Professional Documents

Culture Documents

FX5-4LC Data

FX5-4LC Data

Uploaded by

Puji AntoroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FX5-4LC Data

FX5-4LC Data

Uploaded by

Puji AntoroCopyright:

Available Formats

JY997D73701B Side

B

Side

A JAPANESE

Side

B ENGLISH How to obtain manuals On Minor error or major error 3. Wiring

For the necessary product manuals or documents, consult with your local Mitsubishi

Electric representative. ERROR Red Flashing Moderate error or major error WIRING PRECAUTIONS

Off Normal operation • Make sure to cut off all phases of the power supply externally before

Applicable standards

MELSEC iQ-F FX5-4LC FX5-4LC complies with the EC Directive (EMC Directive) and UL standards (UL, cUL).

Further information can be found in the following manual. OUT1 to OUT4 Green

On OUT1 to OUT4 output on attempting installation or wiring work.

Failure to do so may cause electric shock or damage to the product.

Off OUT1 to OUT4 output off • Don't use the input terminals for measurement on a main circuit, since those

→ MELSEC iQ-F FX5 User's Manual (Temperature Control)

Hardware Manual Regarding the standards that relate to the CPU module, please refer to either the

product catalog or consult with your local Mitsubishi Electric representative.

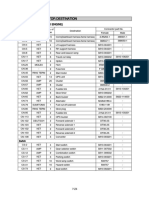

1.4 Terminal Layout

terminals have no measurement category.

• Make sure to properly wire to the spring clamp terminal block in accordance

with the following precautions.

Attention

Failure to do so may cause electric shock, equipment failures, a short-circuit,

Manual Number JY997D73701

This product is designed for use in industrial applications. OUT1 OUT3 wire breakage, malfunctions, or damage to the product.

OUT2 OUT4 - The disposal size of the cable end should follow the dimensions described

Revision B 1. Outline OUT

COM1 COM2 in the manual.

FX5-4LC temperature control module (hereinafter called FX5-4LC) equipped with 4 - Twist the ends of stranded wires and make sure that there are no loose wires.

Date March 2017 NC NC

channel input (thermocouples, resistance thermometer and micro voltage input), 4 - Do not solder-plate the electric wire ends.

points output (open collector transistor) and 4 points current sensor input can perform CT CT

- Do not connect more than the specified number of wires or electric wires of

temperature control. CH1 A B/TC+/VL+ unspecified size.

This manual describes the part names, dimensions, installation, and 1.1 Incorporated Items B b/TC-/VL- - Affix the electric wires so that neither the terminal block nor the connected

specifications of the product. Before use, read this manual and manuals of Check that the following product and items are included in the package: CT CT parts are directly stressed.

relevant products fully to acquire proficiency in handling and operating the CH2 A B/TC+/VL+

product. Make sure to learn all the product information, safety information, and Product FX5-4LC temperature control module B b/TC-/VL- WIRING PRECAUTIONS

precautions.

FX2NC-100MPCB power cable: (1 m, three wire) CT CT

And, store this manual in a safe place so that you can take it out and read it • Make sure to observe the following precautions in order to prevent any

whenever necessary. Always forward it to the end user. Included Items Dust proof protection sheet (1 sheet) CH3 A B/TC+/VL+

damage to the machinery or accidents due to malfunction of the PLC caused

Registration: B b/TC-/VL- by abnormal data written to the PLC due to the effects of noise:

Hardware manual (This manual)

The company name and the product name to be described in this manual are the CT CT - Do not bundle the power line and control line together with or lay them

registered trademarks or trademarks of each company. 1.2 External Dimensions, Part Names CH4 A B/TC+/VL+ close to the main circuit, high-voltage line, load line or power line. As a

[6] B b/TC-/VL- guideline, lay the power line, control line and communication cables at

Effective March 2017 2-4.5 Mounting holes Unit: mm least 100 mm away from the main circuit, high-voltage line, load line or

Specifications are subject to change without notice. power line.

© 2017 MITSUBISHI ELECTRIC CORPORATION [3] For further information on terminal, refer to the following manual. - Ground the shield of the analog input/output cable at one point on the

80 (Mounting hole pitch)

[2] [4] → MELSEC iQ-F FX5 User's Manual (Temperature Control) signal receiving side.

2. Installation However, do not use common grounding with heavy electrical systems.

• Check the interface type and correctly connect the cable. Incorrect wiring

Safety Precautions (Read these precautions before use.) [5]

[7] INSTALLATION (connecting the cable to an incorrect interface) may cause failure of the

90

PRECAUTIONS module and external device.

This manual classifies the safety precautions into two categories:

• Make sure to cut off all phases of the power supply externally before attempting • To terminal blocks or power connectors, connect circuits isolated from

and . [1] installation or wiring work. hazardous voltage by double/reinforced insulation.

Failure to do so may cause electric shock or damage to the product.

Indicates that incorrect handling may cause hazardous • This product is an open type device that must be installed and used within a

3.1 Applicable Cable

conditions, resulting in death or severe injury. [8] control cabinet which satisfies all of the following three requirements. 3.1.1 Spring clamp terminal block

19 8

60 19.2 83 - a cabinet which has conductivity. 1) Suitable wiring

Indicates that incorrect handling may cause hazardous

- a cabinet which has a structure to prevent the fire to spread outside the cabinet.

conditions, resulting in minor or moderate injury or No. of Wire size

property damage. - a cabinet which has sufficient mechanical strength. Temperature

wire per Single wire, Strand wire Ferrule with

MASS (Weight): Approx. 0.3 kg • Use the product within the generic environment specifications described in the rating

[9] terminal (Material: Copper wire) insulation sleeve

User's Manual (Hardware) for the CPU module to be used.

Depending on the circumstances, procedures indicated by may also [10] Outer painting color: Munsell 0.6B7.6/0.2

Never use the product in areas with excessive dust, oily smoke, conductive dusts, AWG24 to 16 AWG23 to 19

cause severe injury. corrosive gas (salt air, Cl 2 , H 2 S, SO 2 or NO 2 ), flammable gas, vibration or One wire 80°C or more

It is important to follow all precautions for personal safety. (0.2 to 1.5 mm2) (0.25 to 0.75 mm2)

impacts, or expose it to high temperature, condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire, malfunctions, 2) Wire end treatment

Associated Manual deterioration or damage may occur. Strip the cable about 10 mm from the tip to connect a wire ferrule at the

striped area. Failure to do so may result in electric shock or short circuit

Manual name Manual No. Description INSTALLATION between adjacent terminals because the conductive part. If the wire strip

MELSEC iQ-F FX5 PRECAUTIONS length is too short, it may result in the poor contact to the spring clamp

Explains temperature control terminal part.

User's Manual SH-081799ENG • Do not touch the conductive parts of the product directly.

module. When using a wire ferrule with an insulating sleeve, choose a wire with

(Temperature Control) Doing so may cause device failures or malfunctions.

proper cable sheath referring to the above outside dimensions, otherwise

Describes the details of input/ • When drilling screw holes or wiring, make sure that cutting and wiring debris do

the wire cannot be inserted easily.

