Professional Documents

Culture Documents

Air Safety PRP

Air Safety PRP

Uploaded by

normalCopyright:

Available Formats

You might also like

- Sample Request Letter To Conduct A StudyDocument2 pagesSample Request Letter To Conduct A StudyGail A89% (9)

- HVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesDocument18 pagesHVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesFabiola Olivares100% (2)

- TEMPLATE FOR OPERATIONAL QUALIFICATION PROTOCOL - Pharmaceutical GuidanceDocument7 pagesTEMPLATE FOR OPERATIONAL QUALIFICATION PROTOCOL - Pharmaceutical GuidanceMSL India100% (2)

- Process Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2Document12 pagesProcess Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2MykolaNo ratings yet

- Pharma Book Final-1Document270 pagesPharma Book Final-1Anil Kumar88% (33)

- Hvac System ValidationDocument53 pagesHvac System Validationtarique1189040100% (2)

- Instructional PlanDocument12 pagesInstructional PlanChristopher R. Bañez IINo ratings yet

- MSP ProceduresDocument18 pagesMSP ProcedurestarunNo ratings yet

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- SIEMENS Corrective and Preventive ActionDocument9 pagesSIEMENS Corrective and Preventive ActionOlakunle AwoniyiNo ratings yet

- SOP DocumentDocument10 pagesSOP Documentsh78129No ratings yet

- QSP 07 CAPA Rev 1Document4 pagesQSP 07 CAPA Rev 1kmvimal36No ratings yet

- GMP Audit Report - QCSDocument16 pagesGMP Audit Report - QCSALOKE GANGULY100% (2)

- Validation Plan For Hvac: (Heating, Ventilation and Air Conditioning)Document51 pagesValidation Plan For Hvac: (Heating, Ventilation and Air Conditioning)constantin.iacomi3837100% (1)

- CPN Electronics Quality ManualDocument32 pagesCPN Electronics Quality Manualfogelman900% (1)

- Title: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesDocument21 pagesTitle: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesbpharmbaNo ratings yet

- BRSM Form 009 - QMS MDD IsvDocument16 pagesBRSM Form 009 - QMS MDD IsvAnonymous q8lh3fldWMNo ratings yet

- QMS Control of Equipment Validation and MaintenanceDocument3 pagesQMS Control of Equipment Validation and MaintenanceKamran VardagNo ratings yet

- QSP 7.5 Documented Information Rev 01Document8 pagesQSP 7.5 Documented Information Rev 01Ulhas KavathekarNo ratings yet

- QC ManualDocument15 pagesQC ManualAbuAbdullah KhanNo ratings yet

- Quality System Manual DOC. No. QSM - 04 REV. No. 01 Quality Management System Date Page No. 1 of 4Document4 pagesQuality System Manual DOC. No. QSM - 04 REV. No. 01 Quality Management System Date Page No. 1 of 4Sekar KrishNo ratings yet

- PSM Audit Procedure Final 1Document14 pagesPSM Audit Procedure Final 1Simon TounsiNo ratings yet

- 003 Change ControlDocument7 pages003 Change Controlkardam.bajajfNo ratings yet

- QSP-000001 - Rev 15 - Quality Management Systems Manual207Document24 pagesQSP-000001 - Rev 15 - Quality Management Systems Manual207Cornel SanduNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Monitoring and Measurement of Product and ProcessesDocument8 pagesMonitoring and Measurement of Product and ProcessestriveshNo ratings yet

- BRSM Form 009 Qms MDD - TJDocument15 pagesBRSM Form 009 Qms MDD - TJAnonymous q8lh3fldWMNo ratings yet

- Sabp Z 017Document59 pagesSabp Z 017Hassan MokhtarNo ratings yet

- Quality Manual: Advanced Metrology Calibration LaboratoryDocument32 pagesQuality Manual: Advanced Metrology Calibration LaboratorymffmadiNo ratings yet

- APQP Supplier ProcedureDocument20 pagesAPQP Supplier ProcedurepharmatonNo ratings yet

- NEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance ProcedureDocument13 pagesNEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance Procedurealialharbi021No ratings yet

- Management RevuewDocument4 pagesManagement RevuewEDWARD ACHEAMPONGNo ratings yet

- Quality Management System Manual: QM-00 Index (Full Text)Document5 pagesQuality Management System Manual: QM-00 Index (Full Text)Sara AbahmaneNo ratings yet

- Quality Management System Manual: QM-00 Index (Full Text)Document5 pagesQuality Management System Manual: QM-00 Index (Full Text)Quality and Safety Consultants Co.No ratings yet

- HVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesDocument10 pagesHVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesSandro SotomayorNo ratings yet

- OPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceDocument15 pagesOPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- Validation Plan For Purified Water Generation and Distribution SystemDocument49 pagesValidation Plan For Purified Water Generation and Distribution SystemPrashansa Shrestha100% (2)

- NRC Inspection ManualDocument18 pagesNRC Inspection Manualelsayed abdemagiedNo ratings yet

- Cleaning Validation Cleaning Validation Is A Validation Program To VerifyDocument27 pagesCleaning Validation Cleaning Validation Is A Validation Program To Verify董彬彬100% (2)

- 00 Saip 72Document6 pages00 Saip 72Erin JohnsonNo ratings yet

- 4.0 - Quality Management SystemsDocument6 pages4.0 - Quality Management SystemsDn MldoNo ratings yet

- Abc Company Limited Quality Management System Manual: Procedure For Performance EvaluationDocument3 pagesAbc Company Limited Quality Management System Manual: Procedure For Performance EvaluationISODCC DSPINo ratings yet

- Saep 349 PDFDocument41 pagesSaep 349 PDFRami ElloumiNo ratings yet

- QCP Installation of Ahu FahuDocument7 pagesQCP Installation of Ahu FahuThulani DlaminiNo ratings yet

- QSP 05 Internal AuditsDocument7 pagesQSP 05 Internal Auditskmvimal36No ratings yet

- AC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Document9 pagesAC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Ravi Kumar100% (1)

- BRSM Form 009 - QMS MDD HMDDocument14 pagesBRSM Form 009 - QMS MDD HMDAnonymous q8lh3fldWMNo ratings yet

- ISO 13485 Quality Manual Example 3Document34 pagesISO 13485 Quality Manual Example 3phongbuitmvNo ratings yet

- NRC Inspection ManualDocument15 pagesNRC Inspection Manualelsayed abdemagiedNo ratings yet

- SOP For Validation Master PlanDocument19 pagesSOP For Validation Master Planmansi.mehta1503No ratings yet

- PDPMAN-FM-119 - Quality Assurance Tender Evaluation Report - Rev4Document4 pagesPDPMAN-FM-119 - Quality Assurance Tender Evaluation Report - Rev4LesegoNo ratings yet

- HVAC SYSTEM RE-QUALIFICATION PROTOCOL - Pharmaceutical Guidance PDFDocument22 pagesHVAC SYSTEM RE-QUALIFICATION PROTOCOL - Pharmaceutical Guidance PDFShubam SharmaNo ratings yet

- Supplier Quality Manual: ModificationDocument36 pagesSupplier Quality Manual: ModificationSuresh VeluNo ratings yet

- Procedure Number: QAP-08.6 Revision: AJ Page 1 of 17 Corrective and Preventive Action Procedure 1.0 PurposeDocument17 pagesProcedure Number: QAP-08.6 Revision: AJ Page 1 of 17 Corrective and Preventive Action Procedure 1.0 PurposeGonzalo InnNo ratings yet

- Validation ProtocolDocument63 pagesValidation ProtocolDarlenis RodriguezNo ratings yet

- Sabp Z 017Document72 pagesSabp Z 017Salvatore MasalaNo ratings yet

- 2022 Maintenance Pillar Handbook (180-240)Document61 pages2022 Maintenance Pillar Handbook (180-240)verimbomonarcaNo ratings yet

- HVAC ValidationDocument15 pagesHVAC Validationpiyusharora1964100% (4)

- QAP - 1 Project QAPDocument77 pagesQAP - 1 Project QAPnevinpaul1234No ratings yet

- 63 Leak TesterDocument6 pages63 Leak Testersystacare remediesNo ratings yet

- Internal AuditDocument4 pagesInternal AuditYogesh bhatNo ratings yet

- Quality System Process Manual (In Accordance With ISO 9001:2015) Distribution & Change ControlDocument1 pageQuality System Process Manual (In Accordance With ISO 9001:2015) Distribution & Change Controlsasi10000No ratings yet

- Plantwide Control: Recent Developments and ApplicationsFrom EverandPlantwide Control: Recent Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Food Safety PolicyDocument1 pageFood Safety PolicynormalNo ratings yet

- FDA Draft Guidance - Enforcement of IND Safety Reporting RequirementsDocument4 pagesFDA Draft Guidance - Enforcement of IND Safety Reporting RequirementsnormalNo ratings yet

- Employee Safety SurveyDocument2 pagesEmployee Safety SurveynormalNo ratings yet

- Safety Costs CalculatorDocument12 pagesSafety Costs CalculatornormalNo ratings yet

