Professional Documents

Culture Documents

Seminar

Seminar

Uploaded by

nageshshingane7Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Seminar

Seminar

Uploaded by

nageshshingane7Copyright:

Available Formats

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

GOVERNMENT COLLEGE OF

ENGINEERING YAVATMAL

[DEPARTMENT OF CIVIL ENGINEERING]

(ACEDEMIC YEAR: - 2023-24)

SEMINAR REPORT ON

‘CONCRETE ROAD CONSTRUCTION’

SUBMITED BY

ROLL NO 24- MANJUSHA MALAMKAR

ROLL NO 26- NAGESH SHINGANE

ROLL NO 33- RAKSHA ZADE

UNDER THE GUIDANCE OF

PROF. K. P. NANDURKAR

(CIVIL ENGINEERING DEPARTMENT)

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

GOVERNMENT COLLEGE OF

ENGINEERING, YAVATMAL

[DEPARTMENT OF CIVIL ENGINEERING]

(ACEDEMIC YEAR: - 2023-24)

CERTIFICATE

This is to certify that Mr. NAGESH TOTARAM SHINGANE of final year (VIIth Semester),

Civil Engineering, and PRN NO: 2010121191026 has successfully completed “Seminar” as a

fulfilment for VII Semester in Civil Engineering of Government College of Engineering,

Yavatmal.

Mentor

Mr. K. P. Nandurkar

Ast. Prof. in civil Egg. Department

Dr. M. N. Qureshi Dr. P. M. Khodke

Head of Civil Engg. Department Principal

GCOE, Yavatmal. GCOE, Yavatmal.

PLACE: - YAVATMAL

DATE: - / /2023

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

GOVERNMENT COLLEGE OF

ENGINEERING, YAVATMAL

[DEPARTMENT OF CIVIL ENGINEERING]

(ACEDEMIC YEAR: - 2023-24)

CERTIFICATE

This is to certify that Miss. MANJUSHA VISHWESHAR MALAMKAR of final year (VIIth

Semester), Civil Engineering, and PRN NO: 2010121191024 has successfully completed

“Seminar” as a fulfilment for VII Semester in Civil Engineering of Government College of

Engineering, Yavatmal.

Mentor

Mr. K. P. Nandurkar

Ast. Prof. in civil Egg. Department

Dr. M. N. Qureshi Dr. P. M. Khodke

Head of Civil Engg. Department Principal

GCOE, Yavatmal. GCOE, Yavatmal.

PLACE: - YAVATMAL

DATE: - / /2023

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

GOVERNMENT COLLEGE OF

ENGINEERING, YAVATMAL

[DEPARTMENT OF CIVIL ENGINEERING]

(ACEDEMIC YEAR: - 2023-24)

CERTIFICATE

This is to certify that Miss. RAKSHA SUNIL ZADE of final year (VIIth Semester), Civil

Engineering, and PRN NO: 2010121191033 has successfully completed “Seminar” as a

fulfilment for VII Semester in Civil Engineering of Government College of Engineering,

Yavatmal.

Mentor

Mr. K. P. Nandurkar

Ast. Prof. in civil Egg. Department

Dr. M. N. Qureshi Dr. P. M. Khodke

Head of Civil Engg. Department Principal

GCOE, Yavatmal. GCOE, Yavatmal.

PLACE: - YAVATMAL

DATE: - / /2023

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

ACKNOWLEDGMENT

We avail this opportunity to express our deep sense of gratitude and hole hearted thanks to

our guide Prof. K.P. Nandurkar for the completion of Seminar work and gives valuable guidance,

inspiration and affection. We also acknowledgment over whelming gratitude and immense

respect to our Honourable Dr. P.M. Khodke, principal, Govt. College of Eng. And Dr. M. N.

Qureshi Head, Civil Engineering Department.

We are also thankful to our entire Asst. Prof. of Civil Engineering Department for

providing necessary facilities to bring the work to end.

Last but not least, we would like to thanks to our parents for providing constant support during

this work. We express our thanks to all our friends who help us directly or indirectly for the

success or completion of project.

(Students of Third year civil Engg, Govt. college of Engg. Yavatmal)

Place: Yavatmal

Date: / /2023

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

ABSTRACT

This report focuses on the details of road construction. In this report cement concrete road

construction work are covered. The cement concrete roads are in the form of monolithic slabs of

cement concrete.

The analysis on the component and the functions of these road will be conducted to further

understand the importance of road in construction. The case study was studied at Wardada,

Mehkar, Dist.-Buldhana, 443301.

The main objective of field work is to collect necessary information from work of

execution of road and get knowledge about different roads construction work done in the field.

The report gives a brief information about Quality of material, components of road, equipment

used in it, method of construction, pavements, etc.

The main objective of road construction is to provide dustless and sanitary surface.

Cement concrete roads does not develop corrugations and hence it grants noiseless surface. It can

be designed more accurately for load distribution. Cement concrete roads is practically

unaffected by weather and temperature.

For studying construction of of roads we need to study the equipment used in it, how to

operate it, the processing of construction of roads. And this all information we have to gather

from site engineering. Overall, this report gives information about road construction work.

Through this report we understand the importance of cement concrete road construction.

Cement concrete roads are strong and durable and are unaffected much by weathering agencies.

They give good visibility at night. Cement concrete roads provide dustless and sanitary surface.

Cement concrete roads does not develop corrugations and hence it grants noiseless surface.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

INDEX

COVER PAGE…………...……………………………………..…………………………....…...i

CERTIFICATE …….……………….......………………..……………………..……...…..…...ii

ACKNOWLEDGEMENT ….………………………………………..……...………...…..…...iii

ABSTRACT……………………………………………………………………………….…….iv

CHAPTER 1: INTRODUCTION ….….…………………………..………..………...…...…...1

1.1 Functions …………………………..………….….……..……..…..……….…..……...….......1

1.2 Flexible pavement ………………….….…….…….……..……….....…….…..……...……....1

1.3 Advantages of flexible pavement …………...……………..……………..….……….…...…2

1.4 Rigid pavement ……………………………...…….………….….……….…....……...……...2

1.5 Advantages of rigid pavement ……………….…………………………….…….….………2

CHAPTER 2: DETAILED INFORMATION …….…….…………...……….…………...…....3

2.1 History of road ……………………………………….….….………………. ….…….…...…3

2.2Milestones in the history of flexible pavements ………….…….…...……. …. ….…...…...…3