MELSEC iQ-F FX5U output specifications, wiring and not enter the ventilation slits of the PLC.

[1] Terminal block Failure to do so may cause fire, equipment failures or malfunctions. - Strand wire/single wire - Ferrule with insulation sleeve

CPU module JY997D53401 i n s ta l l a t i o n o f t h e FX 5 U C P U [6] Name plate

(Spring clamp terminal block) • The dust proof sheet should be affixed to the ventilation slits before installation Insulation sleeve Contact area

Hardware Manual module from MELSEC iQ-F FX5U (Crimp area)

User's Manual (Hardware). [7] DIN rail mounting groove and wiring work to block foreign objects such as cutting and wiring debris.

[2] Extension cable

(DIN rail: DIN 46277, 35 mm wide) However, when the installation work is completed, make sure to remove the sheet

MELSEC iQ-F FX5U Explains FX5U CPU module [3] Direct mounting hole: 2 holes of φ4.5 to provide adequate ventilation.

User's Manual JY997D55301 specification details for I/O, wiring, [8] DIN rail mounting hook 10 mm

(mounting screw: M4 screw) Failure to do so may cause fire, equipment failures or malfunctions. 10 mm

(Hardware) installation, and maintenance. • Install the product on a flat surface.

[4] Operation status display LEDs [9] Pullout tab

Describes the details of input/ [5] Extension connector (for next module) [10] Power connector If the mounting surface is rough, undue force will be applied to the PC board, 2 to 2.8 mm 16 to 18 mm

MELSEC iQ-F FX5UC output specifications, wiring and thereby causing nonconformities.

1.3 Indications of LEDs • Install the product securely using a DIN rail or mounting screws. The following table shows wire ferrules and tools for wire ferrules

CPU module JY997D61001 installation of the FX5UC CPU

compatible with the terminal block. Use of items other than these may result

Hardware Manual module from MELSEC iQ-F FX5UC • Connect the extension cables securely to their designated connectors.

LED display LED color Status Indication Loose connections may cause malfunctions. in not being able to remove the wire ferrule, so carefully check that the wire

User's Manual (Hardware).

ferrule can be unplugged.

MELSEC iQ-F FX5UC Ex pla ins FX 5U C CP U mod ule On Power on For further information on mounting, refer to the following manual. <Reference product>

POWER Green

User's Manual JY997D61401 specification details for I/O, wiring, Off Power off or module failure → MELSEC iQ-F FX5U CPU module Hardware Manual

(Hardware) installation, and maintenance. → MELSEC iQ-F FX5U User's Manual (Hardware) Manufacturer Model Wire size Crimp tool

On Normal operation → MELSEC iQ-F FX5UC CPU module Hardware Manual AI 0.5-10 WH 0.5 mm2

RUN Green → MELSEC iQ-F FX5UC User's Manual (Hardware)

Off Error AI 0.75-10 GY 0.75 mm2

PHOENIX CONTACT

CRIMPFOX 6

GmbH & Co. KG AI 1.0-10 1.0 mm2

AI 1.5-10 1.5 mm2

3) Connecting a cable 4. Specification 4.4 Performance Specifications Items Specifications

• When ferrules with insulation sleeve are used

Insert a wire with the ferrule with insulation sleeve into the wire insertion DESIGN Items Specifications When CTL-12-S36-8 is used: 0.0 to 100.0 A

opening and push the wire. PRECAUTIONS When CTL-12-S36-10 is used: 0.0 to 100.0 A

Two-position control, PID control,

• When stranded wires and solid wires are used Control method When CTL-12-S56-10 is used: 0.0 to 100.0 A

• Make sure to set up the following safety circuits outside the PLC to ensure safe Heating/cooling PID control, Cascade control Heater current measured

Push the open/close button of the terminal block with a flathead When CTL-12L-8 is used: 0.0 to 100.0 A

system operation even during external power supply problems or PLC failure. value

screwdriver. While pushing the open/close button, insert the wire into the Control operation period 250 ms/4ch When CTL-6-P is used: 0.0 to 30.0 A

Otherwise, malfunctions may cause serious accidents.

insertion opening until the wire reaches the back, and then release the When CTL-6-P-H is used: 0.0 to 30.0 A

open/close button. - Most importantly, set up the following: an emergency stop circuit, a protection Measured temperature

Refer to section 4.7 When CTL-6-S-H is used: 0.0 to 30.0 A

Then, pull the wire lightly and check that it is clamped securely. circuit, an interlock circuit for opposite movements (such as normal vs. reverse range

<Reference> rotation), and an interlock circuit (to prevent damage to the equipment at the Larger one between ±5% of input value and ±2

upper and lower positioning limits). Heater disconnection Alarm is detected (Variable within range from 0.0 to 100.0 Measurement precision

A (Excluding precision of current sensor)

Manufacturer Model - Note that when the CPU module detects an error, such as a watchdog timer detection A by GX Works3.)

error, during self-diagnosis, all outputs are turned off. Also, when an error that Sampling period 0.5 sec.

PHOENIX CONTACT GmbH & Co. 0: Not used, 1: Monitor, 2: Monitor+Alarm,

SZS 0.4×2.5 VDE cannot be detected by the CPU module occurs in an input/output control block, Operation mode

KG output control may be disabled.

3: Monitor+Alarm+Control (Selected by GX Works3) 4.7 Measured Temperature Range

External circuits and mechanisms should be designed to ensure safe • The photocoupler is used to insulate the analog input

4) Disconnecting a cable machinery operation in such a case. Input type Measurement precision

Push the open/close button of the wire to be disconnected with a flathead area and transistor output area from the PLC.

screwdriver. Pull out the wire with the open/close button pushed. - Note that when an error occurs in a relay, transistor or triac of an output circuit, • The DC/DC converter is used to insulate the power K -200 to +1300°C (-100 to +2400°F)

the output might stay on or off. Insulation method

supply from the analog input area and transistor J -200 to +1200°C (-100 to +2100°F)

3.2 Example of Input/output Wiring For output signals that may lead to serious accidents, external circuits and

output area.

mechanisms should be designed to ensure safe machinery operation in such a case.

24 V DC FX5-4LC • Channels are insulated from each other. T -200 to +400°C (-300 to +700°F)

DESIGN Number of occupied I/O S 0 to 1700°C (0 to 3200°F)

Power supply 8 points

PRECAUTIONS points R 0 to 1700°C (0 to 3200°F)

Grounding • Simultaneously turn on and off the power supplies of the CPU module and

extension modules.

4.5 Input Specifications E -200 to +1000°C (0 to 1800°F)

(Grounding resistance: Load OUT1

Output

100 Ω or less) COM1 Items Specifications B 0 to 1800°C (0 to 3000°F)

STARTUP AND

Compensating lead wire ch *1

Number of input points 4 points N 0 to 1300°C (0 to 2300°F)

MAINTENANCE

TC+

Thermocouple PRECAUTIONS K, J, R, S, E, T, B, N JIS C 1602-1995, PLII 0 to 1200°C (0 to 2300°F)

TC- Thermocouple

• Do not disassemble or modify the PLC. PLII, W5Re/W26Re, U, L

Shielded wire W5Re/W26Re 0 to 2300°C (0 to 3000°F)

Doing so may cause fire, equipment failures, or malfunctions. 3-wire type Pt100 JIS C 1604-1997,

ch For repair, contact your local Mitsubishi Electric representative. U -200 to +600°C (-300 to +700°F)

A *2 Input type*1 Resistance 3-wire type JPt100 JIS C 1604-1981

Resistance thermometer • Do not drop the product or exert strong impact to it.