- OHSAS 18001 - 2007 Summary of ChangesDocument12 pagesOHSAS 18001 - 2007 Summary of ChangesnormalNo ratings yet

- Principles of BS OHSAS 18001Document2 pagesPrinciples of BS OHSAS 18001normalNo ratings yet

- Safety Report Completion and Circulation InstructionsDocument1 pageSafety Report Completion and Circulation InstructionsnormalNo ratings yet

- Basic SafetyDocument13 pagesBasic SafetynormalNo ratings yet

- All Check List SafetyDocument5 pagesAll Check List SafetynormalNo ratings yet

- Safety and The Red Bead ExperimentDocument6 pagesSafety and The Red Bead ExperimentnormalNo ratings yet

- Safety 1Document15 pagesSafety 1normalNo ratings yet

- SafetyDocument3 pagesSafetynormalNo ratings yet

- Field Safety Corrective Action 2 12 1-Fsca enDocument1 pageField Safety Corrective Action 2 12 1-Fsca ennormalNo ratings yet

- 2009 OHSAS Standards and Certificates Survey Results DataDocument75 pages2009 OHSAS Standards and Certificates Survey Results DatanormalNo ratings yet

- Use of Safety and Process Standards in The Lifecycle of Medical Devices - Initial Conceptual DraDocument1 pageUse of Safety and Process Standards in The Lifecycle of Medical Devices - Initial Conceptual DranormalNo ratings yet

- R 21-04 Safety Work PermitDocument2 pagesR 21-04 Safety Work PermitnormalNo ratings yet

- Appendix 8A - Safety ChecklistDocument4 pagesAppendix 8A - Safety ChecklistnormalNo ratings yet

- Notification No99 Bio Safety JapanDocument8 pagesNotification No99 Bio Safety JapannormalNo ratings yet

- Safety 1Document15 pagesSafety 1normalNo ratings yet

- DOE O 231.1A CHG 1 Environment, Safety and Health ReportingDocument11 pagesDOE O 231.1A CHG 1 Environment, Safety and Health ReportingnormalNo ratings yet

- Safety WireDocument8 pagesSafety WirenormalNo ratings yet

- AITM-040, Rev. 2 - 05.03.2014 - Health & Safety Employee IndoctrinationDocument13 pagesAITM-040, Rev. 2 - 05.03.2014 - Health & Safety Employee IndoctrinationnormalNo ratings yet

- WW Qualen V Safety MGMTDocument24 pagesWW Qualen V Safety MGMTnormalNo ratings yet

- FOD and Safety Inspection ChecklistDocument1 pageFOD and Safety Inspection ChecklistnormalNo ratings yet

- Slaying Workplace Safety CostsDocument14 pagesSlaying Workplace Safety CostsnormalNo ratings yet

- Safety FMEADocument4 pagesSafety FMEAnormalNo ratings yet

- Safety Award WinnnersDocument11 pagesSafety Award WinnnersnormalNo ratings yet

- Behavioral Safety Audit FormDocument1 pageBehavioral Safety Audit FormnormalNo ratings yet

- 2011 OHSAS Standards and Certificates Survey Results DataDocument99 pages2011 OHSAS Standards and Certificates Survey Results DatanormalNo ratings yet

- Safety WireDocument5 pagesSafety WirenormalNo ratings yet

- Keybords Google AdsDocument91 pagesKeybords Google AdsAaditya PokhrelNo ratings yet

- Parent Child Relationships PDFDocument6 pagesParent Child Relationships PDFEffe FizfeNo ratings yet

- Prevalence and Associated Risk Factors of Sepsis Among Neonates Admitted Into Neonatal Intensive Care Units of Public Hospitals in DhakaDocument12 pagesPrevalence and Associated Risk Factors of Sepsis Among Neonates Admitted Into Neonatal Intensive Care Units of Public Hospitals in DhakaAnonymous SMLzNANo ratings yet

- VgsbwgyhcxbDocument24 pagesVgsbwgyhcxbmebibegNo ratings yet

- Ayushman Bharat General Surgery List 5Document3 pagesAyushman Bharat General Surgery List 5Rahul SakalleNo ratings yet

- Land Acquisition Act 2013Document53 pagesLand Acquisition Act 2013pankaj suryaNo ratings yet

- Fitness and Health 2015Document6 pagesFitness and Health 2015cn_cadillacmiNo ratings yet

- Lapkin Dini Feb 2023Document10 pagesLapkin Dini Feb 2023s6fjfw77v7No ratings yet

