Professional Documents

Culture Documents

Section 02765

Section 02765

Uploaded by

a.shwekh0 ratings0% found this document useful (0 votes)

10 views17 pagesOriginal Title

section 02765

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

0 ratings0% found this document useful (0 votes)

10 views17 pagesSection 02765

Section 02765

Uploaded by

a.shwekhCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

Download as pdf

You are on page 1of 17

SECTION 02765

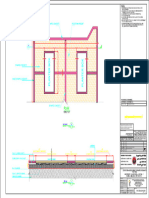

‘STAMPED PATTERN CONCRETE PAVEMENT

PART 1 GENERAL

1.01 DESCRIPTION OF WORK

A.

‘The work in this Section involves coloring tresh ready-mixed concrete and

embossing authentic looking patterns of brick, stone or wood into the

partially set concrete pavement.

This Section also covers furnishing of all labor, materials, tools, and

equipment required by the Contractor to complete the Work

1.02 SECTION INCLUDES.

A. Stamped Textured Concrete Pavement

1.03 RELATED SECTIONS

moo >

mn

Section 02200 Earth Work

Section 02232 Roadway Base

Scetion 02100 Concrete Formwork

Section 03200 Concrete Reinforcement

Section 03300 —_Cast-In Place Concrete

Section 07920 Sealants and Caulking

1.04 REFERENCES

A

June 2021

a

The referred codes and standards are intended to provide an acceptable

level of quality for matorials, products and workmanship. In case of conflict

between these standards and the text of this Specification, the

Specification text shall govern,

The latest revision of the referred codes and standards shall be used

wherever applicable. In case of conflict, the Contractor shall propose

equipment, materials and processes conforming to one group of codes

and standards.