2.3 Requirements of a pavement …………………………….……...…..…….…....……...…...…3

2.4Types of Pavements ……………...……………….……….…………...……. ….……...….…4

2.5Flexible Pavements ……………………….………………. ….………..…. ….….…...…...…4

2.6Types of Flexible Pavements ………………………………..….………..…...….……...….…5

2.6.1Conventional flexible pavements ………………………….………...………………...….…5

2.6.2Full - depth asphalt pavements …………………………….………. ….…………...………5

2.6.3 Contained rock asphalt mats ……………………………………….......……...................…6

2.7 Typical layers of a flexible pavement……………….……………...…………………………6

2.7.1 Seal Coat ……………………………………………………..……….…..……...............…6

2.7.2 Tack Coat …………………………………………………..……….…..……...………...…6

2.7.3Prime Coat …………………………………………………..……….…..……...………..…6

2.7.4 Surface course………………………………………………..……….…..……...…………6

2.7.5 Binder course ………………………………………………..……….…..……...….........…7

2.7.6 Base course …………………………………………………..……….…..……...…………7

2.7.7Sub- Base course ……………………………………………..……….…..……...……….…7

2.7.8Sub grade.. ………………………………………………….………. ….………..…...…….7

2.8 Failure of flexible pavements ……………………………….………. ….…….....………….7

2.9 Rigid pavements ……………………………….……………………. ….….…........….…….7

2.9.1 Types of rigid pavements ………………………. ….…….………. ….….…...….....……...7

2.9.2 Jointed Plain Concrete Pavement ………………………. ….………. ….….…..........….…9

2.9.3 Jointed Reinforced Concrete Pavement ……………………………. ….….…...….…….…9

2.9.4 Continuous Reinforced Concrete Pavement ………………………. ….…...…...……….…9

CHAPTER 3: METHODOLOGY ……………….……………...……..……….…......……...11

3.1Types of rigid pavement……………………….………...…………………….….…….….…11

3.1.1Jointed plain concrete pavement (JPCP) …………………...……...……….….….....….…11

3.1.1.1 Suitability ………………………………………………….…………….….…...…....…11

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

3.1.2Jointed reinforced concrete pavement (JRCP) ………………….………….….…...………13

3.1.2.1 Suitability…………………………………………………………. …. ….….…...…..…14

3.1.3 Continuously Reinforced Cement Concrete Pavement (CRCP)……….……….......…...…14

3.1.3.1 Suitability ……………………………………………………...……….….….......…..…14

3.1.4pre-stressed concrete pavement (PCP)…………………………….…...........…………..…15

3.1.4.1 Suitability………………………………………….……….………….……….…….…..16

CHAPTER 4: SCOPE OF WORK ……...….…………………………..…….…….….….….17

CHAPTER V: CONCLUSION ………...………………………………………….…….……18

CHAPTER VI: REFRENCES ………...……….………………….……………….….………19

CHAPTER VII: SITE PHOTOS …………….……………………………………..…………20

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

CHAPTER 1

1.INTRODUCTION

Pavement or Road is an open, generally public way for the passage of vehicles, people, and

animals. Pavement is finished with a hard smooth surface. It helped make them durable and

able to withstand traffic and the environment. They have a life span of between 20 – 30 years.

Many people rely on paved roads to move themselves and their products rapidly and reliably.

Road pavements deteriorate over time due to-

The impact of traffic, particularly heavy vehicles.

Environmental factors such as weather, pollution.

1.1 Functions: -

One of the primary functions is load distribution. It can be characterized by the tire loads, tire

configurations, repetition of loads, and distribution of traffic across the pavement, and

vehicle speed.

Pavement material and geometric design can affect quick and efficient drainage. These

eliminating moisture problems such as mud and pounding (puddles).

Drainage system consists of: Surface drainage: Removing all water present on the pavement

surface, sloping, chambers, and kerbs.

Subsurface drainage: Removing water that seep into or is contained in the underlying

subgrade.

1.2 Flexible Pavements: -

Bitumen has been widely used in the construction of flexible pavements for a long time. This

is the most convenient and simple type of construction. The cost of construction of single lane

bituminous pavement varies from 20 to 30 lakhs per km in plain areas. In some applications,

however, the performance of conventional bitumen may not be considered satisfactory

because of the following reasons

In summer season, due to high temperature, bitumen becomes soft resulting in bleeding, rutting

and segregation finally leading to failure of pavement.

In winter season, due to low temperature, the bitumen becomes brittle resulting in cracking,

ravelling and unevenness which makes the pavement unsuitable for use. In rainy season,

water enters the pavement resulting into pot holes and sometimes total removal of bituminous

layer. In hilly areas, due to sub-zero temperature, the freeze thaw and heave cycle takes

place. Due to freezing and melting of ice in bituminous voids, volume expansion and

contraction occur. This leads to pavements failure. The cost of bitumen has been rising

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

continuously. In near future, there will be scarcity of bitumen and it will be impossible to

procure bitumen at very high costs.

1.3 Advantages of Flexible Pavement: -

Cost-effectiveness: Flexible pavement is less expensive to maintain than rigid pavement.

Design versatility: Flexible pavement can be applied during the pre-construction stage.

Ease of maintenance: Flexible pavement is easy to repair and can be opened and patched.

Quick construction: Flexible pavement can be constructed quickly.

Safety: Flexible pavement contributes to enhanced safety.

1.4 Rigid Pavements

Rigid pavements, though costly in initial investment, are cheap in long run because of low

maintenance costs. There are various merits in the use of Rigid pavements (Concrete

pavements) are summarized below:

Bitumen is derived from petroleum crude, which is in short supply globally and the price of

which has been rising steeply. India imports nearly 70% of the petroleum crude. The demand

for bitumen in the coming years is likely to grow steeply, far outstripping the availability.

Hence it will be in India's interest to explore alternative binders. Cement is available in

sufficient quantity in India, and its availability in the future is also assured. Thus, cement

concrete roads should be the obvious choice in future road programmes.

1.5 Advantages of Rigid Pavement: -

Besides the easily available of cement, concrete roads have a long life and are practically

maintenance-free.

Another major advantage of concrete roads is the savings in fuel by commercial vehicles to

an extent of 14-20%. The fuel savings themselves can support a large programme of

concreting.

Cement concrete roads save a substantial quantity of stone aggregates and this factor must be

considered when a choice pavements is made,

Concrete roads can withstand extreme weather conditions – wide ranging temperatures,

heavy rainfall and water logging.

Though cement concrete roads may cost slightly more than a flexible pavement initially, they

are economical when whole-life-costing is considered.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

CHAPTER 2

2.DETAILED INFORMATION

2.1 History of Road: -

The road construction is one of the most ancient human activities. The human society has early

understood the importance of a road network. The Roman Empire based its duration among

others-laws, discipline-on a road network of about 87.000km. The new era of pavement

construction begun in the 18th century by a number of genius engineers like Telford, McAdam.

The invention of vehicle (1885) gave an enormous impulse to the development on the road

engineering. The extend use of materials-bitumen, concrete-and much more the application of

new design methods indispensable to cover the nowadays demands on both speed and weight of

the existing vehicles. Today the pavement techniques must also confront the factor environment

namely emissions, energy consumption, health potential effect. The future challenges are:

research on asphalt rejuvenators, expansion in application of bio asphalt, low energy asphalt

mixes, use of the NANO-techniques.