B thermometer 2-wire type/3-wire type L 0 to 900°C (0 to 1600°F)

Pt100 or Pt1000 Doing so may cause damage. Pt1000 JIS C 1604-2013

b (3-wire type) Micro voltage input DC0 to 10 mV, DC0 to 100 mV

Shielded wire DISPOSAL Micro voltage input

Pt100 (3-wire type) -200 to +600°C (-300 to +1100°F)

ch PRECAUTIONS Refer to MELSEC iQ-F FX5 User's Manual (Temperature

A Measurement precision*2

Control) JPt100 (3-wire type) -200 to +500°C (-300 to +900°F)

B Resistance thermometer*2 • Please contact a certified electronic waste disposal company for the

Shielded wire Pt1000 environmentally safe recycling and disposal of your device. Within ±1.0°C Pt1000 (2-wire type/3-wire type) -200.0 to +650.0°C (-328 to +1184°F)

*3

B (2-wire type) When ambient

However, within ± 2.0°C while input

b TRANSPORTATION temperature is 4.8 Output Specifications

value is -150 to -100°C / within ± 3.0°C

PRECAUTIONS 0 to 55°C

Cold contact temperature while input value is -200 to -150°C

ch Items Specifications

VL+ • The product is a precision instrument. During transportation, avoid impacts larger compensation error Within ±1.8°C

Micro voltage input than those specified in the general specifications by using dedicated packaging When ambient Number of output points 4 points

VL- However, within ± 3.6°C while input

boxes and shock-absorbing palettes. temperature is

Shielded wire value is -150 to -100°C / within ± 5.4°C Output method NPN open collector transistor output

Failure to do so may cause failures in the product. After transportation, verify -20 to 0°C

AC Power supply while input value is -200 to -150°C

ch operation of the product and check for damage of the mounting part, etc. Rated load voltage 5 to 24 V DC

CT 0.1°C (0.1°F), 1.0°C (1.0°F), 0.5 μV or 5.0 μV

Current sensor (CT) Resolution Maximum load voltage 30 V DC or less

CT 4.1 Applicable CPU Module Varies depending on input range of used sensors.

Controlled Maximum load current 100 mA

object Shielded wire Model name Applicability Sampling period 250 ms/4ch

ch : represents the channel number. FX5U CPU module Ver. 1.050 or later Effect of external Leak current in OFF status 0.1 mA or less

*1 When using a thermocouple, use specified compensating lead wires. resistance (When Approx. 0.125 μV/Ω ON voltage 1.5 V (When maximum load current)

FX5UC CPU module*1 Ver. 1.050 or later thermocouple is used)

*2 When you use a resistance thermometer, the resistance of the lead wire is Control output cycle 0.5 to 100.0 sec.

low, use a wire without a resistance difference between the lead wire. *1 FX5-CNV-IFC or FX5-C1PS-5V is necessary to connect FX5-4LC to the FX5UC Effect of input lead wire 3-wire type Approx. 0.03%/Ω of full scale.

*3 Make sure to short-circuit the [B] and [b] terminals when a 2-wire resistance CPU module. resistance 10 Ω or less per 1-wire

thermometer is input. (When resistance Approx. 0.04%/Ω of full scale.

2-wire type This manual confers no industrial property rights or any rights of any other kind,

3.2.1 Power Connector 4.2 General Specifications thermometer is used) 7.5 Ω or less per 1-wire nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

For further information on the power supply wiring and power cable, refer to the The items other than the following are equivalent to those of the CPU module.

Input impedance 1 MΩ or more held responsible for any problems involving industrial property rights which may

following manual. For the general specification, refer to the following manual. occur as a result of using the contents noted in this manual.

→ MELSEC iQ-F FX5 User's Manual (Temperature Control) → MELSEC iQ-F FX5U User's Manual (Hardware) Approx. 0.20 mA

→ MELSEC iQ-F FX5UC User's Manual (Hardware) Sensor current

(When resistance thermometer is used) Warranty

Exclusion of loss in opportunity and secondary loss from warranty liability

(Green) Items Specifications Operation when input is

Regardless of the gratis warranty term, Mitsubishi shall not be liable for compensation to:

disconnected/ Upscale/Downscale

Dielectric withstand (1) Damages caused by any cause found not to be the responsibility of Mitsubishi.

( Black ) 500 V AC for 1 minute Operation when input is (When resistance thermometer is used)

voltage Between all terminals and (2) Loss in opportunity, lost profits incurred to the user by Failures of Mitsubishi products.

( Red ) short-circuited

Insulation 10 MΩ or higher by 500 V DC ground terminal (3) Special damages and secondary damages whether foreseeable or not, compensation for

resistance insulation resistance tester *1 A different input can be selected for each channel. accidents, and compensation for damages to products other than Mitsubishi products.

(4) Replacement by the user, maintenance of on-site equipment, start-up test run

*2 To stabilize the measurement precision, warm-up (supply power) the system for

3.3 Grounding 4.3 Power Supply Specifications

and other tasks.

30 minutes or more after power-on.

Ground the PLC as stated below.

• Perform class D grounding. (Grounding resistance: 100 Ω or less) Items Specifications

4.6 Current Sensor (CT) Input Specifications For safe use

• Ground the PLC independently if possible. Power supply voltage 24 V DC +20%, -15%

If the PLC cannot be grounded independently, perform the "Shared grounding" Items Specifications This product has been manufactured as a general-purpose part for general

shown below. External Operation continues when the

Allowable instantaneous industries, and has not been designed or manufactured to be incorporated in

power instantaneous power failure is shorter than Number of input points 4 points

For details, refer to the following manual. power failure time a device or system used in purposes related to human life.

supply 5 ms.

→ MELSEC iQ-F FX5U User's Manual (Hardware) When using this product in the United States or Before using the product for special purposes such as nuclear power, electric

→ MELSEC iQ-F FX5UC User's Manual (Hardware) Current consumption 25 mA Canada, use current sensors with UL/cUL Listed power, aerospace, medicine or passenger movement vehicles, consult with

Other Other Other Internal Power supply voltage 5 V DC and/or CSA certified such as XOBA and XOBA7. Mitsubishi Electric.

PLC equipment PLC equipment PLC equipment When using current sensors in countries other This product has been manufactured under strict quality control. However

power Current sensor

supply Current consumption 140 mA than the above, we recommend the following. when installing the product where major accidents or losses could occur if the

CTL-12-S36-8, CTL-12-S36-10, CTL-12-S56-10, product fails, install appropriate backup or failsafe functions in the system.

