Professional Documents

Culture Documents

Corrugated Metal Gaskets WJ15

Corrugated Metal Gaskets WJ15

Uploaded by

Chan Yong SoonOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Corrugated Metal Gaskets WJ15

Corrugated Metal Gaskets WJ15

Uploaded by

Chan Yong SoonCopyright:

Available Formats

CORRUGATED METAL GASKETS

PROPERTIES AND APPLICATION

Corrugated gaskets without layer

There are different types of metal gaskets, like flat, groove, tongue and sectional

ones. They are used where compressibility (elasticity) of sealing material is not

required. The construction of such gaskets based on the principle of different

hardness of adjacent materials. These gaskets come in various shapes and there

are almost no limits concerning their size.

MW12

The corrugated metal gaskets have been proven to be both reliable and cost-

effective for the application on flanges and heads where bolt loading is sufficient.

Their operation principle is based on different degrees of hardness of adjacent MW12A

materials. The sealing effect is produced by the constant load to which a gasket

is exposed. They are used in applications, which require mechanical strength,

thermal conductivity, as well as temperature and corrosion resistance. They are

particularly useful when compressibility is not a factor and where sufficient MW12AE

clamping force is available. Metal gaskets feature greater mechanical strength,

better heat transfer and resistance to higher temperatures and pressures, and can

offer advantages over the clad type gaskets in certain applications. MW13A

MW22A

Corugated gaskets with soft layer

Corrugated metal is covered with graphite, ceramic or PTFE layers. An additional MW23A

finishing layer is applied depending on the requirements of the medium to be sealed.

Such gaskets are used on uneven or distorted sealing surfaces, where more elastic

materials with better sealing performance are needed.

MW12C

The corrugated metal gaskets with soft layer on both sides are used in low-pressure

applications in large diameter flue gas ducts at high temperatures. The use of

corrugated gaskets eliminates the problem of difficult handling whith large non-

metal gaskets used in those applications. They are suitable for gas pipes and valve

caps, or wherever acids, oils and chemicals are found. They can be used at lower

pressures and higher temperatures.

6. CORRUGATED METAL GASKETS

ADVANTAGES

- Outstanding mechanical strength and thermal conductivity.

- Capable of withstanding high temperatures.

- There are almost no limitations regarding size.

- Solid construction provides stability even for large diameters and ensures

trouble-free handling and installation.

SHAPE AND CONSTRUCTION

The metal gaskets are produced in several types to meet the most demanding

applications. Shapes: Round, Oval, Rectangular, etc.

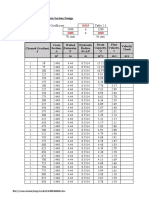

MATERIALS FOR METAL AND CORUGATED METAL GASKETS

Material ASTM DIN Material No.

Low Carbon Steel Soft iron (CS) 1.0333

Stainless steel AISI 304 1.4301

Stainless steel AISI 316, 316 L 1.4401, 1.4404

Stainless steel AISI 321 1.4541

Stainless steel AISI 316 Ti 1.4571

D

SIZE

The gasket constructions with an outside diameter 1000 mm is usually made

in one piece, larger dimensions are welded. Welding is also recommen-

ded for cost-effectiveness.

Profile

The metal is 0.5 mm thick and the corrugation pitch is 3 mm, 4 mm, 5 mm or

6 mm depending on the width and size of the gaskets. The thickness of

corrugation is approx. 1mm to 1.5 mm, depending on gasket size. Corrugated

b

metal is covered with graphite, ceramic or PTFE layers in thickness 0.5 mm - 2 mm.

