Professional Documents

Culture Documents

Bending Risk Assessment

Bending Risk Assessment

Uploaded by

Athar KhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bending Risk Assessment

Bending Risk Assessment

Uploaded by

Athar KhanCopyright:

Available Formats

Description

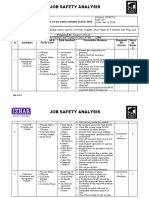

LEAD Contracting & Trading ASAB FACILITIES UPGRADE PROJECT P/L Job Risk Assessment

Rev. No. 0 Date: Issued for Reviewed & Approval

Risk assessment performed for: bending of 30” pipeline

Location: ASAB.

DATE: 23/8/2004

Team member: Mr. Manaf daoud Construction manager

Mr.Elias douka pipeline supervisor

Mr.Sameh ahmed HSE manager

Mr.Thaier Dahmach HSE Supervisor

A-RISK ASSESSMENT SCOPE

THE SCOPE OF THIS RISK ASSESSMENT IS RELATED TO BENDING OF 30” PIPELINE USING BENDING MACHINE .

B- HAZARD IDENTIFICATION

AFTER DISCUSSION, THE FOLLOWING HAZARDS WERE IDENTIFIED, AND NEED TO BE ASSESSED:

Working in desert weather.

Moving oversized & heavy equipment

Lifting pipe

Bending operations hazardous.

Unsafe acts / condition

Refueling by using diesel & lubricant

Waste collection

Activity Hazard involved Consequences Probability Risk rating Minimize risk to acceptable level by:

Bending PTW to be implemented & approved, Safety

Vehicles accident

of 30” induction for drivers. All vehicles are certified,

related trauma,

pipeline Movement of in good condition & equipped with desert tools,

stuck in sand

personnel in daily obey to national & company speed limit, fasten

absence & lack of M M

basis between seat belt, first aid kit available, emergency

communication in

ROW & camp. phone list & mobile phone available, journey

case of

management system to be applied during

accident/incident

working hours

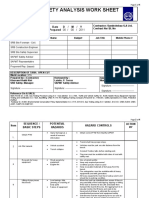

Working in desert Weather M M Adequate quantities of water available for all

conditions & heat employees, first aid certified personnel to be

exhaustion distribute in all over work activities, keep

weather.

suffering from dousing the body continuously with a cool

heat stress fluids

Identified O/H Lines, maintain safe distance,

Contact with OH flagman to guide the machines, all involved

Lines, collision of persons to have acknowledgment of electrical

Moving oversized

transportation M M hazard, escorted by vehicle, overhang flag will

& heavy equipment

injury, property be used on all exposed points

damage.

Certified operators & equipments, lifting gear &

Struck by moving

equipment to be color coded & inspected prior

equipment,

to start any activities, banksman to guide the

Lifting pipe Falling objects, M M operation, standing under or between the load

fatality or asset

& equipment banned, tagline will be utilized on

damages

all lifts, TBT to be conducted prior to start work.

Ensure the bending machine in a clear open

Rupture of lifting area to maintain good access not in the vicinity

accessories, of overhead or underground service, competent

Bending operations crushing & M M person trained properly for bending operations,

jamming fingers, don't stand under the pipe during insert or

hands & legs, remove the pipe from the machine, all

employees to wear appropriate P.P.E

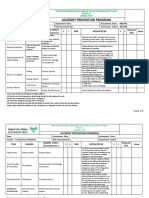

Ensure that whole working crew know &

understand their daily work activities and its

associated hazardous, reduce the potential of

Slips, trips &

Unsafe acts / working nearby moving machinery & lifting

falls, minor/major M M

condition operations as practical applicable, all employees

injury, falls

to wear appropriate P.P.E, house keeping of the

area and good segregation for the construction

material

Refueling to be carried out by designated

Spills & leaks,

person only, regular check & maintenance to

Refueling by using ground, fire

M M the equipment, fire extinguisher available at

diesel & lubricant contamination by

site, fully adherence to the environmental

toxic substances

policy

Waste collection Possibly soil M M All waste to be collected & maintain high

contamination or standard of housekeeping, waste management

plant uncontrolled to be adhered

waste on site

C- CONCLUSION

According to the above, the following recommendations must be fulfilled 9in order to carry out this activity safely:

