Professional Documents

Culture Documents

ID0002 Rev F

ID0002 Rev F

Uploaded by

James ĐỗCopyright:

Available Formats

You might also like

- PPE MatrixDocument1 pagePPE Matrixajayjanardhankasle75% (4)

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionRating: 5 out of 5 stars5/5 (2)

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 pageDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- 40981Document23 pages40981Verdes CouchNo ratings yet

- Used Car Inspection Checklist: BrakesDocument2 pagesUsed Car Inspection Checklist: BrakesFreetxt ApiNo ratings yet

- PQR Wps WPQ FormatDocument12 pagesPQR Wps WPQ FormatessnelsonNo ratings yet

- Math Quest Further Maths VCE 12 (2016 Edition)Document786 pagesMath Quest Further Maths VCE 12 (2016 Edition)NhiNo ratings yet

- Hammer Service Log MC60Document2 pagesHammer Service Log MC60RezaNo ratings yet

- GoAudits - Chiller Commissioning Checks (Sample)Document1 pageGoAudits - Chiller Commissioning Checks (Sample)bala pandiyanNo ratings yet

- Checklist RIGDocument3 pagesChecklist RIGMiguel CastilloNo ratings yet

- Hammer Service Log MP80Document2 pagesHammer Service Log MP80RezaNo ratings yet

- Inspection and Test Plan - Sprinkler System - Rev 01Document7 pagesInspection and Test Plan - Sprinkler System - Rev 01Anonymous ixIhrPM2No ratings yet

- Bridge Steering SystemDocument1 pageBridge Steering SystemVeri YuliantoNo ratings yet

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- GEC WW HSE TPL 08E Rev00 - Crane Inspection - XLSX TemplateDocument1 pageGEC WW HSE TPL 08E Rev00 - Crane Inspection - XLSX TemplateArturo Alejandro Maldonado VelásquezNo ratings yet

- Crawler CraneDocument2 pagesCrawler CraneFarukBasyoriNo ratings yet

- RubbingDocument1 pageRubbingBadre SEBBAHINo ratings yet

- Ultrasound Repair and TroubleshootingDocument4 pagesUltrasound Repair and TroubleshootingOliver GonzalezNo ratings yet

- Specifications: 2010 Steering Steering Wheel and Column - Equinox & TerrainDocument117 pagesSpecifications: 2010 Steering Steering Wheel and Column - Equinox & Terrainvictorinox dlcbNo ratings yet

- Storage Tank Maintenance 1677413042Document107 pagesStorage Tank Maintenance 1677413042RICK SENSONo ratings yet

- 2 Tower Crane Checklist PDFDocument3 pages2 Tower Crane Checklist PDFAzaim AnaqiNo ratings yet

- S.No Model JC No Advisor Tech. Job Type KMS: 1 XL100 3999 Ratnakar Ravi Paid /serviceDocument4 pagesS.No Model JC No Advisor Tech. Job Type KMS: 1 XL100 3999 Ratnakar Ravi Paid /serviceMani kumar MaddelaNo ratings yet

- Specifications: 2010 Steering Steering Wheel and Column - Equinox & TerrainDocument117 pagesSpecifications: 2010 Steering Steering Wheel and Column - Equinox & Terrainvictorinox dlcbNo ratings yet

- Fan Installation-1Document3 pagesFan Installation-1Abderrahim AbarayNo ratings yet

- Alongside: Yes Yes Yes YesDocument3 pagesAlongside: Yes Yes Yes Yesshaiful rizanNo ratings yet

- Hose Reel Inspection ChecklistDocument2 pagesHose Reel Inspection ChecklistMi doremiNo ratings yet

- Folk LiftDocument1 pageFolk LiftAlamindris DrisNo ratings yet

- Scope of MatrixDocument2 pagesScope of Matrixanup singhNo ratings yet

- 3 Mobile Crane ChecklistDocument5 pages3 Mobile Crane ChecklistEriq100% (1)

- 8 Vehicle Pre-Operational Checklist PDFDocument2 pages8 Vehicle Pre-Operational Checklist PDFjusticeNo ratings yet