Independent grounding Shared grounding Common grounding CTL-12L-8, CTL-6-P, CTL-6-P-H, CTL-6-S-H

(Best condition) (Good condition) (Not allowed) (manufactured by U.R.D. Co., Ltd.)

• Bring the grounding point close to the PLC as much as possible so that the

Allowable input current 0 to 182.2 mArms HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

ground cable can be shortened.

JY997D73701B Side

B

Side

A JAPANESE

Side

B ENGLISH How to obtain manuals On Minor error or major error 3. Wiring

For the necessary product manuals or documents, consult with your local Mitsubishi

Electric representative. ERROR Red Flashing Moderate error or major error WIRING PRECAUTIONS

Off Normal operation • Make sure to cut off all phases of the power supply externally before

Applicable standards

MELSEC iQ-F FX5-4LC FX5-4LC complies with the EC Directive (EMC Directive) and UL standards (UL, cUL).

Further information can be found in the following manual. OUT1 to OUT4 Green

On OUT1 to OUT4 output on attempting installation or wiring work.

Failure to do so may cause electric shock or damage to the product.

Off OUT1 to OUT4 output off • Don't use the input terminals for measurement on a main circuit, since those

→ MELSEC iQ-F FX5 User's Manual (Temperature Control)

Hardware Manual Regarding the standards that relate to the CPU module, please refer to either the

product catalog or consult with your local Mitsubishi Electric representative.

1.4 Terminal Layout

terminals have no measurement category.

• Make sure to properly wire to the spring clamp terminal block in accordance

with the following precautions.

Attention

Failure to do so may cause electric shock, equipment failures, a short-circuit,

Manual Number JY997D73701

This product is designed for use in industrial applications. OUT1 OUT3 wire breakage, malfunctions, or damage to the product.

OUT2 OUT4 - The disposal size of the cable end should follow the dimensions described

Revision B 1. Outline OUT

COM1 COM2 in the manual.

FX5-4LC temperature control module (hereinafter called FX5-4LC) equipped with 4 - Twist the ends of stranded wires and make sure that there are no loose wires.

Date March 2017 NC NC

channel input (thermocouples, resistance thermometer and micro voltage input), 4 - Do not solder-plate the electric wire ends.

points output (open collector transistor) and 4 points current sensor input can perform CT CT

- Do not connect more than the specified number of wires or electric wires of

temperature control. CH1 A B/TC+/VL+ unspecified size.

This manual describes the part names, dimensions, installation, and 1.1 Incorporated Items B b/TC-/VL- - Affix the electric wires so that neither the terminal block nor the connected

specifications of the product. Before use, read this manual and manuals of Check that the following product and items are included in the package: CT CT parts are directly stressed.

relevant products fully to acquire proficiency in handling and operating the CH2 A B/TC+/VL+

product. Make sure to learn all the product information, safety information, and Product FX5-4LC temperature control module B b/TC-/VL- WIRING PRECAUTIONS

precautions.

FX2NC-100MPCB power cable: (1 m, three wire) CT CT

And, store this manual in a safe place so that you can take it out and read it • Make sure to observe the following precautions in order to prevent any

whenever necessary. Always forward it to the end user. Included Items Dust proof protection sheet (1 sheet) CH3 A B/TC+/VL+

damage to the machinery or accidents due to malfunction of the PLC caused

Registration: B b/TC-/VL- by abnormal data written to the PLC due to the effects of noise:

Hardware manual (This manual)

The company name and the product name to be described in this manual are the CT CT - Do not bundle the power line and control line together with or lay them

registered trademarks or trademarks of each company. 1.2 External Dimensions, Part Names CH4 A B/TC+/VL+ close to the main circuit, high-voltage line, load line or power line. As a

[6] B b/TC-/VL- guideline, lay the power line, control line and communication cables at

Effective March 2017 2-4.5 Mounting holes Unit: mm least 100 mm away from the main circuit, high-voltage line, load line or

Specifications are subject to change without notice. power line.

© 2017 MITSUBISHI ELECTRIC CORPORATION [3] For further information on terminal, refer to the following manual. - Ground the shield of the analog input/output cable at one point on the

80 (Mounting hole pitch)

[2] [4] → MELSEC iQ-F FX5 User's Manual (Temperature Control) signal receiving side.

2. Installation However, do not use common grounding with heavy electrical systems.

• Check the interface type and correctly connect the cable. Incorrect wiring

Safety Precautions (Read these precautions before use.) [5]

[7] INSTALLATION (connecting the cable to an incorrect interface) may cause failure of the

90

PRECAUTIONS module and external device.

This manual classifies the safety precautions into two categories:

• Make sure to cut off all phases of the power supply externally before attempting • To terminal blocks or power connectors, connect circuits isolated from

and . [1] installation or wiring work. hazardous voltage by double/reinforced insulation.

Failure to do so may cause electric shock or damage to the product.

Indicates that incorrect handling may cause hazardous • This product is an open type device that must be installed and used within a

3.1 Applicable Cable

conditions, resulting in death or severe injury. [8] control cabinet which satisfies all of the following three requirements. 3.1.1 Spring clamp terminal block

19 8

60 19.2 83 - a cabinet which has conductivity. 1) Suitable wiring

Indicates that incorrect handling may cause hazardous

- a cabinet which has a structure to prevent the fire to spread outside the cabinet.

conditions, resulting in minor or moderate injury or No. of Wire size

property damage. - a cabinet which has sufficient mechanical strength. Temperature

wire per Single wire, Strand wire Ferrule with

MASS (Weight): Approx. 0.3 kg • Use the product within the generic environment specifications described in the rating

[9] terminal (Material: Copper wire) insulation sleeve

User's Manual (Hardware) for the CPU module to be used.

Depending on the circumstances, procedures indicated by may also [10] Outer painting color: Munsell 0.6B7.6/0.2

Never use the product in areas with excessive dust, oily smoke, conductive dusts, AWG24 to 16 AWG23 to 19

cause severe injury. corrosive gas (salt air, Cl 2 , H 2 S, SO 2 or NO 2 ), flammable gas, vibration or One wire 80°C or more

It is important to follow all precautions for personal safety. (0.2 to 1.5 mm2) (0.25 to 0.75 mm2)

impacts, or expose it to high temperature, condensation, or rain and wind.

If the product is used in such conditions, electric shock, fire, malfunctions, 2) Wire end treatment

Associated Manual deterioration or damage may occur. Strip the cable about 10 mm from the tip to connect a wire ferrule at the

striped area. Failure to do so may result in electric shock or short circuit

Manual name Manual No. Description INSTALLATION between adjacent terminals because the conductive part. If the wire strip

MELSEC iQ-F FX5 PRECAUTIONS length is too short, it may result in the poor contact to the spring clamp

Explains temperature control terminal part.

User's Manual SH-081799ENG • Do not touch the conductive parts of the product directly.

module. When using a wire ferrule with an insulating sleeve, choose a wire with

(Temperature Control) Doing so may cause device failures or malfunctions.

proper cable sheath referring to the above outside dimensions, otherwise

Describes the details of input/ • When drilling screw holes or wiring, make sure that cutting and wiring debris do

the wire cannot be inserted easily.