SASO Saudi Arabia Standards Organization

4. SASO Stool Bars for the Reinforcement of Concrete

2. SASO 224 Steel Fabric for Reinforcement of Concrete

02765-1 Contract No.PIC F-8186

#

SECTION 02765

SJAMPED PAIIERN CONCRETE PAVEMENT

3. SASO 226 Methods for Sampling of Concrete Aggregates

4. SASO1068 —_ Ready-Mixed Concrete

D. AASHTO ‘American Association of State Highway and

Transportation Omticials

1. T259 Resistance of Concrete to Chloride lon

Penetration

2. 1260 ‘Sampling and Testing of Chloride lon in

Concrete and Conerete Raw Materials

E. Aci ‘American Concrete Institute

1. ACI 201.2R Guide to Durable Concrete

2.ACI211.1 ‘Standard Practice for Selecting Proportion for

Normal, Heavyweight and Mass Concrete

3. ACI 225R Guide to the Selection and Use of Hydraulic

Cement

4, ACI 232.2R Use of Fly Ash in Concrete

5. ACI 234 Guide for the Use of Silica Fume in Concrete

6. ACI 301 Specifications for Structural Concrete

7. ACI 302.18 Guide for Concrete Floor and Slab Construction

8. ACI 304R Guide for Measuring, Mixing, Transporting a

Placing Conerete

9. ACI 305R Hot Weather Conereting

10.ACI 309R Guide for Consolidation of Concrete

11.ACI 318 RM Building Code Requirements for Structural

Concrete and Commentary

F. ASTM ‘American Society for Testing and Materials

1. ASTM A184M Standard Specification for Fabricated Deformed

Steel Bar Mats for Concrete Reinforcement

June 2021 2765-2 Contract No.PIC F-8186

° R

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

2. ASTM A185, Standard Specification for Steel Welded Wire

Reinforcement, Plain, for Concrete

3. ASTMA615M Standard Specification for Vetormed and Plain

Billet-Stee! Bars for Concrete Reinforcement

4. ASTM C31M Standard Practice for Making and Curing Test

‘Specimens in the Field

5. ASTM C33M Standard Specification for Concrete Aggregates

6. ASTM C94M Standard Specification for Ready-Mixed

Concrete

7. ASTMC143M Standard Test Method for Slump of Hydraulic

Cement Concrete

8. ASTM C150 Standard Specification for Portland Cement

9 ASTM C172 Standard practice for Sampling Freshly Mixed

Concrete

10.ASTMC173M —_Standard Test Method for Air Content of Freshly

Mixed concrete by the Volumetric Method

11. ASTM C231 Standard Test Method for Air Content of Froshly

Mixed Concrete by the Pressure Method

12.ASTM C260 Standard Specification for Air-Entraining

Admixtures for Concrete

13.ASTM C309 Standard Specification for Liquid

Membrane-Forming Compounds for Curing,

Concrete

14.ASTMC494M Standard Specification for Chemical Admixtures

for Concrete

15.ASTM C642 Standard Test Method for Doneity, Absorption,

and Voids in Hardened Concrete

46.ASTM C070 ‘Standard Specification for Pigments for

Integrally Colors

er

une 221 Uzree-8 pntract No.PIC F-8186

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

17.ASTMC1077 _ Standard Practice for Laboratories Testing

Concrete and Concrete Aggregates for Use in

Construction and Criteria for Laboratory

Evaluation

18. ASTM E3z9 ‘Standard Specitication tor Agencies Engaged in,

the Testing and/or Inspection of Materials Used in

Construction

1.05 DEFINITIONS

A

June 2021

bonding agent: A substance applied to a suitable substrate to create a

bond between it and a succeeding layer.

colored concrete: Manufacturer made colors that can be placed “integral”

to the mix or "Dry Shake” which is dusted on.

curing compound: A liquid that can be applied as a coating to the surface

of newly placed concrete to retard the loss of water or, in the case of

pigmented compounds, and also to reflect heat so as to provide an

opportunity for the concrete to develop its properties in a favorable

temperature and moisture environment.

float finish: A rather rough, granular concrete surface texture obtained by

finishing with a float.

floating: The operation of finishing a fresh concrete or mortar surface by

use of a float, preceding troweling when that is to be the final finish,

release agent: A powdered, colored, bond-breaker formulated to break the

bond between mat-type concrete texturing tools and the surface of the

color-hardened concrete while imprinting variegated or mottled

appearance.

sawcutting concrete: Using a power concrete saw to cut patterns into the

concrete as soon as the concrete has hardened.

scoring concrete: Decorative lines placed in concrete with “groovers.”

Groovers come in various depthe and widths.

screeded concrete: Concrete with smooth top layer.

sealer: A liquid that is applied to the surface of hardened concrete to either

prevent or decrease the penetration of liquid or gaseous media

Involves coloring fresh ready-mixed concrete and

¢ looking patterns of stone or wood Into partially

stamped concrete:

embossing authent

set concrete.

02765-4

n

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

L. stamping. Used to add patter ty pavernents, by dipping stamps into paint

or translucent glaze (or painting onto the stamp) and applying pressure to

the stamp onto the pavements. It provides a handmade slightly random

look,

M. texture: This is the visual or tactile surface characteristic.

N. tooling: The act of compacting and contouring a material in a joint

1.06 SUBMITTALS

A. The Contractor shall submit to the Royal Commission, under the

provisions of SECTION 01340, the following items for review and approval

before commencing Work:

1, Product Data

a) For each type of manufactured material and product indicated.

2 esign Mives

a) For each stamped concrete pavement mix. Include alternative mix

designs when characteristics of materials, project conditions, weather,

test results, or other circumstances warrant adjustment.

3. Matorial Certificates

@) Material certificates signed by manufacturers and Cuntiactur cerlifying

that each of the following materials complies with requirements:

41) Cementitious materials and aggregates.

2) Stee! reinforcement and reinforcement accessories.

3) Admixtures.

4) Applied finish materials.

5) Curing compounds.

b) Warranty certificate signed by Manufacturer and Contractor certifying

that material complies with requirements and color stability for at least

five years,

1.07 QUALITY CONTROL

‘A. The Contractor shall be responsible for the quality of work and shall

develop and propose programs and methods of construction and testing to

June 2021 2765-5 Contract No.PIC F-8188

, +

0

June 2021

a

SECTION 02765

‘STAMPED PATTERN CONCRETE PAVEMENT

achieve the specified quality to the approval of the Royal Commission in

accordance with SECTION 01400.

Quality Assurance

4. Installer Qualifications

a) An experienced installer who has completed stamped cement

concrete pavement similar in material, design, and extent to that

indicated for this Project, and whose work has resulted in

construction with a record of successful in-service performance.

2. Ready-Mixed Concrete Manufacturer Qualifications

a) Manufacturer of ready-mixed concrete products complying with

ASTM C94 requirements, for production facilities and

equipment.

3. Testing Agency Qualifications

a) An independent testing agency, acceptable to Royal

Commission having jurisdiction, qualified according to ASTM

©1077 and E329, to conduct the testing indicated,

4. Source Limitations

a) Obtain each type or class of cementitious material of the same

brand from the same manufacturer's plant, and each aggregate

from one source.

o

Mock-Up

a) Cast mock-up, minimum 600 x 600 mm of stamped cement

concrete pavement to demonstrate typical pattem, texture,

surface finish, color, and standard of workmanship.

