Professional Documents

Culture Documents

BrederoShaw PDS 3LPP

BrederoShaw PDS 3LPP

Uploaded by

dipankarbasakOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BrederoShaw PDS 3LPP

BrederoShaw PDS 3LPP

Uploaded by

dipankarbasakCopyright:

Available Formats

the

GLOBAL

LEADER

in pipe coating solutions.

3LPP PRODUCT DATA SHEET

Three Layer Polypropylene Coating

Oil & Gas pipelines

3

2 Large diameter pipelines

Small diameter pipelines

FBE 2 Copolymer Adhesive 3 Polypropylene High operating temperatures

PRODUCT DESCRIPTION

Bredero Shaw is the world’s leading provider of Three Layer Polypropylene Systems (3LPP).

Bredero Shaw’s 3LPP System is a multilayer coating composed of three functional components. High abrasion environments

This anti-corrosion system consists of a high performance fusion bonded epoxy (FBE) followed by

a copolymer adhesive and an outer layer of polypropylene which provides the toughest, most

durable pipe coating solution available. 3LPP Systems provide excellent pipeline protection for

small and large diameter pipelines with moderate operating temperatures.

FEATURES AND BENEFITS

High Temperature Corrosion Protection Excellent Mechanical Protection

The FBE component of the 3LPP System The tough outer layer of polypropylene

provides excellent adhesion to steel, thereby protects pipelines during transportation and

providing superior long term corrosion installation thereby reducing costly repairs

resistance and protection of pipelines while also providing added in-ground

operating at high temperatures. The superior protection against shear forces, chemicals and

adhesion properties of the FBE also results in abrasive soil conditions. By increasing the

excellent resistance to cathodic disbondment thickness of the polypropylene outer layer, the

which reduces the total cost of cathodic 3LPP System can provide the highest level of

protection during the operation of the mechanical protection across many diverse

pipeline. environments without requiring the use of

costly select backfill.

Engineered Solutions

Global Availability

Advanced manufacturing techniques allow the

3LPP System to be customized to your Bredero Shaw has a network of 27 coating

specific project. The system can be applied to plants strategically located across 6 continents

various pipe diameters from 90 mm (3.5”) to to minimize pipe transportation costs. The

over 1220 mm (48”). 3LPP System can also 3LPP System can be manufactured in a single

be applied in a wide range of thicknesses to plant or in multiple coating plants to improve

cost effectively meet unique project project logistics. High capacity within the

specifications and performance requirements. Bredero Shaw plant network allows the client

to benefit from single source advantages,

ultimately providing more cost effective

management of pipe coating needs.

www.brederoshaw.com

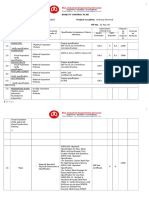

TYPICAL PRODUCT PROPERTIES

PROPERTY 3LPP

Minimum Pipe Diameter 90 mm (3.5”)

Maximum Pipe Diameter 1220 mm + (48”+)

Minimum Pipe Length 5.5 m (18’)

Maximum Pipe Length 24.4 m (80’)

Minimum Recommended Operating Temperature -40°C (-40°F)

3LPP

Maximum Recommended Operating Temperature 110°C (230°F)*

Values shown are typical and may vary from plant to plant. Consult Bredero Shaw for special requirements.

* The 3LPP product can be used at higher temperatures under certain conditions.

APPROVALS

CSA Z245.21 DIN 30678 ISO 9001:2000

DIN 30670 NF A49-711

PRODUCT APPLICATION PROCESS

Americas

Bredero Shaw

A ShawCor Company

3838 N. Sam Houston Pkwy E.

Suite 300

Houston, Texas Preheat Blast Clean Grind Surface Surface

Defects Inspection

77032-3400, USA

Telephone: +1-281-886-2350

Fax: +1-281-886-2353

Shaw Pipe

A ShawCor Company

Two Executive Place,

1824 Crowchild Trail, N.W.,

Calgary, Alberta

T2M 3Y7, Canada Extruded Extruded FBE Application Induction Final Surface

Telephone: +1-403-263-2255 Polypropylene Copolymer Heat Treatment

Fax: +1-403-264-3649

Europe/Africa/Russia

Bredero Shaw

A ShawCor Company

Imperial Dock

Leith, Edinburgh, EH6 7DT Quench Stockpile

Scotland, UK Electrical

Telephone: +44-131-553-9600 Inspection

Fax: +44-131-553-9699

Bredero Shaw Norway

A ShawCor Company PLANTS

P.O. Box 214

N-7301 Orkanger Fontana, California Pearland, Texas (planned) Monterrey, Mexico

Norway

Telephone: +47-72-46-60-60

Fax: +47-72-46-60-70 Veracruz, Mexico Belo Horizonte, Brazil Leith, Scotland

Middle East Ellon, Scotland Orkanger, Norway Enerhen/Warri, Nigeria

Bredero Shaw

A ShawCor Company

P.O.Box 1789, Onne, Nigeria Jubail, Saudi Arabia Ras Al Khaimah, UAE

Suite 402, Al Reem Plaza

Buhairah Corniche, Sharjah, U.A.E Rayong, Thailand Kuantan, Malaysia Kabil, Batam Island, Indonesia

Telephone: +971-6-573-7374

Fax: +971-6-573-7379

Kembla Grange, Australia

Far East/Australia

Bredero Shaw

A ShawCor Company BREDERO SHAW: THE GLOBAL LEADER IN PIPE COATING SOLUTIONS

101 Thomson Road

#17-01/02 United Square Bredero Shaw is the world leader in pipe coating solutions, with more than 75 years of experience, over 27 pipe

Singapore 307591 coating facilities on 6 continents and the largest team of technical and service specialists in the business. Bredero Shaw

Telephone: +65-6732-2355

Fax: +65-6732-9073 offers technologically advanced solutions for anti-corrosion coatings, protective and weight coatings, thermal flow

assurance coatings, internal coatings, custom coatings and field joints for both onshore and offshore applications.

This broad range of products and services provides Bredero Shaw with the unique capability to service the full

spectrum of pipeline protection and flow assurance requirements. Consult your Bredero Shaw representative for

your unique project requirements.

www.brederoshaw.com

The information contained herein is indicative of the types of coatings provided by Bredero Shaw, and is not intended to be a guarantee that a particular coating will be

suitable for a given application. Since many unique environmental, operating, and design conditions must be considered, the user shall determine the suitability of the

coating for the intended use and assume all the risks and liabilities in connection therewith. Bredero Shaw’s liability is stated in our standard conditions of sale.

PDS_AC_PE_rev017

You might also like

- Geely CK 2008 03Document297 pagesGeely CK 2008 03ВикторNo ratings yet

- EDI Flexair MiniPanel Spec SheetDocument2 pagesEDI Flexair MiniPanel Spec SheetKalyan Patil0% (1)

- Workover OperationsDocument73 pagesWorkover Operationsmissaoui100% (2)

- 3LPP Three Layer Polypropylene CoatingDocument3 pages3LPP Three Layer Polypropylene CoatingCarlos Maldonado SalazarNo ratings yet

- 3-Layer Polypropylene Coating: High Temperature Corrosion ProtectionDocument2 pages3-Layer Polypropylene Coating: High Temperature Corrosion Protectiona.hasan670100% (1)

- 3LPP Three Layer Polypropylene CoatingDocument3 pages3LPP Three Layer Polypropylene CoatingCarlos Maldonado SalazarNo ratings yet

- Coating FINALDocument44 pagesCoating FINALbhanumech100% (1)

- 3-Layer Polyethylene Coating: Long Term Corrosion ProtectionDocument2 pages3-Layer Polyethylene Coating: Long Term Corrosion Protectiona.hasan670No ratings yet

- 3LPE Low Temp Pipe CoatingDocument2 pages3LPE Low Temp Pipe CoatingChegg ChemNo ratings yet

- BrederoShaw PDS 3LPPDocument2 pagesBrederoShaw PDS 3LPPHamzaHashimNo ratings yet

- Brederoshaw Pds 3lpeDocument2 pagesBrederoshaw Pds 3lpejleonosNo ratings yet

- PP Proc1Document23 pagesPP Proc1lemuel bacsaNo ratings yet

- Hemipleat Tenkay Cartridge enDocument2 pagesHemipleat Tenkay Cartridge enherysyam1980No ratings yet

- Thermo-Lag 270 PDS-FireproofingDocument2 pagesThermo-Lag 270 PDS-FireproofingMohamed SedkyNo ratings yet

- TubingDataChartsDocument16 pagesTubingDataChartsoliver morellNo ratings yet

- Downdraft LRDocument4 pagesDowndraft LRkenNo ratings yet

- Bayou Products NO-AEGDocument4 pagesBayou Products NO-AEGhamza laribiNo ratings yet

- PE Media Densidad PresionesDocument2 pagesPE Media Densidad Presionesfffae123No ratings yet

- 2LPP and 3LPP Custom Coating: Two-And Three-Layer Polypropylene Anti-Corrosion Custom CoatingsDocument2 pages2LPP and 3LPP Custom Coating: Two-And Three-Layer Polypropylene Anti-Corrosion Custom Coatingsa.hasan670No ratings yet

- FlexPipe Linepipe HT Product Data SheetDocument2 pagesFlexPipe Linepipe HT Product Data SheetSaidNo ratings yet

- PS-10-13 en A4 PDFDocument36 pagesPS-10-13 en A4 PDFUlises MurielNo ratings yet

- JRGC Series TRI SHiELD FLTR Purple Engineering 1Document2 pagesJRGC Series TRI SHiELD FLTR Purple Engineering 1Idiot CommunityNo ratings yet

- Fuel Resistant Coatings: EC-776 EC-776SRDocument6 pagesFuel Resistant Coatings: EC-776 EC-776SRpokleNo ratings yet

- BrederoShaw Pertamina Balongan Presentation 2015-04-09Document51 pagesBrederoShaw Pertamina Balongan Presentation 2015-04-09FerryNo ratings yet

- Emitterline LeverDocument2 pagesEmitterline LevervictorNo ratings yet

- Disk Diffuser - ITA-ENG - Rev1 - MailDocument6 pagesDisk Diffuser - ITA-ENG - Rev1 - MailDaniele BacchiNo ratings yet

- 11 - SupaSep LGPDocument8 pages11 - SupaSep LGPDylan DooleyNo ratings yet

- GI-Endura Technical DocumentDocument24 pagesGI-Endura Technical DocumentsidhusatrupNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Module 2 Field Joint CoatingsDocument68 pagesModule 2 Field Joint CoatingsAbdul Wajid AliNo ratings yet

- Black Eagle Hose BE 4466-UKDocument44 pagesBlack Eagle Hose BE 4466-UKmhollowayNo ratings yet

- BrederoShaw PDS 3LPE PDFDocument2 pagesBrederoShaw PDS 3LPE PDFErick HoganNo ratings yet

- Hemipleat Gold Cone Cartridge enDocument2 pagesHemipleat Gold Cone Cartridge enherysyam1980No ratings yet

- Durco Mark 3: ASME (ANSI) Chemical Process PumpsDocument36 pagesDurco Mark 3: ASME (ANSI) Chemical Process PumpsMohd Danial HNo ratings yet

- Protective & Marine Coatings: Industrial Enamel Voc ComplyingDocument4 pagesProtective & Marine Coatings: Industrial Enamel Voc ComplyingAna CabreraNo ratings yet

- Polyolefin Pipe Inuslation - AerofoamDocument150 pagesPolyolefin Pipe Inuslation - AerofoamIrshad BPNo ratings yet

- Neenah Filtration PresentationDocument11 pagesNeenah Filtration PresentationSurajPandeyNo ratings yet

- Hepworth - Soil and Waste Systems 8th Version 06th July 2020 1Document44 pagesHepworth - Soil and Waste Systems 8th Version 06th July 2020 1Anand KumarNo ratings yet

- Features & Benefits: Compatible Field Joint CoatingsDocument2 pagesFeatures & Benefits: Compatible Field Joint CoatingsshantilalNo ratings yet

- Vpci - 386 Acrylic Primer/Topcoat: FeaturesDocument2 pagesVpci - 386 Acrylic Primer/Topcoat: FeaturesDenish Tiko AkbarNo ratings yet

- Cobetter BGPP160 FilterDocument1 pageCobetter BGPP160 FilterVictor LiangNo ratings yet

- Pall Water - Membranes and Modules - Microza UNA Microfiltration ModulesDocument2 pagesPall Water - Membranes and Modules - Microza UNA Microfiltration ModulesallioucheNo ratings yet

- Polylon 1900 (3853091)Document4 pagesPolylon 1900 (3853091)JOCELYN MEDINANo ratings yet

- KrahTehnJuhendENGpreview PDFDocument28 pagesKrahTehnJuhendENGpreview PDFQuerubin R Yolando Jr.No ratings yet

- SLM R 280 WebDocument6 pagesSLM R 280 WebIntaek JoNo ratings yet

- EDI FlexAir Magnum Spec SheetDocument2 pagesEDI FlexAir Magnum Spec SheetMurukan PadmanabhanNo ratings yet

- GTS-PP-120: 3 LayerDocument2 pagesGTS-PP-120: 3 Layershoaib1985100% (1)

- Product Data Sheet Triplexpro-210 Advanced Plasma Spray Gun: What'S New?Document8 pagesProduct Data Sheet Triplexpro-210 Advanced Plasma Spray Gun: What'S New?kartalizmatik54No ratings yet

- Brederoshaw Pds 3lpeDocument2 pagesBrederoshaw Pds 3lpeadvis79No ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSAnhera enterpriseNo ratings yet

- 3.2. Flowstrong Yellowbox - Product SpecsDocument16 pages3.2. Flowstrong Yellowbox - Product SpecsHussain Al SanonaNo ratings yet

- WP PPR - Thermopipe SubmittalDocument36 pagesWP PPR - Thermopipe SubmittalMohammad Rashad BarakatNo ratings yet

- Đĩa Phân Phối Khí TinhDocument2 pagesĐĩa Phân Phối Khí TinhVu DongNo ratings yet

- Carbocoat 150 Universal Primer PDSDocument2 pagesCarbocoat 150 Universal Primer PDSdibujante3No ratings yet

- AB-3P 2010 EnglishDocument12 pagesAB-3P 2010 EnglishJoseph ChongNo ratings yet

- 253 PDS AiDocument4 pages253 PDS AiHrvoje RuzicNo ratings yet

- 2179-CM CNDocument6 pages2179-CM CNHữu Khánh NguyễnNo ratings yet

- Passive Corrosion Prevention For Flanges and Valves: Product InformationDocument3 pagesPassive Corrosion Prevention For Flanges and Valves: Product InformationAnant RubadeNo ratings yet

- Trisorb 50-50 Catalogo Nuevo 1Document2 pagesTrisorb 50-50 Catalogo Nuevo 1esancheeNo ratings yet

- 3lpe & 3lpeDocument7 pages3lpe & 3lpenareshvartakNo ratings yet

- GPH-060 110Document3 pagesGPH-060 110Ben KeeNo ratings yet

- Stress Analysis of Steam Piping SystemDocument6 pagesStress Analysis of Steam Piping SystemDaniel Camilo SalamancaNo ratings yet

- Eddy Current Testing Equipment Scope in IndiaDocument19 pagesEddy Current Testing Equipment Scope in IndiaDanielNo ratings yet

- Threaded Joints in Steam Piping - Pipelines, Piping and Fluid Mechanics Engineering - Eng-TipsDocument3 pagesThreaded Joints in Steam Piping - Pipelines, Piping and Fluid Mechanics Engineering - Eng-TipsMohamedNo ratings yet

- 1129634728isrm SM Rock Stress Determination 1987 PDFDocument20 pages1129634728isrm SM Rock Stress Determination 1987 PDFDavid Almanza PerezNo ratings yet

- Tables For EN 10216-2 PDFDocument18 pagesTables For EN 10216-2 PDFAli BariNo ratings yet

- Steelworks Products and Tinsmithing ToolsDocument39 pagesSteelworks Products and Tinsmithing ToolsEli SuarezNo ratings yet

- Resume Piping Superintendent GedeandiDocument5 pagesResume Piping Superintendent GedeandiandidipayadnyaNo ratings yet

- Itp S8 CivilDocument12 pagesItp S8 CivilAnonymous G3jRndEbVNo ratings yet

- Air Compressor Installation: Engine ComponentDocument20 pagesAir Compressor Installation: Engine ComponentEduardo JuliánNo ratings yet

- Tabla Asme b31.1Document1 pageTabla Asme b31.1agustin100% (1)

- Report Date MSG Material Material Description Mat TypDocument524 pagesReport Date MSG Material Material Description Mat Typaneelbaig100% (1)

- SOUR WATER STRIPPER & DISPOSAL SYSTEM AT BERRI GAS PLANT PROGRESS MEASUREMENT SYSTEM REPORT Project ID BI-10-01628Document2 pagesSOUR WATER STRIPPER & DISPOSAL SYSTEM AT BERRI GAS PLANT PROGRESS MEASUREMENT SYSTEM REPORT Project ID BI-10-01628Er Md AamirNo ratings yet

- 01 Preliminary Design Project Summary Report FINAL 2016 07 08 PDFDocument127 pages01 Preliminary Design Project Summary Report FINAL 2016 07 08 PDFaayestaranNo ratings yet

- Repair Procedure - Zpi-3lpe-01Document3 pagesRepair Procedure - Zpi-3lpe-01Suresh KrishnanNo ratings yet

- Heated Tubing BrochureDocument5 pagesHeated Tubing BrochureGerrard ArchuletaNo ratings yet

- 14M OperatorsManualDocument16 pages14M OperatorsManualrsilvavilesNo ratings yet

- Modeling Mechanical Hydraulic Systems in SimscapeDocument42 pagesModeling Mechanical Hydraulic Systems in Simscapebee1406760% (1)

- FM Hdpe AccesoriosDocument2 pagesFM Hdpe AccesoriosWuills GutierrezNo ratings yet

- Pipe Stress AnalysisDocument7 pagesPipe Stress AnalysisTushar NaikNo ratings yet

- (International Centre For Mechanical Sciences 394) Károly Jármai, József Farkas (Eds.) - Mechanics and Design of Tubular Structures-Springer-Verlag Wien (1998) PDFDocument343 pages(International Centre For Mechanical Sciences 394) Károly Jármai, József Farkas (Eds.) - Mechanics and Design of Tubular Structures-Springer-Verlag Wien (1998) PDFJoel Medeiros100% (1)

- Simona PE 100 AP-Line: Pipes and Fittings For Transporting SolidsDocument6 pagesSimona PE 100 AP-Line: Pipes and Fittings For Transporting SolidsBexy Nathaly DiazNo ratings yet

- Co2 Fire Extinguishing SystemDocument20 pagesCo2 Fire Extinguishing Systemm2110No ratings yet

- PA / 1G / 1F: This Is The Flat Position, in Which The Welder Has The Piece Right Below The Torch, ThisDocument8 pagesPA / 1G / 1F: This Is The Flat Position, in Which The Welder Has The Piece Right Below The Torch, ThisHitesh MhatreNo ratings yet

- Alarm Valve GongDocument4 pagesAlarm Valve GongAnonymous 7z6OzoNo ratings yet

- QCVN 13-2018-BXD National Technical Regulation On Car Parking (Eng)Document29 pagesQCVN 13-2018-BXD National Technical Regulation On Car Parking (Eng)lwin_oo2435100% (1)

- Flue Gas Recirculation Equipment SpecificationDocument12 pagesFlue Gas Recirculation Equipment Specificationssmith2007No ratings yet

- 01 Samss 029Document23 pages01 Samss 029faisalNo ratings yet

- Constant Hanger and SupportDocument3 pagesConstant Hanger and Supportivan jhonatanNo ratings yet