MELSEC iQ-F FX5U output specifications, wiring and not enter the ventilation slits of the PLC.

[1] Terminal block Failure to do so may cause fire, equipment failures or malfunctions. - Strand wire/single wire - Ferrule with insulation sleeve

CPU module JY997D53401 i n s ta l l a t i o n o f t h e FX 5 U C P U [6] Name plate

(Spring clamp terminal block) • The dust proof sheet should be affixed to the ventilation slits before installation Insulation sleeve Contact area

Hardware Manual module from MELSEC iQ-F FX5U (Crimp area)

User's Manual (Hardware). [7] DIN rail mounting groove and wiring work to block foreign objects such as cutting and wiring debris.

[2] Extension cable

(DIN rail: DIN 46277, 35 mm wide) However, when the installation work is completed, make sure to remove the sheet

MELSEC iQ-F FX5U Explains FX5U CPU module [3] Direct mounting hole: 2 holes of φ4.5 to provide adequate ventilation.

User's Manual JY997D55301 specification details for I/O, wiring, [8] DIN rail mounting hook 10 mm

(mounting screw: M4 screw) Failure to do so may cause fire, equipment failures or malfunctions. 10 mm

(Hardware) installation, and maintenance. • Install the product on a flat surface.

[4] Operation status display LEDs [9] Pullout tab

Describes the details of input/ [5] Extension connector (for next module) [10] Power connector If the mounting surface is rough, undue force will be applied to the PC board, 2 to 2.8 mm 16 to 18 mm

MELSEC iQ-F FX5UC output specifications, wiring and thereby causing nonconformities.

1.3 Indications of LEDs • Install the product securely using a DIN rail or mounting screws. The following table shows wire ferrules and tools for wire ferrules

CPU module JY997D61001 installation of the FX5UC CPU

compatible with the terminal block. Use of items other than these may result

Hardware Manual module from MELSEC iQ-F FX5UC • Connect the extension cables securely to their designated connectors.

LED display LED color Status Indication Loose connections may cause malfunctions. in not being able to remove the wire ferrule, so carefully check that the wire

User's Manual (Hardware).

ferrule can be unplugged.

MELSEC iQ-F FX5UC Ex pla ins FX 5U C CP U mod ule On Power on For further information on mounting, refer to the following manual. <Reference product>

POWER Green

User's Manual JY997D61401 specification details for I/O, wiring, Off Power off or module failure → MELSEC iQ-F FX5U CPU module Hardware Manual

(Hardware) installation, and maintenance. → MELSEC iQ-F FX5U User's Manual (Hardware) Manufacturer Model Wire size Crimp tool

On Normal operation → MELSEC iQ-F FX5UC CPU module Hardware Manual AI 0.5-10 WH 0.5 mm2

RUN Green → MELSEC iQ-F FX5UC User's Manual (Hardware)

Off Error AI 0.75-10 GY 0.75 mm2

PHOENIX CONTACT

CRIMPFOX 6

GmbH & Co. KG AI 1.0-10 1.0 mm2

AI 1.5-10 1.5 mm2

3) Connecting a cable 4. Specification 4.4 Performance Specifications Items Specifications

• When ferrules with insulation sleeve are used

Insert a wire with the ferrule with insulation sleeve into the wire insertion DESIGN Items Specifications When CTL-12-S36-8 is used: 0.0 to 100.0 A

opening and push the wire. PRECAUTIONS When CTL-12-S36-10 is used: 0.0 to 100.0 A

Two-position control, PID control,

• When stranded wires and solid wires are used Control method When CTL-12-S56-10 is used: 0.0 to 100.0 A

• Make sure to set up the following safety circuits outside the PLC to ensure safe Heating/cooling PID control, Cascade control Heater current measured

Push the open/close button of the terminal block with a flathead When CTL-12L-8 is used: 0.0 to 100.0 A

system operation even during external power supply problems or PLC failure. value

screwdriver. While pushing the open/close button, insert the wire into the Control operation period 250 ms/4ch When CTL-6-P is used: 0.0 to 30.0 A

Otherwise, malfunctions may cause serious accidents.

insertion opening until the wire reaches the back, and then release the When CTL-6-P-H is used: 0.0 to 30.0 A

open/close button. - Most importantly, set up the following: an emergency stop circuit, a protection Measured temperature

Refer to section 4.7 When CTL-6-S-H is used: 0.0 to 30.0 A

Then, pull the wire lightly and check that it is clamped securely. circuit, an interlock circuit for opposite movements (such as normal vs. reverse range

<Reference> rotation), and an interlock circuit (to prevent damage to the equipment at the Larger one between ±5% of input value and ±2

upper and lower positioning limits). Heater disconnection Alarm is detected (Variable within range from 0.0 to 100.0 Measurement precision

A (Excluding precision of current sensor)

Manufacturer Model - Note that when the CPU module detects an error, such as a watchdog timer detection A by GX Works3.)

error, during self-diagnosis, all outputs are turned off. Also, when an error that Sampling period 0.5 sec.

PHOENIX CONTACT GmbH & Co. 0: Not used, 1: Monitor, 2: Monitor+Alarm,

SZS 0.4×2.5 VDE cannot be detected by the CPU module occurs in an input/output control block, Operation mode

KG output control may be disabled.

3: Monitor+Alarm+Control (Selected by GX Works3) 4.7 Measured Temperature Range

External circuits and mechanisms should be designed to ensure safe • The photocoupler is used to insulate the analog input

4) Disconnecting a cable machinery operation in such a case. Input type Measurement precision

Push the open/close button of the wire to be disconnected with a flathead area and transistor output area from the PLC.

screwdriver. Pull out the wire with the open/close button pushed. - Note that when an error occurs in a relay, transistor or triac of an output circuit, • The DC/DC converter is used to insulate the power K -200 to +1300°C (-100 to +2400°F)

the output might stay on or off. Insulation method

supply from the analog input area and transistor J -200 to +1200°C (-100 to +2100°F)

3.2 Example of Input/output Wiring For output signals that may lead to serious accidents, external circuits and

output area.

mechanisms should be designed to ensure safe machinery operation in such a case.

24 V DC FX5-4LC • Channels are insulated from each other. T -200 to +400°C (-300 to +700°F)

DESIGN Number of occupied I/O S 0 to 1700°C (0 to 3200°F)

Power supply 8 points

PRECAUTIONS points R 0 to 1700°C (0 to 3200°F)

Grounding • Simultaneously turn on and off the power supplies of the CPU module and

extension modules.