In India, new flexible pavements during twentieth century were designed by California Bearing

Ratio method, an empirical method, based on subgrade strength measured in terms of CBR value

which was, with the advent of twenty first century, taken over by Mechanistic Empirical

methods.

Flexible pavements are a versatile form of pavement that have been used for several years. They

are considered one of the most important developments in modern road construction history.

Flexible pavements are called “flexible” because the total pavement structure “bends” or

“deflects” due to traffic loads. A flexible pavement structure is generally composed of several

layers of materials which can accommodate this “flexing”.

2.2 Milestones in the history of flexible pavements:

In the twentieth century, new flexible pavements in India were designed by the California

Bearing Ratio method.

In 1798, McAdam moved to Falmouth, Cornwall, where he continued his experiments in

road making under a government appointment.

In 1910, a retired employee of Warren Brothers invented Warrenite-Bitulithic, which

consisted of a thin, approximately 25 mm thick layer of sheet asphalt.

Telford pavements began to show likeness to today's modern HMA pavements.

2.3 Requirements of a pavement

An ideal pavement should meet the following requirements:

Sufficient thickness to distribute the wheel load stresses to a safe value on the sub-grade soil.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

Structurally strong to withstand all types of stresses imposed upon it.

Adequate coefficient of friction to prevent skidding of vehicles,

Smooth surface to provide comfort to road users even at high speed,

Produce least noise from moving vehicles,

Dust proof surface so that traffic safety is not impaired by reducing visibility, •

Impervious surface, so that sub-grade soil is well protected, and

Long design life with low maintenance cost.

2.4 Types of Pavements: -

The pavements can be classified based on the structural performance into two, flexible

pavements and rigid pavements. In flexible pavements, wheel loads are transferred by grain to-

grain contact of the aggregate through the granular structure. The flexible pavement, having less

flexural strength, acts like a flexible sheet (e.g., bituminous road). On the contrary, in rigid

pavements, wheel loads are transferred to sub-grade soil by flexural strength of the pavement and

the pavement acts like a rigid plate (e.g., cement concrete roads). In addition to these, composite

pavements are also available. A thin layer of flexible pavement over rigid pavement is an ideal

pavement with most desirable characteristics. However, such pavements are rarely used in new

construction because of high cost and complex analysis required.

2.5 Flexible Pavements: -

Flexible pavements will transmit wheel load stresses to the lower layers by grain-to-grain

transfer through the points of contact in the granular structure (see Figure 2.5.1)

Figure 2.1: Load transfer in granular structure

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

Figure 2.2 Deflection on flexible pavement

The wheel load acting on the pavement will be distributed to a wider area, and the stress

decreases with the depth. Taking advantage of this stress distribution characteristic, flexible

pavements normally have many layers. Hence, the design of flexible pavement uses the concept

of layered system. Based on this, flexible pavement may be constructed in a number of layers

and the top layer has to be of best quality to sustain maximum compressive stress, in addition to

wear and tear. The lower layers will experience lesser magnitude of stress and low-quality

material can be used. Flexible pavements are constructed using bituminous materials. These can

be either in the form of surface treatments (such as bituminous surface treatments generally

found on low volume roads) or, asphalt concrete surface courses (generally used on high volume

roads such as national highways). Flexible pavement layers reflect the deformation of the lower

layers on to the surface layer (e.g., if there is any undulation in sub-grade then it will be

transferred to the surface layer). In the case of flexible pavement, the design is based on overall

performance of flexible pavement, and the stresses produced should be kept well below the

allowable stresses of each pavement layer.

2.6 Types of Flexible Pavements

The following types of construction have been used in flexible pavement:

Conventional layered flexible pavement,

Full - depth asphalt pavement, and

Contained rock asphalt mat (CRAM).

2.6.1 Conventional flexible pavements are layered systems with high quality expensive

materials are placed in the top where stresses are high-, and low-quality cheap materials are

placed in lower layers.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

2.6.2 Full - depth asphalt pavements are constructed by placing bituminous layers directly on

the soil sub-grade. This is more suitable when there is high traffic and local materials are not

available.

2.6.3 Contained rock asphalt mats are constructed by placing dense/open graded aggregate

layers in between two asphalt layers. Modified dense graded asphalt concrete is placed above the

sub-grade will significantly reduce the vertical compressive strain on soil sub-grade and protect

from surface water.

2.7 Typical layers of a flexible pavement

Typical layers of a conventional flexible pavement include seal coat, surface course, tack coat,

binder course, prime coat, base course, sub-base course, compacted sub-grade, and natural sub-

grade.

2.7.1 Seal Coat: -

Seal coat is a thin surface treatment used to water-proof the surface and to provide skid

resistance.

2.7.2 Tack Coat: -

Tack coat is a very light application of asphalt, usually asphalt emulsion diluted with water. It

provides proper bonding between two layer of binder course and must be thin, uniformly cover

the entire surface, and set very fast.

2.7.3 Prime Coat: -

Prime coat is an application of low viscous cutback bitumen to an absorbent surface like granular

bases on which binder layer is placed. It provides bonding between two layers. Unlike tack coat,

prime coat penetrates into the layer below, plugs the voids, and forms a water tight surface.

Figure 2.3 Typical cross section of a flexible pavement

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

2.7.4 Surface course: -

Surface course is the layer directly in contact with traffic loads and generally contains superior

quality materials. They are usually constructed with dense graded asphalt concrete (AC). The

functions and requirements of this layer are:

It provides characteristics such as friction, smoothness, drainage, etc. Also, it will prevent the

entrance of excessive quantities of surface water into the underlying base, sub-base and sub-

grade,

It must be tough to resist the distortion under traffic and provide a smooth and skid- resistant

riding surface,

It must be water proof to protect the entire base and sub-grade from the weakening effect of

water.

2.7.5 Binder course: -

This layer provides the bulk of the asphalt concrete structure. Its chief purpose is to distribute

load to the base course The binder course generally consists of aggregates having less asphalt

and doesn't require quality as high as the surface course, so replacing a part of the surface course

by the binder course results in more economical design.

2.7.6 Base course: -

The base course is the layer of material immediately beneath the surface of binder course and it

provides additional load distribution and contributes to the sub-surface drainage It may be

composed of crushed stone, crushed slag, and other untreated or stabilized materials.

2.7.7 Sub-Base course: -

The sub-base course is the layer of material beneath the base course and the primary functions

are to provide structural support, improve drainage, and reduce the intrusion of fines from the

sub-grade in the pavement structure If the base course is open graded, then the sub-base course

with more fines can serve as a filler between sub-grade and the base course A sub-base course is

not always needed or used. For example, a pavement constructed over a high quality, stiff sub-

grade may not need the additional features offered by a subbase course. In such situations, sub-

base course may not be provided.