All vehicles are certified, in good condition & equipped with desert tools

First aid kit available, emergency phone list & mobile phone available

Journey management system to be applied during working hours

,Adequate quantities of water available for all employees

Keep dousing the body continuously with cool fluids

Identified O/H Lines, maintain safe distance, flagman to guide the machines

Certified operators & equipments, lifting gear & equipment to be color-coded & inspected prior to start any activities

Banksman to guide the operation

Tagline will be utilized on all lifts

.TBT to be conducted prior to start work

Ensure the bending machine in a clear open area to maintain good access not in the vicinity of overhead or underground service

Competent person trained properly for bending operation

All employees to wear appropriate P.P.E

D- PTW requirement

The following PTW will be required:

Hot work permit HWP

You might also like

- Solutions Manual (Instructor's Manual) For A Concise Introduction To Logic 9th Edition by Hurley Sample ChapterDocument16 pagesSolutions Manual (Instructor's Manual) For A Concise Introduction To Logic 9th Edition by Hurley Sample Chapterdan100% (2)

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentrashid zaman57% (7)

- Work Method Statement PDFDocument8 pagesWork Method Statement PDFUsiwo Abed Soteria Otowa100% (4)

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- JSA For Pipe Line DemolitionDocument7 pagesJSA For Pipe Line DemolitionSiraj Mohamed Ikbal80% (5)

- JSA FOR Painting Works On Storage TanksDocument6 pagesJSA FOR Painting Works On Storage TanksHaseeb Nouman Abbasi100% (2)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham80% (5)

- 1963 Ford GalaxieDocument190 pages1963 Ford GalaxieLuis100% (2)

- Method Statement For Access Road & Platform Construction in Hill Area (HSE)Document5 pagesMethod Statement For Access Road & Platform Construction in Hill Area (HSE)Rajesh100% (1)

- 027 - JSA - For Station Civil Work at KP-000 - IncorporatedDocument4 pages027 - JSA - For Station Civil Work at KP-000 - IncorporatedsathishkumarNo ratings yet

- 028 - JSA - Hydrotesting - 27-02-2012Document7 pages028 - JSA - Hydrotesting - 27-02-2012sathishkumarNo ratings yet

- Job Safety Analysis - Cement SiloDocument9 pagesJob Safety Analysis - Cement SiloMohammed Minhaj100% (1)

- All Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicableDocument6 pagesAll Personnel To Attend Daily Site Safety Meeting and Review Site Safety Plan. Also, in Place Traffic Manage-Ment Plan / TMP ApplicablecrnkarlosNo ratings yet

- SMP For DMIRS Mine Shaft RehabilitationDocument8 pagesSMP For DMIRS Mine Shaft RehabilitationEugene MalatynskiNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- 1 Earth WorksDocument5 pages1 Earth WorksMuhammad Shahid Iqbal100% (1)

- Jsa Brick WorkDocument4 pagesJsa Brick WorkRavi thokalNo ratings yet

- Tie - in Mechanical Installation JHADocument7 pagesTie - in Mechanical Installation JHAmalik jahanNo ratings yet

- Job Safety Analysis - Cement SiloDocument7 pagesJob Safety Analysis - Cement SiloArgi Bramantara100% (1)

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 pagesOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Job Safety Analysis Work Sheet: Date Prepared D / M / YDocument4 pagesJob Safety Analysis Work Sheet: Date Prepared D / M / Ykkalvi0% (1)

- JSA Installation-Fire-Alarm-SystemDocument12 pagesJSA Installation-Fire-Alarm-Systemuz9143895No ratings yet

- Job Safety & Environmental Analysis WorksheetDocument2 pagesJob Safety & Environmental Analysis WorksheetCherry BetonioNo ratings yet

- Hazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)Document9 pagesHazard Identification Plan (Hip) & Site Visit:: 16"U/G Hwyh Gosp-3 Downstream Disposal Header (Asphalt Road)javithNo ratings yet

- Hazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012Document1 pageHazard Identification, Risk Assessment & Control Measures: NCC/BMRCL/PH-2B/P2/69 (B) /MS-012somashekhar. ncclNo ratings yet

- Lifting Operations - Risk AssessmentDocument3 pagesLifting Operations - Risk AssessmentkhanalNo ratings yet

