Professional Documents

Culture Documents

Astm E1272 02 2012

Astm E1272 02 2012

Uploaded by

yessueOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Astm E1272 02 2012

Astm E1272 02 2012

Uploaded by

yessueCopyright:

Available Formats

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1272 − 02 (Reapproved 2012)

Standard Specification for Laboratory Glass

Graduated Cylinders1

This standard is issued under the fixed designation E1272; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Laboratory Glassware

1.1 This specification covers requirements for glass gradu-

3. Classification

ated cylinders for precision and general purpose grades suitable

for laboratory purposes. 3.1 Cylinders shall be in the following styles:

1.1.1 Class A—Each cylinder of precision grade shall be 3.1.1 Style I—Beaded lip with pour spout,

marked with the letter “A” to signify compliance with appli- 3.1.2 Style II—Ground standard taper () neck, or

cable construction and accuracy requirements. Cylinders may 3.1.3 Style III—Beaded lip with pour spout and reinforcing

be marked with an identification number (serial number) at the bead near top.

option of the manufacturer.

1.1.2 Class B—General purpose cylinders are of the same 4. Requirements

basic design as Class A cylinders. However, volumetric toler- 4.1 Style I cylinders shall be calibrated either “to deliver” or

ances for Class B cylinders shall be within twice the specified “to contain.” Style II and Style III cylinders shall be calibrated

range allowed for Class A cylinders. These cylinders need not “to contain.” The cylinders shall be calibrated at 20°C and the

iTeh Standards

be marked with their class designation.

1.1.3 Product with a stated capacity not listed in this

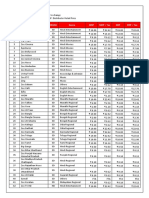

volumetric tolerances shall be in accordance with Table 1. (See

Practice E542 for calibration definitions and procedures.)

4.1.1 Cylinders shall be of borosilicate glass conforming to

standard may be specified in class A tolerance when product

(https://standards.iteh.ai)

conforms to the tolerance range of the next smaller volumetric

standard product listed in Table 1.

the requirements for Type I, Class A of Specification E438.

4.2 Shape—Cylinders shall be of one piece consisting in

2. Referenced Documents Document Preview

general of a top, a graduated portion of uniform diameter and

a base. The shape shall permit complete emptying and thor-

2.1 ASTM Standards:2 ough cleaning. The pour-out of Style I, in sizes of 1000 mL and

E438 Specification for Glasses in LaboratoryASTM Apparatus below, shall be located in a vertical plane bisecting within 65°

E1272-02(2012)

E542 Practice for Calibration of Laboratory Volumetric one of the corners on the hexagonal base. For sizes 2000 mL

https://standards.iteh.ai/catalog/standards/sist/7151ba9b-be83-4f1e-a47e-f46955c69946/astm-e1272-022012

Apparatus and above, the pour-out shall bisect within 65° the center of

E675 Specification for Interchangeable Taper-Ground Stop- one of the flat section or one of the corners of the base. The

cocks And Stoppers pour-out of Style III shall not protrude beyond the glass

E920 Specification for Commercially Packaged Laboratory reinforcing bead with construction such that, upon falling, the

Apparatus bead shall strike a flat surface before the pour-out or lip.

E921 Specification for Export Packaged Laboratory Appa- 4.2.1 Base—The base shall be hexagonal and the construc-

ratus tion shall be such that the empty cylinder (without stopper for

E1133 Practice for Performance Testing of Packaged Labo- Style II), in capacities above 10 mL, shall stand on a surface

ratory Apparatus for United States Government Procure- inclined 15° with the horizontal and, in capacities of 10 mL or

ments less, shall stand on a surface inclined 10° with the horizontal.

E1157 Specification for Sampling and Testing of Reusable

4.3 Dimensions—The dimensions shall be as shown in

Table 1 The glass stoppers of Style II shall conform to

1

This specification is under the jurisdiction of ASTM Committee E41 on Specification E675.

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on 4.4 Graduation Markings—Graduation markings shall be

Apparatus.

Current edition approved Nov. 1, 2012. Published November 2012. Originally sharply defined lines of uniform width not more than 0.4 mm.

approved in 1989. Last previous edition approved in 2007 as E1272 – 02(2007). Graduation markings shall be perpendicular to the vertical axis

DOI: 10.1520/E1272-02R12.

