Professional Documents

Culture Documents

40 FRP Membrane Housing

40 FRP Membrane Housing

Uploaded by

Lalu Adam Akmal IsnenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

40 FRP Membrane Housing

40 FRP Membrane Housing

Uploaded by

Lalu Adam Akmal IsnenCopyright:

Available Formats

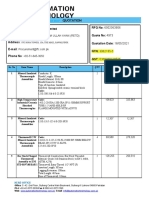

4" FRP Membrane Housing Contents

1 Explanation Model 02

2 End Entry Specification 02

3 End Entry Components 02

4 Side Entry Specification 03

5 Side Entry Components 03

6 Quality Assurance 04

7 Certificates 05

8 Projects 05

9 Addendum Drawings 06

9–1 W40E300 FRP membrane housing drawing..................06

9–2 W40E450 FRP membrane housing drawing..................06

9–3 W40E600 FRP membrane housing drawing..................07

9–4 W40E1000 FRP membrane housing drawing................07

9–5 W40S300 FRP membrane housing drawing..................08

9–6 W40S450 FRP membrane housing drawing..................08

9–7 W40S600 FRP membrane housing drawing..................09

9–8 W40S1000 FRP membrane housing drawing................09

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

4" FRP Membrane Housing

☆ Composite Construction for Best Chemical Compatibility

& Corrosion Resistance.

☆ Unique Mirror Finish ID.

☆ Smooth Inner Wall & Brightly Baking Surface.

☆ Length From 1 Element to 4 Elements.

☆ Adapters, Interconnectors & Mounting Clamps Available.

☆ Inlet & Outlet, Size & Quantity Can be Selected.

☆ Certified by ASME, ISO9001, ISO14001 and GB/T2800.

Technical Specification Test

Material: Fiberglass and epoxy. Burst Test : 6 times of its design pressure.

Working Pressure: 150–1000 PSI. Cycle Test: 100000 times.

Operating Temperature: -7 °C–49 °C. Hydraulic Test: 100% quality assurance test with 1.2 times

Connection: End port, side port optional. stage elevation.

Operating pH Range: 3–11. Barcol Hardness Test: Repeated once every 1.5 meters.

Cleaning pH Range: 2–12 (≤ 30 min). Test every membrane housing, not sampling.

Higher Technology, Cleaner Water! 01

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

Explanation Model

Explanation of Codes of Winder Membrane Pressure Vessels

W 40 E 300 -2

Brand Name

Membrane of Element Inside

Membrane Housing Diameter: 4"

Feed/Concentrate Port Type: End Port E Membrane Housing Max

(Side Port S) Operating Pressure: 300 PSI

End Entry

Specification

Design

Operating Feed port Permeate port Element

Model No. pressure Connection

temperature (inch) (inch) length

(PSI)

W40E150 150 -10 °C–49 °C 3/4" NPTF 1/2" NPTF End Port 40" × (1–4)

W40E300 300 -10 °C–49 °C 3/4" NPTF 1/2" NPTF End Port 40" × (1–4)

W40E450 450 -10 °C–49 °C 3/4" NPTF 1/2" NPTF End Port 40" × (1–4)

W40E600 600 -10 °C–49 °C 3/4" NPTF 1/2" NPTF End Port 40" × (1–4)

W40E1000 1000 -10 °C–49 °C 3/4" NPTF 1/2" NPTF End Port 40" × (1–4)

End Entry

Components

Component assembly diagram of Components detail of 4" end

4" end entry membrane housing entry membrane housing

02 Higher Technology, Cleaner Water!

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

Serial-Number Description Material

① Permeate port ABS

② Inner hexagonal head bolt M6*1 304

③ Crescent film SA-213, 304

④ Pressure head PP + 30% FG

⑤ Sealing rings EPDM

Side Entry

Specification

Design

Operating Feed Port Permeate Port Element

Model No. Pressure Connection

Temperature (inch) (inch) Length

(PSI)

W40S150 150 -10 °C–49 °C DN25 1" 1/2" NPTF Side port 40" × (1–4)

