Professional Documents

Culture Documents

Bl-SOP-067 Environmental SOP

Bl-SOP-067 Environmental SOP

Uploaded by

nishthaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bl-SOP-067 Environmental SOP

Bl-SOP-067 Environmental SOP

Uploaded by

nishthaCopyright:

Available Formats

B L LIFESCIENCES PVT. LTD.

28-D, Sector-31, Ecotech-I, Greater Noida, Gautam Buddha Nagar, Uttar Pradesh-(India)

Standard Operating Procedure

Title Environmental Monitoring of Clean Room Effective Date 01-07-2022

Document No. BL/SOP/067 Review Date 30-06-2024

Revision No. 01 Page No. 1 of 5

Objective

To Monitor the environmental conditions in which product is being manufactured to

safeguard the Quality of the product.

1. Scope

This procedure is applicable to all clean rooms area of B L Lifesciences Pvt. Ltd., Unit-I &

Unit-II.

2. Responsibility

The Q.A. Department is responsible for environment monitoring of clean room.

3. Procedure

The following methods are employed to monitor the environment of clean room.

4.1 Particulate cleanliness of clean room and clean room classification

4.1.1 Reference.

4.1.1.1 14644

4.1.1.2 Drugs & Cosmetics Act.1940 (Schedule M).

4.1.1.3 Clean Room is classified as class 10,000 at rest condition and

class 100000 at operation condition. The limits of particle count

and the number of locations for sampling in each section are as

follows (Reference: Drug & Cosmetic Act 2010 (Schedule M))

and (Reference: Table 1 of ISO 14644-1):

4.1.1.4 Environmental Conditions. The following environmental

conditions to be maintained in clean room refer to table I and

controlled rooms.

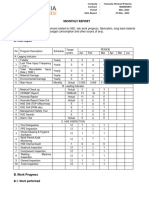

Sr. No. Parameters Requirements Schedule

01 Temperature 20- 26°C Thrice a day

02 Humidity 40- 60%

Pressure in Std. Alert Action Limit Schedule

Dispensing Value Limit

Room (Pascal)

01 Dispensing

20 18 Less than 18

Room

02 White Zone 35 33 Less than 33

03 Gray Zone 20 18 Less than 18

04 All Pass

Boxes/ Dress Thrice a day

5 3 Less than 3

cabinet (mm

of water)

05 Particulate Six monthly

352000Of 0.5µ and 2930 of 5µ.

matter in air (external agency)

06 HEPA No leakage Yearly (external

Name Designation Signature Date

Prepared by Munjraj Singh AM QC 01-07-2022

Reviewed by Priyanka Sachan Manager QA 01-07-2022

Approved by Hemant Singh GM Operations 01-07-2022

B L LIFESCIENCES PVT. LTD.

28-D, Sector-31, Ecotech-I, Greater Noida, Gautam Buddha Nagar, Uttar Pradesh-(India)

Standard Operating Procedure

Title Environmental Monitoring of Clean Room Effective Date 01-07-2022

Document No. BL/SOP/067 Review Date 30-06-2024

Revision No. 01 Page No. 2 of 5

Integrity test agency)

07 No of Air Six monthly

NLT 20

Change rate (external agency)

08 Microbial. At least

Max 50cfu/ Plate

Monitoring once a week (Self)

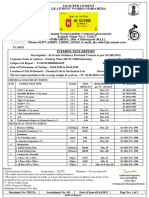

Pressure in

Clean Room

01 Clean Room

20 18 Less than 18

Inside

02 Gray Zone 35 33 Less than 33

03 White Zone 20 18 Less than 18 Thrice a day

04 Staging

05 03 Less than 03

Room

Pressure in

Microbioloical

(LAB)

01 Staging

05 03 Less than 03

Room

02 Change

20 18 Less than 18

Room 1st

03 Change

35 33 Less than 33

Room 2nd Thrice a day

04 Buffer Room 50 48 Less than 48

05 Laminar

30 28 Less than 28

Room

06 Less than 38

Change III 40 38

07 Media

35 32 Less than 32

Preparation

08 Change

20 18 Less than 18

Room 1st

4.1.1.5 Alert Limit: The following alert limits to be observed while

production is on. In case pressure drop below alert limit we

should stop the production and investigate the reason for the

same and followed by corrective action.

