Professional Documents

Culture Documents

Data Sheet 316L

Data Sheet 316L

Uploaded by

khalidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet 316L

Data Sheet 316L

Uploaded by

khalidCopyright:

Available Formats

Grade Data Sheet

HIDAYATH 316, 316L, 316H

Grade 316 is the standard molybdenum-bearing range is not recommended if subsequent

austenitic grade, second stainless steel in aqueous corrosion resistance is important.

importance to 304. The molybdenum gives 316 Grade 316L is more resistant to carbide

better overall corrosion resistant properties precipitation and can be used in the above

than Grade 304, particularly higher resistance temperature range. Grade 316H has higher

to pitting and crevice corrosion in chloride strength at elevated temperatures and is

environments. It is readily brake or roll formed, sometimes used for structural and pressure-

welded, soldered and cut by both thermal and containing applications at temperatures above

mechanical methods. The austenitic structure about 500°C, but the titanium stabilised grade

gives excellent toughness, even down to 316Ti is often a more appropriate choice.

cryogenic temperatures.

Heat Treatment

Grade 316L, the low carbon version of 316, is Solution Treatment (Annealing)

highly resistant to sensitisation (grain boundary Heat to 1010-1120°C and cool rapidly. These

carbide precipitation) and so is extensively used grades cannot be hardened by thermal

in heavy gauge welded components (about treatment.

5mm and over). Grade 316H, with its higher

carbon content has some application at elevated Welding

temperatures, as does stabilised grade 316Ti. Excellent weldability by all standard fusion

Nitrogen-strengthened versions also exist as methods, both with and without filler metals. AS

316N and 316LN. 1554.6 pre-qualifies welding of 316 with Grade

316 and 316L with Grade 316L rods or

.Corrosion Resistance electrodes (or their high silicon equivalents).

Excellent in a range of atmospheric Heavy welded sections in Grade 316 require

environments and many corrosive media - post-weld annealing for maximum corrosion

generally more resistant than 304. Subject to resistance. This is not required for 316L. Grade

pitting and crevice corrosion in warm chloride 316Ti may also be used as an alternative to 316

environments, and to stress corrosion cracking for heavy section welding.

above about 60°C. Considered resistant to

pitting corrosion in potable water with up to Machining

about 1000mg/L chlorides at ambient A “Ugima” improved machinability version of

temperatures, reducing to about 300mg/L at grade 316 is available in round and hollow bar

60°C. products. Ugima machines significantly better

than standard 316 or 316L, giving higher

316 is usually regarded as the standard “marine machining rates and lower tool wear in many

grade” stainless steel, but it is not fully operations.

resistant to sea water. In many marine

environments 316 does exhibit surface “Dual Certification”

corrosion, usually visible as brown staining. This It is common for 316 and 316L to be stocked in

is particularly associated with crevices and “Dual Certified” form, particularly in plate, pipe

rough surface finish. and round bar. These items have chemical and

mechanical properties complying with both 316

and 316L specifications. Such dual certified

product may be unacceptable for high

temperature applications.

.There is usually no difference in corrosion

resistance between 316 and 316L.

Typical Applications

Food processing equipment. Laboratory

Heat Resistance equipment. Architectural panelling, railings &

Good oxidation resistance in intermittent trim. Boat fittings. Chemical containers. Heat

service to 870°C and in continuous service to exchangers. Screens for mining, quarrying &

925°C. Continuous use of 316 in the 425-860°C water filtration. Threaded fasteners. Springs.

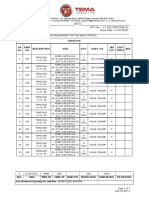

Grade Data Sheet

HIDAYATH 316, 316L, 316H

Specified Properties

These properties are specified for flat rolled product (plate, sheet and coil) in ASTM A240/A240M.

Similar but not necessarily identical properties are specified for other products such as pipe and

bar in their respective specifications.