W40S300 300 -10 °C–49 °C DN25 1" 1/2" NPTF Side port 40" × (1–4)

W40S450 450 -10 °C–49 °C DN25 1" 1/2" NPTF Side port 40" × (1–4)

W40S600 600 -10 °C–49 °C DN25 1" 1/2" NPTF Side port 40" × (1–4)

W40S1000 1000 -10 °C–49 °C DN25 1" 1/2" NPTF Side port 40" × (1–4)

Side Entry

Components

Component assembly diagram of Components detail of 4" side

4" side entry membrane housing entry membrane housing

Higher Technology, Cleaner Water! 03

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

Serial-Number Description Material

① Inner hexagonal head bolt M6*1 304

② Crescent film SA-213, 304

③ Pressure head 2205

④ Sealing rings EPDM 512

⑤ Adaptor 2205

⑥ Adaptor O ring EPDM 512

Quality Assurance

Barcol hardness test:

repeated once every 1.5

meters.

Hydraulic test:

100% quality assurance

test with 1.2 times

stage elevation. Keep

pressure for 2 minutes

to ensure no leakage.

Burst test :

6 times of its design

pressure.

Cycle test:

100000 times.

04 Higher Technology, Cleaner Water!

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

Certificates

ASME CNAS28001 ISO9001 ISO14001

Projects

Gansu chemical plant water Biel Crystal water treatment April Fine Paper water treatment

process engineering. May 2014 engineering. May 2015 engineering. May 2015

Daya Bay Cnooc's refinery project. Qingdao wastewater reclamation Dalian Hengli petrochemical water

July 2016 project. Aug 2016 treatment project. Nov 2017

Higher Technology, Cleaner Water! 05

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

Addendum Drawings

1. W40E300 FRP membrane housing drawing

2. W40E450 FRP membrane housing drawing

06 Higher Technology, Cleaner Water!

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

3. W40E600 FRP membrane housing drawing

4. W40E1000 FRP membrane housing drawing

Higher Technology, Cleaner Water! 07

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

5. W40S300 FRP membrane housing drawing

6. W40S450 FRP membrane housing drawing

08 Higher Technology, Cleaner Water!

Mia Chen

sales02@winder1976.com sales06@winder1976.com

www.winder1976.com WhatsApp: +86-18832881267 (Skype)

7. W40S600 FRP membrane housing drawing

8. W40S1000 FRP membrane housing drawing

Higher Technology, Cleaner Water! 09

You might also like

- Instrument Hookup DWGDocument26 pagesInstrument Hookup DWGkassimhos83% (6)

- Alco Parts Catalogue 2018Document18 pagesAlco Parts Catalogue 2018John Kittsteiner100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- INTERMEC EasyCoder PC4 Service ManualDocument114 pagesINTERMEC EasyCoder PC4 Service ManualC LNo ratings yet

- Ergonomic Interventions For Electricians in Fossil-Fueled Power PlantsDocument48 pagesErgonomic Interventions For Electricians in Fossil-Fueled Power PlantsSushayan HunsasukNo ratings yet

- Axeon Membrane Housings LDocument6 pagesAxeon Membrane Housings Loky satrioNo ratings yet

- FRONT 2,5-V/SA 5-EX-4 BK - 1708298: Key Commercial DataDocument4 pagesFRONT 2,5-V/SA 5-EX-4 BK - 1708298: Key Commercial Dataedy985No ratings yet

- Sensor de FlujoDocument2 pagesSensor de FlujoDany Chl100% (1)

- Sridhan Level SwitchDocument95 pagesSridhan Level SwitchvaibhavnriitmNo ratings yet

- Terminal Blcok Ex e Increased SafetyDocument2 pagesTerminal Blcok Ex e Increased SafetyEmmanuelPETITNo ratings yet

- Pressure VesselsDocument14 pagesPressure VesselsChevronelleNo ratings yet

- ETIN Tubing ClampsDocument8 pagesETIN Tubing ClampsVijenth VergheseNo ratings yet