- Focus On Field EpidemiologyDocument6 pagesFocus On Field EpidemiologyFrancescoBarberoNo ratings yet

- How To Use The Obagi Nu Derm System With Inance Fade Cream and RetinolDocument4 pagesHow To Use The Obagi Nu Derm System With Inance Fade Cream and RetinolEuro AccessNo ratings yet

- Full Download Conceptual Foundations The Bridge To Professional Nursing Practice 6th Edition Friberg Test BankDocument36 pagesFull Download Conceptual Foundations The Bridge To Professional Nursing Practice 6th Edition Friberg Test Banklundvallsmiths2266100% (40)

- Case StudyDocument7 pagesCase StudyJoseph ValenciaNo ratings yet

- (Ebook) CISSP Business Continuity Planning - BCPDocument67 pages(Ebook) CISSP Business Continuity Planning - BCPIon VladNo ratings yet

- Republic Act No. 8749Document72 pagesRepublic Act No. 8749Vanjared OcampoNo ratings yet

- Lung CancerDocument45 pagesLung CancerNurul AzizahNo ratings yet

- Daftar Obat Emergency KitDocument8 pagesDaftar Obat Emergency KitvidyaNo ratings yet

- Nutrition For Wellness: 2010 Cengage-WadsworthDocument26 pagesNutrition For Wellness: 2010 Cengage-WadsworthTes Say EamNo ratings yet

- Masterkure 260-V1-Asean-0614 - Concrete - Building EngineeringDocument4 pagesMasterkure 260-V1-Asean-0614 - Concrete - Building Engineeringkpher29No ratings yet

- Ebn - MGDocument5 pagesEbn - MGLemuel Glenn BautistaNo ratings yet

- Operation Mother Hunter HunterDocument7 pagesOperation Mother Hunter Huntercowtankerous387No ratings yet

- In The Court of Appeal of The Democratic Socialist Republic of Sri LankaDocument13 pagesIn The Court of Appeal of The Democratic Socialist Republic of Sri LankaMalith DhananjayaNo ratings yet

- Krishn PradumnDocument55 pagesKrishn Pradumnjitendra kumarNo ratings yet

- (Yaqiqa-77714328650) Roy Waidler, Editor - Select Articles On Amanita Muscaria and Amanita Pantherina-Outlands Community Press (2019)Document240 pages(Yaqiqa-77714328650) Roy Waidler, Editor - Select Articles On Amanita Muscaria and Amanita Pantherina-Outlands Community Press (2019)José Manuel MejíaNo ratings yet

- Soal Kelas XI KTSPDocument13 pagesSoal Kelas XI KTSPFarid HidayatNo ratings yet

- 56-Article Text-444-2-10-20221223Document7 pages56-Article Text-444-2-10-20221223fauziah qurrota a'yuniNo ratings yet

- Lasa NorumDocument17 pagesLasa NorumIFRS Citra HusadaNo ratings yet

- CTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyDocument46 pagesCTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyashwanNo ratings yet

Air Safety PRP

Air Safety PRP

Uploaded by

normalOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Safety PRP

Air Safety PRP

Uploaded by

normalCopyright:

Available Formats

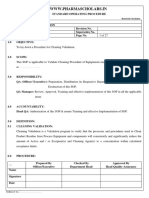

Doc.

Number: Title: AIR SAFETY PRP Page 1 of 2

Prepared by: Quality Systems Coordinator Revision No: 00

Sign:

Reviewed by: QAE Manager Status: Current

Sign:

Authorized by: Operations Manager Issue Date:

31/01/08

1. PURPOSE

- Controlling product contamination from use of unclean air.

- Controlling micro growth in air supply systems used in processing areas

2. SCOPE

-This procedure covers ventilation systems, air conditioning systems and

compressed air supplies at manufacturing plant.

3. ABBREVIATIONS

QAD – Quality Assurance Dept

QAEM – Quality Assurance & Environment Manager

KO – Coca-Cola Company

TB – Technical Bulletin

4. PROGRAM

4.1 Air conveyors

- All air used in air conveyors is filtered to remove dust and other

contaminants. The filters are checked for damage and cleanliness as per

Maintenance Schedule: SH-EM-WA-02 Dirty filters will either be

cleaned or replaced as is necessary

- Filter sizes will be as follows:

Location System Filter size

Dry area Air conveyors 25micron

4.2 Compressed air

- Compressed air supply is filtered using filters <50microns in size.