2.7.8 Sub-grade: -

The top soil or sub-grade is a layer of natural soil prepared to receive the stresses from the layers

above. It is essential that at no time soil sub-grade is overstressed. It should be compacted to the

desirable density, near the optimum moisture content.

2.8 Failure of flexible pavements: -

The major flexible pavement failures are fatigue cracking, rutting, and thermal cracking. The

fatigue cracking of flexible pavement is due to horizontal tensile strain at the bottom of the

asphaltic concrete. The failure criterion relates allowable number of load repetitions to tensile

strain and this relation can be determined in the laboratory fatigue test on asphaltic concrete

specimens. Rutting occurs only on flexible pavements as indicated by permanent deformation or

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

rut depth along wheel load path. Two design methods have been used to control rutting: one to

limit the vertical compressive strain on the top of subgrade and other to limit rutting to a

tolerable amount (12 mm normally). Thermal cracking includes both low-temperature cracking

and thermal fatigue cracking.

2.9 Rigid pavements: - Rigid pavements have sufficient flexural strength to transmit the wheel

load stresses to a wider area below. A typical cross section of the rigid pavement is shown in

Figure 3. Compared to flexible pavement, rigid pavements are placed either directly on the

prepared sub-grade or on a single layer of granular or stabilized material. Since there is only one

layer of material between the concrete and the sub-grade, this layer can be called as base or sub-

base course.

Figure 2.4 Typical Cross section of Rigid pavement

In rigid pavement, load is distributed by the slab action, and the pavement behaves like an elastic

plate resting on a viscous medium (Figure 2.9). Rigid pavements are constructed by Portland

cement concrete (PCC) and should be analysed by plate theory instead of layer theory, assuming

an elastic plate resting on viscous foundation. Plate theory is a simplified version of layer theory

that assumes the concrete slab as a medium thick plate which is plane before loading and to

remain plane after loading. Bending of the slab due to wheel load and temperature variation and

the resulting tensile and flexural stress.

2.9.1 Types of Rigid Pavements: -

Rigid pavements can be classified into four types:

Jointed plain concrete pavement (JPCP),

Jointed reinforced concrete pavement (JRCP),

Continuous reinforced concrete pavement (CRCP), and

Pre-stressed concrete pavement (PCP).

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

Figure 2.5 Elastic plate resting on viscous foundation

Figure 2.6 Elastic plate resting on viscous foundation

2.9.2 Jointed Plain Concrete Pavement: -

Are plain cement concrete pavements constructed with closely spaced contraction joints. Dowel

bars or aggregate interlocks are normally used for load transfer across joints. They normally have

a joint spacing of 5 to 10m.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

2.9.3 Jointed Reinforced Concrete Pavement: -

Although reinforcements do not improve the structural capacity significantly, they can

drastically increase the joint spacing to 10 to 30m. Dowel bars are required for load transfer.

Reinforcements help to keep the slab together even after cracks.

2.9.4 Continuous Reinforced Concrete Pavement: -

Complete elimination of joints is achieved by reinforcement.

Failure criteria of rigid pavements: -

Traditionally fatigue cracking has been considered as the major, or only criterion for rigid

pavement design. The allowable number of load repetitions to cause fatigue cracking depends on

the stress ratio between flexural tensile stress and concrete modulus of rupture. Of late, pumping

is identified as an important failure criterion. Pumping is the ejection of soil slurry through the

joints and cracks of cement concrete pavement, caused during the downward movement of slab

under the heavy wheel loads. Other major types of distress in rigid pavements include faulting,

spalling, and deterioration.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

CHAPTER 3

3.METHODOLOGY

Rigid pavements are high stiffness pavement with the main structural layer is plain cement

concrete. Because of high stiffness in contrast to flexible pavement the deformation of the

underlying layer to the concrete layer that may appear in not reflected the pavement surface.

However, after a certain period, a surface crack may appear on the concrete slab.

Basically, a rigid pavement consists of a PCC layer and a subset layer. in some of the cases,

Asphalt layer is used over the continuously reinforced concrete layer. Studies have shown that

with an Asphalt layer no top can provide a long life with other advantages such as noise reducing

properties.

The base difference between unreinforced jointed reinforced and continuously reinforced in first

two joints are constructed also the longitudinal direction or construction joints. whereas

transverse joints are not provided in case of continuously reinforced.

Depending on the reinforcement and non-reinforcement, pavements are divided into four parts

3.1 There are four types of rigid pavements: -

Jointed plain concrete pavement (JPCP)

Jointed reinforced concrete pavement (JRCP)

Continuous reinforced concrete pavement (CRCP)

Pre-stressed concrete pavement (PCP)

3.1.1 Jointed plain concrete pavement (JPCP): -

Jointed plain concrete pavement (JPCP) is a type of pavement that uses contraction joints to

control cracking. JPCP does not use any reinforcing steel. The transverse joint spacing is

selected so that temperature and moisture stresses do not produce intermediate cracking between

joints.

JPCP is made up of concrete slabs with regular transverse and longitudinal joints. The joints

control the location of natural cracks, which occur at the joints and not elsewhere in the slabs.

JPCP doesn't contain any steel reinforcement.

Following are the types of Jointed plain concrete pavement (JPCP)

1. Dowelled type

2. Undowelled type

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

The site where I joined for seminar is construction of Jointed plain concrete pavement (JPCP).

And they used undowelled type construction. So, they did not use dowelled bar for construction

of rigid pavement. The road site is of plotting Because that road has low traffic density so most

suitable pavement was JPCP.

Design parameters: -

The first step in designing a JPCP is to determine the design parameters, such as the traffic

volume, the subgrade strength, the climate conditions, the pavement thickness, and the joint

spacing. These parameters affect the performance and durability of the pavement and should be

based on reliable data and standards. You can use software tools, such as the American

Association of State Highway and Transportation Officials (AASHTO) Mechanistic Empirical

Pavement Design Guide (MEPDG), to help you with the design calculations.

Following Steps Are Involved in Construction of Undowelled JPCP

Step 1 - Preparation of Subgrade: -

Subgrade is that portion of the earth roadbed which after having been constructed to

reasonably close conformance with the lines, grades, and cross-sections indicated on the

plans, receives the base or surface material. In a fill section, the subgrade is the top of the

embankment or the fill.

Step 2 - Preparation of Base Course: -

The base course is the bottom layer of a road. It's made of a mixture of crushed stone and

sand. The base course provides strength, stiffness, and durability to the natural formation. It

also absorbs traffic loads so the subgrade doesn't deform.

Step 3 - Preparation of Plain Cement Concrete Bed: -

The objective of plain cement concrete alias PCC is to arrange a firm impermeable bed to

RCC in the foundation where the soil is soft and flexible. It is mostly applied over brick flat

soling or devoid of brick flat soling. It is also known as Cement Concrete (CC) or Blinding

Concrete. The thickness of PCC bed is six inches (6”). The M15 grade of concrete used for

pcc construction. For compaction needle vibrator is used.