2

of the cylinder and parallel to each other. Adjacent graduation

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

markings shall be spaced at least 1 mm from center to center.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Markings shall be applied by one of the following methods:

the ASTM website. etched and filled with a permanent pigment; etched through a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

You might also like

- Astm D1384-05Document8 pagesAstm D1384-05Boris100% (1)

- 52 Week+Marathon+Training+Plan+ +sheet1+Document2 pages52 Week+Marathon+Training+Plan+ +sheet1+Mukund JhaNo ratings yet

- Esd's No-Evidence Motion For Summary JudgmentDocument18 pagesEsd's No-Evidence Motion For Summary JudgmentDallasObserver100% (1)

- Glass Volumetric (Transfer) Pipets: Standard Specification ForDocument2 pagesGlass Volumetric (Transfer) Pipets: Standard Specification ForAhmed AlzubaidiNo ratings yet

- E675-02 (2012) Standard Specification For InterchangeDocument11 pagesE675-02 (2012) Standard Specification For InterchangeAhmed AlzubaidiNo ratings yet

- E288 Standard Speci Cation For Laboratory Glass Volumetric Flasks PDFDocument3 pagesE288 Standard Speci Cation For Laboratory Glass Volumetric Flasks PDFBryan Mesala Rhodas GarciaNo ratings yet

- Astm e 1293-02 R07 Especificacion para Pipetas de MedicionDocument3 pagesAstm e 1293-02 R07 Especificacion para Pipetas de MedicionGERMAN FRANCISCO AMBROSIO QUISPENo ratings yet

- Is 13349 (Penstock)Document16 pagesIs 13349 (Penstock)praval84100% (1)

- HPLC Solutions For EnvironmentalDocument28 pagesHPLC Solutions For EnvironmentalsimyacitalNo ratings yet

- Laboratory Glass Volumetric Flasks, Special Use: Standard Specification ForDocument2 pagesLaboratory Glass Volumetric Flasks, Special Use: Standard Specification ForEric Gozzer100% (1)

- Glass Measuring Pipets: Standard Specification ForDocument3 pagesGlass Measuring Pipets: Standard Specification ForMiroslav ThôngNo ratings yet

- Astm e 288-06 Especificacion para FiolasDocument3 pagesAstm e 288-06 Especificacion para FiolasGERMAN FRANCISCO AMBROSIO QUISPENo ratings yet

- Laboratory Glass Microvolumetric Vessels (Volumetric Flasks and Centrifuge Tubes)Document4 pagesLaboratory Glass Microvolumetric Vessels (Volumetric Flasks and Centrifuge Tubes)Ahmed AlzubaidiNo ratings yet

- Laboratory Glass Volumetric Flasks: Standard Specification ForDocument3 pagesLaboratory Glass Volumetric Flasks: Standard Specification ForAhmed Alzubaidi100% (2)

- Glass Serological Pipets (General Purpose and Kahn) : Standard Specification ForDocument2 pagesGlass Serological Pipets (General Purpose and Kahn) : Standard Specification ForAhmed AlzubaidiNo ratings yet

- E 288 Â " 03 - RTI4OADocument3 pagesE 288 Â " 03 - RTI4OAhans ccNo ratings yet

- Glass Volumetric (Transfer) Pipets: Standard Specification ForDocument2 pagesGlass Volumetric (Transfer) Pipets: Standard Specification ForOlga Karina Toro SayasNo ratings yet

- E 288 Â " 94 R98 - RTI4OC05NFI5OADocument3 pagesE 288 Â " 94 R98 - RTI4OC05NFI5OAhans ccNo ratings yet

- Astm e 287-02 R07 Especificacion para BuretasDocument3 pagesAstm e 287-02 R07 Especificacion para BuretasGERMAN FRANCISCO AMBROSIO QUISPENo ratings yet

- Disposable Glass Culture Tubes: Standard Specification ForDocument2 pagesDisposable Glass Culture Tubes: Standard Specification ForpravkovoilaNo ratings yet

- Astm E694 18Document4 pagesAstm E694 18yessueNo ratings yet

- Astm e 1044 - 96Document2 pagesAstm e 1044 - 96MarceloNo ratings yet

- Astm C1048 04Document3 pagesAstm C1048 04aaryankorlekarNo ratings yet

- E 287 Â " 02 - RTI4NWDocument3 pagesE 287 Â " 02 - RTI4NWhans ccNo ratings yet

- Disposable Glass Culture Tubes: Standard Specification ForDocument2 pagesDisposable Glass Culture Tubes: Standard Specification Forhans ccNo ratings yet

- A517a517m-17 1.04 PDFDocument4 pagesA517a517m-17 1.04 PDFlean guerreroNo ratings yet

- Glass Westergren Tube, Reusable: Standard Specification ForDocument3 pagesGlass Westergren Tube, Reusable: Standard Specification ForAhmed AlzubaidiNo ratings yet

- E 714 - 94 R04 - RtcxnaDocument2 pagesE 714 - 94 R04 - RtcxnajayakumarNo ratings yet

- A1028-03 (2015) Standard Specification For Stainless Steel Bars For Compressor and Turbine AirfoilsDocument4 pagesA1028-03 (2015) Standard Specification For Stainless Steel Bars For Compressor and Turbine Airfoilstjt4779No ratings yet

