Professional Documents

Culture Documents

Pa6 Black

Pa6 Black

Uploaded by

workatarCopyright:

Available Formats

You might also like

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDocument29 pagesElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (72)

- FRP Piping Design Manual - Sep-06Document27 pagesFRP Piping Design Manual - Sep-06Sabir Nasim100% (3)

- Material Data Sheet PA 6 GF30 Black: Main FeaturesDocument2 pagesMaterial Data Sheet PA 6 GF30 Black: Main FeaturesmohanNo ratings yet

- TECAMID 66 GF30 Black 0Document1 pageTECAMID 66 GF30 Black 0VTHafnergmx.deNo ratings yet

- Tecatron Gf40 Black en All 201711Document2 pagesTecatron Gf40 Black en All 201711JorgeMariscalNo ratings yet

- HZ Tecaflon PVDF Natural Se de 201709Document1 pageHZ Tecaflon PVDF Natural Se de 201709Ha Tran KhiemNo ratings yet

- TECAPEEK PVX Black 7 PDFDocument1 pageTECAPEEK PVX Black 7 PDFHARSHANo ratings yet

- HZ Tecafine PMP Natural in de 201604Document1 pageHZ Tecafine PMP Natural in de 201604Luis Alberto Silva NavarroNo ratings yet

- TECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)Document1 pageTECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)yatheendravarmaNo ratings yet

- TECAPEEK CF30 Black 7 PDFDocument1 pageTECAPEEK CF30 Black 7 PDFHARSHANo ratings yet

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- TECAPEEK GF30 Natural - Stock ShapesDocument1 pageTECAPEEK GF30 Natural - Stock ShapesHARSHANo ratings yet

- TECACOMP PPA LDS Black 4108 0Document2 pagesTECACOMP PPA LDS Black 4108 0H. BeatsNo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- TECASINT 1011 Natural - Stock ShapesDocument2 pagesTECASINT 1011 Natural - Stock ShapesGreeshmaNo ratings yet

- Ficha Técnica Nylon MolyDocument1 pageFicha Técnica Nylon MolyHector ArciniegasNo ratings yet

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- PET Glide DatabladDocument1 pagePET Glide DatabladMuhammad IrfanNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDocument1 pageMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Polystone P Homopolymer: Technical Data SheetDocument1 pagePolystone P Homopolymer: Technical Data Sheetmuchamad yasinNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- VASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENDocument1 pageVASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENIsrael AristaNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- TECASINT 2011 Natural 14Document1 pageTECASINT 2011 Natural 14e.montgomeryNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- PA6G MoSDocument1 pagePA6G MoSjhax90No ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- PET Technical Handbook 1Document61 pagesPET Technical Handbook 1karismaNo ratings yet

- Sustatron Pps GF 40: Technical Data SheetDocument1 pageSustatron Pps GF 40: Technical Data SheetyatheendravarmaNo ratings yet

- Durafide 6165A6 TDSDocument6 pagesDurafide 6165A6 TDSCassianNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetGeorge DonosaNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Datasheet SustaPEEK ENDocument1 pageDatasheet SustaPEEK ENazwar1105No ratings yet

- polarlite-UK 4mmDocument4 pagespolarlite-UK 4mmoportunidade.engenharia.slzNo ratings yet

- Policarbonato Teijin Panlite Ad-5503Document1 pagePolicarbonato Teijin Panlite Ad-5503marioNo ratings yet

- Duracon M90 44Document2 pagesDuracon M90 44PradeepNo ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Dome Slab Detail R1Document1 pageDome Slab Detail R1dipesh sharmaNo ratings yet

- Stone Pattern DetailsDocument31 pagesStone Pattern DetailsjlobregongNo ratings yet

- Greater Bridgeport Combined Sewer Overflow Guide For ResidentsDocument2 pagesGreater Bridgeport Combined Sewer Overflow Guide For ResidentsBridgeportCT100% (1)

- 20Document14 pages20Sileshi BekeleeNo ratings yet

- Fatigue of WeldmentsDocument222 pagesFatigue of WeldmentsAjay MenonNo ratings yet

- An Analysis On Bearing Capacity Variations of Expansions Soils Blended With Groundnut Shell AshDocument6 pagesAn Analysis On Bearing Capacity Variations of Expansions Soils Blended With Groundnut Shell AshVivek SenNo ratings yet