4.2 Monitoring of Bio-burden Using Petri Dishes.

Name Designation Signature Date

Prepared by Munjraj Singh AM QC 01-07-2022

Reviewed by Priyanka Sachan Manager QA 01-07-2022

Approved by Hemant Singh GM Operations 01-07-2022

B L LIFESCIENCES PVT. LTD.

28-D, Sector-31, Ecotech-I, Greater Noida, Gautam Buddha Nagar, Uttar Pradesh-(India)

Standard Operating Procedure

Title Environmental Monitoring of Clean Room Effective Date 01-07-2022

Document No. BL/SOP/067 Review Date 30-06-2024

Revision No. 01 Page No. 3 of 5

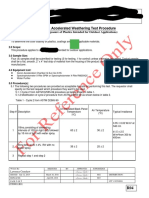

4.1.2 The following test must be done on monthly basis.

4.1.2.1 Prepare nutrient agar medium with appropriate water to sterilize

121°C for 15 minutes.

4.1.2.2 Pour approx. 25ml media at a temperature around 60°C in to

petridish under a laminar air flow.

4.1.2.3 Allow the media to solidify and cover the petri-dish.

4.1.2.4 Expose petri-dishes in clean areas which are fumigated and

sanitized. 19 petri dishes to be placed at per location chart

(INSP/F26A, B, C).

4.1.2.5 Expose for 2 hours removing the cover of petridish.

4.1.2.6 Finger impressions, Dress impression of different operator are

also taken.

4.1.2.7 The floor, working table and wall impression also taken at

different places.

4.1.2.8 Plate will be exposed as per the approved lay out plan.

4.1.2.9 One petri-dish plate is also incubated for negative control.

4.1.2.10 Microbial count of compressed air also checked.

4.1.2.11 Microbial count of personnel also checked at least one male and

one female twice a week.

4.1.2.12 Plate should be exposed twice a week for environmental

monitoring and floor, working table and wall should monitored

twice a month (INSP/F19).

4.2 Incubation of petri – dishes and Colony Counting.

4.2.1 Cover the petri dishes and incubate at 30-35°C for 48 hours and at 20-

25°C for further 72 hours. Remove dishes from incubator, count the

bacterial colonies developed after 48 hours of incubation at 30-35°C

and fungal colonies after 72 hours of further incubation at 20 – 25°C

and record these findings.

4.3 Interpretation of result

All products are being terminally sterilized. If colony counts are higher

than above limits, corrective actions are to be taken by increasing

sanitization and fumigation etc.

Bacterial Count Fungal Count

Alert limit Action Limit Alert limit Action Limit

AREA

(CFU) (CFU) (CFU) (CFU)

Dispensing 40 50 Nil Nil

Clean Room 40 50 Nil Nil

Microbiological 40 50 Nil Nil

(LAB)

Control of fumigation for clean room

Name Designation Signature Date

Prepared by Munjraj Singh AM QC 01-07-2022

Reviewed by Priyanka Sachan Manager QA 01-07-2022

Approved by Hemant Singh GM Operations 01-07-2022

B L LIFESCIENCES PVT. LTD.

28-D, Sector-31, Ecotech-I, Greater Noida, Gautam Buddha Nagar, Uttar Pradesh-(India)

Standard Operating Procedure

Title Environmental Monitoring of Clean Room Effective Date 01-07-2022

Document No. BL/SOP/067 Review Date 30-06-2024

Revision No. 01 Page No. 4 of 5

4.3.1 Control on Personnel Hygiene and Sanitation of Employees Working in

the Clean Room.

4.3.2 Personnel hygiene / cleanliness instructions

4.3.2.1 Entry to the clean room section is allowed to the authorized

personal only. The entrants are expected to wear well-cleaned

clothes, proper cut hair & nails. Regular checking of workers.

4.3.2.2 Wash their hands with antiseptic solution available in washing

area.

4.3.2.3 After washing hands dry the hands with hand dryer

4.3.2.4 Wear the Clean Room Dress. (A lint free & well-cleaned uniform

(overall and head –covering).