1) Build mock-up in the location and of the size indicated or, if

not indicated, as directed by the Royal Commission.

2) Notify the Royal Commission 7 days in advance of dates and

times when mock-up will be constructed,

3) Obtain the Royal Commission's approval of mock-up before

ctarting conetrustion.

4) Maintain mock-up during construction in an undisturbed

condition as a standard for judging the completed work.

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

6. Comply with ACI 301 “Specification tor Structural Concrete” unless

modified by the requirements of the Contract Documents.

1.08 HEALTH AND SAFETY CONSIDERATIONS

A

All works undertaken in relation to this Specification are to be completed in

full accordance with the respective health and safety requirements

established by the following:

1. Kingdom of Saudi Arabia

a) Legislation, Regulation, Standards and Codes.

2. Royal Commission Regulations

a) Standards, Contractual Conditions, and Health and Safety

Systems.

3. Contractor

a) Health and Safety Standards and Systems as accepted by the

Royal Commission.

B. In the absence of any of the above, best accepted industry practice

shall be employed throughout.

199 JOR CONDITIONS

°.

Colured Cunvele Envirunmental Requirements Schedule placement of

concrete to minimize exposure to wind and hot sun before curing materials

is applied. Avoid placing concrete if rain is forecast within 24 hours.

Protect fresh concrete from moisture.

Schedule delivery of concrete to provide consistent mix times from

batching until discharge.

4.40 DELIVERY, HANDLING AND STORAGE

A

June 2021

The Contractor shall deliver, handle and store equipment and material

units in accordance with SECTIONS 01600 and 01610, as well as the

following requirements:

1. Maletial delivery, handling and storage for concrete required shall be in

accordance with SECTION 03300.

2. Material delivery, handling and storage for reinforcing steel bars

required shall be in accordance with SECTION 03200.

9. Deliver color, curing and rials in original sealed

2765-7

lo

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

containers, marked with name of manufacturer and identification of

contents.

4. Store color, curing and sealing materials under waterproof covers, on

planking clear of ground, in a dry location and under cover to protect

from moieture.

5. Protect color, curing and sealing materials from dirt, staining, water,

wind and damage during handling

PART 2 PRODUCTS.

2.01 GENERAL

A. All goods and products covered by these Specifications shall be procured,

when available, from an in-Kingdom manufacturer. Procur

goods and products manufactured out-of-Kingdom m

the Roval Commission,

2.02 FORMS

A. Form Materials

1. Form shall be of plywood, metal, metal-ramed ply

approved panel-lype materials to provide full-depth, continuous, true

and smooth exposed surtaces.

2. Flexible or curved forms shall be used to provide curvature for curves

of a radius of 30 m or less.

3. Form materials shall be in accordance with requirements of SECTION

03100.

2.03 STEEL REINFORCEMENT

A. Reinforcing Bars, Steel Bar Mats, Joint Dowel Bars and Bar Supports

Concrete reinforcement shall be in accordance with the requirements of

SECTION 03200.

2.04 CONCRETE MATERIALS

A. Portland Cement

1. Portland cement shall be in accordance with the requirements of

‘SECTION 03300.

B. Aggregates and Water

1. Aggregates and water shall be in accordance with the requirements of

June 2021 02765-8 Contract No.PIC F-8186

: #

SECTION 02765

‘STAMPED PATTERN CONCRETE PAVEMENT

SECTION 03300.

2.05 ADMIXTURES

A. Mineral and Chemical Admixturee

1, Admixtures materials and requirements shall be as specified in

SECTION 09300.

2.06 COLOR MATERIALS

A. Color Dry-Shake Hardener

1. Hardener shall be factory-packaged dry combination of portland

cement, graded quartz aggregate, coloring pigments, and

plasticizing admixture. Coloring pigments shall be finely ground,

non-fading mineral oxides interground with cement. Color hardener

shall meet ASTM C979 for color stability.

2. Color shall be as selected by the Royal Commission from

manufacturer's standard range.

R. Colored-Powder Release Agent

1. Release agent shall be faclory-packayed dry combination of

surface conditioning and dispersing agents, interground with

coloring pigments that facilitate release of stamp mats. Coloring

pigments shall be finely ground, non-fading mineral oxides

interground with cement. Release agent shall meet ASTM C979 for

color stability

2. Color shall be as selected by the Royal Commission from

manufacturer's standard range.