- Statistics For Business and Economics 11th Ed Intro TXT - D. Anderson Et Al. Cengage 2011 BbsDocument302 pagesStatistics For Business and Economics 11th Ed Intro TXT - D. Anderson Et Al. Cengage 2011 Bbsqazalbash1109588No ratings yet

- Thermax Mr.R.kulkarniDocument26 pagesThermax Mr.R.kulkarniPhani Kumar100% (1)

- Masterseal 620 TdsDocument3 pagesMasterseal 620 TdsNadeem Khan SelaniNo ratings yet

- Friction and LubricationDocument16 pagesFriction and Lubricationsaimk shakeelNo ratings yet

- L-02 Analysis and Design of One-Way Slab System (Part I) (Fall 2020) - ColorDocument48 pagesL-02 Analysis and Design of One-Way Slab System (Part I) (Fall 2020) - Colorkamran aliNo ratings yet

- Lecture 6 - Groundwater Flow-UnsteadyDocument24 pagesLecture 6 - Groundwater Flow-Unsteadyph4318No ratings yet

- 14 Draw Off Nozzle Hydraulics PDFDocument12 pages14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNo ratings yet

- Studies On Strength and Durability of Concrete Made With Manufactured SandDocument5 pagesStudies On Strength and Durability of Concrete Made With Manufactured SandEditor IJTSRDNo ratings yet

- Underground Construction TechnologyDocument74 pagesUnderground Construction TechnologyChin Thau WuiNo ratings yet

- Design Catalogue: FOR Reconstruction of Earthquake Resistant HousesDocument191 pagesDesign Catalogue: FOR Reconstruction of Earthquake Resistant HousesNishan GajurelNo ratings yet

- NR 322102 Aerospace Structures IIDocument13 pagesNR 322102 Aerospace Structures IISrinivasa Rao G100% (2)

- A-Chapter1 Theory of Elastic StabilityDocument8 pagesA-Chapter1 Theory of Elastic StabilityFaizanNo ratings yet

- Visual Quality Inspection of Structural Concrete BuildingDocument37 pagesVisual Quality Inspection of Structural Concrete BuildingjoshuaisraeliNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetPrasanna AbeysekaraNo ratings yet

- VRF System Vs Chiller SystemDocument14 pagesVRF System Vs Chiller Systemgowrish80_bmsNo ratings yet

- Comparative Study and Analysis of The Lateral and Vertical Loads of Pile FoundationDocument5 pagesComparative Study and Analysis of The Lateral and Vertical Loads of Pile FoundationRahul KolateNo ratings yet

- Basic Concepts&Processes of Road and Bridge MaintenanceDocument60 pagesBasic Concepts&Processes of Road and Bridge MaintenanceMichael DixonNo ratings yet

- Advanced Concrete Technology Past Paper Questions 1Document11 pagesAdvanced Concrete Technology Past Paper Questions 1Asad QaziNo ratings yet

- HVU2 Adhesive Capsule: Anchor Design (ETAG 001) / Rods&Sleeves / ConcreteDocument14 pagesHVU2 Adhesive Capsule: Anchor Design (ETAG 001) / Rods&Sleeves / ConcreteBrijesh VedNo ratings yet

- Residential Morcellement at Gros Billot - New Grove District of Grand-PortDocument83 pagesResidential Morcellement at Gros Billot - New Grove District of Grand-PortAKASH FERAGNo ratings yet

- Project PropellerDocument19 pagesProject PropellerDaniel ArangoNo ratings yet

- Tensile Tests and Failure Analysis of Concrete: J. Struct. Eng., 1986, 112 (11) : 2462-2477Document16 pagesTensile Tests and Failure Analysis of Concrete: J. Struct. Eng., 1986, 112 (11) : 2462-2477angelNo ratings yet

Pa6 Black

Pa6 Black

Uploaded by

workatarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pa6 Black

Pa6 Black

Uploaded by

workatarCopyright:

Available Formats

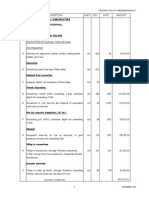

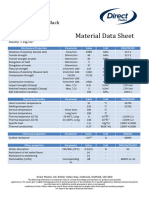

Material data sheet

PA 6 black

Chemical Designation: Polyamide 6

DIN-abbreviation: PA 6

Colour / Fillers: black opaque / molybdenum disulfide

Density: 1,14 g/cm³

Data generated directly after machining

(standard climate Germany).