- E 890 Â " 94 R98 - RTG5MC05NFI5OADocument2 pagesE 890 Â " 94 R98 - RTG5MC05NFI5OAhans ccNo ratings yet

- Sni+03 6868 2002Document3 pagesSni+03 6868 2002abanghasanNo ratings yet

- Asme E1096 - 86 (2011)Document3 pagesAsme E1096 - 86 (2011)Francisco Jiménez AlejandroNo ratings yet

- Glass Westergren Tube, Disposable: Standard Specification ForDocument2 pagesGlass Westergren Tube, Disposable: Standard Specification ForAhmed AlzubaidiNo ratings yet

- E 287 Â " 94 R98 - RTI4NY05NFI5OADocument3 pagesE 287 Â " 94 R98 - RTI4NY05NFI5OAhans ccNo ratings yet

- E 923 Â " 97 - RTKYMY05NWDocument3 pagesE 923 Â " 97 - RTKYMY05NWhans ccNo ratings yet

- E 237 Â " 02 - RTIZNWDocument4 pagesE 237 Â " 02 - RTIZNWhans ccNo ratings yet

- D3603-07 - Standard Test Method For Rust-Preventing Characteristics of Steam Turbine Oil in The Presence of Water (Horizontal Disk Method)Document6 pagesD3603-07 - Standard Test Method For Rust-Preventing Characteristics of Steam Turbine Oil in The Presence of Water (Horizontal Disk Method)JoanneLimNo ratings yet

- Astm D1751 18Document1 pageAstm D1751 18hasanabdul5923No ratings yet

- Astm A-252Document9 pagesAstm A-252Dayana HernandezNo ratings yet

- D402D402M-14 Standard Test Method For Distillation of Cutback Asphalt - AASHTO No. T78Document5 pagesD402D402M-14 Standard Test Method For Distillation of Cutback Asphalt - AASHTO No. T78Alabbas FadhelNo ratings yet

- Pressure Vessel Plates, Alloy Steel, Molybdenum: Standard Specification ForDocument3 pagesPressure Vessel Plates, Alloy Steel, Molybdenum: Standard Specification ForCarlos CmbbNo ratings yet

- E 961 Â " 97 - RTK2MS05NWDocument2 pagesE 961 Â " 97 - RTK2MS05NWhans ccNo ratings yet

- Pressure Vessel Plates, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceDocument3 pagesPressure Vessel Plates, Carbon-Manganese-Silicon Steel, For Moderate and Lower Temperature ServiceSama UmateNo ratings yet

- Dishes, Evaporating, Platinum: Standard Specification ForDocument3 pagesDishes, Evaporating, Platinum: Standard Specification ForAhmed AlzubaidiNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Intermediate-And Higher-Temperature ServiceDocument3 pagesPressure Vessel Plates, Carbon Steel, For Intermediate-And Higher-Temperature ServiceJorge Andres Montoya QuirozNo ratings yet

- Distillation of Cutback Asphaltic D402 08Document5 pagesDistillation of Cutback Asphaltic D402 08Pedro AlvelaisNo ratings yet

- E288Document3 pagesE288Muhammad Masood Abbas100% (1)

- Pressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenDocument3 pagesPressure Vessel Plates, Alloy Steel, Chromium-Molybdenum-TungstenSama UmateNo ratings yet

- Astm D1384 04Document3 pagesAstm D1384 04fuenmayor.lilibethNo ratings yet

- Pharmaceutical Glass Graduates: Standard Specification ForDocument3 pagesPharmaceutical Glass Graduates: Standard Specification ForAhmed AlzubaidiNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Intermediate-And Higher-Temperature ServiceDocument3 pagesPressure Vessel Plates, Carbon Steel, For Intermediate-And Higher-Temperature Servicekaushik21185No ratings yet

- Blood Sedimentation Tube, Wintrobe, Glass, Reusable: Standard Specification ForDocument2 pagesBlood Sedimentation Tube, Wintrobe, Glass, Reusable: Standard Specification Forhans ccNo ratings yet

- Wa0040.Document14 pagesWa0040.robert nick eusebio teheranNo ratings yet

- Astm A351Document6 pagesAstm A351Rahul SinghNo ratings yet

- Pressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceDocument4 pagesPressure Vessel Plates, Carbon Steel, For Moderate-And Lower-Temperature ServiceAminNo ratings yet

- Common Laboratory Glass Funnels: Standard Specification ForDocument2 pagesCommon Laboratory Glass Funnels: Standard Specification ForAhmed AlzubaidiNo ratings yet

- A 516 - A 516M - 17Document4 pagesA 516 - A 516M - 17picottNo ratings yet

- Astm C305-MixingDocument3 pagesAstm C305-MixingFolik AsitNo ratings yet

- Astm F3125 F3125M 18Document6 pagesAstm F3125 F3125M 18Amine ait talebNo ratings yet