- Commissioning Report of Lakshmi Winder - 72 at M/S. Jay Textiles, Unit - 1, PollachiDocument4 pagesCommissioning Report of Lakshmi Winder - 72 at M/S. Jay Textiles, Unit - 1, PollachiSwathi PriyaNo ratings yet

- 19.DG Inspection ChecklistDocument1 page19.DG Inspection ChecklistP.M.K anthNo ratings yet

- Mechanic TrainingDocument3 pagesMechanic TrainingSiril MonNo ratings yet

- Mandatory Requirements For Monthly Inspection of TanksDocument1 pageMandatory Requirements For Monthly Inspection of TanksJiss MathewNo ratings yet

- Crane Lift Site ChecklistDocument1 pageCrane Lift Site Checklistum erNo ratings yet

- Mold Inspection SpecificationDocument6 pagesMold Inspection SpecificationNaukowyDrpNo ratings yet

- Hydro Technical Structure For Phase 2 of KKNPP: Checklist For Tetrapod CastingDocument2 pagesHydro Technical Structure For Phase 2 of KKNPP: Checklist For Tetrapod CastingMAHA LINGAMNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- 10MLD GandhinagarDocument3 pages10MLD GandhinagarBUKA RAMAKANTHNo ratings yet

- QAF5175 Rev 0 Crane - Inspection - ChecklistDocument2 pagesQAF5175 Rev 0 Crane - Inspection - ChecklistMohamed El-SawahNo ratings yet

- 100 2BW Cut4 LHP 01e P4Document1 page100 2BW Cut4 LHP 01e P4Manyathela HopaneNo ratings yet

- TM Fi Audit SheetDocument4 pagesTM Fi Audit SheetMani kumar MaddelaNo ratings yet

- Derr 2023 009988Document2 pagesDerr 2023 009988Ngwa ElvisNo ratings yet

- Tabla de ComparacionDocument1 pageTabla de ComparacionRoger Andres OrdoñezNo ratings yet

- BearingsDocument10 pagesBearingsafif atmaja100% (1)

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistDocument1 pageHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioNo ratings yet

- Diagnosis 4Document47 pagesDiagnosis 4Miguel Ángel RodríguezNo ratings yet

- Formwork Check ListDocument1 pageFormwork Check ListnadunNo ratings yet

- 2021 - Chennai MMDDocument11 pages2021 - Chennai MMDsenthilkumar rNo ratings yet

- Elevator Five Year Safety Test Report: WWW - Lni.Wa - Gov/Tradeslicensing/ElevatorsDocument2 pagesElevator Five Year Safety Test Report: WWW - Lni.Wa - Gov/Tradeslicensing/ElevatorsjhoniNo ratings yet

- Part C TugsDocument3 pagesPart C TugstuyenbsrNo ratings yet

- 2.how To Fix VS1295 LED - MBDocument41 pages2.how To Fix VS1295 LED - MBRichard emerson Lazcano barajasNo ratings yet

- Job Completion Report Presentation - Hydrostatic Rig-123Document16 pagesJob Completion Report Presentation - Hydrostatic Rig-123mnscsc713321No ratings yet

- Gear Types Supported by GEARPAK: 1 Involute GearsDocument2 pagesGear Types Supported by GEARPAK: 1 Involute Gearscmm5477No ratings yet

- Job Completion Report Presentation of R-169Document16 pagesJob Completion Report Presentation of R-169mnscsc713321No ratings yet

- Solución Problema For Neola PDFDocument9 pagesSolución Problema For Neola PDFLuis RojasNo ratings yet

- GM552-55219-104-PL-RP-0015 - Lowering in ReportDocument1 pageGM552-55219-104-PL-RP-0015 - Lowering in ReportBestun AhmedNo ratings yet

- Truck Inspection ChecklistDocument3 pagesTruck Inspection ChecklistSouma MazumdarNo ratings yet

- T.Hayi: PT-TBDocument2 pagesT.Hayi: PT-TBMohamed SelimNo ratings yet

- Qtrinh Shimadzu Mux10Document3 pagesQtrinh Shimadzu Mux10Kuni KazeNo ratings yet

