Professional Documents

Culture Documents

2c Polyaspartic Anticorrosion Coatings

2c Polyaspartic Anticorrosion Coatings

Uploaded by

majidhajnasrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2c Polyaspartic Anticorrosion Coatings

2c Polyaspartic Anticorrosion Coatings

Uploaded by

majidhajnasrCopyright:

Available Formats

NEUBURG SILICEOUS EARTH IN 2C POLYASPARTIC

ANTI-CORROSION COATING, PVC 30 %

SILLITIN Z 86 and AKTISIL PF 777 vs. Classical Fillers

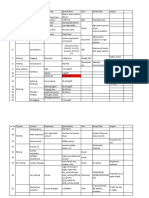

FORMULATION SUMMARY

Control* Variation of filler

Neuburg Siliceous Earth gains the following

Desmophen NH 1520

combined benefits compared to classical fillers

Polyaspartic ester, 13.2

amine-functional resin Substitution Improved storage stability and application in

Desmophen VP LS 2142 of higher film thickness without rheological

Reactive diluent, blocked 4.1 Barite additive

cycloaliphatic diamine Strong matting effect; higher gloss feasible with

Component A

Dewatering agent, zeolite 1.8 Sillitin V 85, higher brightness with Sillitin Z 89

by

or Silfit Z 91

Solvent 7.5 equal volume of

Additives 1.5 Better hiding power enabling TiO2 savings

Titanium dioxide 9.4 Good abrasion resistance, excellent adhesion

Zinc aluminum phosphate 9.4 Barite / Wollas- Sillitin Aktisil

Talc** tonite Z 86 PF 777

Markedly improved corrosion protection:

Barite 3 µm 37.9 • Sillitin Z 86 with best balanced properties

due to reduced corrosion / delamination at

Filler varied 19.0 / 12.3 25.6 23.4 23.4 scribe and excellent protection & adhesion on

unscribed surface, preferably for strong ionic

Desmodur N 3600 exposure

Hardener, low viscosity 15.2

B

HDI polyisocyanurate • Aktisil PF 777 offering lowest corrosion at

scribe and with almost no delamination

Total parts by weight 100.0 distinctly best protective performance for

Solids content w/w [%] intense humid environment

92

* Without rheological additive, based on Covestro formulation / ** Pure talc unfeasible

IMPROVED FEATURES

Processing Properties Barite Barite /Talc Wollastonite Sillitin Z 86 Aktisil PF 777

Incorporation of filler good difficult good moderate moderate

Fineness of grind [µm] 10 15 10 < 10 < 10

Storage Stability poor poor poor perfect perfect

Component A, 28 d 50°C

Viscosity 86

Component A+B [Pa*s] 14

Rheometer 23 °C

3.9

Searle system

0.6 0.5 0.8 0.6 0.5 0.9 0.6

at 0.1 s-1 at 1000 s-1

Increasing DFT 400 µm

Sagging resistance

Without rheological additive

100 µm

<25 µm 40 µm 25 µm

up to dry film thickness [µm]

RETAINED FEATURES EXPERIMENTAL

Experimental

Without significant difference or minor effects

• Drying characteristic • Preparation

Drying stage T 4 (DIN 53150) 5 – 6 h Dissolver equipped with bead mill agitator

Dry-Through time (similar to ASTM D 5895) 4 h 20 min 2000 rpm

• Good Adhesion • Application / Conditioning

Cross-cut test [GT]: 0 - 1 By air pressure on cold rolled grit-blasted steel, 1 µm

SA 2 ½, DFT 120 µm, drying 14d 23°C / 50% RH

VM-2/0521/05.2021 (TB/PP – NSE in 2C-Polyaspartic formulations)

NEUBURG SILICEOUS EARTH IN 2C POLYASPARTIC

ANTI-CORROSION COATING, PVC 30 %

SILLITIN Z 86 and AKTISIL PF 777 vs. Classical Fillers

IMPROVED FEATURES

Barite Barite / Talc Wollastonite Sillitin Z 86 Aktisil PF 777

Optical / Mechanical Properies

Gloss 91 87 91

Degree at 60° Matting

28

11

Dry film thickness for 113

109

good hiding power

DFT [µm] for contrast ratio 98 % 20 - 25 % savings

98

86

83

Abrasion loss 266

TaberTest S-42, Load 5.4 N

[mg/100 revolutions] 178 176 185

129

Barite Barite / Talc Wollastonite Sillitin Z 86 Aktisil PF 777

Anti-Corrosion Properties

Reduced corrosion

at scribe

Salt Spray Test

1500 h

Surface:

No blistering / corrosion

in or under coating,

good adhesion

Scribe:

Corrosion strong strong moderate moderate low

Delamination moderate moderate strong low moderate - strong

Reduced corrosion / delamination

at scribe

Humidity Test

1500 h

Surface:

Apart from barite

no blistering / corrosion,

good adhesion

5 (S4)

acc. ISO 4628-2

Scribe:

Corrosion not evaluable low low low very low

Delamination strong low completely low very low

VM-2/0521/05.2021 (TB/PP – NSE in 2C-Polyaspartic formulations)

You might also like

- Yd-011 TdsDocument4 pagesYd-011 TdsOswaldo Manuel Ramirez Marin100% (2)

- TA Price List 2007 EngDocument55 pagesTA Price List 2007 Engpopmart21No ratings yet

- LF710F TDS Agcce 01-2020Document3 pagesLF710F TDS Agcce 01-2020Robert SkibaNo ratings yet

- BNT 2Document3 pagesBNT 2ahetesham marufNo ratings yet

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- LF200 TDSDocument3 pagesLF200 TDSRobert SkibaNo ratings yet

- Abecote 320: Epoxy Enamel CoatingDocument2 pagesAbecote 320: Epoxy Enamel CoatingAshvin ParmessurNo ratings yet

- Protective & Marine Coatings: Zinc Clad XIDocument4 pagesProtective & Marine Coatings: Zinc Clad XIfdpc1987No ratings yet

- Finishes - Parex DPR Sand Best FinishDocument2 pagesFinishes - Parex DPR Sand Best Finishsaffronbuilders9No ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Carboguard 193: Selection & Specification DataDocument4 pagesCarboguard 193: Selection & Specification DataGraciele SantosNo ratings yet

- Abecote 384Document2 pagesAbecote 384engramir07No ratings yet

- 3 6077 RTVDocument2 pages3 6077 RTVgkretroNo ratings yet

- Cymel-Nf-3041 en A4Document1 pageCymel-Nf-3041 en A4DidarNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Ucar Latex R-362 - Mielco PDFDocument3 pagesUcar Latex R-362 - Mielco PDFForever0% (1)

- Nipol NBRDocument4 pagesNipol NBRVinod KumarNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Shell Gadus S5 T460: Previously Shell Stamina HdsDocument1 pageShell Gadus S5 T460: Previously Shell Stamina HdsShova MuhammadNo ratings yet

- POLYPLEX ISO NPG SOLID SURFACE RESIN - EN - LetterDocument2 pagesPOLYPLEX ISO NPG SOLID SURFACE RESIN - EN - LetterOXY Composite TechNo ratings yet

- High Temperature Grease: DescriptionDocument2 pagesHigh Temperature Grease: Descriptionvicky kNo ratings yet

- Sikafloor 2420Document3 pagesSikafloor 2420Nguyen Anh TuanNo ratings yet

- Carbothane 133 FLV PDSDocument2 pagesCarbothane 133 FLV PDSHomer SilvaNo ratings yet

- Masterinject 1320 TdsDocument2 pagesMasterinject 1320 TdsMASDOUA RédhaNo ratings yet

- Belzona 1391 Dta SheetDocument4 pagesBelzona 1391 Dta SheetMuthuKumarNo ratings yet

- Cymel-Nf-3030 en A4Document1 pageCymel-Nf-3030 en A4DidarNo ratings yet

- Sillitin Z89 PDFDocument2 pagesSillitin Z89 PDFAngga PratamaNo ratings yet

- Carbozinc Data SheetDocument2 pagesCarbozinc Data SheetIra Purnama SariNo ratings yet

- Sika Poxitar MyDocument3 pagesSika Poxitar Myhijur ChenNo ratings yet

- Jet-Lube Marine Grade Anti-SeizeDocument1 pageJet-Lube Marine Grade Anti-SeizeDon HowardNo ratings yet

- Nickel Anti-Seize Compound: - Bolts - Flanges - FittingsDocument1 pageNickel Anti-Seize Compound: - Bolts - Flanges - FittingsGregory Alan Francisco IINo ratings yet