B

Tip: A x B x b (oval) GASKET ORDERING EXAMPLE

STANDARD SIZE:

CORRUGATED GASKET M12A,

A EN1514-4 DN100, PN40,

Material: 1.4571/Graphite

R1

F

NON-STANDARD DIMENSION:

E

CORRUGATED GASKET M12A,

D=946 mm, D=914 mm, S=3.5 mm,

R

Material: AISI316Ti/Graphite

You might also like

- Dowel Pin Tolerances PDFDocument4 pagesDowel Pin Tolerances PDFHenrique Marques100% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- KM Instructor Course Phase 1aDocument22 pagesKM Instructor Course Phase 1anozza_1No ratings yet

- FFT Aura Fence Installation Manual v1.1.2Document104 pagesFFT Aura Fence Installation Manual v1.1.2Usman Zouque100% (2)

- 26 - LCCI L3 AC - Sep 2019 - ASE 20104 - MSDocument15 pages26 - LCCI L3 AC - Sep 2019 - ASE 20104 - MSKhin Zaw Htwe100% (6)

- Corrugated Metal Gaskets Wj15 r1Document1 pageCorrugated Metal Gaskets Wj15 r1Bảo Trung LêNo ratings yet

- Heat Exchanger GasketsDocument3 pagesHeat Exchanger GasketsAnghelo AlcaldeNo ratings yet

- Marine Fire and Gas Dampers: Type JFDDocument8 pagesMarine Fire and Gas Dampers: Type JFDTakrimi IsmailNo ratings yet

- Dowel Pin SpecificationsDocument4 pagesDowel Pin Specificationsjitendra patelNo ratings yet

- Heat Exchanger GasketDocument3 pagesHeat Exchanger GasketGurinder SinghNo ratings yet

- Spiral Wound Gaskets Donit TesnitDocument0 pagesSpiral Wound Gaskets Donit Tesnitjhony1523No ratings yet

- Spiral Wound Gaskets PDFDocument4 pagesSpiral Wound Gaskets PDFSumit ChaurasiaNo ratings yet

- Maltec T Thermocouple - DpstarGroupDocument17 pagesMaltec T Thermocouple - DpstarGroupletphuongNo ratings yet

- Spiral Wound GasketsDocument6 pagesSpiral Wound GasketsezihamzahNo ratings yet

- Aust BrochureDocument8 pagesAust BrochureHPPARIKHNo ratings yet

- Maxiflex Spiral Wound Gaskets Product DocumentDocument5 pagesMaxiflex Spiral Wound Gaskets Product DocumentPham Thien TruongNo ratings yet

- BT3 - Pagod Na KoDocument6 pagesBT3 - Pagod Na KoJessa ObraNo ratings yet

- Spring MaterialsDocument4 pagesSpring MaterialssohamkoliNo ratings yet

- Mi P GasketsDocument15 pagesMi P Gasketsnaveen1981_nrNo ratings yet

- Klinger Kammprofiles Austr PDFDocument5 pagesKlinger Kammprofiles Austr PDFAnonymous nw5AXJqjdNo ratings yet

- Experimental Analysis of Mig and Tig Welding With Parameter Optimization For Welding StrengthDocument5 pagesExperimental Analysis of Mig and Tig Welding With Parameter Optimization For Welding StrengthChandra Sekar100% (1)

- NH NST NPT NPSHDocument2 pagesNH NST NPT NPSHsechooNo ratings yet

- Gaskets GeneralDocument9 pagesGaskets GeneralpkolNo ratings yet

- Steel Self-Piercing Tapping Screws For The Application of Gypsum Panel Products or Metal Plaster Bases To Wood Studs or Steel StudsDocument5 pagesSteel Self-Piercing Tapping Screws For The Application of Gypsum Panel Products or Metal Plaster Bases To Wood Studs or Steel StudsirsanNo ratings yet

- KLINGERDocument4 pagesKLINGERJalal AlbadriNo ratings yet

- Metal Injection Molded PartsDocument6 pagesMetal Injection Molded PartsDaniel Felipe Garzon CuervoNo ratings yet

- 4 MaterialsDocument5 pages4 MaterialsAzaher ShaikhNo ratings yet

- Gasket Design and AnalysisDocument32 pagesGasket Design and AnalysisJay MahajanNo ratings yet

- Metal O-Ring PDFDocument8 pagesMetal O-Ring PDFanon_481226617No ratings yet

- SSINA - Designer's Handbook - Stainless Steel FastenersDocument23 pagesSSINA - Designer's Handbook - Stainless Steel FastenersSerguei DobrinNo ratings yet

- Zamil Steel Buildings Design Manual: 1.5. Skylight PanelsDocument1 pageZamil Steel Buildings Design Manual: 1.5. Skylight PanelsvuvandanNo ratings yet