Location Filter size

Blow molding 25 micron filter

Doc. Number: Title: AIR SAFETY PRP Page 2 of 2

Prepared by: Quality Systems Coordinator Revision No: 00

Sign:

Reviewed by: QAE Manager Status: Current

Sign:

Authorized by: Operations Manager Issue Date:

31/01/08

4.3 Environment Air quality

- Air quality in processing areas will be monitored by environmental swabs.

Refer to Micro Monitoring plan SH-QA-PR-04 and Air Quality report

form SH-QA-FM-05

5. TRAINING

- All personnel involved in carrying out this procedure will be trained as per

Training Program SH-CP-PR-03 in the following areas:

• This procedure and the appropriate documentation.

6. CORRECTIVE ACTION

The QAEM will take corrective action if this programme is found to be

ineffective. The corrective action may include:

• Retraining of associates

• Revising the programme

Any corrective action is done as per Corrective Action programme SH-CP-PR-05.

7. RECORDS

In the course of implementing this programme, all records generated shall be

maintained as detailed in the Record Keeping Program SH-CP-PR-06.

8. REFERENCES

This programme addresses requirements:

a. BO-RQ-770

b. SANS 049 “Food Hygiene management”

You might also like

- Sample Request Letter To Conduct A StudyDocument2 pagesSample Request Letter To Conduct A StudyGail A89% (9)

- HVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesDocument18 pagesHVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesFabiola Olivares100% (2)

- TEMPLATE FOR OPERATIONAL QUALIFICATION PROTOCOL - Pharmaceutical GuidanceDocument7 pagesTEMPLATE FOR OPERATIONAL QUALIFICATION PROTOCOL - Pharmaceutical GuidanceMSL India100% (2)

- Process Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2Document12 pagesProcess Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2MykolaNo ratings yet

- Pharma Book Final-1Document270 pagesPharma Book Final-1Anil Kumar88% (33)

- Hvac System ValidationDocument53 pagesHvac System Validationtarique1189040100% (2)

- Instructional PlanDocument12 pagesInstructional PlanChristopher R. Bañez IINo ratings yet

- MSP ProceduresDocument18 pagesMSP ProcedurestarunNo ratings yet

- Qad Sop 129Document4 pagesQad Sop 129Hemendra DaveNo ratings yet

- SIEMENS Corrective and Preventive ActionDocument9 pagesSIEMENS Corrective and Preventive ActionOlakunle AwoniyiNo ratings yet

- SOP DocumentDocument10 pagesSOP Documentsh78129No ratings yet

- QSP 07 CAPA Rev 1Document4 pagesQSP 07 CAPA Rev 1kmvimal36No ratings yet

- GMP Audit Report - QCSDocument16 pagesGMP Audit Report - QCSALOKE GANGULY100% (2)

- Validation Plan For Hvac: (Heating, Ventilation and Air Conditioning)Document51 pagesValidation Plan For Hvac: (Heating, Ventilation and Air Conditioning)constantin.iacomi3837100% (1)

- CPN Electronics Quality ManualDocument32 pagesCPN Electronics Quality Manualfogelman900% (1)

- Title: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesDocument21 pagesTitle: Table of Contents Section: QM 0.1: Quality Manual As Per ICH GuidelinesbpharmbaNo ratings yet

- BRSM Form 009 - QMS MDD IsvDocument16 pagesBRSM Form 009 - QMS MDD IsvAnonymous q8lh3fldWMNo ratings yet

- QMS Control of Equipment Validation and MaintenanceDocument3 pagesQMS Control of Equipment Validation and MaintenanceKamran VardagNo ratings yet

- QSP 7.5 Documented Information Rev 01Document8 pagesQSP 7.5 Documented Information Rev 01Ulhas KavathekarNo ratings yet

- QC ManualDocument15 pagesQC ManualAbuAbdullah KhanNo ratings yet

- Quality System Manual DOC. No. QSM - 04 REV. No. 01 Quality Management System Date Page No. 1 of 4Document4 pagesQuality System Manual DOC. No. QSM - 04 REV. No. 01 Quality Management System Date Page No. 1 of 4Sekar KrishNo ratings yet

- PSM Audit Procedure Final 1Document14 pagesPSM Audit Procedure Final 1Simon TounsiNo ratings yet

- 003 Change ControlDocument7 pages003 Change Controlkardam.bajajfNo ratings yet

- QSP-000001 - Rev 15 - Quality Management Systems Manual207Document24 pagesQSP-000001 - Rev 15 - Quality Management Systems Manual207Cornel SanduNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Monitoring and Measurement of Product and ProcessesDocument8 pagesMonitoring and Measurement of Product and ProcessestriveshNo ratings yet