- Crusher Backing: Technical InformationDocument1 pageCrusher Backing: Technical InformationjohnNo ratings yet

- Epicon ARG: Technical DatasheetDocument3 pagesEpicon ARG: Technical DatasheetBogdanBNo ratings yet

- Cymel-Nf-2000a en A4Document2 pagesCymel-Nf-2000a en A4DidarNo ratings yet

- Naphthaplast G 808Document2 pagesNaphthaplast G 808imran jamalNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Mastertop 1220 AseanDocument3 pagesMastertop 1220 AseanDoby YuniardiNo ratings yet

- Carboguard 1207 PDSDocument4 pagesCarboguard 1207 PDSmartinbeyerNo ratings yet

- 21 - Resins For Road Marking PaintsDocument4 pages21 - Resins For Road Marking Paintsraj jangid100% (1)

- Rhodina BBZ - TDS (NDPC)Document2 pagesRhodina BBZ - TDS (NDPC)Miguel ArizaNo ratings yet

- RZ 7238Document2 pagesRZ 7238Mehrdad NejatiNo ratings yet

- Shell Albida EP 2 GreaseDocument2 pagesShell Albida EP 2 GreasearyawigiNo ratings yet

- BELZONA 1111 Product Specification SheetDocument2 pagesBELZONA 1111 Product Specification SheetMohamed NouzerNo ratings yet

- Corotech v157 - Tds en OkfDocument3 pagesCorotech v157 - Tds en OkfNasreldin SamyNo ratings yet

- Durebild STE: Surface Tolerant High Build High Solids Epoxy CoatingDocument3 pagesDurebild STE: Surface Tolerant High Build High Solids Epoxy CoatinglivefreakNo ratings yet

- ACRYSOL™ TT-935: Rheology ModifierDocument4 pagesACRYSOL™ TT-935: Rheology ModifierJuan EstebanNo ratings yet

- WWW Epochemie Com Products Cycloaliphatic AminesDocument2 pagesWWW Epochemie Com Products Cycloaliphatic AminesNIKESH PRAKASHNo ratings yet

- Amercoat 450HDocument2 pagesAmercoat 450HJairo ArroyoNo ratings yet

- Nitomortar HBDocument4 pagesNitomortar HBMansoor AliNo ratings yet

- Ti Pure R 706 TdsDocument2 pagesTi Pure R 706 TdsLuis Angel MendozaNo ratings yet

- Lube Oil ParametersDocument1 pageLube Oil ParametersGanapathi SankarNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- LacDocument6 pagesLacJason McCaffreyNo ratings yet

- Epoxy 2kDocument3 pagesEpoxy 2kMitra YuningsihNo ratings yet

- General Properties Rheological Properties: PVC Paste Resin (Homopolymer)Document2 pagesGeneral Properties Rheological Properties: PVC Paste Resin (Homopolymer)AminulIslamNo ratings yet

- ThermalStar BeadBoard Void Insulation Product Data B33039Document2 pagesThermalStar BeadBoard Void Insulation Product Data B33039abdellahchajadine1996No ratings yet

- SP Eng NLGI 1,2,3 2012 OctDocument3 pagesSP Eng NLGI 1,2,3 2012 OctundraazolbayarNo ratings yet

- Watertite SA 15Document2 pagesWatertite SA 15Alexi ALfred H. TagoNo ratings yet

- Carbomastic15BNX EngDocument2 pagesCarbomastic15BNX Engfazeel mohammedNo ratings yet

- Naturelle S2 Wire Rope Lubricant A TDSDocument2 pagesNaturelle S2 Wire Rope Lubricant A TDSJohn MithuNo ratings yet

- S01 Autoclear 2 0 Reducer Slow GBENDocument17 pagesS01 Autoclear 2 0 Reducer Slow GBENmajidhajnasrNo ratings yet

- 730AL - 264 Additives ProductguideDocument20 pages730AL - 264 Additives ProductguidemajidhajnasrNo ratings yet

- RR 5224Document3 pagesRR 5224majidhajnasrNo ratings yet

- Tds - TDS 480 Jotafloor Coating Euk GBDocument5 pagesTds - TDS 480 Jotafloor Coating Euk GBmajidhajnasrNo ratings yet