- 4.3tata Steel - Risk AssessmentDocument4 pages4.3tata Steel - Risk AssessmentEverest Engineering RentalsNo ratings yet

- Jsa For Drilling WellDocument5 pagesJsa For Drilling WellAnna JisabaNo ratings yet

- HMDS Monthly Risk Assessment BlankDocument3 pagesHMDS Monthly Risk Assessment BlankAli BelkhiriNo ratings yet

- IPC SHF SafetyDocument30 pagesIPC SHF SafetyAyman SalahNo ratings yet

- Generic TPL JsaDocument83 pagesGeneric TPL JsaSanjay Kumar GhadaiNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document5 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair Vanmazhy100% (1)

- Risk Assessment-1 PDFDocument17 pagesRisk Assessment-1 PDFDayanandaNo ratings yet

- S.No Job Steps Hazards Preventative Measures Responsible PersonDocument3 pagesS.No Job Steps Hazards Preventative Measures Responsible Personmd_rehan_2No ratings yet

- 20-RAS-Transformer InstallationDocument2 pages20-RAS-Transformer InstallationWalid MarhabaNo ratings yet

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- Ast Jsa - Piping FabricationDocument3 pagesAst Jsa - Piping Fabricationmd_rehan_2No ratings yet

- Risk Assesment Excavation & BackfillingDocument5 pagesRisk Assesment Excavation & BackfillingMuhammad Jamshid100% (3)

- Job Safety Analysis: Shaybah NGL Recovery Plant DepartmentDocument4 pagesJob Safety Analysis: Shaybah NGL Recovery Plant DepartmentMadhan KannanNo ratings yet

- Hip & Jsa For Abqq-472Document13 pagesHip & Jsa For Abqq-472javithNo ratings yet

- Jsa For Cable JointingDocument4 pagesJsa For Cable JointingthennarasuNo ratings yet

- Metering Skid ErectionDocument4 pagesMetering Skid ErectionNature BeautiesNo ratings yet

- Annex DD Appendix 1 Example Excavation Risk Assessment PDFDocument3 pagesAnnex DD Appendix 1 Example Excavation Risk Assessment PDFEdgard Laurenz Montellano GeronimoNo ratings yet

- JSA For SURGE VESSEL WorkDocument6 pagesJSA For SURGE VESSEL Workathul subashNo ratings yet

- Cable Laying Pouch & Sachet BuildingDocument4 pagesCable Laying Pouch & Sachet Buildingasifreza96No ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- Replacement of Flowmeter - Risk AssessmentDocument3 pagesReplacement of Flowmeter - Risk Assessmentanishdev660% (5)

- TA AsbestosDocument8 pagesTA AsbestosTony ZhangNo ratings yet

- Fill-Up This Card Before Commencement of Critical WorksDocument4 pagesFill-Up This Card Before Commencement of Critical WorksSiddhant choudharyNo ratings yet

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- Red Tile Placing JSADocument5 pagesRed Tile Placing JSAShahid BhattiNo ratings yet

- GOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchDocument6 pagesGOSP-5 (60) Placing Red Tile &caution Tape Inside The TrenchShahid BhattiNo ratings yet

- Risk Assess T-07 - Mobile Crane OperationsDocument2 pagesRisk Assess T-07 - Mobile Crane OperationsMAB AliNo ratings yet

- Drain Line Work JSA HSE ProfessionalsDocument2 pagesDrain Line Work JSA HSE ProfessionalsSamadov 13No ratings yet

- JSA For Errection of Batching PlantDocument4 pagesJSA For Errection of Batching Plantasamrat582No ratings yet

- PARCO - Mid Country Refinery: Job Safety AnalysisDocument6 pagesPARCO - Mid Country Refinery: Job Safety AnalysisGyanendra Narayan NayakNo ratings yet

- Jsa For Chemical Ware HouseDocument4 pagesJsa For Chemical Ware Housesalauddin0mohammedNo ratings yet

- Drain Line Work JSADocument2 pagesDrain Line Work JSAm.rehanhseNo ratings yet

- GSK 218M CNC System Connection and PLC ManualDocument192 pagesGSK 218M CNC System Connection and PLC ManualsunhuynhNo ratings yet