Main features

- high toughness - resistant to many oils, greases and fuels

- good wear properties - good slide and wear properties

- high strength

- improved surface hardness

Target Industries

- mechanical engineering

- automotive industry

Characteristics

mechanical properties parameter value unit norm comment

Modulus of elasticity 1) For tensile test:

1 mm / min 3300 MPa DIN EN ISO 527-2 1)

(tensile test) specimen type 1b

2) For flexual test:

Tensile strength 50 mm / min 84 MPa DIN EN ISO 527-2 span 64 mm, norm

Tensile strength at yield 50 mm / min 82 MPa DIN EN ISO 527-2 specimen.

3) Specimen

Elongation at yield 50 mm / min 5 % DIN EN ISO 527-2 10 x 10 x 10 mm

Elongation at break 50 mm / min 37 % DIN EN ISO 527-2 4) Specimen

10 x10 x 50 mm,

Flexural strength 2 mm / min, 10 N 110 MPa DIN EN ISO 178 2) modulus range

between 0,5 and 1%

Modulus of elasticity compression.

2 mm / min, 10 N 3100 MPa DIN EN ISO 178

(flexural test) 5) For Charpy test:

support span 64 mm,

1% / 2% / 5% norm specimen. n. b.

Compression strength 17/32/79 MPa EN ISO 604 3)

5 mm / min, 10 N = not broken

Compression modulus 5 mm / min, 10 N 2900 MPa EN ISO 604 4) 6) Specimen in

4 mm thickness

Impact strength (Charpy) max. 7,5 J n. b. kJ/m² DIN EN ISO 179-1eU 5)

Notched impact strength

max. 7,5 J 5 kJ/m² DIN EN ISO 179-1eA

(Charpy)

Ball indentation hardness 160 MPa ISO 2039-1 6)

Material data sheet

PA 6 black

thermal properties parameter value unit norm comment

Glass transition temperature 51 °C DIN EN ISO 11357 1)

1) Found in public

Melting temperature 220 °C DIN EN ISO 11357 sources.

2) Found in public

Service temperature short term 160 °C 2) sources.Individual

Service temperature long term 100 °C testing regarding

application conditions is

Thermal expansion (CLTE) 23-60 °C, long 8 10-5 K-1 DIN EN ISO 11359-1;2 mandatory.

Thermal expansion (CLTE) 23-100 °C, long 8 10-5 K-1 DIN EN ISO 11359-1;2

Specific heat 1.6 J/(g*K) ISO 22007-4:2008

Thermal conductivity 0.37 W/(K*m) ISO 22007-4:2008

electrical properties parameter value unit norm comment

Silver electrode, 1) Specimen in

surface resistivity 1014 Ω DIN IEC 60093 1)

23 °C, 12% r.h. 20 mm thickness

2) Due to the black

Silver electrode, colourant and moisture

volume resistivity 1014 Ω*cm DIN IEC 60093 2) uptake oft he material

23 °C, 12% r.h. the electrical insulation

properties cannot be

Dielectric strength 23 °C, 50% r.h. 30 kV/mm ISO 60243-1 3) 100% guaranteed,

despite single

Platin electrode, measurements

Resistance to tracking (CTI) 23 °C, 50% r.h., 600 V DIN EN 60112 suggesting otherwise

3) Specimen in

solvent A 1 mm thickness

other properties parameter value unit norm comment

Water absorption 24 h / 96 h (23 °C) 0.3 / 0.6 % DIN EN ISO 62 1) 1) Ø ca. 50 mm,

h = 13 mm

2) (+) limited resistance

3) Corresponding

Resistance to hot water/bases (+) - 2) means no listing at UL

(yellow card). The

information might be

Resistance to weathering (+) taken from resin, stock

shape or estimation.

Individual testing

regarding application

Flammability (UL94) corresponding to HB DIN IEC 60695-11-10 3) conditions is

mandatory.

Our information and statements reflect the current state of our knowledge and shall inform about our products and their applications. They do not assure or

guarantee chemical resistance, quality of products and their merchantability in a legally binding way. Our products are not defined for use in medical or dental

implants. Existing commercial patents have to be observed. The corresponding values and information are no minimum or maximum values, but guideline values

that can be used primarily for comparison purposes for material selection. These values are within the normal tolerance range of product properties and do not

represent guaranteed property values. Therefore they shall not be used for specification purposes. Unless otherwise noted, these values were determined by

tests at reference dimensions (typically rods with diameter 40-60 mm according to DIN EN 15860) on extruded and machined specimen. As the properties depend

on the dimensions of the semi-finished products and the orientation in the component (esp. in reinforced grades), the material may not be used without a separate

testing under individual circumstances. The customer is solely responsible for the quality and suitability of products for the application and has to test usage and

processing prior to use. Technical changes reserved.