4.3.2.5 It shall be ensured that workmen is free from any type of

contagious disease. Yearly medical checkup is carried out by the

company as per company schedule.

4.3.2.6 After entering the room workmen should have to clean the work

table/ instrument/ machine with cleaning solution before starting

the work. The same will be repeated while leaving the worktable

after completing the duty.

4.3.3 The Uniform (overall & Head –Covering), Shall Be Lint Free and Well

Cleaned Once in A Week (PRD/F12). The Above Cleaning / Washing

Is Arranged by The Out Side Party.

4.3.4 Clean room section cloth shall not be worn in non-classified area.

4.3.5 The floor of the clean room should be swabbed daily with the antiseptic

liquid.

4.3.6 The electric & electronic fixtures such as tube light, telephone etc. are

cleaned under the supervision of electrician. During such cleaning

packaging material, products are stored in coverings.

4.4 Environment Control Instructions

4.4.1 Smoking chewing, eating & drinking is not allowed in factory premises.

4.4.2 It shall be ensured daily by in-charge and quality control. that the clean

room section is free from dust. Windows are permanently closed.

4.4.3 Doors are always kept closed except while entering/leaving the clean

room. The entire packaging materials/containers/ equipment/

instrument being entered to the clean room shall be dust free

(PRD/F6).

4.5 Sanitation and general housekeeping in the clean room cleaning frequency

4.5.1 Control on the air coming through HEPA filters from the air handling

units.

4.5.2 For ensuring the clean air inside the clean room, the air comes through

the air-handling unit with HEPA filters placed.

Name Designation Signature Date

Prepared by Munjraj Singh AM QC 01-07-2022

Reviewed by Priyanka Sachan Manager QA 01-07-2022

Approved by Hemant Singh GM Operations 01-07-2022

B L LIFESCIENCES PVT. LTD.

28-D, Sector-31, Ecotech-I, Greater Noida, Gautam Buddha Nagar, Uttar Pradesh-(India)

Standard Operating Procedure

Title Environmental Monitoring of Clean Room Effective Date 01-07-2022

Document No. BL/SOP/067 Review Date 30-06-2024

Revision No. 01 Page No. 5 of 5

4.5.3 Pre filters of all AHU to be cleaned as per the approved schedule,

regularly (MNT/F06).

4.6 Control on the material movement in and out of the clean room

4.6.1 The entry and exit of the material and components respectively are

highly controlled in the clean room. All the components coming inside

the clean room are transferred through the dynamic pass box after the

UV light treatment to ensure the disinfection of the material (PRD/F07).

All the finished products are also transferred through the dynamic pass

box only.

5. Reference

ISO 13485:2016 Clause 7.5.1. & Schedule M ISO 14644-1 in respective area.

6. Forms/Formats

Clean Room Cleaning Log Book PRD/F07A

Bio-burden of Clean Room INSP/F06

Validation Master Plan EMS-01A

Environmental Monitoring INSP/F17A

7. Revision History

Revision No. Reason for Change

01 Incorporation of Corporate office address in Header of the SOP format

00 New issuance of SOP with review date information on header.

Revise the SOP as per requirement of ISO 13485:2016 & ISO 9001:2015

8. Distribution Record

Copy No. Department

Master Copy Quality Assurance Department

Controlled Copy 01 Quality Control Department

Controlled Copy 02 Production Department

Name Designation Signature Date

Prepared by Munjraj Singh AM QC 01-07-2022

Reviewed by Priyanka Sachan Manager QA 01-07-2022

Approved by Hemant Singh GM Operations 01-07-2022

You might also like

- Example of Marijuana Lab Test Certificate of Analysis From Infinite Chemical Analysis LabsDocument4 pagesExample of Marijuana Lab Test Certificate of Analysis From Infinite Chemical Analysis LabsFergus Burns0% (1)

- J.K. White Cement Works GOTAN, NAGAUR (Raj.) - 342902 White Portland CementDocument1 pageJ.K. White Cement Works GOTAN, NAGAUR (Raj.) - 342902 White Portland CementakhlsNo ratings yet