- Antena WindomDocument17 pagesAntena WindomJack RodriguezNo ratings yet

- Different Types of Computer - Based On Size, Purpose and Working PrincipalDocument4 pagesDifferent Types of Computer - Based On Size, Purpose and Working PrincipalVelmurugan JeyavelNo ratings yet

- Cummins Engine Overhaul 6 BTDocument117 pagesCummins Engine Overhaul 6 BTEmmanuel R. Siwila100% (2)

- Wave Optics MCQDocument8 pagesWave Optics MCQGuru ki physicsNo ratings yet

- Process Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFDocument13 pagesProcess Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFAldo PabloNo ratings yet

- Electrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument1 pageElectrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsAdamNo ratings yet

- (2091) Lecture Notes Electrochemistry E.pdf - TMPDocument43 pages(2091) Lecture Notes Electrochemistry E.pdf - TMPRamJiPandeyNo ratings yet

- Gful/Stfaf/) /SF/ / HGTF Udel/ X'G) K5 (: Khwopa College of EngineeringDocument11 pagesGful/Stfaf/) /SF/ / HGTF Udel/ X'G) K5 (: Khwopa College of EngineeringBibek ThapaNo ratings yet

- In Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunDocument22 pagesIn Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunTomáš GajdaNo ratings yet

- Thermoeconomic Modeling and Analysis of sCO2 Brayton CycleDocument21 pagesThermoeconomic Modeling and Analysis of sCO2 Brayton Cycley_durNo ratings yet

- String HandlingDocument33 pagesString HandlingSushíl kanikeNo ratings yet

- Technical Catalogue eSV-SpecialVersion 50-60HzDocument264 pagesTechnical Catalogue eSV-SpecialVersion 50-60HzRichard Marco Antonio Obando LopezNo ratings yet

- Accuracy and Precision Are Two Important Concepts in ScienceDocument3 pagesAccuracy and Precision Are Two Important Concepts in ScienceCrystel Joy CamasisNo ratings yet

- Biochem Scale Up.Document9 pagesBiochem Scale Up.Ana Lorraine DalilisNo ratings yet

- 1 Rigid PavementsDocument5 pages1 Rigid PavementsUmar FarooqNo ratings yet

- FlowCon EVS Tech 08.2013Document7 pagesFlowCon EVS Tech 08.2013Jeff Anderson CollinsNo ratings yet

- CS602 MCQS For Final Term Verified by MastersDocument277 pagesCS602 MCQS For Final Term Verified by MastersjackNo ratings yet

- CSEC June 2009 Mathematics P1 v2Document13 pagesCSEC June 2009 Mathematics P1 v2get thosebooksNo ratings yet

- Google Neural Machine Translation SystemDocument23 pagesGoogle Neural Machine Translation SystemCarlangaslangasNo ratings yet

- Exercise 1. P-T Diagram of PropaneDocument14 pagesExercise 1. P-T Diagram of PropanesamantaNo ratings yet

- Quarter 4, LAS-1-2: Learning Activity Sheets (LAS) For Business Mathematics Grade 11Document4 pagesQuarter 4, LAS-1-2: Learning Activity Sheets (LAS) For Business Mathematics Grade 11Cristian Dominic Escarlan100% (2)

- Chapter 5Document26 pagesChapter 5yohans shegawNo ratings yet

- Brosur SHIMGEDocument38 pagesBrosur SHIMGENesto Lab IndonesiaNo ratings yet

- Assignment#3Document2 pagesAssignment#3Ashish ManwarNo ratings yet

- ImageScan HD User Manual Rev ADocument52 pagesImageScan HD User Manual Rev AmrscribdNo ratings yet

- Chi SquareDocument2 pagesChi SquarePrasanth Kurien Mathew100% (3)

- Manual tm-10098 Rev 05-27-08Document203 pagesManual tm-10098 Rev 05-27-08Alhgasjsghjagjsdajlsd Asdalsdlkaksd100% (1)

- STH Poster Winter 2013Document2 pagesSTH Poster Winter 2013SakuragiNo ratings yet

ID0002 Rev F

ID0002 Rev F

Uploaded by

James ĐỗOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ID0002 Rev F

ID0002 Rev F

Uploaded by

James ĐỗCopyright:

Available Formats

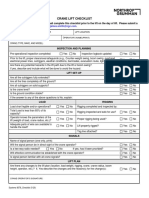

ID-0002 Rev F

Mill Spindle Inspection Report

Technician Cell#

Serial Number Date

Model

Why is the Spindle being replaced?