Date: 2018/02/20

You might also like

- Elemental Bill of Quantities For 3 Bedroom Apartment BlockDocument29 pagesElemental Bill of Quantities For 3 Bedroom Apartment BlockAliyu Shehu83% (72)

- FRP Piping Design Manual - Sep-06Document27 pagesFRP Piping Design Manual - Sep-06Sabir Nasim100% (3)

- Material Data Sheet PA 6 GF30 Black: Main FeaturesDocument2 pagesMaterial Data Sheet PA 6 GF30 Black: Main FeaturesmohanNo ratings yet

- TECAMID 66 GF30 Black 0Document1 pageTECAMID 66 GF30 Black 0VTHafnergmx.deNo ratings yet

- Tecatron Gf40 Black en All 201711Document2 pagesTecatron Gf40 Black en All 201711JorgeMariscalNo ratings yet

- HZ Tecaflon PVDF Natural Se de 201709Document1 pageHZ Tecaflon PVDF Natural Se de 201709Ha Tran KhiemNo ratings yet

- TECAPEEK PVX Black 7 PDFDocument1 pageTECAPEEK PVX Black 7 PDFHARSHANo ratings yet

- HZ Tecafine PMP Natural in de 201604Document1 pageHZ Tecafine PMP Natural in de 201604Luis Alberto Silva NavarroNo ratings yet

- TECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)Document1 pageTECAFINE PMP Natural - Stock Shapes (Rods, Plates, Tubes)yatheendravarmaNo ratings yet

- TECAPEEK CF30 Black 7 PDFDocument1 pageTECAPEEK CF30 Black 7 PDFHARSHANo ratings yet

- Propertie NilonDocument3 pagesPropertie Nilonmuhammad daffaNo ratings yet

- TECAPEEK GF30 Natural - Stock ShapesDocument1 pageTECAPEEK GF30 Natural - Stock ShapesHARSHANo ratings yet

- TECACOMP PPA LDS Black 4108 0Document2 pagesTECACOMP PPA LDS Black 4108 0H. BeatsNo ratings yet

- Tecasint 1011 Natural 0Document1 pageTecasint 1011 Natural 0Suraj_73No ratings yet

- TECASINT 1011 Natural - Stock ShapesDocument2 pagesTECASINT 1011 Natural - Stock ShapesGreeshmaNo ratings yet

- Ficha Técnica Nylon MolyDocument1 pageFicha Técnica Nylon MolyHector ArciniegasNo ratings yet

- TRO CX7323 - E11 - Ad PDFDocument2 pagesTRO CX7323 - E11 - Ad PDFJosip DuvnjakNo ratings yet

- Riteflex 640aDocument3 pagesRiteflex 640aazaleaemersonNo ratings yet

- Celanex 3316Document5 pagesCelanex 3316klausoshoNo ratings yet

- Styrolution PS 165N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 165N/L: General Purpose Polystyrene (GPPS)Inês MorgadoNo ratings yet

- Property Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL 4M License Grade Code HM 8355 (THT)MohamadMostafaviNo ratings yet

- PET Glide DatabladDocument1 pagePET Glide DatabladMuhammad IrfanNo ratings yet

- PA6EDocument1 pagePA6EDiego ReggianiniNo ratings yet

- Pa 6 GF 30 (En)Document1 pagePa 6 GF 30 (En)Alessandro WeissNo ratings yet

- POM KEPITAL F30-03 enDocument2 pagesPOM KEPITAL F30-03 enAthonioMourinhoNo ratings yet

- HOSTAFORM® C 9021 TF-enDocument4 pagesHOSTAFORM® C 9021 TF-enshahin_723No ratings yet

- Material Data Sheet: Urban@plastum - CZ WWW - Plastum.czDocument1 pageMaterial Data Sheet: Urban@plastum - CZ WWW - Plastum.czDavis GNo ratings yet

- TDS Nylon V3.011-EnDocument3 pagesTDS Nylon V3.011-Enmartinf090574No ratings yet