- SOP For Bioburden TestDocument2 pagesSOP For Bioburden TestBejoy Karim100% (1)

- News Printing 40: Itc Limited - PSPD, Unit: Tribeni Specification SheetDocument2 pagesNews Printing 40: Itc Limited - PSPD, Unit: Tribeni Specification SheetApoorva PattnaikNo ratings yet

- Integrity SOPs For VeinDocument3 pagesIntegrity SOPs For VeinziadddNo ratings yet

- CTO - Mother Grace & CoDocument6 pagesCTO - Mother Grace & CoMathan FlufyNo ratings yet

- Test Report: Applicant AddressDocument4 pagesTest Report: Applicant AddressAntonio Aquino OsorioNo ratings yet

- 羽林GB32610英文检测报告Document5 pages羽林GB32610英文检测报告A ANo ratings yet

- 羽林GB32610英文检测报告Document5 pages羽林GB32610英文检测报告A ANo ratings yet

- PHM Top Monthly Report - Maret 2022 (Review Agus Rohmad)Document4 pagesPHM Top Monthly Report - Maret 2022 (Review Agus Rohmad)Agus Rohmad NurhidayahNo ratings yet

- December 2022Document3 pagesDecember 2022imranul haqNo ratings yet

- DCC RattanDocument8 pagesDCC RattanJose PadraicNo ratings yet

- F 207 TiOCl2 Pumping & Drum Cleaning FinalDocument1 pageF 207 TiOCl2 Pumping & Drum Cleaning Finalaadarshpardhi121No ratings yet

- Urea 2R - D18680 - 5Document3 pagesUrea 2R - D18680 - 5Ahmed Abd ElmonemNo ratings yet

- HSE - Monthly Report - June 2015. Rev.01 by - Arber Dogani Example StatisticsDocument8 pagesHSE - Monthly Report - June 2015. Rev.01 by - Arber Dogani Example StatisticsArber DoganiNo ratings yet

- 4 Ply Surgical Mask ASTM F2100 - IndiaDocument3 pages4 Ply Surgical Mask ASTM F2100 - IndiaMd. Moniruzzaman Precision GroupNo ratings yet

- HL40001 2020-5 SGSDocument4 pagesHL40001 2020-5 SGSMd. Moniruzzaman Precision GroupNo ratings yet

- QX REPORT-handsanitizerDocument3 pagesQX REPORT-handsanitizerWaeil MakkiNo ratings yet

- SOP For Bubble Point TestDocument4 pagesSOP For Bubble Point TestBejoy KarimNo ratings yet

- Healer'S Lab. (Unit Ii) : Plot No. 33 Hpsidc Exten. Baddi, Distt-Solan (H.P.)Document14 pagesHealer'S Lab. (Unit Ii) : Plot No. 33 Hpsidc Exten. Baddi, Distt-Solan (H.P.)Subhash ChandNo ratings yet

- Carousel AntimicrobialDocument5 pagesCarousel AntimicrobialoktaNo ratings yet

- Report N°: 23021000F6Document2 pagesReport N°: 23021000F6chrisexportersworldsNo ratings yet

- Standalone Financial Results, Limited Review Report For December 31, 2016 (Result)Document4 pagesStandalone Financial Results, Limited Review Report For December 31, 2016 (Result)Shyam SunderNo ratings yet

- CertiFicate1 MergedDocument15 pagesCertiFicate1 Mergedab505450No ratings yet

- Col Base (Light Ivory) 80: Itc Limited - PSPD, Unit: Tribeni Specification SheetDocument2 pagesCol Base (Light Ivory) 80: Itc Limited - PSPD, Unit: Tribeni Specification SheetApoorva PattnaikNo ratings yet

- Risk Management To Performing Quality Test For Waving Some User PointsDocument3 pagesRisk Management To Performing Quality Test For Waving Some User PointsIrshadAlamNo ratings yet

- SDFDocument1 pageSDFabasakNo ratings yet

- ISO 18184:2019 Textiles-Determination of Antiviral Activity of Textile ProductsDocument4 pagesISO 18184:2019 Textiles-Determination of Antiviral Activity of Textile ProductsRômulo Leão Silva NerisNo ratings yet

