Swap v0.7Document83 pagesSOP For Microwave Swap v0.7Ronie MarxistNo ratings yet

- Kenwood TK-980 Service ManualDocument62 pagesKenwood TK-980 Service ManualAyon BaxterNo ratings yet

- Daikin Techno Commercial Offer For Govt Project, New Delhi (R1)Document12 pagesDaikin Techno Commercial Offer For Govt Project, New Delhi (R1)sachin231979No ratings yet

- TK-780 Supplement (Version 2.0)Document69 pagesTK-780 Supplement (Version 2.0)Luis Martinez Ruiz MorelosNo ratings yet

- Quotation: Chinese Mart Limited Unit 803 8 F Elite Industrial CTR 883 Cheung Sha Wan RD, Kowloon, Hong KongDocument2 pagesQuotation: Chinese Mart Limited Unit 803 8 F Elite Industrial CTR 883 Cheung Sha Wan RD, Kowloon, Hong KongKimberly GrantNo ratings yet

- tdfm136b InstallDocument31 pagestdfm136b InstallCristian OsorioNo ratings yet

- 2 PTFE Product SpecificationDocument9 pages2 PTFE Product SpecificationReeshabhdev Gauttam0% (1)

- VFD Adhunik AutomationDocument5 pagesVFD Adhunik Automationabhay80016thNo ratings yet

- Mercury v6 e Specification and Pre-Installation GuideDocument12 pagesMercury v6 e Specification and Pre-Installation Guidelp3993scribdNo ratings yet

- Combo Screen PDFDocument4 pagesCombo Screen PDFAksha NabviNo ratings yet

- 45 CBL 12-05-2020Document16 pages45 CBL 12-05-2020Deelip ZopeNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Radio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual: Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet