Professional Documents

Culture Documents

MONTABERT

MONTABERT

Uploaded by

MiguelCopyright:

Available Formats

You might also like

- 16-400 enDocument145 pages16-400 enluis_erf22No ratings yet

- YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesYL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- AISE 6 (1991) - Specification For Electric Overhead Traveling Cranes For Steel Mill ServiceDocument112 pagesAISE 6 (1991) - Specification For Electric Overhead Traveling Cranes For Steel Mill Servicefaelbritos67% (6)

- Volvo PentaDocument250 pagesVolvo Pentaweler13100% (2)

- Engineered Connectors: XL SystemsDocument93 pagesEngineered Connectors: XL Systemsisrael11288100% (1)

- Me7 Tuner Wizzard - XLSM - 0Document81 pagesMe7 Tuner Wizzard - XLSM - 0lytoselputoamoNo ratings yet

- MC Injection Spec2023Document1 pageMC Injection Spec2023anandan777No ratings yet

- SNXR Series - 2023Document2 pagesSNXR Series - 2023isgectraineeNo ratings yet

- WC67K EngDocument8 pagesWC67K Engclaudio ponceNo ratings yet

- Drills 7 TappersDocument10 pagesDrills 7 TappersBe HappyNo ratings yet

- Funeec Solid Carbide - Price ListDocument12 pagesFuneec Solid Carbide - Price ListdpshradhaNo ratings yet

- Performances and Characteristics: JH21-200 SpecificationDocument2 pagesPerformances and Characteristics: JH21-200 SpecificationAlexandreNo ratings yet

- MRS Extruder: Technical DataDocument1 pageMRS Extruder: Technical DataPedro PeñateNo ratings yet

- Bolts Torque ChartDocument13 pagesBolts Torque ChartkhaireddinNo ratings yet

- Kawaguchi SeriesDocument2 pagesKawaguchi SeriesSuranga PriyadarshanaNo ratings yet

- 05.fabricated HDPE Tee R07Document7 pages05.fabricated HDPE Tee R07kuntasee.duckNo ratings yet

- MEDIDAS TURBINA Dresser Imtm MeretDocument3 pagesMEDIDAS TURBINA Dresser Imtm MeretronaldNo ratings yet

- UPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber SimplexDocument4 pagesUPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber Simplexwaqasasad408No ratings yet

- Catalouge GTRDocument2 pagesCatalouge GTRMr Nilesh ShahNo ratings yet

- Injection Molding Machine Ns SeriesDocument2 pagesInjection Molding Machine Ns SeriesmastersupportNo ratings yet

- A. K. Steels: Cutting Rate ListDocument2 pagesA. K. Steels: Cutting Rate ListRam PatelNo ratings yet

- TNN CNC Lathe Machine CatalogueDocument3 pagesTNN CNC Lathe Machine Catalogueneda100% (1)

- CU400 CU500: Machine SpecificationDocument4 pagesCU400 CU500: Machine SpecificationГеорги НеновNo ratings yet

- Power Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsDocument2 pagesPower Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsRadiadores PlanosNo ratings yet

- SNX-2 Point Series - 2023Document2 pagesSNX-2 Point Series - 2023isgectraineeNo ratings yet

- Flexitallic Tabla de TorqueDocument2 pagesFlexitallic Tabla de TorqueWalter100% (1)

- Torque Chart Spiral Wound GasketsDocument2 pagesTorque Chart Spiral Wound GasketsMocanu MarianNo ratings yet

- Table of Lap Splices 4000 PsiDocument1 pageTable of Lap Splices 4000 PsiGelo GuansingNo ratings yet

- Nonreturn Tilting Disc Check Valve Art c01Document2 pagesNonreturn Tilting Disc Check Valve Art c01zayerirezaNo ratings yet

- C10T10 14Document4 pagesC10T10 14floreswgNo ratings yet

- AFAFR EngDocument16 pagesAFAFR EngcoachanzaiNo ratings yet

- Hunsone CNC Machine CatalogueDocument38 pagesHunsone CNC Machine CatalogueLucy MontfortNo ratings yet

- Okada Top SeriesDocument2 pagesOkada Top SeriessinanNo ratings yet

- Dokumen - Tips - Hatlapa Steering Gear Triton PDFDocument3 pagesDokumen - Tips - Hatlapa Steering Gear Triton PDFThanh Nghị BùiNo ratings yet

- Apex Dynamics, Inc.: AB / ABR SeriesDocument14 pagesApex Dynamics, Inc.: AB / ABR SeriesIqtidar GulNo ratings yet

- Cys-B (16) (TM) (V1016)Document1 pageCys-B (16) (TM) (V1016)Azwan SunlineNo ratings yet

- Charts & Tables Charts & Tables: TEKNOMEGA TOP Busbar Support Fault Level ChartDocument1 pageCharts & Tables Charts & Tables: TEKNOMEGA TOP Busbar Support Fault Level Chartmuqtar4uNo ratings yet

- Round Cutting ListDocument2 pagesRound Cutting ListSachin PatelNo ratings yet

- CU400M CU500M CU580M: Machine SpecificationDocument4 pagesCU400M CU500M CU580M: Machine SpecificationEl nabahin FerasNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- Pinbush - Tyre Coupling 2014Document4 pagesPinbush - Tyre Coupling 2014Priyam NandwanaNo ratings yet

- MRTHD Komac KB350 - Equipos 60000248 PDFDocument1 pageMRTHD Komac KB350 - Equipos 60000248 PDFJairresistenciagt123No ratings yet

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- VALVES Technical Catalog: Catálogo Técnico ValvoleDocument11 pagesVALVES Technical Catalog: Catálogo Técnico ValvoleMohamed Raafat0% (1)

- Hydraulic Swing Beam Shears: WWW - Adira.ptDocument2 pagesHydraulic Swing Beam Shears: WWW - Adira.pttahirNo ratings yet

- Scheda ColdDocument1 pageScheda ColdOleksandr BalychevNo ratings yet

- Structure: MM, MF, FF, FN, K-MMDocument7 pagesStructure: MM, MF, FF, FN, K-MMAji Kurniawan RahmanNo ratings yet

- G-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration NonwovensDocument1 pageG-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration Nonwovensfer17165No ratings yet

- Flange Sizing ProgramDocument15 pagesFlange Sizing Program심판자No ratings yet

- Flange Sizing ProgramDocument15 pagesFlange Sizing Program심판자0% (1)

- Mordaza Epiroc Cc1700 UDocument2 pagesMordaza Epiroc Cc1700 URodolfo Cuadra CanalesNo ratings yet

- Change Torque Chart 11-30-2017Document1 pageChange Torque Chart 11-30-2017Titino AlejandroNo ratings yet

- Pre Ops (Manual) THDocument3 pagesPre Ops (Manual) THismanto31No ratings yet

- Flexitallic CGI Torque Chart Spiral Wound GasketsDocument1 pageFlexitallic CGI Torque Chart Spiral Wound GasketstinzarmoeNo ratings yet

- RCN82 Ultrasonic Heat - Cooling - Meter BackupDocument5 pagesRCN82 Ultrasonic Heat - Cooling - Meter BackupPhạm Hằng NgaNo ratings yet

- Crusher 4Document39 pagesCrusher 4kediliterapiNo ratings yet

- Catalogue WP-SDC CCR CE (MID)Document3 pagesCatalogue WP-SDC CCR CE (MID)control1y1segu-65318No ratings yet

- S F E S F E S F E: Kil Ab Ngineering Kil Ab Ngineering Kil Ab NgineeringDocument3 pagesS F E S F E S F E: Kil Ab Ngineering Kil Ab Ngineering Kil Ab NgineeringDurga PrasadNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument41 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Inova Ball Joints JBSDocument2 pagesInova Ball Joints JBSSympatyagaNo ratings yet

- Product Catalog PDFDocument38 pagesProduct Catalog PDFMbaye DiagneNo ratings yet

- CombineDocument3 pagesCombineJf OngNo ratings yet

- GrappleDocument6 pagesGrappleMiguelNo ratings yet

- RyLind LoaderBucketsDocument9 pagesRyLind LoaderBucketsMiguelNo ratings yet

- RyLind CouplersHitchesDocument4 pagesRyLind CouplersHitchesMiguelNo ratings yet

- Rollout BucketDocument2 pagesRollout BucketMiguelNo ratings yet

- OHB Installation ManualDocument68 pagesOHB Installation Manualbustamate100% (1)

- Modeling and Simulation Course Outline 2011Document2 pagesModeling and Simulation Course Outline 2011Latosha TrevinoNo ratings yet

- Unit 5Document29 pagesUnit 5Dhileepan Kumarasamy0% (1)

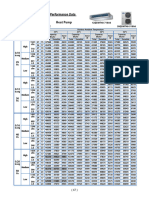

- Ducted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50HzDocument3 pagesDucted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50Hzm.effat3No ratings yet

- P&I - PRICELIST - Per 1 Januari 2016Document47 pagesP&I - PRICELIST - Per 1 Januari 2016MHD FAJRINo ratings yet

- LPG 1 PDFDocument8 pagesLPG 1 PDFHarshitgpt1231No ratings yet

- Cooling TowerDocument6 pagesCooling TowerGianne Karl AlmarinesNo ratings yet

- PTWDocument3 pagesPTWAngel Silva VicenteNo ratings yet

- Arl TR 3567Document72 pagesArl TR 3567AndrewScotsonNo ratings yet

- How Do I Set Up My TIG Welder?: Owner's ManualDocument2 pagesHow Do I Set Up My TIG Welder?: Owner's ManualenricoNo ratings yet

- Condensers PDFDocument32 pagesCondensers PDFSumedh JadhavNo ratings yet

- Compressed Air Systems CatalogDocument12 pagesCompressed Air Systems CatalogMichael FabianNo ratings yet

- Span Tables For Simply Supported Composite BeamsDocument8 pagesSpan Tables For Simply Supported Composite BeamsDenise2512No ratings yet

- PEMP RMD510. M S Ramaiah School of Advanced Studies, Bengaluru PDFDocument42 pagesPEMP RMD510. M S Ramaiah School of Advanced Studies, Bengaluru PDFwarterflyNo ratings yet

- En Service Manual: Crawler DozerDocument41 pagesEn Service Manual: Crawler DozerHelioNo ratings yet

- Trubolt Wedge Anchors ICC ES Evaluation 1460652Document17 pagesTrubolt Wedge Anchors ICC ES Evaluation 1460652Reinel OrjuelaNo ratings yet

- Data Consolidation Patimban SDDocument24 pagesData Consolidation Patimban SDUtari Tri NoviatiNo ratings yet

- C4.4 Trouble ShootingDocument45 pagesC4.4 Trouble ShootingTLK ChannelNo ratings yet

- Data Sheet Helix VE 5205-4-16 E KS 2GDocument1 pageData Sheet Helix VE 5205-4-16 E KS 2GHarshvardhan Mishra100% (1)

- I.S 5624-1993 Foundation BoltsDocument8 pagesI.S 5624-1993 Foundation Boltssandeepgupta202No ratings yet

- Modeling, Design and Control of A Ship Carried 3 DOF Stabilized PlatformDocument9 pagesModeling, Design and Control of A Ship Carried 3 DOF Stabilized PlatformAji Brahma NugrohoNo ratings yet

- CE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksDocument9 pagesCE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksrexdindigulNo ratings yet

- WaterDocument9 pagesWaterRakshit GhanghasNo ratings yet

- Emailing دوسية المهندس ابراهيم النوافلة-1Document61 pagesEmailing دوسية المهندس ابراهيم النوافلة-1ahmadalialhamaida19971015No ratings yet

- Mech GS 2021R2 EN PR08Document20 pagesMech GS 2021R2 EN PR08luc09polettoNo ratings yet

- Homework 17.Document2 pagesHomework 17.Chris HeffnerNo ratings yet

MONTABERT

MONTABERT

Uploaded by

MiguelCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MONTABERT

MONTABERT

Uploaded by

MiguelCopyright:

Available Formats

Worldwide Expert in Hydraulic Equipment

Demolition Range

MPR HSS GSB RSB RPU FPU HGR

CUT Rotary cutters

for Carriers from 2.5 to 50 tons

The perfect tool when excavation systems are

weak and percussion systems are not effective.

Ideal for work on pipelines with hard and compact

materials, to profile concrete walls or rock, for

quarry stopping and demolition applications.

Innovative design of the hydraulic piston

motor ensures a high torque at low speed.

Direct drive allows a minimum non-operational

space between cutters (from 95 up to 160 mm

according to the size of the rotary cutter).

MODEL CUT-20 CUT-35 CUT-50 CUT-60 CUT-80 CUT-105

Excavator weight t 2.5 - 7 6 - 13 9 - 18 15 - 24 20 - 34 30 - 50

Weight kg 240 480 630 1 200 1 610 2 100

Supply flow l/min 45 - 75 60 - 125 80 -170 100 - 220 140 - 250 180 - 340

Operating pressure bar 350 - 180 350 - 180 350 - 180 350 - 180 350 - 210 400 - 220

Hydraulic motor power kW 27 37 50 61 87 112

Rotating speed rpm 130 - 200 110 - 160 100 - 145 90 - 130 80 - 120 70 - 110

Cutting speed m/s 2.3 - 3.6 2.6 - 3.8 2.6 - 3.8 2.7 - 4.1 2.7 - 4.1 2.6 - 4.1

Output torque N.m 2 500 4 560 6 870 9 380 15 650 19 120

Cutting force N 15 000 20 300 27 500 31 800 47 300 53 900

Drum + teeth width (L) mm 520 625 700 850 1 000 1 200

Drum + teeth diameter (Ø) mm 340 450 500 590 660 710

Drain line maxi pressure bar 1 1 1 1 1 1

MPR Multiprocessor

for Carriers from 3.5 to 70 ton

Applications

Montabert® Multiprocessors utilize a variety of interchangeable jaws that allow

demolition contractors to customize this attachment for various applications.

Pulverizing, cutting, cracking and shearing are all functions the Montabert®

Multiprocessor performs, which eliminates the need for multiple excavators and

attachments on a job site.

Features and Benefits

Precison and handling : 360-degree hydraulic rotation ( braking

starting from MPR 10) and compact size create precise positioning

when processing materials.

Extended life span Hardox® 400 steel structure provides extreme

durability and strength.

Performances : Five available jaw types with easily interchangeable

teeth and blade serve multiple demolition, scrap and recycling

applications.

Hydraulic speed valve generates a shorter work cycle.

MODEL MPR-03 MPR-05 MPR-10 MPR-15 MPR-20 MPR-25 MPR-35 MPR-45 MPR-55

Excavator Weight t 3,5 / 5,5 5,5/10 10/15 15/20 21/27 28/35 35/45 45/55 50/70

Weight kg 392 625 1 060 1 686 2 050 2 700 3 670 4 500 5 500

Rotation Flow l/min 5 5 5 30 30 50 50 50 50

Rotation Pressure bar 60 60 60 120 120 120 120 120 120

Open/Close Flow l/min 50 110 140 200 210 300 350 450 500

Open/Close Pressure bar 220 220/350 350 350 350 350 350 350 350

Dimensions A mm 1 140 1 350 1 600 1 930 2 100 2 370 2 600 2 750 2 950

B mm 770 790 910 1 150 1 270 1 390 1 630 1 700 1 800

F1 t 25 50 70 80 100 130 140 155 170

F2 t 32 75 105 125 150 205 218 245 265

F3 t 62 100 175 200 250 335 360 390 420

MPR + “CC” D mm 372 545 650 750 860 1 100 1 230 1 300 1 500

ConCrete jaws

PD : +++ / SD: + mm 15 20 25 30 35 40 45 50 50

D mm - 530 630 750 860 1 110 1 230 1 300 1 500

MPR + “CB” mm - 20 25 40 50 55 60 65 70

ComBination jaws :

Concrete / Steel mm - 100 110 150 250 300 330 400 550

PD : ++ / SD : ++

mm - - - 120 180 220 240 260 280

D mm 170 215 300 340 420 520 580 630 700

MPR + “ST” mm 30 30 35 40 50 60 65 70 80

Steel shear jaws

PD : +++ / SD : +++ mm - 120 130 180 250 320 360 450 600

mm - - 100 140 200 240 260 300 320

MPR + “PV” D mm - 420 500 580 685 880 960 1 030 1 120

Pulverizing jaws

PD : + / SD : +++ mm - 20 25 30 35 40 45 50 50

MPR + “TK” D mm - - - 240 275 340 360 410 450

Tank jaws

PD : +++ / SD : + mm - - - 10 15 20 25 30 35

PD : Primary demolition / SD : Secondary demolition : +++ Particularly recommended

++ Usable

+ Not recommended

HSS Hydraulic steel shear

for Carriers from 15 to 100 tons

Montabert® Hydraulic Steel Shears are the optimal cutting tool for your demolition,

scrap processing and recycling needs. Whether you are cutting steel structures in

a building or processing materials on the ground, the Montabert® Hydraulic Steel

Shears combine extreme versatility, strength, efficiency and durability, making them

the right attachment for the job.

Applications

The Hydraulic Steel Shears can be used for: • Scrap processing.

• Demolition.

• Recycling.

Features and benefits

• 360-degree hydraulic rotation allows for precise cutting at any angle.

• Main cutting blades can be rotated four times for extra long life.

• Interchangeable nose blade allows the tip of the shear to effectively pierce material

and hold it in place while cutting.

• Complete structure is made of Hardox® 400 steel providing extreme durability and

strength.

• Strong cutting force works to accurately cut your toughest materials.

• Deep and wide jaw opening helps cut larger materials

and increase productivity.

• Hydraulic speed valve generates a shorter work cycle.

MODEL HSS-15 HSS-20 HSS-30 HSS-40 HSS-55 HSS-70

Excavator Weight (Arm mounted) t 15 / 23 21 / 30 28 / 35 44 / 50 50 / 60 75 / 100

Weight kg 1 650 2230 2990 4 440 5 600 7 650

A mm 2 627 2 870 3 265 4 010 4 465 4 930

B mm 870 925 1 062 1 240 1 470 1 640

C mm 650 x 680 650 x 680 650 x 680 720 x 800 720 x 800 900 x 1 000

D mm 415 460 580 690 840 880

E mm 329 363 463 556 712 786

Rotation Flow l/min 30 40 50 50 50 50

Rotation Pressure bar 120 120 120 120 120 120

Open/Close Flow l/min 150/250 200/300 280/350 350/500 400/600 500/800

Open/Close Pressure bar 350 350 350 350 350 350

Rotation 360° 360° 360° 360° 360° 360°

mm 50 60 70 85 110 130

mm 240 300 420 480 540 620

mm 160 200 260 320 360 420

GSB Grilled screening bucket

for Carriers 13 to 30 tons

Applications

Ideal for specialized works such as:

• Sorting demolition material for reuse in roads, trenches...

• Cleaning stony terrain.

Features and benefits

• 3 easy interchangeable grills available (50 x 200, 28 x 100, 50 x 50 mm).

• Complete structure made in Hardox® 400, for improved durability.

• High productivity with the high speed alternate jumping movement of the grills.

• Increased durability thanks to the safety valve protecting the hydraulic circuit of

the bucket (pressure and flow).

• Low level of vibration transmitted to the carrier boom.

MODEL GSB-15 GSB-20

Excavator Weight t 13 / 20 20 / 30

Weight kg 1 200 1 650

A mm 1 200 1 500

B mm 1 290 1 410

C mm 1 220 1 430

D mm 1 000 1 187

Oil Flow l/min 130 130

Pressure bar 230 230

Capacity l 750 1 400

RSB Rotary screening bucket

for Carriers 7 to 35 tons

Applications

Ideal for specialized work such as screening natural material, quarry residues, sand

and dry soils, as well as for clearing river-beds.

Features and benefits

• Large choice of screening basket for easy changing and versatility (20 x 20, 30 x 30,

40 x 40, 50 x 50, 60 x 60, 70 x 70, 80 x 80 mm).

• Strong frame structure made in Hardox® 400 for better protection of the basket,

also in heavy duty jobs

• Increased productivity with easy loading bucket shape, 6 teeth as standard and flat

bottom frame

• Less maintenance with special sealing against the dust.

MODEL RSB-07 RSB-10 RSB-14 RSB-18 RSB -24

Excavator Weight t 7 / 10 10 / 14 14 / 18 18 / 24 24 / 35

Weight kg 490 750 1 235 1 650 2 400

L mm 900 1 000 1 200 1 500 2 000

Oil flow l/min 25 60 60 60 60

Pressure bar 130 160 160 160 160

Capacity l 400 750 1 000 1 500 2 200

Applications

The pulverizers

Montabert® Pulverizers are the ultimate hydraulic crushing attachments for your demolition and recycling needs. Designed to

maximize productivity, there are two ranges of Pulverizers for two main applications : primary and secondary demolition.

Features and benefits

• Exchangeable teeth and well protected hydraulic components increase productivity and minimize downtime.

• Serrated blades hold rebar in place for precise cutting.

• Hydraulic speed valve generates a shorter work cycle.

• High clamping force works to crush your toughest materials.

• Wide jaw opening helps process thick concrete.

• Hardox® 400 steel structure provides extreme durability and strength.

• and for the Rotating pulverizer a 360-degree hydraulic rotation allows pulverizing hard to reach materials accurately

and efficiently.

RPU Rotating pulverizers

for Carriers 12 to 50 tons

Rotating pulverizers are designed to break construction material and to cut

rebars in reinforced concrete.

Whether crushing or sorting materials on a structure or on the ground, the Montabert®

Rotating Pulverizer’s special design provides the strength and durability that make it

the right attachment for the job.

MODEL RPU-12 RPU-15 RPU-18 RPU-22 RPU-30 RPU-40

Excavator Weight t 12 / 15 15 / 19 18 / 23 22 / 30 29 / 38 38 / 50

Weight kg 1 250 1 535 1 865 2 435 3 200 4 220

A mm 1 855 2 015 2 177 2 425 2 734 3 065

B mm 635 700 805 915 1 010 1 165

C mm 635 680 812 903 1 005 1 100

D mm 404 404 454 454 490 490

E mm 379 379 410 410 446 446

F1 ton 130 170 210 260 340 420

F2 ton 72 92 110 138 275 341

F3 ton 47 59 71 88 118 146

Rotation Flow l/min 30 30 30 30 50 50

Rotation Pressure bar 120 120 120 120 120 120

Open/Close Flow l/min 110 / 160 140 / 200 180 / 230 250 / 300 300 / 350 350 / 400

Open/Close Pressure bar 350 350 350 350 350 350

FPU Fixed Pulverizers

for Carriers 18 to 35 tons

Fixed Pulverizers are specifically adapted for :

- Secondary demolition: separation or reduction of demolished

material to facilitate loading and transportation

- Recycling: separating rebars from concrete.

MODEL FPU-18 FPU-22

Excavator Weight t 18 / 28 22 / 35

Weight kg 2 040 2 575

A mm 1 650 1 765

B mm 2 180 2 313

C mm 650 650

D mm 903 1 017

F1 t 235 270

F2 t 120 137

F3 t 72 94

G mm 290 350

H mm 480 530

I mm 900 990

Open/Close Flow I/min 180/230 250/300

Open/Close Pressure bar 350 350

HGR Handling grapple

for Carriers 3 to 60 tons

Applications

The design and clamping force of the Montabert® “HGR” Handling

Grapples make them the natural choice for sorting and moving

demolished materials, rock, handling of various materials, urban

waste, garbage and dramatically reduce loading times.

Features and benefits

• Can be used with a complete range of carriers from 3 t to 60 t.

• Compact, manageable, fast and versatile.

• Continuous 360° hydraulic rotation enables the equipment to be

used in all situations in order to improve production and prevent

risk of injury to operators.

• Complete structure made in Hardox® 400 for improved durability.

• High safety clamping force thanks to the block valve (except

HGR-03),which keeps the grapple closed and prevents cylinder

oil leaks.

• Interchangeable blades.

• Rotation braking starting from HRG 15.

.

MODEL HGR-03 HGR-05 HGR-08 HGR-13 HGR-15 HGR-17 HGR-22 HGR-30 HGR-41

Excavator Weight t 3/5 5/8 8 / 12 13 / 15 15 / 22 17 / 22 22 / 30 30 / 40 40 / 60

Weight kg 270 518 646 900 1 082 1 218 1 844 2 456 3 640

A mm 1 040 1 528 1 630 1 737 1 827 1 827 2 033 2 200 2 500

B mm 400 600 700 800 800 1 000 1 200 1 400 1500

C mm 310 x 350 405 x 560 405 x 560 405 x 560 650 x 680 650 x 680 650 x 680 720 x 840 720 x 840

D mm 849 1 085 1 130 1 260 1 273 1 273 1 521 1 650 1 850

F1 t 2 3 3,5 4 6 6 8 10 14

M mm 925 1 180 1 270 1 400 1 440 1 440 1 700 1 870 2 085

N mm 690 1 090 1 090 1 230 1 250 1 250 1 500 1 500 1 750

Rotation Flow l/min 5 5 5 5 30 30 30 50 50

Rotation Pressure bar 150 150 150 150 120 120 120 120 120

Open/Close Flow l/min 20 25 30 40 50 50 60 120 130

Open/Close Pressure bar 320 320 320 320 320 320 320 320 320

Your distributor :

Montabert : present in the world market in more

than 100 countries.

Optimize the performance of your demolition

attachments by contacting our experienced network

to deal with your queries.

Montabert will provide you with its expert

knowledge at the time of start-up, as well as advice

on maintenance with original spare parts, technical

support and training.

MONTABERT SAS - 203, route de Grenoble - 69800 Saint Priest, France - tel : +33-(0)4 72 22 97 97 - fax: +33-(0)4 72 22 97 56

montabert_marketing@diiattachments.com / www.montabert.com

Nothing contained in this brochure is intended to extend any warranty or representation expressed or implied, regarding the products described herein. Any such

warranties or other terms and conditions of sale products shall be in accordance with Montabert standards terms and conditions of sales for such products, which are

available upon request. Specifications and machines can be modified at any time and without notice. © 2008 by Montabert SAS – 86687589 EN (09-2008)

You might also like

- 16-400 enDocument145 pages16-400 enluis_erf22No ratings yet

- YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesYL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- AISE 6 (1991) - Specification For Electric Overhead Traveling Cranes For Steel Mill ServiceDocument112 pagesAISE 6 (1991) - Specification For Electric Overhead Traveling Cranes For Steel Mill Servicefaelbritos67% (6)

- Volvo PentaDocument250 pagesVolvo Pentaweler13100% (2)

- Engineered Connectors: XL SystemsDocument93 pagesEngineered Connectors: XL Systemsisrael11288100% (1)

- Me7 Tuner Wizzard - XLSM - 0Document81 pagesMe7 Tuner Wizzard - XLSM - 0lytoselputoamoNo ratings yet

- MC Injection Spec2023Document1 pageMC Injection Spec2023anandan777No ratings yet

- SNXR Series - 2023Document2 pagesSNXR Series - 2023isgectraineeNo ratings yet

- WC67K EngDocument8 pagesWC67K Engclaudio ponceNo ratings yet

- Drills 7 TappersDocument10 pagesDrills 7 TappersBe HappyNo ratings yet

- Funeec Solid Carbide - Price ListDocument12 pagesFuneec Solid Carbide - Price ListdpshradhaNo ratings yet

- Performances and Characteristics: JH21-200 SpecificationDocument2 pagesPerformances and Characteristics: JH21-200 SpecificationAlexandreNo ratings yet

- MRS Extruder: Technical DataDocument1 pageMRS Extruder: Technical DataPedro PeñateNo ratings yet

- Bolts Torque ChartDocument13 pagesBolts Torque ChartkhaireddinNo ratings yet

- Kawaguchi SeriesDocument2 pagesKawaguchi SeriesSuranga PriyadarshanaNo ratings yet

- 05.fabricated HDPE Tee R07Document7 pages05.fabricated HDPE Tee R07kuntasee.duckNo ratings yet

- MEDIDAS TURBINA Dresser Imtm MeretDocument3 pagesMEDIDAS TURBINA Dresser Imtm MeretronaldNo ratings yet

- UPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber SimplexDocument4 pagesUPS Cable Lengths - Tentative Calculations: Machine # Auto Cone Ring Card Drawing B Drawing F Unilap Comber Simplexwaqasasad408No ratings yet

- Catalouge GTRDocument2 pagesCatalouge GTRMr Nilesh ShahNo ratings yet

- Injection Molding Machine Ns SeriesDocument2 pagesInjection Molding Machine Ns SeriesmastersupportNo ratings yet

- A. K. Steels: Cutting Rate ListDocument2 pagesA. K. Steels: Cutting Rate ListRam PatelNo ratings yet

- TNN CNC Lathe Machine CatalogueDocument3 pagesTNN CNC Lathe Machine Catalogueneda100% (1)

- CU400 CU500: Machine SpecificationDocument4 pagesCU400 CU500: Machine SpecificationГеорги НеновNo ratings yet

- Power Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsDocument2 pagesPower Press Punching Machine JB23 Series: The Machine of Whole Structure and CharacteristicsRadiadores PlanosNo ratings yet

- SNX-2 Point Series - 2023Document2 pagesSNX-2 Point Series - 2023isgectraineeNo ratings yet

- Flexitallic Tabla de TorqueDocument2 pagesFlexitallic Tabla de TorqueWalter100% (1)

- Torque Chart Spiral Wound GasketsDocument2 pagesTorque Chart Spiral Wound GasketsMocanu MarianNo ratings yet

- Table of Lap Splices 4000 PsiDocument1 pageTable of Lap Splices 4000 PsiGelo GuansingNo ratings yet

- Nonreturn Tilting Disc Check Valve Art c01Document2 pagesNonreturn Tilting Disc Check Valve Art c01zayerirezaNo ratings yet

- C10T10 14Document4 pagesC10T10 14floreswgNo ratings yet

- AFAFR EngDocument16 pagesAFAFR EngcoachanzaiNo ratings yet

- Hunsone CNC Machine CatalogueDocument38 pagesHunsone CNC Machine CatalogueLucy MontfortNo ratings yet

- Okada Top SeriesDocument2 pagesOkada Top SeriessinanNo ratings yet

- Dokumen - Tips - Hatlapa Steering Gear Triton PDFDocument3 pagesDokumen - Tips - Hatlapa Steering Gear Triton PDFThanh Nghị BùiNo ratings yet

- Apex Dynamics, Inc.: AB / ABR SeriesDocument14 pagesApex Dynamics, Inc.: AB / ABR SeriesIqtidar GulNo ratings yet

- Cys-B (16) (TM) (V1016)Document1 pageCys-B (16) (TM) (V1016)Azwan SunlineNo ratings yet

- Charts & Tables Charts & Tables: TEKNOMEGA TOP Busbar Support Fault Level ChartDocument1 pageCharts & Tables Charts & Tables: TEKNOMEGA TOP Busbar Support Fault Level Chartmuqtar4uNo ratings yet

- Round Cutting ListDocument2 pagesRound Cutting ListSachin PatelNo ratings yet

- CU400M CU500M CU580M: Machine SpecificationDocument4 pagesCU400M CU500M CU580M: Machine SpecificationEl nabahin FerasNo ratings yet

- 2 Axis TurningDocument1 page2 Axis TurningMinh Sang TrầnNo ratings yet

- Pinbush - Tyre Coupling 2014Document4 pagesPinbush - Tyre Coupling 2014Priyam NandwanaNo ratings yet

- MRTHD Komac KB350 - Equipos 60000248 PDFDocument1 pageMRTHD Komac KB350 - Equipos 60000248 PDFJairresistenciagt123No ratings yet

- Yadon YC1Document1 pageYadon YC1Baihaki St100% (1)

- VALVES Technical Catalog: Catálogo Técnico ValvoleDocument11 pagesVALVES Technical Catalog: Catálogo Técnico ValvoleMohamed Raafat0% (1)

- Hydraulic Swing Beam Shears: WWW - Adira.ptDocument2 pagesHydraulic Swing Beam Shears: WWW - Adira.pttahirNo ratings yet

- Scheda ColdDocument1 pageScheda ColdOleksandr BalychevNo ratings yet

- Structure: MM, MF, FF, FN, K-MMDocument7 pagesStructure: MM, MF, FF, FN, K-MMAji Kurniawan RahmanNo ratings yet

- G-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration NonwovensDocument1 pageG-Tex PCF Range Geotextiles: Soil Seperation & Drainage & Filtration Nonwovensfer17165No ratings yet

- Flange Sizing ProgramDocument15 pagesFlange Sizing Program심판자No ratings yet

- Flange Sizing ProgramDocument15 pagesFlange Sizing Program심판자0% (1)

- Mordaza Epiroc Cc1700 UDocument2 pagesMordaza Epiroc Cc1700 URodolfo Cuadra CanalesNo ratings yet

- Change Torque Chart 11-30-2017Document1 pageChange Torque Chart 11-30-2017Titino AlejandroNo ratings yet

- Pre Ops (Manual) THDocument3 pagesPre Ops (Manual) THismanto31No ratings yet

- Flexitallic CGI Torque Chart Spiral Wound GasketsDocument1 pageFlexitallic CGI Torque Chart Spiral Wound GasketstinzarmoeNo ratings yet

- RCN82 Ultrasonic Heat - Cooling - Meter BackupDocument5 pagesRCN82 Ultrasonic Heat - Cooling - Meter BackupPhạm Hằng NgaNo ratings yet