- Mechanical Data Sheet - Air Filter (031-GN-002AB)Document5 pagesMechanical Data Sheet - Air Filter (031-GN-002AB)Gaurav PandeyNo ratings yet

- Acc PPC - NFR - 23 - 2021Document1 pageAcc PPC - NFR - 23 - 2021Amit VermaNo ratings yet

- Balance - TestingDocument20 pagesBalance - TestingNguyen Thi Phuong LinhNo ratings yet

- Pdir 5PM Ad3532001 - 1a31892004b 04.06.2022Document1 pagePdir 5PM Ad3532001 - 1a31892004b 04.06.2022RohitNo ratings yet

- TC WC W 37 Sept 23 7 Days.Document1 pageTC WC W 37 Sept 23 7 Days.Sabyasachi BangalNo ratings yet

- Ultratech Cement 7 Days Test Report Week 37Document3 pagesUltratech Cement 7 Days Test Report Week 37Venkatesh VictoryNo ratings yet

- 13 SOP Classification of Clean RoomsDocument5 pages13 SOP Classification of Clean RoomsNoor Javed50% (2)

- Wonder Cement OPC 53Document2 pagesWonder Cement OPC 53sudhaNo ratings yet

- Stability Data - Activated Charcoal 300mgDocument2 pagesStability Data - Activated Charcoal 300mgtajul.rnd.database1No ratings yet

- 12 MM Aggregate Third Party Test Report PDFDocument3 pages12 MM Aggregate Third Party Test Report PDFsyed sulemanNo ratings yet

- Monthly HSE Statistic Performance ReportDocument2 pagesMonthly HSE Statistic Performance ReportBrijgopal YadavNo ratings yet

- Moa of Azi - IpDocument10 pagesMoa of Azi - IpcqaNo ratings yet

- Enseigne NF P92-507 M1Document5 pagesEnseigne NF P92-507 M1thierryethkNo ratings yet

- DCL Report - Hygitech HSDocument2 pagesDCL Report - Hygitech HSFarhan RashidNo ratings yet

- SA-PT REPORT - ConverterDocument7 pagesSA-PT REPORT - ConverterAbdelRahman Essam FawzyNo ratings yet

- Toa Fluid Report Inspectorate001 PWTR POWER TRANSFORMERDocument6 pagesToa Fluid Report Inspectorate001 PWTR POWER TRANSFORMER0502208864No ratings yet

- Training JH PillarDocument41 pagesTraining JH PillarSelvamNo ratings yet

- LTP0258. R04 (Accelerated Weathering Test Procedure)Document3 pagesLTP0258. R04 (Accelerated Weathering Test Procedure)rajesh kumarNo ratings yet

- JK 43 Opc Test CertificateDocument1 pageJK 43 Opc Test CertificateRavi kumar100% (1)

- CERTIFICATE OF PRODUCT QUALITY JET A - 1 Gasoilene 2000,000BBL-1Document2 pagesCERTIFICATE OF PRODUCT QUALITY JET A - 1 Gasoilene 2000,000BBL-1Sephiwe MafilikaNo ratings yet

- Eb EditableDocument2 pagesEb EditableCorporación JolucavaNo ratings yet

- Biotech Testing: ServigesDocument4 pagesBiotech Testing: ServigesanjaleeNo ratings yet

- Inspection and Test Report: Page 1 of 3Document3 pagesInspection and Test Report: Page 1 of 3Chan StephenNo ratings yet

- Test ReportDocument8 pagesTest ReportNishantNo ratings yet

- Environmental Report of Paharpur Cooling TowerDocument6 pagesEnvironmental Report of Paharpur Cooling Towersumit singhNo ratings yet

- Acc CementDocument1 pageAcc CementAbhinav BharatNo ratings yet

- WK No. 01 - Acc Suraksha Power (PPC)Document1 pageWK No. 01 - Acc Suraksha Power (PPC)deepuke80No ratings yet

- Test Certificate: Reference No.Document3 pagesTest Certificate: Reference No.Maninder ChaudharyNo ratings yet

- Milli Pore Test ReportDocument4 pagesMilli Pore Test Reportsuraj rawatNo ratings yet