Step 4 - Preparation of Top layer Pavement: -

For construction of top layer of concrete, we use M20 grade of concrete. The bulk volume of

concrete is required for concreting for that reason contractor uses Ready Mix Concrete. The

transit mixer of 7 m^3 sizes are used for transportation of concrete from concrete plant to

site. The of top surface is six inches (6”). So, the total thickness of road is 1 foot. For

compaction surface vibrator is used.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

Long handle float: -This equipment used for compaction and levelling both the purposes.

For surface finishing long handle float is also used at site. The standard size of long handle

float is 7" wide and it comes in different lengths up to 5 feet. It gives a smooth finish for the

concrete. It is attached with a long handle for the finishing works or large concrete surfaces.

It is made from high quality tempered flexible steel; the blade also features round ends

prevent marking and gouging while creating a smooth surface.

Tinning Equipment: - After drying of upper surface of concrete Tinning process is started.

Tinning is process of forming uniform transverse grooves in the plastic concrete. It is done

when another layer of concrete is to applied on the surface, for better jointing. Tinning is

done by both hand tinning tool or mechanical tinning machine. The tinning device uses a

texturizing comb with steel tines spaced as specified. The grooves are placed in the

pavement to provide additional skid resistance and eliminate hydroplaning.

Step - Curing of road surface: -

Curing is the process of maintaining a satisfactory moisture content and a favourable

temperature in con- Crete during the period immediately following placement so that

hydration of the cement may continue until the desired properties are developed to a

sufficient degree to meet the requirements of service. By seven days, your concrete should be

cured to at least 70 percent of its full strength. You will probably be able to drive on it

without damaging it, although you may want to hold off on rolling heavy equipment over it.

In 28 days, you can treat your concrete as fully hardened.

3.1.1.1 Suitability: -

Jointed plain concrete pavement (JPCP) is suitable for low-volume roads that carry light to

moderate traffic loads and have low maintenance requirements. JPCP is suitable for a wide range

of applications such as:

Motorways, Highways, Main and secondary roads, Agricultural roads, Urban roads, Squares,

Passage, Garden Roads etc.

3.1.2 Jointed reinforced concrete pavement (JRCP): -

CRCP uses reinforcement rather than transverse joints for crack control. Longitudinal joints are

still used. Transverse random cracks are expected in the slab, usually at 3 to 7-foot intervals (see

Figure 621.1). The continuous reinforcement in the pavement holds the cracks tightly together.

CRCP can be used for concrete pavement new construction and concrete overlays for TI ≥ 13.0

in all climate regions except High Mountain and High Desert. It can also be used for widening

and replacement of existing lanes where there is adequate space to construct. CRCP may cost

more initially than other types of casts in place pavement due to the added cost of the

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

reinforcement, but can be more cost-effective over the life of the pavement on high volume

routes due to improved long-term performance and reduced maintenance. Because there are no

sawn transverse joints, CRCP should provide better ride quality and less maintenance than

Jointed Plain Concrete Pavement (JPCP)

Jointed plain concrete pavement (JPCP, Figure 3.1.2.1) uses contraction joints to control

cracking and does not use any reinforcing steel. Transverse joint spacing is selected such that

temperature and moisture stresses do not produce intermediate cracking between joints. This

typically results in a spacing no longer than about 6.1 m (20 ft.). Dowel bars are typically used at

transverse joints to assist in load transfer. Tie bars are typically used at longitudinal joints.

Figure 3.1 Contraction Joint

3.1.2.1 Suitability: -

Jointed reinforced concrete pavement (JRCP) is often used in areas with heavy truck traffic or

high wheel loads. The reinforcement helps to control cracking and improve the overall strength

of the pavement.

JRCP is suitable for areas where: -

Heavy truck traffic or high wheel loads are anticipated

Crack free slabs or cracked slabs are designed

Concrete slab stiffness is improved

Transverse joint spacing is longer than that for JPCP

Mid-panel cracks are held together

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

3.1.3 Continuously Reinforced Cement Concrete Pavement (CRCP): -

It is also known as CRCP, it does not have transverse joints, expect the construction joints or

expansion joints. These construction joints provided at specific position such as bridges. In this

concrete pavements, high reinforcement is used minimum usually at 0.6 percentage of the cross

section of the slab. They also contain tie bars across the longitudinal joints.

3.1.3.1 Suitability: -

Continuously Reinforced Concrete Pavement (CRCP) is a permanent road surfacing material. It's

designed for roads with high commercial traffic and where closing the road for maintenance is

difficult.

Figure 3.2 Continuously Reinforced Cement Concrete

Advantages Of Continuously Reinforced Cement Concrete Pavement

High structural strength

Durability

Non-skid surface

Good visibility at night, wet or dry

Improved riding comfort

Reduced maintenance

Long-life performance

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

CRCP uses reinforcing steel to eliminate transverse joints in Favor of tightly maintained cracks.

The reinforcing steel is used in combination with other design properties such as slab thickness

and concrete materials to prevent traffic and environmental distresses.

CRCP is intended for roads with:

Very high volume of commercial traffic

Difficulty closing the road for maintenance

Initial smoothness maintained for decades

Minimal maintenance during that time

3.1.4 pre-stressed concrete pavement (PCP): -

PCP uses panels that are precast off-site instead of cast in-place, which is basically the only

difference between PCP and JPCP. Figure 621.1 does not show PCP because after installing the

panels the section views of PCP are same as JPCP. The precast panels are linked together with

dowel bars and should have tied bars like JPCP, at least in the outer or inner lanes. PCP offers

the following advantages: 620-2 Highway Design Manual December 31, 2020

Improved concrete mixing and curing as they are controlled in a precast yard. • Shorter lane

closure times than using conventional concrete for JPCP, which is beneficial when there are

short construction windows. The primary disadvantage of PCP is the high cost of fabrication,

transportation and installation. PCP also needs a levelling system at the base underneath the

precast panels during construction to even out the loads on the slab and avoid uneven deflections

or stresses that could lead to faulting, slab settlement, and/or premature cracking. Although PCP

is not currently included in the Standard Specs and Plans, it has been used since 2010 in

California and should be considered.

Figure 3.3 Pre-stressed concrete pavement Terminology

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

3.1.4.1 Suitability: -

Prestressed concrete pavements are designed to withstand tensile forces caused by external loads.

They can be designed with fewer joints and less probability of cracking than conventional rigid

pavements. This can lead to extended pavement life and reduced maintenance requirements.

Prestressed concrete pavements are suitable for:

Highways and airfields

Industrial buildings

Medium and long span bridges

Advantages Of Prestressed Concrete: -

Resists higher stresses than normal RCC structures

Free from cracks

Rapid construction with better quality control

Less maintenance required

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

CHAPTER 4

4.MATERIAL, EQUIPMENT & MACHNARIES USED IN ROAD CONSTRUCTION

4.1 MATERIAL USED IN ROAD CONSTRUCTION

A wide variety of materials are used in the construction of roads these are soils (naturally

occurring or processed), aggregates (fine aggregates or coarse aggregates obtained from rocks),

binders like lime, bituminous materials, and cement, and miscellaneous materials used as

admixtures for improved performance of roads under heavy loads and traffic.