- Glass Micro Folin Pipet, Disposable: Standard Specification ForDocument3 pagesGlass Micro Folin Pipet, Disposable: Standard Specification ForAhmed AlzubaidiNo ratings yet

- A 184 - A 184M - 06 (2011) PDFDocument3 pagesA 184 - A 184M - 06 (2011) PDFأسامة وحيد الدين رمضانNo ratings yet

- The Declaration of IndependenceDocument20 pagesThe Declaration of IndependenceEdisonSambiliNo ratings yet

- Refiners Rhapsody 49 TheobatDocument80 pagesRefiners Rhapsody 49 TheobatIyere GiftNo ratings yet

- Chimdi Chukwu - Design of A Low-Cost Remote Monitoring System For Nigerian Aquaculture Using Wi-Fi and Onchip Web ServerDocument5 pagesChimdi Chukwu - Design of A Low-Cost Remote Monitoring System For Nigerian Aquaculture Using Wi-Fi and Onchip Web ServerChimdi ChukwuNo ratings yet

- Self Care Deficit NCPDocument3 pagesSelf Care Deficit NCPJUSTIN ALZATENo ratings yet

- 2022 n1620 - Travel Services n6 QP Jun Edited FopmaDocument23 pages2022 n1620 - Travel Services n6 QP Jun Edited FopmayoungegyptbassonNo ratings yet

- Oracle® Accounts Receivable Deductions Settlement: Implementation Guide Release 12.2Document108 pagesOracle® Accounts Receivable Deductions Settlement: Implementation Guide Release 12.2yadavdevenderNo ratings yet

- Unix Course Material - Tata ElxsiDocument112 pagesUnix Course Material - Tata ElxsiKesani Venkat Narsimha ReddyNo ratings yet

- Rizam Piat PresentationDocument17 pagesRizam Piat PresentationMohd RizNo ratings yet

- Digital Marketing Strategy and Marketing Mix UploadDocument39 pagesDigital Marketing Strategy and Marketing Mix UploadAmisha LalNo ratings yet

- Microcontroller For Embedded Systems RIC-651Document27 pagesMicrocontroller For Embedded Systems RIC-651এম.এস.এম রবিনNo ratings yet

- Design of Buried Rigid Pipes: StandardsDocument26 pagesDesign of Buried Rigid Pipes: StandardsVarun VermaNo ratings yet

- (Download PDF) On The Trail of Capital Flight From Africa The Takers and The Enablers Leonce Ndikumana Editor Full Chapter PDFDocument69 pages(Download PDF) On The Trail of Capital Flight From Africa The Takers and The Enablers Leonce Ndikumana Editor Full Chapter PDFhadlerktat100% (6)

- Republic V FNCBDocument6 pagesRepublic V FNCBMp Cas100% (1)

- Company Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact PersonDocument18 pagesCompany Name Address1 Address2 Area City Pincode Contact Number Designation Mobile URL Email ID Remarks Contact Personmurugesh18100% (1)

- Oracle Built in Packages.9781565923751.16316Document841 pagesOracle Built in Packages.9781565923751.16316Bhavdip Pather0% (1)

- Tentree'sDocument6 pagesTentree's陈皎月No ratings yet

- Convection and Radiation Heat TransferDocument14 pagesConvection and Radiation Heat TransferSalman ShalwaniNo ratings yet

- Assignment 1-3Document2 pagesAssignment 1-3Modi NiharNo ratings yet

- Case Study: Distributed Scrum Project For Dutch RailwaysDocument7 pagesCase Study: Distributed Scrum Project For Dutch RailwaysDark LordNo ratings yet

- Alternator AKSA AK6480Document8 pagesAlternator AKSA AK6480Cris_eu09No ratings yet

- Upper TrainingDocument7 pagesUpper TrainingManav SharmaNo ratings yet

- 2006 T300 Body Builders ManualDocument76 pages2006 T300 Body Builders ManualСергей Орлов100% (1)

- Nanya Technology Corporation'S Opposition To Rambus' Motion To Compel Nanya Technology Corporation To Produce DocumentsDocument7 pagesNanya Technology Corporation'S Opposition To Rambus' Motion To Compel Nanya Technology Corporation To Produce Documentssabatino123No ratings yet

- Asset Master Enhancement Documentation PDFDocument2 pagesAsset Master Enhancement Documentation PDFMohd IrfanNo ratings yet

- Tata Sky ALC Channel ListDocument13 pagesTata Sky ALC Channel ListIndianMascot33% (3)

- Limits, Fits and TolerancesDocument17 pagesLimits, Fits and TolerancesSarswati SuryawanshiNo ratings yet

- Manual Malahiteam En-1Document38 pagesManual Malahiteam En-1giuseppi conte100% (1)