- BRSM Form 009 Qms MDD - TJDocument15 pagesBRSM Form 009 Qms MDD - TJAnonymous q8lh3fldWMNo ratings yet

- Sabp Z 017Document59 pagesSabp Z 017Hassan MokhtarNo ratings yet

- Quality Manual: Advanced Metrology Calibration LaboratoryDocument32 pagesQuality Manual: Advanced Metrology Calibration LaboratorymffmadiNo ratings yet

- APQP Supplier ProcedureDocument20 pagesAPQP Supplier ProcedurepharmatonNo ratings yet

- NEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance ProcedureDocument13 pagesNEOPRSP011 - Rev. 00 - Pages 11 - Plant Operation Quality Assurance Procedurealialharbi021No ratings yet

- Management RevuewDocument4 pagesManagement RevuewEDWARD ACHEAMPONGNo ratings yet

- Quality Management System Manual: QM-00 Index (Full Text)Document5 pagesQuality Management System Manual: QM-00 Index (Full Text)Sara AbahmaneNo ratings yet

- Quality Management System Manual: QM-00 Index (Full Text)Document5 pagesQuality Management System Manual: QM-00 Index (Full Text)Quality and Safety Consultants Co.No ratings yet

- HVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesDocument10 pagesHVAC System Qualification Protocol (Validation) - Pharmaceutical GuidelinesSandro SotomayorNo ratings yet

- OPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceDocument15 pagesOPERATION QUALIFICATION PROTOCOL FOR AIR HANDLING UNIT - Pharmaceutical GuidanceMohamad IsmailNo ratings yet

- Validation Plan For Purified Water Generation and Distribution SystemDocument49 pagesValidation Plan For Purified Water Generation and Distribution SystemPrashansa Shrestha100% (2)

- NRC Inspection ManualDocument18 pagesNRC Inspection Manualelsayed abdemagiedNo ratings yet

- Cleaning Validation Cleaning Validation Is A Validation Program To VerifyDocument27 pagesCleaning Validation Cleaning Validation Is A Validation Program To Verify董彬彬100% (2)

- 00 Saip 72Document6 pages00 Saip 72Erin JohnsonNo ratings yet

- 4.0 - Quality Management SystemsDocument6 pages4.0 - Quality Management SystemsDn MldoNo ratings yet

- Abc Company Limited Quality Management System Manual: Procedure For Performance EvaluationDocument3 pagesAbc Company Limited Quality Management System Manual: Procedure For Performance EvaluationISODCC DSPINo ratings yet

- Saep 349 PDFDocument41 pagesSaep 349 PDFRami ElloumiNo ratings yet

- QCP Installation of Ahu FahuDocument7 pagesQCP Installation of Ahu FahuThulani DlaminiNo ratings yet

- QSP 05 Internal AuditsDocument7 pagesQSP 05 Internal Auditskmvimal36No ratings yet

- AC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Document9 pagesAC7109 Rev D - Nadcap Audit Criteria For Coatings (To Be Used On or AFTER 18-Aug-13)Ravi Kumar100% (1)

- BRSM Form 009 - QMS MDD HMDDocument14 pagesBRSM Form 009 - QMS MDD HMDAnonymous q8lh3fldWMNo ratings yet

- ISO 13485 Quality Manual Example 3Document34 pagesISO 13485 Quality Manual Example 3phongbuitmvNo ratings yet

- NRC Inspection ManualDocument15 pagesNRC Inspection Manualelsayed abdemagiedNo ratings yet

- SOP For Validation Master PlanDocument19 pagesSOP For Validation Master Planmansi.mehta1503No ratings yet

- PDPMAN-FM-119 - Quality Assurance Tender Evaluation Report - Rev4Document4 pagesPDPMAN-FM-119 - Quality Assurance Tender Evaluation Report - Rev4LesegoNo ratings yet

- HVAC SYSTEM RE-QUALIFICATION PROTOCOL - Pharmaceutical Guidance PDFDocument22 pagesHVAC SYSTEM RE-QUALIFICATION PROTOCOL - Pharmaceutical Guidance PDFShubam SharmaNo ratings yet

- Supplier Quality Manual: ModificationDocument36 pagesSupplier Quality Manual: ModificationSuresh VeluNo ratings yet

- Procedure Number: QAP-08.6 Revision: AJ Page 1 of 17 Corrective and Preventive Action Procedure 1.0 PurposeDocument17 pagesProcedure Number: QAP-08.6 Revision: AJ Page 1 of 17 Corrective and Preventive Action Procedure 1.0 PurposeGonzalo InnNo ratings yet

- Validation ProtocolDocument63 pagesValidation ProtocolDarlenis RodriguezNo ratings yet