Soil constitutes the primary material for the foundation, subgrade, or even the pavement (for

low-cost roads with low traffic in rural areas). When the highway is constructed on an

embankment at the desired level, soil constitutes the primary embankment material; further,

since all structures have to ultimately rest on and transmit loads to 'mother earth', soil and rock

also serve as foundation materials.

Soil is invariably used after some process of stabilisation such as compaction and strengthening

by adding suitable admixtures for improving the performance of the road. Mineral aggregates

obtained from rocks form the major component of the sub-bases

and bases of highway pavements of almost all types. A detailed study of their properties is

therefore essential. Binder materials such as bitumen and cement mixed with appropriate types

and proportions of aggregates are used for the construction of superior types of roads that are

characterised by their durability and load carrying capacity.

4.2 EQUIPMENT & MACHNARIES USED IN ROAD CONSTRUCTION

Road rollers

Paver

Excavators

Mixer

4.2.1Road Rollers:

The principle on which a road roller is working is the application of pressure which is slowly

increased and is then gradually decreased. Road roller machine is used soon after asphalt is laid

down on road. The equipment is rolled to compact the asphalt. This equipment is similar to its

name and work. Mostly, three wheels are there in the machines. The two rear one is built in

regular tyres while the front one is built in hard metal. Some road roller machines are built in two

wheels only both in hard metals. The wheels play a significant role in compacting the asphalt. It

needs water on the wheel when it rolls on the asphalt. The type of roller machines used in road

construction project depends on the specific projects.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

Following are the types of roller:

Rubber-tyred rollers:

The rubber-tyred rollers are found to be very efficient in the compaction of earth subgrades,

granular soils in base course, final operations for bituminous surface dressings, etc. These rollers

provide a slight kneading action with the direct pressure due to rolling.

Pneumatic rollers:

pneumatic roller consists of a flat platform below which number of smooth rubber-tyred wheels

are mounted on two or more axles. The platform is then loaded with sand bags or some other

weight and the roller is moved by trolling

Sheep's foot rollers:

These are also known as tamping rollers. This type of roller consists of hollow steel cylinder or

cylinders, each about 1.20 m long and 1.20 m in diameter with 180 mm to 230 mm projections

extending out from the curved surface of the cylinder.

Smooth wheeled rollers:

A smooth wheeled roller is a multi-purpose road machinery (roller) which is used for various

purposes and for practically all types of roads. These rollers are suitable for compaction of more

ranges of soils, preferably granular soils and pavement different layers materials. These rollers

are particularly helpful in compacting soils and other materials where a crushing action is

advantageous.

4.2.2 Paver:

A paver (road paver finisher, asphalt finisher, road paving machine) is a piece of construction

equipment used to lay asphalt concrete or Portland cement concrete on roads, bridges, parking

lots and other such places. It lays the material flat and provides minor compaction.

4.2.3Excavators:

Excavators are heavy construction equipment consisting of a boom, dipper (or stick), bucket and

cab on a rotating platform known as the "house". [1] The house sits atop an undercarriage with

tracks or wheels. They are a natural progression from the steam shovels and often mistakenly

called power shovels.[citation needed] All movement and functions of a hydraulic excavator are

accomplished through the use of hydraulic fluid, with hydraulic cylinders and hydraulic motors.

[2] Due to the linear actuation of hydraulic cylinders, their mode of operation is fundamentally

different from cable-operated excavators which use winches and steel ropes to

accomplish the movements.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

4.2.4 Mixer:

A concrete mixer (often colloquially called a cement mixer) is a device that homogeneously

combines cement, aggregate such as sand or gravel, and water to form concrete. A typical

concrete mixer uses a revolving drum to mix the components. For smaller volume works,

portable concrete mixers are often used so that the concrete can be made at the construction site,

giving the workers ample time to use the concrete before it hardens. An alternative to a machine

is mixing concrete by hand. This is usually done in a wheelbarrow; however, several companies

have recently begun to sell modified turps for this purpose.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

SCOPE OF WORK

INDIA ‘s Ministry of Road Transport and Highways has decided to move towards making rigid

pavement the default mode of construction on national highways. The decision, taken after

considering factors related to service life, fuel consumption, weather conditions, maintenance

costs and natural resources, primarily aims to promote environment friendly construction

practices in execution of road projects. The pavement is crucial part of any road project and

needs to withstand traffic load without deteriorating or deforming to the extent that it becomes

unusable during the design life period.

The Ministry of Road Transport and Highways (MoRTH) plans to build 60,000 km of roads

in the next five years at a rate of 40 km per day.

The government's target for 2022-23 is to construct 18,000 km of highways at a rate of 50

km per day. This is 33% higher than the previous fiscal year's target.

The government has announced 23 expressways with target completion dates between March

2023 and March 2025.

In the first half of FY21, highway construction project awards increased by 140%-year over-

year.

Asphalt and concrete are the two materials most often used in road construction. The type of

material used is decided based on factors like cost and traffic volume.

Road construction can have negative effects on the environment, including:

Silt clogging streams and affecting fish habitats

Increased emissions of greenhouse gases and air pollutants

200,000 km. of national highways are expected to be completed by 2023. Target of FY-19 is to

award 15,000 km. of projects and construct 10,000 of national highways.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

CONCLUSION

We have experienced all the concerned activities of construction of rigid pavement and face all

the consequences at the site with following things. Became familiar with the organization's

hierarchy. Visited the site's industrial surroundings and workplace culture. Understood site

protocol. Comprehended the methods and procedures employed in road construction. Our issue

became clear after we arrived. Verified the obligations of each worker at the site about their

responsibilities. Handling and storage of materials understood. We had a very good experience

and exposure at the site through theoretical and practical study that we did and practical

experiences that we have taken are to make a lot of difference when we go for the work in

construction industry. We suggest that every student in Civil Engineering should do the Seminar.

Thus, we confidently conclude that the period of Seminar will be beneficial and helpful to us in

our near future. under the Seminar work of civil engineering department of Government College

of Engineering, Yavatmal. We will be exposed to the site environment of industrial work

culture.by completing this seminar we will be able to update the knowledge and status of

industry conversant with the new Civil Engineering Techniques.

SEMINAR REPORT ON CONCRETE ROAD

GOVERNMENT COLLEGE OF ENGINEERING, YAVATMAL.

REFERENCES

1. Er. D Kumar Chowdary and Dr.Y. P Joshi (2014)."A Detailed Study of CBR Method for

Flexible Pavement Design" Int. Journal of Engineering Research and Application, Vol.