- Air DuctsDocument6 pagesAir DuctsmohamedroyaleyeuaeNo ratings yet

- LT0359 6Document12 pagesLT0359 6Jhampier Sánchez ZambranoNo ratings yet

- Circular Saw - Technical DescriptionDocument17 pagesCircular Saw - Technical DescriptionPuneeth KumarNo ratings yet

- SP CFC Centerfire ConsumablesDocument4 pagesSP CFC Centerfire ConsumablesYip DavidNo ratings yet

- Stainless Steel Brochure LRDocument8 pagesStainless Steel Brochure LRHuỳnh TrươngNo ratings yet

- CatalogDocument12 pagesCatalogamirii.hafsaNo ratings yet

- Hot Dip GalvanizDocument3 pagesHot Dip GalvanizRyan Adriadi NNo ratings yet

- Hot Dip Galvanizing For FastenersDocument3 pagesHot Dip Galvanizing For FastenersIrwin CastroNo ratings yet

- Bolted ConnectionsDocument9 pagesBolted ConnectionsClaudioDuarte100% (1)

- Srs GasketsDocument7 pagesSrs GasketsRanganathan SekarNo ratings yet

- Dowel Pins and Extractable Dowels PDFDocument4 pagesDowel Pins and Extractable Dowels PDFtech81No ratings yet

- Anchoring of Monolithic Refractories - UkDocument9 pagesAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- Double Jacketed Gaskets - SUNWELL 9001575372051Document4 pagesDouble Jacketed Gaskets - SUNWELL 9001575372051Idris SiddiquiNo ratings yet

- Aalco Metals LTD Stainless Steel 14571 Bar 40Document3 pagesAalco Metals LTD Stainless Steel 14571 Bar 40raduonoNo ratings yet

- Catalog FSWDocument9 pagesCatalog FSWPedro CunhaNo ratings yet

- Flange, Gasket and Piping SelectionDocument21 pagesFlange, Gasket and Piping SelectionNaveed GulzarNo ratings yet

- Joint Design 2 (2001) - Nails, Staples & ScrewsDocument16 pagesJoint Design 2 (2001) - Nails, Staples & Screwssteveh49100% (1)

- Market Survey of Steel Sections: Materials and Construction IiiDocument9 pagesMarket Survey of Steel Sections: Materials and Construction IiiMehul jainNo ratings yet

- ME Assignment 2Document12 pagesME Assignment 2hecavodNo ratings yet

- Ati CatalogDocument20 pagesAti CatalogKalpesh JainNo ratings yet

- Alluminio TeoriaDocument91 pagesAlluminio TeoriaxypangioNo ratings yet

- Sheet MetalDocument41 pagesSheet MetalMa. Bianca Isabelle S. GoNo ratings yet

- Drill Bit - WikipediaDocument55 pagesDrill Bit - Wikipediaaddisugebre2125No ratings yet

- Seamless Tubing and Pipe RedfluidDocument1 pageSeamless Tubing and Pipe RedfluidHorin Relevando SilitongaNo ratings yet

- Garnituri DIN 2697Document12 pagesGarnituri DIN 2697Dumitru SorinaNo ratings yet

- Stainless Steel 316Document1 pageStainless Steel 316Bungsu ZamzamNo ratings yet

- Jewelry Making for Beginners: 32 Projects with MetalsFrom EverandJewelry Making for Beginners: 32 Projects with MetalsRating: 4 out of 5 stars4/5 (2)

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersFrom EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersRating: 3.5 out of 5 stars3.5/5 (2)

- Optimization and Cost Comparison of Reactor Types in A Styrene PRDocument67 pagesOptimization and Cost Comparison of Reactor Types in A Styrene PRChan Yong SoonNo ratings yet

- 9746 33239 3 PBDocument12 pages9746 33239 3 PBChan Yong SoonNo ratings yet

- Report Mini Project Plant Design EthylbenzeneDocument163 pagesReport Mini Project Plant Design EthylbenzeneChan Yong SoonNo ratings yet