- Gmfhs 4 Mo 6 TavljtsfhaaDocument2 pagesGmfhs 4 Mo 6 TavljtsfhaaScribberNo ratings yet

- PSR10LX - Ermeto DIN Fitting Components For High Pressure Hydraulic Tube Fittings - Parker NADocument1 pagePSR10LX - Ermeto DIN Fitting Components For High Pressure Hydraulic Tube Fittings - Parker NAEmilly ChavesNo ratings yet

- Datenblatt CF E 2019Document2 pagesDatenblatt CF E 2019ssekbanNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Wika Type M93X.D1 Pressure Gauge Data SheetDocument5 pagesWika Type M93X.D1 Pressure Gauge Data SheetTrEnD SeT vicky rioNo ratings yet

- ITT ValvesDocument40 pagesITT Valvesseramon100% (1)

- Elpress Catalog 2011Document149 pagesElpress Catalog 2011Mindaugas MockusNo ratings yet

- Diapham Valve PDFDocument8 pagesDiapham Valve PDFthouche007No ratings yet

- Phoenix Contact 3044102 enDocument6 pagesPhoenix Contact 3044102 enDGNo ratings yet

- Pressure and Level TRansmitters KLAY INSTRUMENTSDocument6 pagesPressure and Level TRansmitters KLAY INSTRUMENTSFrancisco Mones RuizNo ratings yet

- ZP00707 GB 2Document40 pagesZP00707 GB 2grandtrading.egNo ratings yet

- T4E Brochure PDFDocument6 pagesT4E Brochure PDFgullenariNo ratings yet

- SLIW57Document4 pagesSLIW57Hanh NguyenNo ratings yet

- Quot 4973Document4 pagesQuot 4973Mudasir ATNo ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- Mueller PDFDocument16 pagesMueller PDFMechanical EngineerNo ratings yet

- 1 WaterProofCatalogueDocument14 pages1 WaterProofCatalogueXanh XanhNo ratings yet

- Strainer Y TypeDocument2 pagesStrainer Y TypeJorgeNo ratings yet

- PEM Self Clinching Self Locking FastenersDocument4 pagesPEM Self Clinching Self Locking FastenersAce Industrial SuppliesNo ratings yet

- En 8000 08 2016 12Document9 pagesEn 8000 08 2016 12Ajit K GNo ratings yet

- Quick Coupler Brochure - GBDocument2 pagesQuick Coupler Brochure - GBMagdy KamelNo ratings yet

- PEM Self Clinching Miniature FastenersDocument6 pagesPEM Self Clinching Miniature FastenersAce Industrial SuppliesNo ratings yet

- Codeline Drawing 80E30Document2 pagesCodeline Drawing 80E30hargote_2No ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- Manual Spray GunDocument6 pagesManual Spray GunSyazwan KhairulNo ratings yet

- SLW26Document4 pagesSLW26Hanh NguyenNo ratings yet

- Technical Data: 1. DescriptionDocument18 pagesTechnical Data: 1. DescriptionitaloNo ratings yet

- Orifice Plate - Monobloc: DatasheetDocument8 pagesOrifice Plate - Monobloc: Datasheetbiomed systechNo ratings yet

- Avk Extension Spindle, Telescopic 04/04-001: For Gate Valves, Key Adaptor #23-32Document3 pagesAvk Extension Spindle, Telescopic 04/04-001: For Gate Valves, Key Adaptor #23-32Arshad IqbalNo ratings yet

- Sika Anchorfix - 2 Tropical: Anchoring Adhesive For Medium To High LoadsDocument7 pagesSika Anchorfix - 2 Tropical: Anchoring Adhesive For Medium To High Loadskamran abbasiNo ratings yet

- Techno Flex-Piping-02Document12 pagesTechno Flex-Piping-02InamMuradNo ratings yet

- National Iranian Gas Company (N.I.G.C.) : S3 / S6 Compressor Stations Special SpecificationDocument10 pagesNational Iranian Gas Company (N.I.G.C.) : S3 / S6 Compressor Stations Special SpecificationNic RicNo ratings yet