4:2248-962.

2. "Khanna S.K & Justo C.E (March 2001)", Highway Engineering, Nem Chand & Bros

Publications, Roorkee (U.A), Eighth Edition

3. IRC:37-2012, "Guidelines for the Design of Flexible Pavements" IRC, New Delhi,

4. ROESLER, J., du Plessis, L., Hung, D., Bush, D., and Harvey, J. 1999, CAL/APT Goal

LLPRS Rigid Phase III: Concrete Test Section 516CT Report. Davis and

Berkeley, CA: University of California Pavement Research Centre. (Research Report

UCPRC-RR- 1999-03)

5. DU PLESSIS, L., Bush, D., Jooste, F., Hung, D. Scheffy, C., Roesler, J. Popescu, L., and

Harvey, J. 2002. HVS Test Results on Fast-Setting Hydraulic Cement Concrete.

Palmdale, California Test Sections. South Tangent. Davis and Berkeley, CA:

University of California Pavement Research Center. (Research Report UCPRC-RR2002-

03)

6. DU PLESSIS, L., Bush, D., Jooste, F., Hung, D., Scheffy, C., Roesler, J. Popescu, L., and

Harvey, J. 2002. HVS Test Results on Fast-Setting Hydraulic Cement

Concrete, Palmdale, California Test Sections, South Tangent. Davis and Berkeley,

CA: University of California Pavement Research Center. (Research Report UCPRC-

RR-2002-03)

SEMINAR REPORT ON CONCRETE ROAD

You might also like

- Advanced Construction Technique 7Document51 pagesAdvanced Construction Technique 7Ujwal Jaiswal67% (3)

- A Project Report On Flexible PavementDocument51 pagesA Project Report On Flexible PavementRais Shaikh69% (13)

- Welding Machine - Project ReportDocument71 pagesWelding Machine - Project ReportTanvi Khurana65% (20)

- Swing Motion Power Geneartion ReportDocument26 pagesSwing Motion Power Geneartion ReportTanvi KhuranaNo ratings yet

- WELL FOUNDATION Project ReportDocument53 pagesWELL FOUNDATION Project ReportRamojiNaik100% (3)

- Electromagnetic Braking System - Project ReportDocument28 pagesElectromagnetic Braking System - Project ReportTanvi Khurana83% (6)

- Method Statement For Cold In-Place Recycling - CementDocument6 pagesMethod Statement For Cold In-Place Recycling - CementNordin Yunus100% (2)

- BSR - NH - Circle - Jaipur - 2019 Final PDFDocument109 pagesBSR - NH - Circle - Jaipur - 2019 Final PDFRohit Bali100% (1)

- Project Front PagesDocument8 pagesProject Front PagesJyothi KsNo ratings yet

- Seminar Report On Reactive Powder Concrete Civil EngineeringDocument21 pagesSeminar Report On Reactive Powder Concrete Civil EngineeringKrishnanand Patat100% (1)

- "Solar Based Air Compressor": Government Polytechnic, JalnaDocument30 pages"Solar Based Air Compressor": Government Polytechnic, JalnaManesh NandanwarNo ratings yet

- Cover Page & CertificateDocument2 pagesCover Page & CertificateSHRAVAN JEEVAL B ANo ratings yet

- Desing & Fabrication of Two Speed Variable Transmission GearboxDocument4 pagesDesing & Fabrication of Two Speed Variable Transmission GearboxVeeru PatelNo ratings yet

- RakeshDocument43 pagesRakeshSampath KalyanNo ratings yet

- Blackbook DraftDocument34 pagesBlackbook DraftHiphop OpNo ratings yet

- Tribhuvan University Institute of Engineering Purwanchal Campus, Dharan-8Document45 pagesTribhuvan University Institute of Engineering Purwanchal Campus, Dharan-8Prabin DevkotaNo ratings yet

- Fabrication and Performance Evalution of Vertical Axis Wind Turbine"Document4 pagesFabrication and Performance Evalution of Vertical Axis Wind Turbine"Kalyan Reddy AnuguNo ratings yet

- I - 6 Batch 2022 Project ReportDocument72 pagesI - 6 Batch 2022 Project Reportvilla srisuryaNo ratings yet

- Final Doc JagadeeshDocument21 pagesFinal Doc JagadeeshS SREENATHNo ratings yet

- Gautam Kumar 1Document46 pagesGautam Kumar 1Prints BindingsNo ratings yet

- Justin PDFDocument5 pagesJustin PDFVortex BoltheNo ratings yet

- Intersection Desing of MS PalyaDocument6 pagesIntersection Desing of MS PalyaKrishnaSahNo ratings yet

- Mechanical Concrete RoadsDocument50 pagesMechanical Concrete RoadsPatha Sagarika100% (1)

- Report On Industrial TrainingDocument40 pagesReport On Industrial Trainingveeresh0% (1)

- Construction of Retaining Wall and Flexible PavementDocument46 pagesConstruction of Retaining Wall and Flexible Pavementatharvpathade25No ratings yet

- Vivek Raj ProjectDocument41 pagesVivek Raj ProjectAxiom XulaNo ratings yet

- FormatDocument11 pagesFormatDinesh Reddy AllalaNo ratings yet

- Umesh Chandra Industrial Training ReportDocument36 pagesUmesh Chandra Industrial Training ReportRohit KondaNo ratings yet

- Projet 212Document5 pagesProjet 212Beeresh DNo ratings yet

- Pedal Oprated Electric MotorDocument47 pagesPedal Oprated Electric MotorSatish RaneNo ratings yet

- Industry ReportDocument132 pagesIndustry Reportvgsuryawanshib20No ratings yet

- Welding Machine - Project ReportDocument62 pagesWelding Machine - Project ReportTanvi KhuranaNo ratings yet

- Project Report of StantDocument34 pagesProject Report of StantKuttusan RockksssNo ratings yet

- Solar Sand RemoverDocument45 pagesSolar Sand RemoverSatish RaneNo ratings yet

- Seminar ReportDocument23 pagesSeminar ReportPramod Kumar HTNo ratings yet

- A Project Report On Design of EarthquakeDocument53 pagesA Project Report On Design of EarthquakeSidd PriyamNo ratings yet

- RRW Rajesh Kumar Yadaw (IWP)Document42 pagesRRW Rajesh Kumar Yadaw (IWP)Noor Hasan AnsariNo ratings yet

- Transportation Manual UpdatedDocument114 pagesTransportation Manual UpdatedAbdulrasheedNo ratings yet

- Electomagnatic Ramming MachineDocument7 pagesElectomagnatic Ramming MachineOfficialRF WRNo ratings yet

- Project Report Format-Part1Document2 pagesProject Report Format-Part1black heartNo ratings yet

- Final UpdateDocument91 pagesFinal UpdatetahameNo ratings yet

- Solarstill Report FypDocument53 pagesSolarstill Report Fypbenzmr869No ratings yet