- MP028 BS EN 771-12011+A12015 CL 5.2.4,5.3.1, 5.3.4 BS EN 772-12011+ A12015, 772-162011, 772-202000Document1 pageMP028 BS EN 771-12011+A12015 CL 5.2.4,5.3.1, 5.3.4 BS EN 772-12011+ A12015, 772-162011, 772-202000jerin sam kurianNo ratings yet

- Quality Weekly Meeting - Summary Results: Hyundai Transys Mexico PowertrainDocument62 pagesQuality Weekly Meeting - Summary Results: Hyundai Transys Mexico PowertrainDiana Palacios InfanteNo ratings yet

- Streamlining Non-Tariff Measures: A Toolkit for Policy MakersFrom EverandStreamlining Non-Tariff Measures: A Toolkit for Policy MakersNo ratings yet

- Surface Test RepotDocument1 pageSurface Test RepotnishthaNo ratings yet

- B L Lifesciences Pvt. LTDDocument2 pagesB L Lifesciences Pvt. LTDnishthaNo ratings yet

- Revised Bioburden SOP BL-MC-005 08.09.21Document7 pagesRevised Bioburden SOP BL-MC-005 08.09.21nishthaNo ratings yet

- Alpha GuardDocument2 pagesAlpha GuardnishthaNo ratings yet

- B L Lifesciences Pvt. LTD.: Corporate Office: A-245, Okhla Industrial Area, Phase-I, New Delhi, IndiaDocument1 pageB L Lifesciences Pvt. LTD.: Corporate Office: A-245, Okhla Industrial Area, Phase-I, New Delhi, IndianishthaNo ratings yet

- Surface Testing SOP 08.09.21Document5 pagesSurface Testing SOP 08.09.21nishthaNo ratings yet

- Performed By: - Reviewed ByDocument4 pagesPerformed By: - Reviewed BynishthaNo ratings yet

- Air Monitoring by Settle Plate BL-MC-03 01.09.2021Document3 pagesAir Monitoring by Settle Plate BL-MC-03 01.09.2021nishthaNo ratings yet

- Micro Biological PerformanceDocument1 pageMicro Biological PerformancenishthaNo ratings yet

- QA Screening QuestionsDocument3 pagesQA Screening QuestionsnishthaNo ratings yet

- BOT-71 X 12345678 Yyyy-Mm Yyyy-Mm: ModelDocument1 pageBOT-71 X 12345678 Yyyy-Mm Yyyy-Mm: ModelnishthaNo ratings yet

- Ram Kumar BiolifeDocument3 pagesRam Kumar BiolifenishthaNo ratings yet

- Form No. Effective Date Review Date Raw Material Stock RegisterDocument1 pageForm No. Effective Date Review Date Raw Material Stock RegisternishthaNo ratings yet

- BMR Cpd-SagmDocument23 pagesBMR Cpd-SagmnishthaNo ratings yet

- Incoming Material Inspection Report: D 31, Site Iv, Kasna, Greater Noida 201 306, U. P., IndiaDocument1 pageIncoming Material Inspection Report: D 31, Site Iv, Kasna, Greater Noida 201 306, U. P., IndianishthaNo ratings yet

- 2021 Calendar Portrait Sunday StartDocument1 page2021 Calendar Portrait Sunday StartnishthaNo ratings yet

- Purchasing ProcdureDocument5 pagesPurchasing ProcdurenishthaNo ratings yet

- BL Eng 01aDocument1 pageBL Eng 01anishthaNo ratings yet

- MFR Double 350 ML CPDA - 150 LTRDocument21 pagesMFR Double 350 ML CPDA - 150 LTRnishthaNo ratings yet

- Bobs Big PMBOK SheetDocument2,618 pagesBobs Big PMBOK SheetTom SmithNo ratings yet

- Admissible and Inadmissible ExpensesDocument2 pagesAdmissible and Inadmissible Expensesjhansiaj06No ratings yet

- Marketing ManagementDocument2 pagesMarketing ManagementTrisha Mae Lyrica CastroNo ratings yet