C. Integral Color

1. Option in lieu of color hardener, shall be a factory-packaged

product containing the correct dosage for the cement content in the

mix design to create the desired color. To produce integrally

colored cement, a coloring agent shall be added during the mixing

piucess. The culuring ayent for integrally culuied concrete stall

moot tho roquiromonte of ASTM C070.

2 Color shall he as selected by the Royal Commission from

June 2021 Contract No PIC F-81868

SECTION 02765

‘STAMPED PATTERN CONCRETE PAVEMENT

D. Liquid Release

1. Liquid release shall be a factory-pachaged product thal is culurless,

odorless and evaporates without leaving a residue. It is formulated

to break the bond between mat-type or stamp type concrete tools.

2.07 IMPRINTING TOOLS.

A. Stamp Mats

1, Semi-tigid polyurethane mats with projecting textured and ridged

underside, capable of imprinting texture and joint patterns on

plastic concrete

2. Mattype tools to provide an embossed surface emulating wood,

natural stone, or ollier taletials.

B. Cuvkie Culler-Type

1. When flim is used; the film should stretch dunng stamping,

rounding edges of the pattern and keeping conurete fur slicking

to tools.

2. For imprinting brick, cobblestone, tile or other patterns.

©. The manufacturer of such tools shall provide adequate training to the

Contractor. The Contractor shall submit documentation to the Royal

‘Commission that he has been trained by the tool manufacturer.

2.08 CURING AND SEALING MATERIALS.

A. Evaporation Retarders

. Evapuralion relarders shall be waterborne, monomolecular fim

forming, manufactured for application to fresh concrete.

B. Surface Penetrating Sealer

1. The surface penetrating sealer slrall be specifically required by the

color hardener manufacturer. All materials shall be subject to

approval by the Royal Commission. The surface penetrating

sealanil shall meet the following performance criteria, based on

application of solution in accordance with the manufacturer's

recommended procedures and rates:

a) A water miscible, penetrating salt and liquid water repellent

Nt that will provide internal steel corrosion protection.

une 2u21 \uzr65-10 Contract No.PIC F-8186

SECTION 02765

‘STAMPED PATTERN CONCRETE PAVEMENT

b) Treatment shall not affect skid resistance or surface texture.

©) Treated concrete surfaces submitted to an ASTM C642

moisture absorption test or 2% in 50 days shall not absorb more

than 1% moisture in 48 hours.

) Treated concrete surfaces subjected to 90 day chloride ion

penetration tet (AASHTO 1260, 7260) shall not permit the

Penetration of more than 0.9 kg (1.5 Ib) of chloride per cubic

meter (cubic yard) of concrete at the 1.58 to 12.7 mm (‘/16 to %

in.) depth, and not more than 0.45 kg (0.75 Ib) of chloride per

cubic meter (cubic yard) f concrete at the 12.7 to 25.4 mm (% to

in.) depth.

€) Surface preparation shall be in accordance with manufacturer's

recommendations.

C. Clear Acrylic Sealer

1. Sealer shall be as per manufacturers standard, waterbome,

membrane forming, medium-gloss, acrylic copolymer emulsion

solution. containing not less than 15% solids by volume: non-

yellowing and UV resistant.

D. Curing Compound

1. Curing compound shall comply with ASTM C309 and as

recommended by the color manufacturer. It shall not affect the skid

resistance of the surface.

E. Combined curing compound and sealer systems are available from

concrete color manufacturers. Usage shall be approved by the Royal

Commission in accordance with manufacturer's recommendations.

2.09 JOINT-FILLER STRIPS_

A. Jointe eeale chall be ac epocifiod in SECTION 07010 and 07020.

210 CONCRETE MIXES

A. Design mixes shall be prepared and proportioned according to ACI

211.1 and 301, for each type and strength of normal-weight concrete,

determined by either laboratory trial mix or field test data bases.

B. A qualified independent testing agency shall be utilized for preparing

92785-11 Contract No PIC F-8186

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

C. Mixes shall be proportioned to provide concrete with the properties

specified in SECTION 03300.

D. Cementitious Materials

1. Limit percentage, by weight, of cementitious materials other than

portland cement in concrete, in accordance with the requirements

in SECTION 03300.

E. Airentraining admixture shall be added at manufacturer's prescribed

rate, to result in concrete at point of placement having an air content

not exceeding requirements specified in SECTION 03300.