1a. What is the symptom? Noise Exceeds 140 F Seized Alarm

1c. When does the symptom occur? Spindle Running Intermittenly

2. Is the spindle physically damaged? Yes No

3. Describe the issue:

Mandatory Troubleshooting

Lubrication

4. Are there leaks around the sight glass? Yes No

5. Did you see 1 to 3 drops of oil during the oil pump cycle? Yes No

Spindle Condition

Inline Spindles

6.Has the spindle motor alignment been verified? Yes No

Yes No

Shim dimension Value:

7. Has the NCE gap been reset with the correct shim?

Axial Alignment Value:

Radial Alignment Value:

Belted Spindles

8. Is the drive sprocket/belt in good condition? Yes No

9. Is the encoder sprocket/belt in good condition? Yes No

10. Has the belt tension been verified? Yes No

Inline & Belted Spindles

11. Look through the alarm history is there any Z-Axis servo Errors alarms generated? Yes No

12. Has a vibration test been performed? If no, run a test and attach to service notification. Yes No

13. Has a motor only vibrations test been performed? If no, run a test and attach to service notification. Yes No

14. Has the spindle been balanced? If no, balance the spindle. Yes No

15. Is the TSC union or coolant collector making noise? Yes No

16. Is the spindle taper in good condition? Yes No

17. Is the spindle fan working? Yes No

18. Is the spindle fan vibrating? Yes No

19. On machines equipped with TSC. Did you performed a Vibration analysis with the TSC

Yes No

Union/Adapter removed?

20. Has the spindle to toolchanger alignment been verified? Yes No

HSK Spindle Only

21. Has the push out been verified? Yes No

22. Has the grippers been greased? If yes, what grease is being used? Yes No Grease:

Drawbar Condition

23. Has the drawbar clamp force been checked? If yes, what is the force value? Yes No Force: lb

24.If the spindle is belted with a carbide drawbar has the face runout been verified? If yes, what is the

Yes No Runout:

value?

25. What is the drawbar shaft runout? Yes No

26. Are the ball bearings and drawbar cup in good condition? Yes No

Tool Holders Condition

27. Are the pull studs in good condition? Yes No

28. Have the pull studs been torqued to spec? Yes No

29. Are the correct pull studs and tool holders being used? Yes No

30. Have the tool holders been balanced? If no, balance them. Yes No

Spindle Deflection Test

31. Has the Spindle Deflection Test been performed? If yes, please what is the push, pull, and lost Yes No Push deflection:

motion values? NOTE: Please only perform this if steps 1-30 have been performed and verified, and the

machine is continuing to have surface finish issues. Pull deflection:

Lost Motion:

Notes/ Observations:

Attach this report, an error report, and any relevent documentation to a service notification in the Haas Service App.

You might also like

- PPE MatrixDocument1 pagePPE Matrixajayjanardhankasle75% (4)

- The Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionFrom EverandThe Complete Rigger's Apprentice: Tools and Techniques for Modern and Traditional Rigging, Second EditionRating: 5 out of 5 stars5/5 (2)

- Daily Cradle Inspection Sheet: No Type of Check Operational Status RemarksDocument1 pageDaily Cradle Inspection Sheet: No Type of Check Operational Status RemarksZubair Khan100% (1)

- 40981Document23 pages40981Verdes CouchNo ratings yet

- Used Car Inspection Checklist: BrakesDocument2 pagesUsed Car Inspection Checklist: BrakesFreetxt ApiNo ratings yet

- PQR Wps WPQ FormatDocument12 pagesPQR Wps WPQ FormatessnelsonNo ratings yet

- Math Quest Further Maths VCE 12 (2016 Edition)Document786 pagesMath Quest Further Maths VCE 12 (2016 Edition)NhiNo ratings yet