Composition Specification (%)

Grade C Mn Si P S Cr Mo Ni N

316 min. - - - - - 16.0 2.00 10.0 -

max. 0.08 2.0 0.75 0.045 0.030 18.0 3.00 14.0 0.10

316L min. - - - - - 16.0 2.00 10.0 -

max. 0.030 2.0 0.75 0.045 0.030 18.0 3.00 14.0 0.10

316H min. 0.04 - - - - 16.0 2.00 10.0 -

max. 0.10 2.0 0.75 0.045 0.030 18.0 3.00 14.0 -

Mechanical Property Specification

Grade Tensile Yield Strength Elongation Hardness

Strength 0.2% Proof (% in

(MPa) (MPa) 50mm) Rockwell B Brinell

min min min (HR B) (HB)

max max

316 515 205 40 95 217

316L 485 170 40 95 217

316H 515 205 40 95 217

316H also has a requirement for a grain size of ASTM No 7 or coarser.

Physical Properties (typical values in the annealed condition)

Grade Density Elastic Mean Coefficient of Thermal Thermal Specific Electrical

3 Modulus Expansion Conductivity Heat Resistivity

(kg/m )

(GPa) 0-100°C 0-315°C 0-538°C at 100°C at 500°C 0-100°C (nΩ.m)

(µm/m/°C) (µm/m/°C) (µm/m/°C) (W/m.K) (W/m.K) ( J/kg.K)

316 & 8000 193 15.9 16.2 17.5 16.3 21.5 500 740

316L/H

Grade Specification Comparison

Grade UNS Euronorm Swedish Japanese

No No Name SS JIS

316 S31600 1.4401 X5CrNiMo17-12-2 2347 SUS 316

316L S31603 1.4404 X2CrNiMo17-12-2 2348 SUS 316L

316H S31609 - - - -

These comparisons are approximate only. The list is intended as a comparison of functionally similar

materials not as a schedule of contractual equivalents. If exact equivalents are needed original

specifications must be consulted.

Limitation of Liability

The information contained in this datasheet is not an exhaustive statement of all relevant information. It is a

general guide for customers to the products and services available from Atlas Steels and no representation is

made or warranty given in relation to this document or the products or processes it describes.

You might also like

- Technicals of 316/lDocument2 pagesTechnicals of 316/lASHISH DOSHINo ratings yet

- Atlas Grade Datasheet 316 Rev Jan 2011 PDFDocument2 pagesAtlas Grade Datasheet 316 Rev Jan 2011 PDFmarklaforestNo ratings yet

- Spec 316Document4 pagesSpec 316andidesisunarnoNo ratings yet

- Atlas Grade Datasheet 316 Rev Jan 2011Document2 pagesAtlas Grade Datasheet 316 Rev Jan 2011d_muamer_116983894No ratings yet

- Stainless Steel Grade 316 (UNS S31600)Document4 pagesStainless Steel Grade 316 (UNS S31600)achari_swapnilNo ratings yet

- Stainless Steel 316, 316L, 316H Grade Data SheetDocument3 pagesStainless Steel 316, 316L, 316H Grade Data SheetbaladiroyaNo ratings yet

- Aisi 316Document4 pagesAisi 316Aliakbar SaifeeNo ratings yet

- Stainless Steel 1.4571 - 316ti: Alloy DesignationsDocument3 pagesStainless Steel 1.4571 - 316ti: Alloy DesignationsRohit choudharyNo ratings yet

- Stainless Steel - Grade 316L - Properties, Fabrication and ApplicationsDocument4 pagesStainless Steel - Grade 316L - Properties, Fabrication and Applicationsjpc0337049No ratings yet

- DS Alloy 316 316LDocument2 pagesDS Alloy 316 316LshenNo ratings yet

- Stainless Steel Grade 316 (UNS S31600)Document5 pagesStainless Steel Grade 316 (UNS S31600)Gangsar DwikaNo ratings yet

- Grade 316 Stainless Steel Technical DataDocument3 pagesGrade 316 Stainless Steel Technical Dataali kajbafNo ratings yet