- SARJIL Mini CRTFDocument6 pagesSARJIL Mini CRTFAbhi •••No ratings yet

- Chaitanya Final (JAGA)Document88 pagesChaitanya Final (JAGA)Jagadish KumarNo ratings yet

- Design and Fabrication of Solar Agricultural Weeder: A Mini Project ReportDocument4 pagesDesign and Fabrication of Solar Agricultural Weeder: A Mini Project ReportVignesh PTNo ratings yet

- Electromagnetic Braking System Project Report PDFDocument28 pagesElectromagnetic Braking System Project Report PDFMohd Salman100% (2)

- Visvesvaraya Technological University: Jnana Sangama, Belagavi-590018Document3 pagesVisvesvaraya Technological University: Jnana Sangama, Belagavi-590018anon_274751928No ratings yet

- "Stability Analysis of Infinite Slope": Seminar For Viii Sem B.E. (2016-17)Document2 pages"Stability Analysis of Infinite Slope": Seminar For Viii Sem B.E. (2016-17)raj naikNo ratings yet

- Effect of Graphite and Copper Tools On MRR and Surface Roughness by Using Mineral Oil While Machining Inconel600 On EdmDocument81 pagesEffect of Graphite and Copper Tools On MRR and Surface Roughness by Using Mineral Oil While Machining Inconel600 On Edmrupa225chandu_327248No ratings yet

- InternshipDocument30 pagesInternshipWankhede SwapnilNo ratings yet

- Visvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineDocument36 pagesVisvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineVinay KumarNo ratings yet

- Front PageDocument11 pagesFront PageSHAKHT FAUJI FAUJINo ratings yet

- Project Front PageDocument3 pagesProject Front Pagecivil examNo ratings yet

- Intenship ReportDocument17 pagesIntenship ReportYdv DeepNo ratings yet

- Visvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineDocument28 pagesVisvesvaraya Technological Univeversity: Design and Fabrication of Semi Automatic Pneumatic Sheet Metal Cutting MachineVinay KumarNo ratings yet

- Project Book Final PDFDocument76 pagesProject Book Final PDFlokeshsanyNo ratings yet

- CSP IMP HalfDocument57 pagesCSP IMP HalfakhilNo ratings yet

- Dayananda Sagar University School of EngineeringDocument9 pagesDayananda Sagar University School of EngineeringMohd AbbasNo ratings yet

- Experimental Investigation of Process Parameters in Electric Discharge Machining For M2 Die SteelDocument2 pagesExperimental Investigation of Process Parameters in Electric Discharge Machining For M2 Die Steelpradeep rocksNo ratings yet

- Shafeeq 123Document136 pagesShafeeq 123Maaz Uddin SiddiquiNo ratings yet

- Lva1 App6891 PDFDocument94 pagesLva1 App6891 PDFPramod DhaigudeNo ratings yet

- 3.1) Soil Compaction - Methods, Tests and EffectDocument18 pages3.1) Soil Compaction - Methods, Tests and EffectJoseph AsfourNo ratings yet

- Vol 2 FinalDocument434 pagesVol 2 FinalSunil ShindekarNo ratings yet

- 4.2 Soil Compaction 2Document40 pages4.2 Soil Compaction 2Musfiqur RahmanNo ratings yet

- MS For Milling and Laying of Asphalt Wearing Course (60 70)Document19 pagesMS For Milling and Laying of Asphalt Wearing Course (60 70)RaheelHashmiNo ratings yet

- 4.1 Earth Works: Bill of Quantities For Roads and PavementsDocument17 pages4.1 Earth Works: Bill of Quantities For Roads and Pavementspratip_b100% (1)

- Block 06 Bhatwari - ResourceRate - MachineDocument3 pagesBlock 06 Bhatwari - ResourceRate - MachineManojNo ratings yet

- Arx Malbikunarvaltarar Fra AmmannDocument24 pagesArx Malbikunarvaltarar Fra AmmannhathamphanNo ratings yet

- The Aggregates 1002Document13 pagesThe Aggregates 1002Jessabelle RamosNo ratings yet

- Mini Project Ece405Document39 pagesMini Project Ece405Ibiamegh AmosNo ratings yet

- Facts World Wide - Roller - Paver - PlanerDocument176 pagesFacts World Wide - Roller - Paver - PlanerAlexander Lopez100% (1)

- Embankment & Pavement LayersDocument144 pagesEmbankment & Pavement LayersNishant KumarNo ratings yet

- Hauling and Compacting Equipment: Adigrat University Collage of Engineering and TechnologyDocument46 pagesHauling and Compacting Equipment: Adigrat University Collage of Engineering and TechnologyhayelomNo ratings yet

- Percentage Boq: Validate Print HelpDocument13 pagesPercentage Boq: Validate Print HelpPratik GuptaNo ratings yet

- Dynapac Soil CompactorsDocument8 pagesDynapac Soil Compactorsjorgemorales416100% (1)

- 2014 Acel Rates: (Minimum Operation 8 Hrs. Per Day)Document4 pages2014 Acel Rates: (Minimum Operation 8 Hrs. Per Day)Shielagil CailoNo ratings yet

- Types of RollersDocument8 pagesTypes of RollersManoj CmNo ratings yet

- Roadworks & Utilities Infra Technical SPECSDocument686 pagesRoadworks & Utilities Infra Technical SPECSAshimolowo BabatundeNo ratings yet

- Cherlopalli Vakulamatha Temple RoadDocument39 pagesCherlopalli Vakulamatha Temple Roadharsha vickyNo ratings yet

- SV212 & SV216 Vibratory RollersDocument4 pagesSV212 & SV216 Vibratory Rollershaiccdk6No ratings yet

- Mine Haul Road Design, Construction and Maintenance Management PDFDocument136 pagesMine Haul Road Design, Construction and Maintenance Management PDFmuhammadfarid100% (1)

- MPWT - Defect WorkDocument118 pagesMPWT - Defect WorkVorn Ra VuthNo ratings yet

- CMPMDocument26 pagesCMPMJoshua LagmanNo ratings yet

- Uniform Standard Specifications For Public Works ConstructionDocument15 pagesUniform Standard Specifications For Public Works ConstructionMEHDI FARROKHINo ratings yet

- Volvo ReportDocument18 pagesVolvo Reportgaganpreet singhNo ratings yet

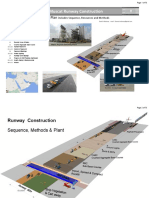

- Muscat Runway Construction: Project Execution PlanDocument73 pagesMuscat Runway Construction: Project Execution PlanRoberto Bujía TorreNo ratings yet

- Modern ConstructionDocument109 pagesModern ConstructionWinfiner WebsiteNo ratings yet

- Various Types of Compaction EquipmentDocument14 pagesVarious Types of Compaction EquipmentJohn Mareos QuidezNo ratings yet