- Hammer Service Log MC60Document2 pagesHammer Service Log MC60RezaNo ratings yet

- GoAudits - Chiller Commissioning Checks (Sample)Document1 pageGoAudits - Chiller Commissioning Checks (Sample)bala pandiyanNo ratings yet

- Checklist RIGDocument3 pagesChecklist RIGMiguel CastilloNo ratings yet

- Hammer Service Log MP80Document2 pagesHammer Service Log MP80RezaNo ratings yet

- Inspection and Test Plan - Sprinkler System - Rev 01Document7 pagesInspection and Test Plan - Sprinkler System - Rev 01Anonymous ixIhrPM2No ratings yet

- Bridge Steering SystemDocument1 pageBridge Steering SystemVeri YuliantoNo ratings yet

- New Mobile Crawler Crane ChecklistDocument2 pagesNew Mobile Crawler Crane ChecklistsunilNo ratings yet

- LTB145D1 Test ReportDocument10 pagesLTB145D1 Test ReportSiddharth BhawsarNo ratings yet

- GEC WW HSE TPL 08E Rev00 - Crane Inspection - XLSX TemplateDocument1 pageGEC WW HSE TPL 08E Rev00 - Crane Inspection - XLSX TemplateArturo Alejandro Maldonado VelásquezNo ratings yet

- Crawler CraneDocument2 pagesCrawler CraneFarukBasyoriNo ratings yet

- RubbingDocument1 pageRubbingBadre SEBBAHINo ratings yet

- Ultrasound Repair and TroubleshootingDocument4 pagesUltrasound Repair and TroubleshootingOliver GonzalezNo ratings yet

- Specifications: 2010 Steering Steering Wheel and Column - Equinox & TerrainDocument117 pagesSpecifications: 2010 Steering Steering Wheel and Column - Equinox & Terrainvictorinox dlcbNo ratings yet

- Storage Tank Maintenance 1677413042Document107 pagesStorage Tank Maintenance 1677413042RICK SENSONo ratings yet

- 2 Tower Crane Checklist PDFDocument3 pages2 Tower Crane Checklist PDFAzaim AnaqiNo ratings yet

- S.No Model JC No Advisor Tech. Job Type KMS: 1 XL100 3999 Ratnakar Ravi Paid /serviceDocument4 pagesS.No Model JC No Advisor Tech. Job Type KMS: 1 XL100 3999 Ratnakar Ravi Paid /serviceMani kumar MaddelaNo ratings yet

- Specifications: 2010 Steering Steering Wheel and Column - Equinox & TerrainDocument117 pagesSpecifications: 2010 Steering Steering Wheel and Column - Equinox & Terrainvictorinox dlcbNo ratings yet

- Fan Installation-1Document3 pagesFan Installation-1Abderrahim AbarayNo ratings yet

- Alongside: Yes Yes Yes YesDocument3 pagesAlongside: Yes Yes Yes Yesshaiful rizanNo ratings yet

- Hose Reel Inspection ChecklistDocument2 pagesHose Reel Inspection ChecklistMi doremiNo ratings yet

- Folk LiftDocument1 pageFolk LiftAlamindris DrisNo ratings yet

- Scope of MatrixDocument2 pagesScope of Matrixanup singhNo ratings yet

- 3 Mobile Crane ChecklistDocument5 pages3 Mobile Crane ChecklistEriq100% (1)

- 8 Vehicle Pre-Operational Checklist PDFDocument2 pages8 Vehicle Pre-Operational Checklist PDFjusticeNo ratings yet

- Commissioning Report of Lakshmi Winder - 72 at M/S. Jay Textiles, Unit - 1, PollachiDocument4 pagesCommissioning Report of Lakshmi Winder - 72 at M/S. Jay Textiles, Unit - 1, PollachiSwathi PriyaNo ratings yet

- 19.DG Inspection ChecklistDocument1 page19.DG Inspection ChecklistP.M.K anthNo ratings yet