- 316 316L 317L Spec Sheet PDFDocument3 pages316 316L 317L Spec Sheet PDFSaúl L Hdez TNo ratings yet

- AISI 316-316L-316TiDocument3 pagesAISI 316-316L-316TibejearuNo ratings yet

- Aalco Metals LTD Stainless Steel 14571 Bar 40Document3 pagesAalco Metals LTD Stainless Steel 14571 Bar 40raduonoNo ratings yet

- Stainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)Document6 pagesStainless Steel Grade 316L Properties Fabrication and Applications (UNS S31603)ganmosesNo ratings yet

- 316l Austenitic Stainless Steel BarDocument3 pages316l Austenitic Stainless Steel Barதமிழன் இராமசாமிNo ratings yet

- SS316 - Comparison With SS316LDocument3 pagesSS316 - Comparison With SS316LAdrianus PrimaNo ratings yet

- 316 & 316LDocument4 pages316 & 316LMechanicalNo ratings yet

- Technical DataDocument1 pageTechnical DataengrodeNo ratings yet

- A4-80 Stainless Steel Grade Specification - Midland Bright SteelsDocument4 pagesA4-80 Stainless Steel Grade Specification - Midland Bright SteelsramonaghergheNo ratings yet

- Alloy321 SpecSheetDocument2 pagesAlloy321 SpecSheetVinod tiwariNo ratings yet

- SS 316Document3 pagesSS 316Deepak SinghNo ratings yet

- Ansi 316Document4 pagesAnsi 316yoyokpurwantoNo ratings yet

- 316 Tech DataDocument1 page316 Tech Datatris khanNo ratings yet

- A4 80Document2 pagesA4 80alwezalokNo ratings yet

- Stainless Steel Grade AISI 321Document2 pagesStainless Steel Grade AISI 321Mitul Rawat100% (1)

- 316 SS Data SheetDocument3 pages316 SS Data SheetellisforheroesNo ratings yet

- SS316 Corrosion RateDocument13 pagesSS316 Corrosion Ratenarayana reddy100% (1)

- Grade Data SheetDocument2 pagesGrade Data Sheetamitkharb111195No ratings yet

- 316L SA 240 Ferguson MetalDocument1 page316L SA 240 Ferguson MetalSugiarto SaptomoNo ratings yet

- Austnitic Stainless Steel 316 316LDocument2 pagesAustnitic Stainless Steel 316 316LbladdeeNo ratings yet

- Specification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541Document2 pagesSpecification Sheet: Alloy 321/321H: (UNS S32100, S32109) W. Nr. 1.4541ex4182No ratings yet

- Materilas-An Overview: 3.1 Austenitic Stainless Steel 316LDocument13 pagesMaterilas-An Overview: 3.1 Austenitic Stainless Steel 316LRS CreationsNo ratings yet

- Data Sheet For Ss 304 GradeDocument2 pagesData Sheet For Ss 304 Grades swami100% (1)

- Stainless Steel Grade 310 (UNS S31000)Document3 pagesStainless Steel Grade 310 (UNS S31000)V BNo ratings yet

- Grade 316 316LDocument9 pagesGrade 316 316LvsajuNo ratings yet

- Unit-2 Metalic Implants-Stainless SteelDocument16 pagesUnit-2 Metalic Implants-Stainless SteelMUKESH SUNDARARAJANNo ratings yet

- Grades of Stainless Steel - Grade 316: SX 316 / 316L Technical DataDocument3 pagesGrades of Stainless Steel - Grade 316: SX 316 / 316L Technical Data03sri03No ratings yet

- Atlas 304 - 304L: Colour Code: Lilac/TurquoiseDocument3 pagesAtlas 304 - 304L: Colour Code: Lilac/TurquoiseOthoniel MunizNo ratings yet

- SS316LNDocument4 pagesSS316LNsamruddhiNo ratings yet

- 316 Tubeing TrisDocument1 page316 Tubeing Triscenter steel110No ratings yet

- A4 70 PDFDocument2 pagesA4 70 PDFputra_sodik6364No ratings yet

- Stainless Steel Grade 630Document6 pagesStainless Steel Grade 630mazaher.ramazaniNo ratings yet