- 1 s2.0 S0048969719357936 MainDocument9 pages1 s2.0 S0048969719357936 MainChan Yong SoonNo ratings yet

- Seminar-Quality Assurance (13-11-2013) - Copy (Repaired)Document200 pagesSeminar-Quality Assurance (13-11-2013) - Copy (Repaired)ASIR DHAYANINo ratings yet

- Load Cell Input ModuleDocument3 pagesLoad Cell Input Moduleabo omrNo ratings yet

- MSDSDocument6 pagesMSDSMuhammad Iqbal NiyaziNo ratings yet

- Dissertation Institutes in DelhiDocument4 pagesDissertation Institutes in DelhiWriteMyCollegePaperCanada100% (1)

- CE 632 Shallow Foundations Part-2 HandoutDocument7 pagesCE 632 Shallow Foundations Part-2 HandoutLouis KiwaNo ratings yet

- Muhammad Alauddin Nur, S.PD., GR.: Arranged byDocument75 pagesMuhammad Alauddin Nur, S.PD., GR.: Arranged byNo HikariNo ratings yet

- Bryce Boerste - Personal College Essay - Draft 2Document3 pagesBryce Boerste - Personal College Essay - Draft 2api-492128881No ratings yet

- TRIAL Poultry Farm Financial Model Excel Template v2.0Document96 pagesTRIAL Poultry Farm Financial Model Excel Template v2.0Muhammad Haroon YousafNo ratings yet

- Introduction To The Data Ethics CompassDocument21 pagesIntroduction To The Data Ethics CompassManjulika TiwariNo ratings yet

- Rail Movement Joints: Products DilatationenDocument0 pagesRail Movement Joints: Products DilatationenmarkicivanNo ratings yet

- Martin Luther 1st ThesisDocument6 pagesMartin Luther 1st Thesisrzaeetief100% (2)

- Maria Margaretha: Personal DetailDocument3 pagesMaria Margaretha: Personal DetailncocikaNo ratings yet

- H2scan 720as-Gc Hydrogen Sensor System ManualDocument22 pagesH2scan 720as-Gc Hydrogen Sensor System ManualMohammed SaberNo ratings yet

- Sharpe, Treynor and Jenson SumDocument2 pagesSharpe, Treynor and Jenson SumNikita ShekhawatNo ratings yet

- Yudkin Music in Medieval EuropeDocument316 pagesYudkin Music in Medieval EuropeAndrew Franklin O'ConnorNo ratings yet

- 40 HasanatDocument4 pages40 HasanatMuhammad KhanNo ratings yet

- Capstone Project ProposalDocument7 pagesCapstone Project Proposalapi-596258184No ratings yet

- Chapter 4 Manual Assembly LinesDocument49 pagesChapter 4 Manual Assembly LinesRohit WadhwaniNo ratings yet

- Newton's Laws of Motion StoryboardsDocument7 pagesNewton's Laws of Motion StoryboardsJudy AndalNo ratings yet

- DTP HomeworkDocument6 pagesDTP Homeworkcffge1tw100% (1)

- Box Culvert / U-Drain Section Design: File:///conversion/tmp/scratch/488560866Document9 pagesBox Culvert / U-Drain Section Design: File:///conversion/tmp/scratch/488560866azwanNo ratings yet

- BF SheetDocument4 pagesBF SheetSudhakar JainNo ratings yet

- Review LeadershipDocument10 pagesReview LeadershipON ChannelIDNo ratings yet

- Standards Stat SurveysDocument41 pagesStandards Stat SurveysGerardo LozzNo ratings yet

- Inpulse PlusDocument2 pagesInpulse Plushabiba hamdaouiNo ratings yet

- Most Suitable Mother Wavelet For Measurement of Power System Harmonics Using DWT in View of IEEE Standard 1459-2000Document6 pagesMost Suitable Mother Wavelet For Measurement of Power System Harmonics Using DWT in View of IEEE Standard 1459-2000Ivan BallesterosNo ratings yet

- Insight in Inpatients With Psychotic Mania Demographic and Clinical FactorsDocument13 pagesInsight in Inpatients With Psychotic Mania Demographic and Clinical FactorsmusdalifahNo ratings yet