- Mechanic TrainingDocument3 pagesMechanic TrainingSiril MonNo ratings yet

- Mandatory Requirements For Monthly Inspection of TanksDocument1 pageMandatory Requirements For Monthly Inspection of TanksJiss MathewNo ratings yet

- Crane Lift Site ChecklistDocument1 pageCrane Lift Site Checklistum erNo ratings yet

- Mold Inspection SpecificationDocument6 pagesMold Inspection SpecificationNaukowyDrpNo ratings yet

- Hydro Technical Structure For Phase 2 of KKNPP: Checklist For Tetrapod CastingDocument2 pagesHydro Technical Structure For Phase 2 of KKNPP: Checklist For Tetrapod CastingMAHA LINGAMNo ratings yet

- Q SheetbvbkkDocument2 pagesQ SheetbvbkkMohamed SelimNo ratings yet

- 10MLD GandhinagarDocument3 pages10MLD GandhinagarBUKA RAMAKANTHNo ratings yet

- QAF5175 Rev 0 Crane - Inspection - ChecklistDocument2 pagesQAF5175 Rev 0 Crane - Inspection - ChecklistMohamed El-SawahNo ratings yet

- 100 2BW Cut4 LHP 01e P4Document1 page100 2BW Cut4 LHP 01e P4Manyathela HopaneNo ratings yet

- TM Fi Audit SheetDocument4 pagesTM Fi Audit SheetMani kumar MaddelaNo ratings yet

- Derr 2023 009988Document2 pagesDerr 2023 009988Ngwa ElvisNo ratings yet

- Tabla de ComparacionDocument1 pageTabla de ComparacionRoger Andres OrdoñezNo ratings yet

- BearingsDocument10 pagesBearingsafif atmaja100% (1)

- HLG HSE SPI FM 016B r00 Crane Inspection ChecklistDocument1 pageHLG HSE SPI FM 016B r00 Crane Inspection ChecklistLemuel PetronioNo ratings yet

- Diagnosis 4Document47 pagesDiagnosis 4Miguel Ángel RodríguezNo ratings yet

- Formwork Check ListDocument1 pageFormwork Check ListnadunNo ratings yet

- 2021 - Chennai MMDDocument11 pages2021 - Chennai MMDsenthilkumar rNo ratings yet

- Elevator Five Year Safety Test Report: WWW - Lni.Wa - Gov/Tradeslicensing/ElevatorsDocument2 pagesElevator Five Year Safety Test Report: WWW - Lni.Wa - Gov/Tradeslicensing/ElevatorsjhoniNo ratings yet

- Part C TugsDocument3 pagesPart C TugstuyenbsrNo ratings yet

- 2.how To Fix VS1295 LED - MBDocument41 pages2.how To Fix VS1295 LED - MBRichard emerson Lazcano barajasNo ratings yet

- Job Completion Report Presentation - Hydrostatic Rig-123Document16 pagesJob Completion Report Presentation - Hydrostatic Rig-123mnscsc713321No ratings yet

- Gear Types Supported by GEARPAK: 1 Involute GearsDocument2 pagesGear Types Supported by GEARPAK: 1 Involute Gearscmm5477No ratings yet

- Job Completion Report Presentation of R-169Document16 pagesJob Completion Report Presentation of R-169mnscsc713321No ratings yet

- Solución Problema For Neola PDFDocument9 pagesSolución Problema For Neola PDFLuis RojasNo ratings yet

- GM552-55219-104-PL-RP-0015 - Lowering in ReportDocument1 pageGM552-55219-104-PL-RP-0015 - Lowering in ReportBestun AhmedNo ratings yet

- Truck Inspection ChecklistDocument3 pagesTruck Inspection ChecklistSouma MazumdarNo ratings yet

- T.Hayi: PT-TBDocument2 pagesT.Hayi: PT-TBMohamed SelimNo ratings yet

- Qtrinh Shimadzu Mux10Document3 pagesQtrinh Shimadzu Mux10Kuni KazeNo ratings yet

- Antena WindomDocument17 pagesAntena WindomJack RodriguezNo ratings yet

- Different Types of Computer - Based On Size, Purpose and Working PrincipalDocument4 pagesDifferent Types of Computer - Based On Size, Purpose and Working PrincipalVelmurugan JeyavelNo ratings yet