- TridentDocument24 pagesTridentPrajod ThiruvambattilNo ratings yet

- 01 August 2023 - Manifest Boat Babo - LNGDocument1 page01 August 2023 - Manifest Boat Babo - LNGSeverinus SHIPBintuniNo ratings yet

- HXGP 116 Detailed Course OutlineDocument2 pagesHXGP 116 Detailed Course OutlinePARDON MATARENo ratings yet

- Notes Receivable and Loan ReceivableDocument21 pagesNotes Receivable and Loan ReceivableLady BelleNo ratings yet

- Caltex Vs PalomarDocument1 pageCaltex Vs PalomarDean Ben100% (2)

- Green Synthesis and Characterization of Silver Nanoparticles, by The Reductive Action of The Aqueous Extract of Blueberry (Vaccinium Corymbosum)Document6 pagesGreen Synthesis and Characterization of Silver Nanoparticles, by The Reductive Action of The Aqueous Extract of Blueberry (Vaccinium Corymbosum)TR DanieleNo ratings yet

- NOTH Menu Aug 22Document10 pagesNOTH Menu Aug 22Devin SwanepoelNo ratings yet

- SGP TR 012Document276 pagesSGP TR 012Kevin Devalentino Versi IINo ratings yet

- 4understanding Calculations in Tableau - TableauDocument4 pages4understanding Calculations in Tableau - TableauChanakya ChanuNo ratings yet

- Unit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep RaghavDocument72 pagesUnit 2 - Basic Instrumentation and Measurement Techniques PPT Notes Material For Sem II Uploaded by Navdeep Raghavavikool1708No ratings yet

- DJ10Document4 pagesDJ10rahulNo ratings yet

- CTDI Phantom User's GuideDocument18 pagesCTDI Phantom User's GuideAida Cristiana SanduNo ratings yet

- Whattolookforinacodereview PDFDocument53 pagesWhattolookforinacodereview PDFvamosraghavaNo ratings yet

- First Quarter Exam in English 9 2019 2020Document4 pagesFirst Quarter Exam in English 9 2019 2020Maria Carmela Rachel GazilNo ratings yet

- Dealroom Embedded Finance v2Document32 pagesDealroom Embedded Finance v2Sushma KazaNo ratings yet

- K3 CD Di Player Manual PDFDocument16 pagesK3 CD Di Player Manual PDFRon DinNo ratings yet

- CAR-T TherapyDocument14 pagesCAR-T TherapyrameshaachariarNo ratings yet

- Analisis de Pesticidas Usandom FragmentacionDocument159 pagesAnalisis de Pesticidas Usandom FragmentacionroxanaNo ratings yet

- Tentang Takal Melalui Lakaran, TMK, Penulisan Atau Lisan Secara Kreatif)Document2 pagesTentang Takal Melalui Lakaran, TMK, Penulisan Atau Lisan Secara Kreatif)Yayang NasrudinNo ratings yet

- A Brief Note On Plants of Medicinal Importance To LivestockDocument84 pagesA Brief Note On Plants of Medicinal Importance To LivestockSunil100% (1)

- Understanding The Transfer of Prepositions: Arabic To EnglishDocument7 pagesUnderstanding The Transfer of Prepositions: Arabic To Englishwaa2000No ratings yet

- SMART VTS Wireless Solutions: Features SVTS-500 SVTS-600 SVTS-700 SVTS-900 SVTS-1200Document6 pagesSMART VTS Wireless Solutions: Features SVTS-500 SVTS-600 SVTS-700 SVTS-900 SVTS-1200Sri KanthNo ratings yet

- Fake TrendyolDocument1 pageFake Trendyol68v9xwsn7jNo ratings yet

- Dir. Master File-NewDocument436 pagesDir. Master File-NewassmexellenceNo ratings yet

- Introduction SlidesDocument23 pagesIntroduction SlidesMathiselvan GopalNo ratings yet

- 7th Mathematics 1,2,3Document3 pages7th Mathematics 1,2,3Khamalesh C.ANo ratings yet

- Module 2 - Consumer Behavior and Marketing StrategiesDocument50 pagesModule 2 - Consumer Behavior and Marketing Strategiesjhunrey vicente100% (1)