4.5 Input Specifications E -200 to +1000°C (0 to 1800°F)

(Grounding resistance: Load OUT1

Output

100 Ω or less) COM1 Items Specifications B 0 to 1800°C (0 to 3000°F)

STARTUP AND

Compensating lead wire ch *1

Number of input points 4 points N 0 to 1300°C (0 to 2300°F)

MAINTENANCE

TC+

Thermocouple PRECAUTIONS K, J, R, S, E, T, B, N JIS C 1602-1995, PLII 0 to 1200°C (0 to 2300°F)

TC- Thermocouple

• Do not disassemble or modify the PLC. PLII, W5Re/W26Re, U, L

Shielded wire W5Re/W26Re 0 to 2300°C (0 to 3000°F)

Doing so may cause fire, equipment failures, or malfunctions. 3-wire type Pt100 JIS C 1604-1997,

ch For repair, contact your local Mitsubishi Electric representative. U -200 to +600°C (-300 to +700°F)

A *2 Input type*1 Resistance 3-wire type JPt100 JIS C 1604-1981

Resistance thermometer • Do not drop the product or exert strong impact to it.

B thermometer 2-wire type/3-wire type L 0 to 900°C (0 to 1600°F)

Pt100 or Pt1000 Doing so may cause damage. Pt1000 JIS C 1604-2013

b (3-wire type) Micro voltage input DC0 to 10 mV, DC0 to 100 mV

Shielded wire DISPOSAL Micro voltage input

Pt100 (3-wire type) -200 to +600°C (-300 to +1100°F)

ch PRECAUTIONS Refer to MELSEC iQ-F FX5 User's Manual (Temperature

A Measurement precision*2

Control) JPt100 (3-wire type) -200 to +500°C (-300 to +900°F)

B Resistance thermometer*2 • Please contact a certified electronic waste disposal company for the

Shielded wire Pt1000 environmentally safe recycling and disposal of your device. Within ±1.0°C Pt1000 (2-wire type/3-wire type) -200.0 to +650.0°C (-328 to +1184°F)

*3

B (2-wire type) When ambient

However, within ± 2.0°C while input

b TRANSPORTATION temperature is 4.8 Output Specifications

value is -150 to -100°C / within ± 3.0°C

PRECAUTIONS 0 to 55°C

Cold contact temperature while input value is -200 to -150°C

ch Items Specifications

VL+ • The product is a precision instrument. During transportation, avoid impacts larger compensation error Within ±1.8°C

Micro voltage input than those specified in the general specifications by using dedicated packaging When ambient Number of output points 4 points

VL- However, within ± 3.6°C while input

boxes and shock-absorbing palettes. temperature is

Shielded wire value is -150 to -100°C / within ± 5.4°C Output method NPN open collector transistor output

Failure to do so may cause failures in the product. After transportation, verify -20 to 0°C

AC Power supply while input value is -200 to -150°C

ch operation of the product and check for damage of the mounting part, etc. Rated load voltage 5 to 24 V DC

CT 0.1°C (0.1°F), 1.0°C (1.0°F), 0.5 μV or 5.0 μV

Current sensor (CT) Resolution Maximum load voltage 30 V DC or less

CT 4.1 Applicable CPU Module Varies depending on input range of used sensors.

Controlled Maximum load current 100 mA

object Shielded wire Model name Applicability Sampling period 250 ms/4ch

ch : represents the channel number. FX5U CPU module Ver. 1.050 or later Effect of external Leak current in OFF status 0.1 mA or less

*1 When using a thermocouple, use specified compensating lead wires. resistance (When Approx. 0.125 μV/Ω ON voltage 1.5 V (When maximum load current)

FX5UC CPU module*1 Ver. 1.050 or later thermocouple is used)

*2 When you use a resistance thermometer, the resistance of the lead wire is Control output cycle 0.5 to 100.0 sec.

low, use a wire without a resistance difference between the lead wire. *1 FX5-CNV-IFC or FX5-C1PS-5V is necessary to connect FX5-4LC to the FX5UC Effect of input lead wire 3-wire type Approx. 0.03%/Ω of full scale.

*3 Make sure to short-circuit the [B] and [b] terminals when a 2-wire resistance CPU module. resistance 10 Ω or less per 1-wire

thermometer is input. (When resistance Approx. 0.04%/Ω of full scale.

2-wire type This manual confers no industrial property rights or any rights of any other kind,

3.2.1 Power Connector 4.2 General Specifications thermometer is used) 7.5 Ω or less per 1-wire nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be

For further information on the power supply wiring and power cable, refer to the The items other than the following are equivalent to those of the CPU module.

Input impedance 1 MΩ or more held responsible for any problems involving industrial property rights which may

following manual. For the general specification, refer to the following manual. occur as a result of using the contents noted in this manual.

→ MELSEC iQ-F FX5 User's Manual (Temperature Control) → MELSEC iQ-F FX5U User's Manual (Hardware) Approx. 0.20 mA

→ MELSEC iQ-F FX5UC User's Manual (Hardware) Sensor current

(When resistance thermometer is used) Warranty

Exclusion of loss in opportunity and secondary loss from warranty liability

(Green) Items Specifications Operation when input is

Regardless of the gratis warranty term, Mitsubishi shall not be liable for compensation to:

disconnected/ Upscale/Downscale

Dielectric withstand (1) Damages caused by any cause found not to be the responsibility of Mitsubishi.

( Black ) 500 V AC for 1 minute Operation when input is (When resistance thermometer is used)

voltage Between all terminals and (2) Loss in opportunity, lost profits incurred to the user by Failures of Mitsubishi products.

( Red ) short-circuited

Insulation 10 MΩ or higher by 500 V DC ground terminal (3) Special damages and secondary damages whether foreseeable or not, compensation for

resistance insulation resistance tester *1 A different input can be selected for each channel. accidents, and compensation for damages to products other than Mitsubishi products.

(4) Replacement by the user, maintenance of on-site equipment, start-up test run

*2 To stabilize the measurement precision, warm-up (supply power) the system for

3.3 Grounding 4.3 Power Supply Specifications

and other tasks.

30 minutes or more after power-on.

Ground the PLC as stated below.

• Perform class D grounding. (Grounding resistance: 100 Ω or less) Items Specifications

4.6 Current Sensor (CT) Input Specifications For safe use

• Ground the PLC independently if possible. Power supply voltage 24 V DC +20%, -15%

If the PLC cannot be grounded independently, perform the "Shared grounding" Items Specifications This product has been manufactured as a general-purpose part for general

shown below. External Operation continues when the

Allowable instantaneous industries, and has not been designed or manufactured to be incorporated in

power instantaneous power failure is shorter than Number of input points 4 points

For details, refer to the following manual. power failure time a device or system used in purposes related to human life.

supply 5 ms.

→ MELSEC iQ-F FX5U User's Manual (Hardware) When using this product in the United States or Before using the product for special purposes such as nuclear power, electric

→ MELSEC iQ-F FX5UC User's Manual (Hardware) Current consumption 25 mA Canada, use current sensors with UL/cUL Listed power, aerospace, medicine or passenger movement vehicles, consult with

Other Other Other Internal Power supply voltage 5 V DC and/or CSA certified such as XOBA and XOBA7. Mitsubishi Electric.

PLC equipment PLC equipment PLC equipment When using current sensors in countries other This product has been manufactured under strict quality control. However

power Current sensor

supply Current consumption 140 mA than the above, we recommend the following. when installing the product where major accidents or losses could occur if the

CTL-12-S36-8, CTL-12-S36-10, CTL-12-S56-10, product fails, install appropriate backup or failsafe functions in the system.