2.11 CONCRETE MIXING

A. Ready-Mixed Concrete

4. Comply with ASTM C94 and refer to $92300 for

specifications and requirements.

PART 3 EXECUTION

3.01 PREPARATION

A Prepared subhase surface shall he proof-rolled to for unstable:

areas and to verify need for additional compaction. Pavement work shall

proceed only after noncomplying conditions have been corrected and

‘subgrade is ready to receive pavement. Refer to SECTION 02232.

B. Loose material shall be removed from compacted subbase surface

immediately before placing concrete.

©. Plan pattern layout, slab dimensions and construction joint locations shall

be coordinated with stamping pattern dimensions, where necessary.

D. Adjacent construction shall be protected from discoloration and spillage

during application of color hardeners, release agents, curing compounds,

and sealers.

3.02 EDGE FORMS AND SCREED CONSTRUCTION

A. Set, brace, and secure edge forms, bulkheads, and intermediate screed

guides for pavement to required lines, grades, and elevations. Forms shall

be installed to allow continuous progress of work; forms shall remain in

place at least 24 hours after placing concrete.

B. Forms shall be cleaned after each use, and coated with form-release

agent to ensure separation from concrete without damage.

June 2021 2766-12 Contract No.PIC F-8186

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT.

C. Refer to SECTION 03100.

303 STEEL REINFORCEMENT.

A. Comply with SECTION 03200, for fabricating reinforcomont, and for

placing and supporting reinforcement.

3.04 JOINTS

A. General

1. Joints and tool edgings shall be constructed true to line, with faces

perpendicular to the surface plane of concrete. Transverse joints shall be

constructed at right angles to centerline, unless otherwise indicated. Refer

to SECTION 03300 for criteria on spacing of joints.

B. Cunstiuction Joints

1. Construction joints shall be set at side and end terminations of

pavement, and at locations where pavement operations are stopped

for more than %4 hour, unless pavement terminates at isolation joints.

2. Bonding agent shall be used at locations where fresh concrete is

placed against hardened or partially hardened concrete surtaces.

C. Isolation Joints

1. Isolation joints shall be formed of preformed joint-filler strips, abutting

concrete curbs, catch basins, manholes, inlets, structures, walks, other

fixed objects and where indicated.

2. Joint fillers shall be extended to full width and depth of joint,

terminating flush with finished concrete surface, unless otherwise

indicated

Joint filers shall be furnished in 1-piece lengths for full width being

placed, where possipie. Where more than one length is required, joint-

iller sections shall be laced or clipped together.

‘Top edge of joint filler shall be protected during concrete placement

with metal, plastic, or other temporary preformed cap. Protective cap

shall be removed after concrete has been placed on bath sides of joint.

D. Dowel Joints

1. Dowel sleeves and dowels, or dowel bar and support assemblies, shall

be installed at joints where indicated.

2. Use dowel sleeves, or lubricate, or asphalt-coat to % of dowel length,

June 2021 2765-13, Contract No PIC F-8186

ao

SECTION 02765

‘STAMPED PATTERN CONCRETE PAVEMENT

to prevent concrete from bonding to one side of joint.

E. Contraction Joints

1. Weakened-plane contraction joints shall be formed by sectioning

concrete into areas as indicated. Contraction joint shall be constructed

for a depth equal to at least 1% of the concrete thickness.

a) Sawed Joints

1) Form contraction joints with power saws, equipped with

shatterproof abrasive or diamond-rimmed blades.

2) Cut 3 mm side joints into concrete, when cutting action will

Not tear, abrade, or otherwise damage surface, and before

concrete develops random contraction cracks.

F. Edging

1, Edges of pavement and joints in concrete shall be tooled after initial

floating with an edging tool to the following radius. Tooling 0

eliminated on concrete eurface.

a) Radius: 6 mm.

3.05 CONCRETE PLACEMENT

A. Placement. consolidation, bonding and hot-weather cancretingSs

accordance with the requirements of SECTION 03300.

3.06 INITIAL CONCRETE FINISHING

A. General

1. Wetting concrete surfanes during sereeding, initial finating, ar finishing

operation is prohibited

B. Float Finish

1. The second floating operation shall begin when bleed water sheen has

disappeared, and the concrete surface has stiffened sufficiently to

permit operatione. Surfaces chall be finiched to true planes. Cut down

high spots and fill low spots. Immediately retloat surface to uniform

gratiular texture.