- Disney Case StudyDocument3 pagesDisney Case StudyRuslan AdibNo ratings yet

- Law 22Document6 pagesLaw 22ram RedNo ratings yet

- 4 SCM Project - Guidelines 2021Document2 pages4 SCM Project - Guidelines 2021Satish KumarNo ratings yet

- DP Penjualan Tba 2023Document32 pagesDP Penjualan Tba 2023greciNo ratings yet

- Rahul Tiwari Profitability VS WelfareDocument20 pagesRahul Tiwari Profitability VS WelfareKshitij KatiyarNo ratings yet

- RKG Eco Mock 3Document6 pagesRKG Eco Mock 3Tushar AswaniNo ratings yet

- Republic of The Philippines: College of Industrial EducationDocument8 pagesRepublic of The Philippines: College of Industrial EducationAngelica AlejandroNo ratings yet

- Sample Pages Complete GUNNER24 Trading and Forecasting CourseDocument16 pagesSample Pages Complete GUNNER24 Trading and Forecasting CourseManish ShahNo ratings yet

- Debt or Equity-Which One Is Better For Your Business?: Name-Avani Shah Roll No-Pgdmrba019Document2 pagesDebt or Equity-Which One Is Better For Your Business?: Name-Avani Shah Roll No-Pgdmrba019avani shahNo ratings yet

- JOB POSTING 15 Mechanical Design Engineer PDFDocument2 pagesJOB POSTING 15 Mechanical Design Engineer PDFManoj KTNo ratings yet

- Lecture 55 AssignmentDocument3 pagesLecture 55 AssignmentMuneeb UllahNo ratings yet

- Notice Under Section 80 CPCDocument2 pagesNotice Under Section 80 CPCRicha Goyal100% (3)

- Annual Report - BPL LTD - FY - 2010-11Document40 pagesAnnual Report - BPL LTD - FY - 2010-11ksachchuNo ratings yet

- Compromise Agreement - AguinaldoDocument6 pagesCompromise Agreement - AguinaldoPatrice Noelle RamirezNo ratings yet

- Clifton-Fine Hospital Organizational Chart: Downloaded FromDocument1 pageClifton-Fine Hospital Organizational Chart: Downloaded FromoyooNo ratings yet

- Deloitte Digital Era Tom v1 PDFDocument68 pagesDeloitte Digital Era Tom v1 PDFميلاد نوروزي رهبرNo ratings yet

- Fayth Ayuste CVDocument1 pageFayth Ayuste CVAb HermosoNo ratings yet

- The Revision of The Product Liability Directive A Key Piece in The Artificial Intelligence Liability Puzzle-2023Document13 pagesThe Revision of The Product Liability Directive A Key Piece in The Artificial Intelligence Liability Puzzle-2023Huy HoàngNo ratings yet

- Ebs Enterprise Command Center Quick Start GuideDocument45 pagesEbs Enterprise Command Center Quick Start GuideMaqbulhusenNo ratings yet

- Chapter 1 Auditing and Assurance Services: Multiple Choice QuestionsDocument9 pagesChapter 1 Auditing and Assurance Services: Multiple Choice Questionsalmira garciaNo ratings yet

- Taxation Ii - DLC Transcript: (February 18, 2019)Document22 pagesTaxation Ii - DLC Transcript: (February 18, 2019)Anselmo Rodiel IVNo ratings yet

- Agsoba Global: Internal MemoDocument2 pagesAgsoba Global: Internal MemoKunle AkingbadeNo ratings yet

- FA5 - Group 1 - Project ProposalDocument33 pagesFA5 - Group 1 - Project ProposalsirdeboyNo ratings yet

- BSBHRM523 Coordinate The Learning and Development of Teams and Individuals Final Draft.Document37 pagesBSBHRM523 Coordinate The Learning and Development of Teams and Individuals Final Draft.Arie BobNo ratings yet

- BBA, Bcom TSRDocument15 pagesBBA, Bcom TSRlavanyajkdigvirtualNo ratings yet

- Business Laws ch-1 Unit 2Document25 pagesBusiness Laws ch-1 Unit 2Kartik Garg100% (1)

- Activity Design BHW X'mas PartyDocument1 pageActivity Design BHW X'mas PartyCharlyn MoyonNo ratings yet