Independent grounding Shared grounding Common grounding CTL-12L-8, CTL-6-P, CTL-6-P-H, CTL-6-S-H

(Best condition) (Good condition) (Not allowed) (manufactured by U.R.D. Co., Ltd.)

• Bring the grounding point close to the PLC as much as possible so that the

Allowable input current 0 to 182.2 mArms HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100-8310, JAPAN

ground cable can be shortened.

You might also like

- Ewd ,,uzj FZJ HDJ HZJ 100-105Document447 pagesEwd ,,uzj FZJ HDJ HZJ 100-105nightevery100% (1)

- M700 M70 Maintenance ManualDocument543 pagesM700 M70 Maintenance ManualDavid ŘezáčNo ratings yet

- Electrical Regulations and Standards - Electrical Installation GuideDocument5 pagesElectrical Regulations and Standards - Electrical Installation GuidelgaungNo ratings yet

- 220 KV Muradnagar AshishDocument29 pages220 KV Muradnagar Ashishashishdixit14feb33% (3)

- Frenic MiniDocument192 pagesFrenic MiniHerrydroidNo ratings yet

- Manuel D'utilisation Convertisseur Phoenix Victron 250VA-375VA-En - NL - FR - DE - ESDocument42 pagesManuel D'utilisation Convertisseur Phoenix Victron 250VA-375VA-En - NL - FR - DE - ESJean Pierre KANYINDANo ratings yet

- Manual Phoenix Inverter 250va 375va Rev 01 enDocument10 pagesManual Phoenix Inverter 250va 375va Rev 01 enViktor BurkertNo ratings yet

- Opc-Vg1-Tl: T-Link Interface Card For FRENIC-VGDocument8 pagesOpc-Vg1-Tl: T-Link Interface Card For FRENIC-VGiqdam94No ratings yet

- FRENIC Ace Solar Pumping ManualDocument78 pagesFRENIC Ace Solar Pumping ManualSINES FranceNo ratings yet

- LR5 - Web Manual (En)Document93 pagesLR5 - Web Manual (En)NhậtQuangNguyễnNo ratings yet

- FX5 4AD ADP Hardware ManualDocument2 pagesFX5 4AD ADP Hardware ManualsunhuynhNo ratings yet

- Fuji FRENICmega Aio ManualDocument29 pagesFuji FRENICmega Aio Manualislam mohamedNo ratings yet

- Iik Kfaps 03Document2 pagesIik Kfaps 03Luis Hernandez.No ratings yet

- HSD PDFDocument12 pagesHSD PDFDinezJdNo ratings yet

- FX3G, FX3U, FX3UC Series Users Manual - Positioning Control EditionDocument242 pagesFX3G, FX3U, FX3UC Series Users Manual - Positioning Control EditionYuwarath Suktrakoon0% (1)

- Digital-Analog Aj65Bt 64davidai Conversion Module: User's Manual, 4-%Document40 pagesDigital-Analog Aj65Bt 64davidai Conversion Module: User's Manual, 4-%rammu2001No ratings yet

- CC-Link Remote IO Module User's Manual Ver.JDocument162 pagesCC-Link Remote IO Module User's Manual Ver.Jrammu2001100% (1)

- Ib 66781 FDocument264 pagesIb 66781 FFederico GroszNo ratings yet

- CC-Link System Master/Local Module CC-Link System Master/Local ModuleDocument312 pagesCC-Link System Master/Local Module CC-Link System Master/Local ModuleHuy Lê PhướcNo ratings yet

- 3.1 MANUAL UPS 10 KVA Tripp-Lite-Owners-Manual-47250 PDFDocument84 pages3.1 MANUAL UPS 10 KVA Tripp-Lite-Owners-Manual-47250 PDFRICARDO TRIANANo ratings yet

- Cc-Link IoDocument181 pagesCc-Link IoJinKi LeeNo ratings yet

- aj65bt_rpi_10a_aj65bt_rpi_10b_user_s_manual_english_controllerDocument26 pagesaj65bt_rpi_10a_aj65bt_rpi_10b_user_s_manual_english_controllerumar bonserNo ratings yet

- F-MPC60B Series: User's ManualDocument146 pagesF-MPC60B Series: User's Manualpika100% (1)

- Trinitron Ssm14n5eDocument64 pagesTrinitron Ssm14n5eoscar tebarNo ratings yet

- 2008-11-19 Installation Manual - Do Kit - pqnfp00t0 - mfl58136507Document25 pages2008-11-19 Installation Manual - Do Kit - pqnfp00t0 - mfl58136507Rey Christian Huamani NizamaNo ratings yet

- Fukuda Denshi FX-2111 ECG - Service ManualDocument128 pagesFukuda Denshi FX-2111 ECG - Service Manualdedy83No ratings yet

- Jy997d16801 GDocument252 pagesJy997d16801 GFrancis HernándezNo ratings yet

- DL Ep1Document128 pagesDL Ep1LiemNo ratings yet

- Silo - Tips - DB Unit Instruction Manual Caution Dynamic Braking Unit Inr hf51196c e PDFDocument32 pagesSilo - Tips - DB Unit Instruction Manual Caution Dynamic Braking Unit Inr hf51196c e PDFHuy NguyễnNo ratings yet

- Installation Manual: FX - 2AD-BDDocument3 pagesInstallation Manual: FX - 2AD-BDRovoltic SpaNo ratings yet

- PLC Programming 9Document504 pagesPLC Programming 9Keo PanhavathNo ratings yet

- Tài liệu Biến tần Fuji MegaDocument806 pagesTài liệu Biến tần Fuji MegaQuy CaoNo ratings yet

- aj65bt g4 s3 user s manual english controllerمهمDocument64 pagesaj65bt g4 s3 user s manual english controllerمهمa.i.y.moammar01No ratings yet

- Peripheral Connection Module Type AJ65BT-G4-S3 User, S ManualDocument68 pagesPeripheral Connection Module Type AJ65BT-G4-S3 User, S Manuala.i.y.moammar01No ratings yet

- Dynamic Brake UnitDocument32 pagesDynamic Brake UnitSaptyawan KasidjoNo ratings yet

- A1sj61bt11 CC Link MasterDocument280 pagesA1sj61bt11 CC Link MasterTetsusaigaNo ratings yet

- CC-Link AJ65SBT Digital IO Compact Building TypeDocument356 pagesCC-Link AJ65SBT Digital IO Compact Building TypeArjun GoudNo ratings yet

- GREE Hw18024pnadDocument24 pagesGREE Hw18024pnadEdward PeñaNo ratings yet

- Pa7300 Quickstart Fan App r1Document9 pagesPa7300 Quickstart Fan App r1Electrónica Melendez FazzNo ratings yet

- A2USHCPU-S1, User, S ManualDocument166 pagesA2USHCPU-S1, User, S Manualtranhuutri1987quangngaiNo ratings yet

- FA5643 FujiDocument38 pagesFA5643 Fujijose carruitero ruizNo ratings yet

- Operation Manual: E/P Regulator ITV1000, IT 2000, ITV3000 SeriesDocument10 pagesOperation Manual: E/P Regulator ITV1000, IT 2000, ITV3000 SeriesNARAYAN SINHANo ratings yet