- Sabp Z 017Document72 pagesSabp Z 017Salvatore MasalaNo ratings yet

- 2022 Maintenance Pillar Handbook (180-240)Document61 pages2022 Maintenance Pillar Handbook (180-240)verimbomonarcaNo ratings yet

- HVAC ValidationDocument15 pagesHVAC Validationpiyusharora1964100% (4)

- QAP - 1 Project QAPDocument77 pagesQAP - 1 Project QAPnevinpaul1234No ratings yet

- 63 Leak TesterDocument6 pages63 Leak Testersystacare remediesNo ratings yet

- Internal AuditDocument4 pagesInternal AuditYogesh bhatNo ratings yet

- Quality System Process Manual (In Accordance With ISO 9001:2015) Distribution & Change ControlDocument1 pageQuality System Process Manual (In Accordance With ISO 9001:2015) Distribution & Change Controlsasi10000No ratings yet

- Plantwide Control: Recent Developments and ApplicationsFrom EverandPlantwide Control: Recent Developments and ApplicationsGade Pandu RangaiahNo ratings yet

- Food Safety PolicyDocument1 pageFood Safety PolicynormalNo ratings yet

- FDA Draft Guidance - Enforcement of IND Safety Reporting RequirementsDocument4 pagesFDA Draft Guidance - Enforcement of IND Safety Reporting RequirementsnormalNo ratings yet

- Employee Safety SurveyDocument2 pagesEmployee Safety SurveynormalNo ratings yet

- Safety Costs CalculatorDocument12 pagesSafety Costs CalculatornormalNo ratings yet

- OHSAS 18001 - 2007 Summary of ChangesDocument12 pagesOHSAS 18001 - 2007 Summary of ChangesnormalNo ratings yet

- Principles of BS OHSAS 18001Document2 pagesPrinciples of BS OHSAS 18001normalNo ratings yet

- Safety Report Completion and Circulation InstructionsDocument1 pageSafety Report Completion and Circulation InstructionsnormalNo ratings yet

- Basic SafetyDocument13 pagesBasic SafetynormalNo ratings yet

- All Check List SafetyDocument5 pagesAll Check List SafetynormalNo ratings yet

- Safety and The Red Bead ExperimentDocument6 pagesSafety and The Red Bead ExperimentnormalNo ratings yet

- Safety 1Document15 pagesSafety 1normalNo ratings yet

- SafetyDocument3 pagesSafetynormalNo ratings yet

- Field Safety Corrective Action 2 12 1-Fsca enDocument1 pageField Safety Corrective Action 2 12 1-Fsca ennormalNo ratings yet

- 2009 OHSAS Standards and Certificates Survey Results DataDocument75 pages2009 OHSAS Standards and Certificates Survey Results DatanormalNo ratings yet

- Use of Safety and Process Standards in The Lifecycle of Medical Devices - Initial Conceptual DraDocument1 pageUse of Safety and Process Standards in The Lifecycle of Medical Devices - Initial Conceptual DranormalNo ratings yet

- R 21-04 Safety Work PermitDocument2 pagesR 21-04 Safety Work PermitnormalNo ratings yet

- Appendix 8A - Safety ChecklistDocument4 pagesAppendix 8A - Safety ChecklistnormalNo ratings yet

- Notification No99 Bio Safety JapanDocument8 pagesNotification No99 Bio Safety JapannormalNo ratings yet

- Safety 1Document15 pagesSafety 1normalNo ratings yet

- DOE O 231.1A CHG 1 Environment, Safety and Health ReportingDocument11 pagesDOE O 231.1A CHG 1 Environment, Safety and Health ReportingnormalNo ratings yet

- Safety WireDocument8 pagesSafety WirenormalNo ratings yet

- AITM-040, Rev. 2 - 05.03.2014 - Health & Safety Employee IndoctrinationDocument13 pagesAITM-040, Rev. 2 - 05.03.2014 - Health & Safety Employee IndoctrinationnormalNo ratings yet

- WW Qualen V Safety MGMTDocument24 pagesWW Qualen V Safety MGMTnormalNo ratings yet

- FOD and Safety Inspection ChecklistDocument1 pageFOD and Safety Inspection ChecklistnormalNo ratings yet

- Slaying Workplace Safety CostsDocument14 pagesSlaying Workplace Safety CostsnormalNo ratings yet

- Safety FMEADocument4 pagesSafety FMEAnormalNo ratings yet

- Safety Award WinnnersDocument11 pagesSafety Award WinnnersnormalNo ratings yet

- Behavioral Safety Audit FormDocument1 pageBehavioral Safety Audit FormnormalNo ratings yet