- Technical Data Sheet PC: Filament SpecificationsDocument3 pagesTechnical Data Sheet PC: Filament SpecificationsVladimir SarmientoNo ratings yet

- Tds A1105 en 2017pdfpdfDocument2 pagesTds A1105 en 2017pdfpdfagungNo ratings yet

- Polystone P Homopolymer: Technical Data SheetDocument1 pagePolystone P Homopolymer: Technical Data Sheetmuchamad yasinNo ratings yet

- ABS - Novodur P2HGVDocument2 pagesABS - Novodur P2HGVarmandoNo ratings yet

- TDS CPE V3.010-EnDocument3 pagesTDS CPE V3.010-EnspicefooNo ratings yet

- VASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENDocument1 pageVASITESA MEXICO Datasheet - Polystone - P - Homopolymer - Grey - ENIsrael AristaNo ratings yet

- Elix ABS E401: Technical InformationDocument3 pagesElix ABS E401: Technical InformationDiegoTierradentroNo ratings yet

- TECASINT 2011 Natural 14Document1 pageTECASINT 2011 Natural 14e.montgomeryNo ratings yet

- Property Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)Document1 pageProperty Test Method Unit Typicalvalue : BL3 License Grade Code HF 4670 (THT)MohamadMostafaviNo ratings yet

- PA6G MoSDocument1 pagePA6G MoSjhax90No ratings yet

- TDS Infinam ST 6100 LDocument5 pagesTDS Infinam ST 6100 LKacperNo ratings yet

- LNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetDocument2 pagesLNP+LUBRICOMP+Compound RFL16 Global Technical Data SheetcoroNo ratings yet

- PET Technical Handbook 1Document61 pagesPET Technical Handbook 1karismaNo ratings yet

- Sustatron Pps GF 40: Technical Data SheetDocument1 pageSustatron Pps GF 40: Technical Data SheetyatheendravarmaNo ratings yet

- Durafide 6165A6 TDSDocument6 pagesDurafide 6165A6 TDSCassianNo ratings yet

- ProductFile 131206155656Document1 pageProductFile 131206155656Michael HajzerNo ratings yet

- Elix ABS P2M-AT: Technical InformationDocument3 pagesElix ABS P2M-AT: Technical InformationDiegoTierradentroNo ratings yet

- CYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetDocument2 pagesCYCOLAC™ Resin - MG37EPX - Americas - Technical - Data - SheetmarceloNo ratings yet

- Bakelite PF 31Document3 pagesBakelite PF 31dioguitomsolhaNo ratings yet

- Technical Data SheetDocument1 pageTechnical Data SheetGeorge DonosaNo ratings yet

- Styrolution PS 158N/L: General Purpose Polystyrene (GPPS)Document3 pagesStyrolution PS 158N/L: General Purpose Polystyrene (GPPS)scribdichigoNo ratings yet

- HOSTAFORM® C 27021 - POM - Unfilled: DescriptionDocument5 pagesHOSTAFORM® C 27021 - POM - Unfilled: Descriptionrahul vermaNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Datasheet SustaPEEK ENDocument1 pageDatasheet SustaPEEK ENazwar1105No ratings yet

- polarlite-UK 4mmDocument4 pagespolarlite-UK 4mmoportunidade.engenharia.slzNo ratings yet

- Policarbonato Teijin Panlite Ad-5503Document1 pagePolicarbonato Teijin Panlite Ad-5503marioNo ratings yet

- Duracon M90 44Document2 pagesDuracon M90 44PradeepNo ratings yet

- Green Cast Setacryl UKDocument4 pagesGreen Cast Setacryl UKgillestalbotNo ratings yet

- MDS102RG600x47 1Document2 pagesMDS102RG600x47 1Khawla BkNo ratings yet

- Nylon 6Document1 pageNylon 6luuiissNo ratings yet

- Technyl Safe C 116FC NCDocument3 pagesTechnyl Safe C 116FC NCkls.thorodinsonNo ratings yet

- Dome Slab Detail R1Document1 pageDome Slab Detail R1dipesh sharmaNo ratings yet

- Stone Pattern DetailsDocument31 pagesStone Pattern DetailsjlobregongNo ratings yet

- Greater Bridgeport Combined Sewer Overflow Guide For ResidentsDocument2 pagesGreater Bridgeport Combined Sewer Overflow Guide For ResidentsBridgeportCT100% (1)