- Installation Instructions Models Xtri-S / Xtri-D / Xtri-R: Building Technologies DivisionDocument8 pagesInstallation Instructions Models Xtri-S / Xtri-D / Xtri-R: Building Technologies DivisionPrabu KhayanganNo ratings yet

- FX3 - Mitsubishi ManualDocument218 pagesFX3 - Mitsubishi ManualCezar SliwinskiNo ratings yet

- Uxj50 PDFDocument32 pagesUxj50 PDFSoledadGarcíaNo ratings yet

- Camara Vivotek IP7330Document10 pagesCamara Vivotek IP7330TecnoSmart100% (1)

- N Series: User ManualDocument20 pagesN Series: User ManualIman HaryantoNo ratings yet

- As 16491 Dl-Ep1 Um WW GB 1072 5Document132 pagesAs 16491 Dl-Ep1 Um WW GB 1072 5Francisco Ivan Silva TapiaNo ratings yet

- Warning: Instruction ManualDocument2 pagesWarning: Instruction ManualAjay MayalNo ratings yet

- Instruction Manual: Compact InverterDocument192 pagesInstruction Manual: Compact Invertersunhuynh100% (1)

- Installation Manual: JY997D32001FDocument1 pageInstallation Manual: JY997D32001Fvuitinhnhd9817No ratings yet

- LG Dry Contact (Only AC 24V) : Installation ManualDocument11 pagesLG Dry Contact (Only AC 24V) : Installation ManualJorge Iván Lans MartinezNo ratings yet

- A-Series HW User ManualDocument85 pagesA-Series HW User Manuallue-ookNo ratings yet

- 1 ApparatusDocument20 pages1 ApparatusHamzik De BrownNo ratings yet

- Before Using The Product: Schémas de CâblageDocument1 pageBefore Using The Product: Schémas de CâblageyoshyiNo ratings yet

- Controlador de Rampa ManualDocument8 pagesControlador de Rampa ManualNelson RaulNo ratings yet

- sl-vpk02 eDocument1 pagesl-vpk02 eAjay MayalNo ratings yet

- qj61bt11n User - S Manual Rukovodstva English ControllerDocument506 pagesqj61bt11n User - S Manual Rukovodstva English ControllerMarcelooverdadeirohotmail.com 676765No ratings yet

- A1SJ61BT11Document280 pagesA1SJ61BT11Sam WangNo ratings yet

- SH 4007 AhDocument398 pagesSH 4007 AhsmsbondNo ratings yet

- Manual - FX 550 ENDocument4 pagesManual - FX 550 ENامين امينNo ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- Myson Power Extra: Spring Return Zone ValveDocument2 pagesMyson Power Extra: Spring Return Zone ValveGarrett O ConnorNo ratings yet

- Technical Data Sheet AMB24-SRDocument3 pagesTechnical Data Sheet AMB24-SRCaio ValérioNo ratings yet

- EN DS MVS3200-LV MVS4480-LV DatasheetDocument2 pagesEN DS MVS3200-LV MVS4480-LV DatasheetDavid SerranoNo ratings yet

- LinearAudio v0 - A New Low-Noise Circuit Approach For PentodesDocument20 pagesLinearAudio v0 - A New Low-Noise Circuit Approach For PentodeslordoffDOCNo ratings yet

- A4954 DatasheetDocument9 pagesA4954 DatasheetAngly1959No ratings yet

- Scattering Mechanisms in Β-Ga2O3 Junctionless SOI MOSFET - Investigation of Electron Mobility and Short Channel EffectsDocument6 pagesScattering Mechanisms in Β-Ga2O3 Junctionless SOI MOSFET - Investigation of Electron Mobility and Short Channel Effects刘锦成No ratings yet

- Mekanikal Dan Elektrikal Part AircondDocument2 pagesMekanikal Dan Elektrikal Part AircondZahin BasriNo ratings yet

- Difference Broken Delta & Open Delta Concept of VT PDFDocument3 pagesDifference Broken Delta & Open Delta Concept of VT PDFTony6783No ratings yet

- Electrical Design Calculations BookDocument121 pagesElectrical Design Calculations BookNurulazmi Bin Abd Rahman100% (2)

- Printed Circuit Board Design Guide - Jan Zumwalt - 2017Document30 pagesPrinted Circuit Board Design Guide - Jan Zumwalt - 2017jwzumwalt100% (2)

- Zelio Control RM22UA32MRDocument7 pagesZelio Control RM22UA32MRsreekanth naiduNo ratings yet

- Ignition Coil Tester: Operating ManualDocument28 pagesIgnition Coil Tester: Operating ManualDJORJENo ratings yet

- AK36Document1 pageAK36Reza PahlepiNo ratings yet

- Report On NF Railway Powerhouse Pandu Substation ScribdDocument36 pagesReport On NF Railway Powerhouse Pandu Substation ScribdnondeshNo ratings yet

- Sistema Elétrico - Destinação Conectores-1 PDFDocument4 pagesSistema Elétrico - Destinação Conectores-1 PDFBárbaraSchizateNo ratings yet

- Fmu 90Document160 pagesFmu 90Christian Lòpez MolinaNo ratings yet

- SCADADocument57 pagesSCADAkailasamvv100% (1)

- Degital Logic Isolation Tele Communication Analog Data Equipment Control Microprocessor System InterfaceDocument8 pagesDegital Logic Isolation Tele Communication Analog Data Equipment Control Microprocessor System InterfaceSIELAB C.A.No ratings yet

- World of Electronics - Inverter Protection PDFDocument1 pageWorld of Electronics - Inverter Protection PDFCiprianIfrimNo ratings yet

- 3.syllabus Deb 1133Document7 pages3.syllabus Deb 1133AngelinaNo ratings yet

- Unisonic Technologies Co., LTD: NPN Silicon Power TransistorsDocument8 pagesUnisonic Technologies Co., LTD: NPN Silicon Power TransistorsPedro ParraNo ratings yet

- EMO Project Perposal 062 055 079Document4 pagesEMO Project Perposal 062 055 079Nassr KhanNo ratings yet

- Dse160 Data SheetDocument2 pagesDse160 Data SheetddzoningcomNo ratings yet

- NEMA TR 1-2000 Transformers, Regulators and ReactorsDocument26 pagesNEMA TR 1-2000 Transformers, Regulators and ReactorsGiuseppe Aliberti100% (1)

- Comparison TableDocument3 pagesComparison TableRodriguez Villalobos NelsonNo ratings yet

- XEL Siemens Price ListDocument5 pagesXEL Siemens Price Listমোঃ মোমিনুল ইসলাম শোভনNo ratings yet

- MCQ Type Questions (ModuleIII) Insulators-Converted-1Document5 pagesMCQ Type Questions (ModuleIII) Insulators-Converted-1Yash MaheshwariNo ratings yet

- EOCQ Ans 21Document2 pagesEOCQ Ans 21Kamran Khan ShaikhNo ratings yet