- ST 321 SpecificationDocument2 pagesST 321 SpecificationEl BaranNo ratings yet

- Stainless Steel Properties and Applications of Grades 310310s Stainless SteelDocument6 pagesStainless Steel Properties and Applications of Grades 310310s Stainless SteelKollan Manivardhan ReddyNo ratings yet

- Alloy 410s Spec SheetDocument2 pagesAlloy 410s Spec SheetALONSO GOMEZNo ratings yet

- Stainless Steel 316Document1 pageStainless Steel 316Bungsu ZamzamNo ratings yet

- Type 316-316L Stainless SteelDocument2 pagesType 316-316L Stainless SteelPravin PawarNo ratings yet

- 316LNDocument3 pages316LNGanesh KcNo ratings yet

- Specification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Document2 pagesSpecification Sheet: Alloy 309/309S/309H: (UNS S30900, S30908, S30909) W. Nr. 1.4833Felipe A. Gutiérrez M.No ratings yet

- Stainless Steel Bar 431 Atlas 431: Colour Code: Signal RedDocument3 pagesStainless Steel Bar 431 Atlas 431: Colour Code: Signal RedNitin AggarwalNo ratings yet

- Atlas Grade Datasheet 630 Rev May 2008Document2 pagesAtlas Grade Datasheet 630 Rev May 2008Pebri ListiyaniNo ratings yet

- 316 316L 317L Spec SheetDocument3 pages316 316L 317L Spec SheetLinnie McleodNo ratings yet

- 1414059256wpdm - Stainless Steel Grade AISI 310Document2 pages1414059256wpdm - Stainless Steel Grade AISI 310Riian ApriansyahNo ratings yet

- SS304 304L Data SheetDocument2 pagesSS304 304L Data SheetPrakash KumarNo ratings yet

- Companyprofile 22Document1 pageCompanyprofile 22khalidNo ratings yet

- Dokumen - Tips - Design of Column in Offshore StructureDocument37 pagesDokumen - Tips - Design of Column in Offshore StructurekhalidNo ratings yet

- PW BRO MagicCleaner EN LowDocument12 pagesPW BRO MagicCleaner EN LowkhalidNo ratings yet

- 1000JMBR5 202007 0.4 - 0.4 NewDocument9 pages1000JMBR5 202007 0.4 - 0.4 NewkhalidNo ratings yet

- SD 6-13-110 Rev 3 Traffic Sign Support Details Single PostDocument1 pageSD 6-13-110 Rev 3 Traffic Sign Support Details Single PostkhalidNo ratings yet

- Ibc P Pages 72-78Document7 pagesIbc P Pages 72-78khalidNo ratings yet

- Zimbabwe Base MetalsDocument1 pageZimbabwe Base MetalsPhineas Khosa NdhlauNo ratings yet

- Precious Palladium Aluminium Based Alloy With High Hardness and WorkabilityDocument9 pagesPrecious Palladium Aluminium Based Alloy With High Hardness and WorkabilityhyyziaNo ratings yet

- Ciclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateDocument1 pageCiclo Di Verniciatura: Proprieta' Tecniche Vedi Schede Tecniche AllegateMaffone NumerounoNo ratings yet

- GXT Mobile Shear Shear Jaw Armor™: Field Installation ManualDocument24 pagesGXT Mobile Shear Shear Jaw Armor™: Field Installation ManualPrudzNo ratings yet

- Approved: Materials Engineering SpecificationDocument2 pagesApproved: Materials Engineering SpecificationRonald AraujoNo ratings yet

- Mcneilus Steel CatalogDocument108 pagesMcneilus Steel Catalogkashyap_structuralNo ratings yet

- Cantor Alloys1Document36 pagesCantor Alloys1Duygu GökkuşNo ratings yet

- AS 1397 (Excerpts From Australian Standard)Document1 pageAS 1397 (Excerpts From Australian Standard)Cao SonNo ratings yet