- 20Document14 pages20Sileshi BekeleeNo ratings yet

- Fatigue of WeldmentsDocument222 pagesFatigue of WeldmentsAjay MenonNo ratings yet

- An Analysis On Bearing Capacity Variations of Expansions Soils Blended With Groundnut Shell AshDocument6 pagesAn Analysis On Bearing Capacity Variations of Expansions Soils Blended With Groundnut Shell AshVivek SenNo ratings yet

- Statistics For Business and Economics 11th Ed Intro TXT - D. Anderson Et Al. Cengage 2011 BbsDocument302 pagesStatistics For Business and Economics 11th Ed Intro TXT - D. Anderson Et Al. Cengage 2011 Bbsqazalbash1109588No ratings yet

- Thermax Mr.R.kulkarniDocument26 pagesThermax Mr.R.kulkarniPhani Kumar100% (1)

- Masterseal 620 TdsDocument3 pagesMasterseal 620 TdsNadeem Khan SelaniNo ratings yet

- Friction and LubricationDocument16 pagesFriction and Lubricationsaimk shakeelNo ratings yet

- L-02 Analysis and Design of One-Way Slab System (Part I) (Fall 2020) - ColorDocument48 pagesL-02 Analysis and Design of One-Way Slab System (Part I) (Fall 2020) - Colorkamran aliNo ratings yet

- Lecture 6 - Groundwater Flow-UnsteadyDocument24 pagesLecture 6 - Groundwater Flow-Unsteadyph4318No ratings yet

- 14 Draw Off Nozzle Hydraulics PDFDocument12 pages14 Draw Off Nozzle Hydraulics PDFMohsin EhsanNo ratings yet

- Studies On Strength and Durability of Concrete Made With Manufactured SandDocument5 pagesStudies On Strength and Durability of Concrete Made With Manufactured SandEditor IJTSRDNo ratings yet

- Underground Construction TechnologyDocument74 pagesUnderground Construction TechnologyChin Thau WuiNo ratings yet

- Design Catalogue: FOR Reconstruction of Earthquake Resistant HousesDocument191 pagesDesign Catalogue: FOR Reconstruction of Earthquake Resistant HousesNishan GajurelNo ratings yet

- NR 322102 Aerospace Structures IIDocument13 pagesNR 322102 Aerospace Structures IISrinivasa Rao G100% (2)

- A-Chapter1 Theory of Elastic StabilityDocument8 pagesA-Chapter1 Theory of Elastic StabilityFaizanNo ratings yet

- Visual Quality Inspection of Structural Concrete BuildingDocument37 pagesVisual Quality Inspection of Structural Concrete BuildingjoshuaisraeliNo ratings yet

- British Steel Universal Beams Ub DatasheetDocument6 pagesBritish Steel Universal Beams Ub DatasheetPrasanna AbeysekaraNo ratings yet

- VRF System Vs Chiller SystemDocument14 pagesVRF System Vs Chiller Systemgowrish80_bmsNo ratings yet

- Comparative Study and Analysis of The Lateral and Vertical Loads of Pile FoundationDocument5 pagesComparative Study and Analysis of The Lateral and Vertical Loads of Pile FoundationRahul KolateNo ratings yet

- Basic Concepts&Processes of Road and Bridge MaintenanceDocument60 pagesBasic Concepts&Processes of Road and Bridge MaintenanceMichael DixonNo ratings yet

- Advanced Concrete Technology Past Paper Questions 1Document11 pagesAdvanced Concrete Technology Past Paper Questions 1Asad QaziNo ratings yet

- HVU2 Adhesive Capsule: Anchor Design (ETAG 001) / Rods&Sleeves / ConcreteDocument14 pagesHVU2 Adhesive Capsule: Anchor Design (ETAG 001) / Rods&Sleeves / ConcreteBrijesh VedNo ratings yet

- Residential Morcellement at Gros Billot - New Grove District of Grand-PortDocument83 pagesResidential Morcellement at Gros Billot - New Grove District of Grand-PortAKASH FERAGNo ratings yet

- Project PropellerDocument19 pagesProject PropellerDaniel ArangoNo ratings yet

- Tensile Tests and Failure Analysis of Concrete: J. Struct. Eng., 1986, 112 (11) : 2462-2477Document16 pagesTensile Tests and Failure Analysis of Concrete: J. Struct. Eng., 1986, 112 (11) : 2462-2477angelNo ratings yet