- Cummins Engine Overhaul 6 BTDocument117 pagesCummins Engine Overhaul 6 BTEmmanuel R. Siwila100% (2)

- Wave Optics MCQDocument8 pagesWave Optics MCQGuru ki physicsNo ratings yet

- Process Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFDocument13 pagesProcess Mineralogy and Application in Mineral Processing and Extractive Metallurgy (Joe Zhou) PDFAldo PabloNo ratings yet

- Electrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsDocument1 pageElectrical Data: General Data:: Data Sheet For Three-Phase Squirrel-Cage-MotorsAdamNo ratings yet

- (2091) Lecture Notes Electrochemistry E.pdf - TMPDocument43 pages(2091) Lecture Notes Electrochemistry E.pdf - TMPRamJiPandeyNo ratings yet

- Gful/Stfaf/) /SF/ / HGTF Udel/ X'G) K5 (: Khwopa College of EngineeringDocument11 pagesGful/Stfaf/) /SF/ / HGTF Udel/ X'G) K5 (: Khwopa College of EngineeringBibek ThapaNo ratings yet

- In Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunDocument22 pagesIn Response To Projectile Movement: Critical Velocity of Electromagnetic Rail GunTomáš GajdaNo ratings yet

- Thermoeconomic Modeling and Analysis of sCO2 Brayton CycleDocument21 pagesThermoeconomic Modeling and Analysis of sCO2 Brayton Cycley_durNo ratings yet

- String HandlingDocument33 pagesString HandlingSushíl kanikeNo ratings yet

- Technical Catalogue eSV-SpecialVersion 50-60HzDocument264 pagesTechnical Catalogue eSV-SpecialVersion 50-60HzRichard Marco Antonio Obando LopezNo ratings yet

- Accuracy and Precision Are Two Important Concepts in ScienceDocument3 pagesAccuracy and Precision Are Two Important Concepts in ScienceCrystel Joy CamasisNo ratings yet

- Biochem Scale Up.Document9 pagesBiochem Scale Up.Ana Lorraine DalilisNo ratings yet

- 1 Rigid PavementsDocument5 pages1 Rigid PavementsUmar FarooqNo ratings yet

- FlowCon EVS Tech 08.2013Document7 pagesFlowCon EVS Tech 08.2013Jeff Anderson CollinsNo ratings yet

- CS602 MCQS For Final Term Verified by MastersDocument277 pagesCS602 MCQS For Final Term Verified by MastersjackNo ratings yet

- CSEC June 2009 Mathematics P1 v2Document13 pagesCSEC June 2009 Mathematics P1 v2get thosebooksNo ratings yet

- Google Neural Machine Translation SystemDocument23 pagesGoogle Neural Machine Translation SystemCarlangaslangasNo ratings yet

- Exercise 1. P-T Diagram of PropaneDocument14 pagesExercise 1. P-T Diagram of PropanesamantaNo ratings yet

- Quarter 4, LAS-1-2: Learning Activity Sheets (LAS) For Business Mathematics Grade 11Document4 pagesQuarter 4, LAS-1-2: Learning Activity Sheets (LAS) For Business Mathematics Grade 11Cristian Dominic Escarlan100% (2)

- Chapter 5Document26 pagesChapter 5yohans shegawNo ratings yet

- Brosur SHIMGEDocument38 pagesBrosur SHIMGENesto Lab IndonesiaNo ratings yet

- Assignment#3Document2 pagesAssignment#3Ashish ManwarNo ratings yet

- ImageScan HD User Manual Rev ADocument52 pagesImageScan HD User Manual Rev AmrscribdNo ratings yet

- Chi SquareDocument2 pagesChi SquarePrasanth Kurien Mathew100% (3)

- Manual tm-10098 Rev 05-27-08Document203 pagesManual tm-10098 Rev 05-27-08Alhgasjsghjagjsdajlsd Asdalsdlkaksd100% (1)

- STH Poster Winter 2013Document2 pagesSTH Poster Winter 2013SakuragiNo ratings yet