- 2011 OHSAS Standards and Certificates Survey Results DataDocument99 pages2011 OHSAS Standards and Certificates Survey Results DatanormalNo ratings yet

- Safety WireDocument5 pagesSafety WirenormalNo ratings yet

- Keybords Google AdsDocument91 pagesKeybords Google AdsAaditya PokhrelNo ratings yet

- Parent Child Relationships PDFDocument6 pagesParent Child Relationships PDFEffe FizfeNo ratings yet

- Prevalence and Associated Risk Factors of Sepsis Among Neonates Admitted Into Neonatal Intensive Care Units of Public Hospitals in DhakaDocument12 pagesPrevalence and Associated Risk Factors of Sepsis Among Neonates Admitted Into Neonatal Intensive Care Units of Public Hospitals in DhakaAnonymous SMLzNANo ratings yet

- VgsbwgyhcxbDocument24 pagesVgsbwgyhcxbmebibegNo ratings yet

- Ayushman Bharat General Surgery List 5Document3 pagesAyushman Bharat General Surgery List 5Rahul SakalleNo ratings yet

- Land Acquisition Act 2013Document53 pagesLand Acquisition Act 2013pankaj suryaNo ratings yet

- Fitness and Health 2015Document6 pagesFitness and Health 2015cn_cadillacmiNo ratings yet

- Lapkin Dini Feb 2023Document10 pagesLapkin Dini Feb 2023s6fjfw77v7No ratings yet

- Focus On Field EpidemiologyDocument6 pagesFocus On Field EpidemiologyFrancescoBarberoNo ratings yet

- How To Use The Obagi Nu Derm System With Inance Fade Cream and RetinolDocument4 pagesHow To Use The Obagi Nu Derm System With Inance Fade Cream and RetinolEuro AccessNo ratings yet

- Full Download Conceptual Foundations The Bridge To Professional Nursing Practice 6th Edition Friberg Test BankDocument36 pagesFull Download Conceptual Foundations The Bridge To Professional Nursing Practice 6th Edition Friberg Test Banklundvallsmiths2266100% (40)

- Case StudyDocument7 pagesCase StudyJoseph ValenciaNo ratings yet

- (Ebook) CISSP Business Continuity Planning - BCPDocument67 pages(Ebook) CISSP Business Continuity Planning - BCPIon VladNo ratings yet

- Republic Act No. 8749Document72 pagesRepublic Act No. 8749Vanjared OcampoNo ratings yet

- Lung CancerDocument45 pagesLung CancerNurul AzizahNo ratings yet

- Daftar Obat Emergency KitDocument8 pagesDaftar Obat Emergency KitvidyaNo ratings yet

- Nutrition For Wellness: 2010 Cengage-WadsworthDocument26 pagesNutrition For Wellness: 2010 Cengage-WadsworthTes Say EamNo ratings yet

- Masterkure 260-V1-Asean-0614 - Concrete - Building EngineeringDocument4 pagesMasterkure 260-V1-Asean-0614 - Concrete - Building Engineeringkpher29No ratings yet

- Ebn - MGDocument5 pagesEbn - MGLemuel Glenn BautistaNo ratings yet

- Operation Mother Hunter HunterDocument7 pagesOperation Mother Hunter Huntercowtankerous387No ratings yet

- In The Court of Appeal of The Democratic Socialist Republic of Sri LankaDocument13 pagesIn The Court of Appeal of The Democratic Socialist Republic of Sri LankaMalith DhananjayaNo ratings yet

- Krishn PradumnDocument55 pagesKrishn Pradumnjitendra kumarNo ratings yet

- (Yaqiqa-77714328650) Roy Waidler, Editor - Select Articles On Amanita Muscaria and Amanita Pantherina-Outlands Community Press (2019)Document240 pages(Yaqiqa-77714328650) Roy Waidler, Editor - Select Articles On Amanita Muscaria and Amanita Pantherina-Outlands Community Press (2019)José Manuel MejíaNo ratings yet

- Soal Kelas XI KTSPDocument13 pagesSoal Kelas XI KTSPFarid HidayatNo ratings yet

- 56-Article Text-444-2-10-20221223Document7 pages56-Article Text-444-2-10-20221223fauziah qurrota a'yuniNo ratings yet

- Lasa NorumDocument17 pagesLasa NorumIFRS Citra HusadaNo ratings yet

- CTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyDocument46 pagesCTD Dossier Preparation: K. Srikantha Reddy K. Srikantha ReddyashwanNo ratings yet