C. Colored Dry-Shake Hardener Finish

1. After initial floating, colored dry-shake material shall be applied to

plastic concrete surfaces according to manufacturer's written

June 2021 o2765-14 Contract No.PIC F-8186

eo

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

instructions and as follows:

a) Uniformly apply at a rate of 3 kg/m’, unless greater amount is

recommended by manufacturer to match pavement color.

b) Uistribute approximately two-thirds of colored dry-shake

material and embed by floating. Follow with second application

of colored dry-shake material distributed at right angles to the

first to ensure uniform color, and embed by floating

D. Color-Powder Release Agent

1. Uniformly distribute onto color-hardened and still-plastic enncrete at a

2

rate of 50 to 100 gim

3.07 STAMPING

A. While initially finished concrete is plastic, accurately align and place stamp

“skins” or semi-rigid mats in sequence, and changing direction of pattern

to avoid visible repeats of pattern over entire area. Uniformly load mats

and press into concrete to produce required imprint pattern and depth of

imprint on concrete surface. Remove stamp mats immediately. Use

special half tools and texture mats at slab edges, walls, and corners. Hand

stamp edges and surfaces unable to be imprinted by stamp mats,

including step risers and treads.

1. Un-embedded release agent shall be removed no fewer than 3 days

after stamping concrete. Surface and joint patterns shall be high-

pressure washed, taking care not to damage stamped concrete.

2. Runoff shall be controlled, collected and legally disposed of.

3.08 CONCRETE PROTECTION, CURING, AND SCALING

A. General

1. Freshly placed conerete shall be protected from premature drying and

excessive hot temperatures. Comply with ACI 206R and follow

recommendations for hot-weather protection during curing

B. Evaporation Retarder

1. Fvaporation retarder shall be applied to concrete surfaces if hot, dry, or

windy conditions exist. Application shall be in accordance with

manufacturer's written instructions, after placing and screeding, and

during initial floating operations.

June 2021 02765-15 . aah “Gohtract No.PIC F-8186

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT

C. Sealer

1. Two coats shall be applied uniformly in continuous operations

according to manufacturer's written instructions. First coat shall be

allowed to dry before applying a second coat.

9.09 TOLERANCES

A. Comply with the following tolerances:

1, Elevation: 6 mm,

2. Thickness: + 10 mm, - 6 mm.

3. Surface: Gap below 3 m long, unleveled straightedge not to exceed 6

mm.

4, Lateral Alignment and Spacing of Dowels: 25 mm,

5. Vertical Alignment of Dowels: 6 mm.

6. Alignment of Dowel-Bar End Relative to Line Perpendicular to

Pavement Edge: Length of dowel 6 mm per 300 mm.

7. Joint Spacing: 75 mm.

8. Contraction Joint Depth: + 6 mm, - 0

9, Joint Width: + 3 mm, - 0

3.10 FIELD QUALITY CONTROL

A. Testing Agency

1. A qualified independent testing and inspecting agency shall be

engaged to sample materials, perform tests, and submit test reports

during concrete placement according to requirements specitied in this

Section. Tests shall be performed according lo ACI 301

3.11 REMOVAL AND PROTECTION

A. Pavement that does not comply with requirements in this Section shall be

removed and replaced,

B. Pavement shall be protected from damage. Construction traffic shall not

be permitted on concrete pavement. Other traffic shall be excluded from

pavement for at least 28 days after placement.

June 2024 02765-16 Contract No.PIC F-8186

SECTION 02765

STAMPED PATTERN CONCRETE PAVEMENT.

C. Pavement shall be maintained free of stains, discoloration, dirt, and other

foreign maletial. Sweep pavernent nol more tan 2 days before date

scheduled for Substantial Completion inspections.

11 CND OF SECTION 02765 ++

June 2021 2765-17 Contract No.PIC F-8186

¥

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5823)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (852)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (898)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (349)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (823)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (403)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shop Drawing: Expansion JointDocument1 pageShop Drawing: Expansion Jointa.shwekhNo ratings yet

- Shop Drawing: Stamped Concrete Promenade Level - 1 Promenade Level - 1Document1 pageShop Drawing: Stamped Concrete Promenade Level - 1 Promenade Level - 1a.shwekhNo ratings yet

- Drawing2 ModelDocument1 pageDrawing2 Modela.shwekhNo ratings yet

- Shop Drawing: Band Stamped Concrete Pedestrian PrecintDocument1 pageShop Drawing: Band Stamped Concrete Pedestrian Precinta.shwekhNo ratings yet