- Haitima Ball Valve 2057np73Document1 pageHaitima Ball Valve 2057np73rafael1978No ratings yet

- Level SwitchesDocument94 pagesLevel SwitchesPremjith SudhakaranNo ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- Nicote Cable Glands CatalogueDocument13 pagesNicote Cable Glands Cataloguekvp0107No ratings yet

- Quick Start Guide For X1&X1-Carbon-v1Document16 pagesQuick Start Guide For X1&X1-Carbon-v1darkoteamNo ratings yet

- Feed-Through Terminal Block - ST 4-HEDI - 3035140: Key Commercial DataDocument13 pagesFeed-Through Terminal Block - ST 4-HEDI - 3035140: Key Commercial DataAndrés AracenaNo ratings yet

- INKA General Catalogue 2021 MAYISDocument276 pagesINKA General Catalogue 2021 MAYISozgurNo ratings yet

- Mx80 Series: Rohs CompliantDocument6 pagesMx80 Series: Rohs Compliantbalasubramani krishnamurthiNo ratings yet

- SR - No - 4 - DI PIPE - Technical Datasheet - C - ClassDocument7 pagesSR - No - 4 - DI PIPE - Technical Datasheet - C - ClassArunprasad MurugesanNo ratings yet

- Inspection TechniquesDocument125 pagesInspection TechniquesAnonymous P9TMWcG100% (1)

- Weko-Seal EPDM Material Specifications : Water/Waste Water ApplicationsDocument4 pagesWeko-Seal EPDM Material Specifications : Water/Waste Water ApplicationscarlosNo ratings yet

- Ham-Let Astava Line of ManifoldsDocument24 pagesHam-Let Astava Line of ManifoldsjcestupinanNo ratings yet

- Ermeto DIN Locknut Adjustable High Pressure Tube Ttings - #Vee10LmomdcfDocument4 pagesErmeto DIN Locknut Adjustable High Pressure Tube Ttings - #Vee10Lmomdcfjcaers1No ratings yet

- Gasket Documents PDFDocument66 pagesGasket Documents PDFramnadh803181No ratings yet

- Excess Flow Valves Bleed Valves and Purge ValvesDocument6 pagesExcess Flow Valves Bleed Valves and Purge ValvesNilesh MistryNo ratings yet

- Yokogawa-WIKA C13WT+series Ed0Document20 pagesYokogawa-WIKA C13WT+series Ed0haisamsarwarNo ratings yet

- Creepresistant Hightemperature FCAW ENGDocument12 pagesCreepresistant Hightemperature FCAW ENGRuben Dario Mamani ArellanoNo ratings yet

- Flanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignDocument9 pagesFlanged Safety Relief Valves - Spring Loaded: Type 447 PTFE-lined Packed Lever H4 Closed Bonnet Bellows DesignSaleh EttehadiNo ratings yet

- 2022 LMI Catalogue WebDocument116 pages2022 LMI Catalogue WebLalu Adam Akmal IsnenNo ratings yet

- CataloguefybrocDocument2 pagesCataloguefybrocLalu Adam Akmal Isnen100% (1)

- Sectional DrawingDocument1 pageSectional DrawingLalu Adam Akmal IsnenNo ratings yet

- CECO Fybroc 1530 Installation ManualDocument22 pagesCECO Fybroc 1530 Installation ManualLalu Adam Akmal IsnenNo ratings yet

- Rota Meter YokogawaDocument32 pagesRota Meter YokogawaLalu Adam Akmal IsnenNo ratings yet

- EN Product Overview Process and Control ValvesDocument33 pagesEN Product Overview Process and Control ValvesLalu Adam Akmal IsnenNo ratings yet

- Optimization of Solar Power Using Diffused ReflectorsDocument15 pagesOptimization of Solar Power Using Diffused ReflectorsEngr Lanre Majek100% (1)

- Hazard IdentificationDocument5 pagesHazard IdentificationSyakirin SpearsNo ratings yet