- Thermal TorchesDocument610 pagesThermal TorcheszbdjahuNo ratings yet

- Apresentação ConceitosDocument23 pagesApresentação ConceitosJoão Otávio PradoNo ratings yet

- Ethylbenzene DehydrogenationDocument12 pagesEthylbenzene DehydrogenationCeciNo ratings yet

- RC01 Manual v1004Document14 pagesRC01 Manual v1004Cesar Adolfo Ortega VivasNo ratings yet

- Volta PotentialDocument3 pagesVolta PotentialantoniocsjNo ratings yet

- 4 1 5 1 Chem Lesson PlanDocument3 pages4 1 5 1 Chem Lesson Planapi-374589174No ratings yet

- Scientific & Technical ReportDocument15 pagesScientific & Technical ReportMariam AsgharNo ratings yet

- Physics PlasmaDocument17 pagesPhysics PlasmaSarabdeep Singh ChaudhryNo ratings yet

- Sp2 Marked w3Document47 pagesSp2 Marked w3Nhut NguyenNo ratings yet

- 6) ElectrochemistryDocument58 pages6) ElectrochemistrySHANJIDA ALI RIANo ratings yet

- Properties:: Carbonic Acid, (HDocument4 pagesProperties:: Carbonic Acid, (HPRAGYA S BABU AIMLNo ratings yet

- 1957-1958 Tribasic Sodium PhosphateDocument2 pages1957-1958 Tribasic Sodium PhosphateSiva KumarNo ratings yet

- AlNi B2Document2 pagesAlNi B2Pei Yu ChenNo ratings yet

- Final Test Series - JEE (Main & Adv) 2023 - Phase-IIDocument3 pagesFinal Test Series - JEE (Main & Adv) 2023 - Phase-IIAkshat GuptaNo ratings yet

- Fermi EnergyDocument20 pagesFermi EnergyMukund BihariNo ratings yet

- Chapter04 Chemical Quantities and Acqueuos ReactionsDocument103 pagesChapter04 Chemical Quantities and Acqueuos ReactionsEdrick RamoranNo ratings yet

- Cathodic Protection of Sea Water Intake Channel 1688916038Document5 pagesCathodic Protection of Sea Water Intake Channel 1688916038youplaiNo ratings yet

- F432-007-3-2020 (Hvac) Single PhaseDocument155 pagesF432-007-3-2020 (Hvac) Single PhaseMohamad Afiq Akmal Bin Mohd NizamNo ratings yet

- Measurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryDocument6 pagesMeasurement of Hindered Phenolic Antioxidant Content in HL Turbine Oils by Linear Sweep VoltammetryMohanadNo ratings yet

- Chemistry HSSC I Paper I (2019)Document12 pagesChemistry HSSC I Paper I (2019)Tayyib Khan100% (1)

- Maintain Engine Cooling SystemDocument101 pagesMaintain Engine Cooling SystemMuhamad Dwi CahyonoNo ratings yet

- Icm ScienceDocument2 pagesIcm Scienceapi-345381848No ratings yet

- Advances in Chemical Engineering Vol. 4 (Elsevier-AP, 1963) PDFDocument385 pagesAdvances in Chemical Engineering Vol. 4 (Elsevier-AP, 1963) PDFAlessandro Di PietriNo ratings yet

- Deney 1 SonDocument6 pagesDeney 1 Songizem.gelekciNo ratings yet

- SJV Selection EjectorsDocument9 pagesSJV Selection Ejectorskumarvns111No ratings yet

- Atoms: Magic Wavelengths For Optical-Lattice Based Cs and RB Active ClocksDocument18 pagesAtoms: Magic Wavelengths For Optical-Lattice Based Cs and RB Active ClocksJoel AuccapucllaNo ratings yet

- Conductive Polymer PDFDocument13 pagesConductive Polymer PDFraju bhowalNo ratings yet

- PEARSON Chemistry Chapter 9 Flashcards - QuizletDocument4 pagesPEARSON Chemistry Chapter 9 Flashcards - Quizletأستغفرالله واتوب اليهNo ratings yet

- Stability of Carbopol Gels Containing Hydrogen PeroxideDocument5 pagesStability of Carbopol Gels Containing Hydrogen PeroxidePatrick BurnsNo ratings yet