- Crusher 4Document39 pagesCrusher 4kediliterapiNo ratings yet

- Catalogue WP-SDC CCR CE (MID)Document3 pagesCatalogue WP-SDC CCR CE (MID)control1y1segu-65318No ratings yet

- S F E S F E S F E: Kil Ab Ngineering Kil Ab Ngineering Kil Ab NgineeringDocument3 pagesS F E S F E S F E: Kil Ab Ngineering Kil Ab Ngineering Kil Ab NgineeringDurga PrasadNo ratings yet

- Slewing Bearing Slewing Ring Slewing Gear Swing CircleDocument41 pagesSlewing Bearing Slewing Ring Slewing Gear Swing Circlezczc32z5No ratings yet

- Inova Ball Joints JBSDocument2 pagesInova Ball Joints JBSSympatyagaNo ratings yet

- Product Catalog PDFDocument38 pagesProduct Catalog PDFMbaye DiagneNo ratings yet

- CombineDocument3 pagesCombineJf OngNo ratings yet

- GrappleDocument6 pagesGrappleMiguelNo ratings yet

- RyLind LoaderBucketsDocument9 pagesRyLind LoaderBucketsMiguelNo ratings yet

- RyLind CouplersHitchesDocument4 pagesRyLind CouplersHitchesMiguelNo ratings yet

- Rollout BucketDocument2 pagesRollout BucketMiguelNo ratings yet

- OHB Installation ManualDocument68 pagesOHB Installation Manualbustamate100% (1)

- Modeling and Simulation Course Outline 2011Document2 pagesModeling and Simulation Course Outline 2011Latosha TrevinoNo ratings yet

- Unit 5Document29 pagesUnit 5Dhileepan Kumarasamy0% (1)

- Ducted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50HzDocument3 pagesDucted Split System 53QDMT48-518A6 Heat Pump 380-415V / 3Ph / 50Hzm.effat3No ratings yet

- P&I - PRICELIST - Per 1 Januari 2016Document47 pagesP&I - PRICELIST - Per 1 Januari 2016MHD FAJRINo ratings yet

- LPG 1 PDFDocument8 pagesLPG 1 PDFHarshitgpt1231No ratings yet

- Cooling TowerDocument6 pagesCooling TowerGianne Karl AlmarinesNo ratings yet

- PTWDocument3 pagesPTWAngel Silva VicenteNo ratings yet

- Arl TR 3567Document72 pagesArl TR 3567AndrewScotsonNo ratings yet

- How Do I Set Up My TIG Welder?: Owner's ManualDocument2 pagesHow Do I Set Up My TIG Welder?: Owner's ManualenricoNo ratings yet

- Condensers PDFDocument32 pagesCondensers PDFSumedh JadhavNo ratings yet

- Compressed Air Systems CatalogDocument12 pagesCompressed Air Systems CatalogMichael FabianNo ratings yet

- Span Tables For Simply Supported Composite BeamsDocument8 pagesSpan Tables For Simply Supported Composite BeamsDenise2512No ratings yet

- PEMP RMD510. M S Ramaiah School of Advanced Studies, Bengaluru PDFDocument42 pagesPEMP RMD510. M S Ramaiah School of Advanced Studies, Bengaluru PDFwarterflyNo ratings yet

- En Service Manual: Crawler DozerDocument41 pagesEn Service Manual: Crawler DozerHelioNo ratings yet

- Trubolt Wedge Anchors ICC ES Evaluation 1460652Document17 pagesTrubolt Wedge Anchors ICC ES Evaluation 1460652Reinel OrjuelaNo ratings yet

- Data Consolidation Patimban SDDocument24 pagesData Consolidation Patimban SDUtari Tri NoviatiNo ratings yet

- C4.4 Trouble ShootingDocument45 pagesC4.4 Trouble ShootingTLK ChannelNo ratings yet

- Data Sheet Helix VE 5205-4-16 E KS 2GDocument1 pageData Sheet Helix VE 5205-4-16 E KS 2GHarshvardhan Mishra100% (1)

- I.S 5624-1993 Foundation BoltsDocument8 pagesI.S 5624-1993 Foundation Boltssandeepgupta202No ratings yet

- Modeling, Design and Control of A Ship Carried 3 DOF Stabilized PlatformDocument9 pagesModeling, Design and Control of A Ship Carried 3 DOF Stabilized PlatformAji Brahma NugrohoNo ratings yet

- CE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksDocument9 pagesCE2306 Design of RC Elements Anna University Question Bank Question Paper 2 Marks and 16 MarksrexdindigulNo ratings yet

- WaterDocument9 pagesWaterRakshit GhanghasNo ratings yet

- Emailing دوسية المهندس ابراهيم النوافلة-1Document61 pagesEmailing دوسية المهندس ابراهيم النوافلة-1ahmadalialhamaida19971015No ratings yet

- Mech GS 2021R2 EN PR08Document20 pagesMech GS 2021R2 EN PR08luc09polettoNo ratings yet

- Homework 17.Document2 pagesHomework 17.Chris HeffnerNo ratings yet