- MCMSB ComProfile Ver2Document39 pagesMCMSB ComProfile Ver2Mohd Fauzi Mohamad YusofNo ratings yet

- Architect Philippines - English - Tagalog Construction TermsDocument3 pagesArchitect Philippines - English - Tagalog Construction TermsJohn Rae R. DomingoNo ratings yet

- Data Warehouse DatabasesDocument28 pagesData Warehouse DatabasesGiri SaranuNo ratings yet

- Mcafee 5.0 GuideDocument6 pagesMcafee 5.0 GuideaBui KANo ratings yet

- Open Channel Flow: Monroe L. Weber-Shirk S Civil Environmental EngineeringDocument62 pagesOpen Channel Flow: Monroe L. Weber-Shirk S Civil Environmental EngineeringGertjan DuniceriNo ratings yet

- Differential Equations in Applied Chemistry PDFDocument129 pagesDifferential Equations in Applied Chemistry PDFAlejandro Monroy VergaraNo ratings yet

- Question: Explain About Data Migration and Cut-Over Activities in SAP Answer: A. Data MigrationDocument20 pagesQuestion: Explain About Data Migration and Cut-Over Activities in SAP Answer: A. Data Migrationvenkat6299No ratings yet

- Manage Your Risk With ThreatModeler OWASPDocument39 pagesManage Your Risk With ThreatModeler OWASPIvan Dario Sanchez Moreno100% (1)

- MEP - MRSA - UkDocument7 pagesMEP - MRSA - UkLuiz HenriqueNo ratings yet

- OptraSculpt Pad PDFDocument2 pagesOptraSculpt Pad PDFSharmaine JucoNo ratings yet

- Arlene DavisDocument2 pagesArlene DavisAviation/Space History LibraryNo ratings yet

- Tender8614 2Document425 pagesTender8614 2Vishal SoniNo ratings yet

- 5.2.1.10 Lab - Check For Updates in Windows 7 and VistaDocument6 pages5.2.1.10 Lab - Check For Updates in Windows 7 and VistaMelany SosaNo ratings yet

- Powertech ™ 6135Sfm85 Diesel Engine: Marine Propulsion Engine SpecificationsDocument2 pagesPowertech ™ 6135Sfm85 Diesel Engine: Marine Propulsion Engine SpecificationspngchanhNo ratings yet

- Amine Sweetening Process DesignDocument12 pagesAmine Sweetening Process Designswapnil2603100% (2)

- Samsung AR18 2PK Fast Cooling Air Conditioner - Samsung ID PDFDocument10 pagesSamsung AR18 2PK Fast Cooling Air Conditioner - Samsung ID PDFPurungparang groupNo ratings yet

- Lead Gloves Revolution InfabDocument1 pageLead Gloves Revolution InfabFranklin FiallosNo ratings yet

- DC ChopperDocument63 pagesDC ChopperMalyaj SrivastavaNo ratings yet

- RIEDEL GEK Anleitung 02 2010 English PDFDocument35 pagesRIEDEL GEK Anleitung 02 2010 English PDFMuchamad SamsudinNo ratings yet

- Sika PDS - E - SikaGrout - 212 GP PDFDocument2 pagesSika PDS - E - SikaGrout - 212 GP PDFKhin Sandi KoNo ratings yet

- Clarifier DesignDocument5 pagesClarifier DesignSwaminathan ThayumanavanNo ratings yet

- Retrofitting The Existing Flare / Burnery For Smoke Less OperationsDocument31 pagesRetrofitting The Existing Flare / Burnery For Smoke Less Operationsmehul10941No ratings yet

- Operation-Maintenance Manual - PHE - ENDocument24 pagesOperation-Maintenance Manual - PHE - ENChan Chi Wong PenNo ratings yet

- Definition of Conceptual FrameworkDocument3 pagesDefinition of Conceptual FrameworkryanNo ratings yet

- NuFlo USB Adapter Troubleshooting TipsDocument7 pagesNuFlo USB Adapter Troubleshooting TipsElkin TorresNo ratings yet