- CH 3Document3 pagesCH 3Viraaj SinghNo ratings yet

- Afsa Corrosion Pocket GuideDocument36 pagesAfsa Corrosion Pocket GuideNuno PachecoNo ratings yet

- NF EN 13445-2 V1/AC1: Décembre 2015Document37 pagesNF EN 13445-2 V1/AC1: Décembre 2015rodrigoperezsimoneNo ratings yet

- SB 150Document4 pagesSB 150AnilNo ratings yet

- Katalog LincolnaDocument612 pagesKatalog LincolnaHaris TrešnjoNo ratings yet

- Oxy-Acetylene Welding: KJ Dicyanoacetylene Cyanogen Decomposes Hydrogen CarbonDocument2 pagesOxy-Acetylene Welding: KJ Dicyanoacetylene Cyanogen Decomposes Hydrogen CarboncharanNo ratings yet

- Characterization of Metals and Alloys: Ramiro Pérez Campos Antonio Contreras Cuevas Rodrigo A. Esparza Muñoz EditorsDocument252 pagesCharacterization of Metals and Alloys: Ramiro Pérez Campos Antonio Contreras Cuevas Rodrigo A. Esparza Muñoz EditorsLino A S RodriguesNo ratings yet

- Thursday 04 To Perform The Rockwell Hardness Test and Determine The Hardness of The Given SpecimenDocument6 pagesThursday 04 To Perform The Rockwell Hardness Test and Determine The Hardness of The Given SpecimenFatima ImamNo ratings yet

- Smaw Final PDFDocument11 pagesSmaw Final PDFHimanshuNarayanSinghNo ratings yet

- Scripta Materialia: Yan Chong, Tilak Bhattacharjee, Jangho Yi, Akinobu Shibata, Nobuhiro TsujiDocument5 pagesScripta Materialia: Yan Chong, Tilak Bhattacharjee, Jangho Yi, Akinobu Shibata, Nobuhiro Tsujidewang_yogesh3No ratings yet

- Introduction To The ASTM Designation SystemDocument6 pagesIntroduction To The ASTM Designation Systemmajor_duan100% (1)

- DeZURIK VPB VPort Ball 031317Document19 pagesDeZURIK VPB VPort Ball 031317Joel VeraNo ratings yet

- مصدر MergedDocument35 pagesمصدر Mergedفاطمة فرزدق مدلل شبرNo ratings yet

- Welder ResumesDocument10 pagesWelder ResumesAbdlHameed FareedahNo ratings yet

- Material Selection and NameDocument6 pagesMaterial Selection and NameHlaingm KyawNo ratings yet

- EMTL 250BB Lab 2 - Hardness Lab Handout-Winter2023Document9 pagesEMTL 250BB Lab 2 - Hardness Lab Handout-Winter2023Desiree FabianNo ratings yet

- PSD CEU 180Sept11-Corrosion PDFDocument17 pagesPSD CEU 180Sept11-Corrosion PDFSam ChoiNo ratings yet

- Zijin Mining - Material Classification System and Characteristics - V2.7 - 20200730ú¿englishúDocument891 pagesZijin Mining - Material Classification System and Characteristics - V2.7 - 20200730ú¿englishúNatasa SindjelicNo ratings yet

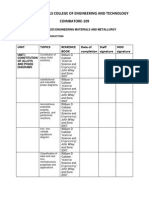

- A.S.L. Pauls College of Engineering and Technology Coimbatore-109Document5 pagesA.S.L. Pauls College of Engineering and Technology Coimbatore-109vkesavakannan4722No ratings yet

- ICSE 2023 Chemistry Paper Class 10Document11 pagesICSE 2023 Chemistry Paper Class 10Harshith AcharyaNo ratings yet

- 17 185 Toricone 01 - R0Document5 pages17 185 Toricone 01 - R0Agni DuttaNo ratings yet

- Pem NutDocument16 pagesPem Nut최영현No ratings yet