Professional Documents

Culture Documents

Dry Dock Checklist by Intertanko

Dry Dock Checklist by Intertanko

Uploaded by

abbasCopyright:

Available Formats

You might also like

- RA Export 20230303-171712 (TEMPLATE-04 Haz) - ID230303164833 - Rev2023-03-03 - Cargo & Ballast Works - Ballast Water Treatment System FailureDocument3 pagesRA Export 20230303-171712 (TEMPLATE-04 Haz) - ID230303164833 - Rev2023-03-03 - Cargo & Ballast Works - Ballast Water Treatment System FailureHarman Sandhu100% (3)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul Wasay100% (1)

- ITP - ROAD WORK-Rev-01Document4 pagesITP - ROAD WORK-Rev-01Ateeq Rahman100% (1)

- IEEE STD 1547.1 2020Document282 pagesIEEE STD 1547.1 2020Emre BENGINo ratings yet

- Social Welfare, Policies and Social ServicesDocument4 pagesSocial Welfare, Policies and Social ServicesRisa Jubilan100% (2)

- Math Teachers Guide 8 QUARTER 3Document66 pagesMath Teachers Guide 8 QUARTER 3Hazel Clemente Carreon68% (82)

- DryDock CompleteDocument24 pagesDryDock Completeashry_tarek100% (2)

- Bengaluru BDA RMP 2031 Volume - 3 - MasterPlanDocument PDFDocument214 pagesBengaluru BDA RMP 2031 Volume - 3 - MasterPlanDocument PDFAnkitaVerma100% (1)

- Intertanko Guidance Dry-Dock ChecklistDocument34 pagesIntertanko Guidance Dry-Dock ChecklistReda Hmr100% (3)

- Risk Assess Forklift DriverDocument12 pagesRisk Assess Forklift DriverNick KrugerNo ratings yet

- Engineer' Stamp: Contractor'S Stamp:: Issued For Approval Joel Pino R. D'Souza 16 Feb. 2020Document2 pagesEngineer' Stamp: Contractor'S Stamp:: Issued For Approval Joel Pino R. D'Souza 16 Feb. 2020dada khalandarNo ratings yet

- Duqm Refinery Company Approval Status: Subcontractor Document Review Cover SheetDocument14 pagesDuqm Refinery Company Approval Status: Subcontractor Document Review Cover SheetibrahimNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- Hirarc SlideDocument19 pagesHirarc SlideKrishnan Mudaliar Bopalan100% (1)

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- RMDJV Pj74 Hiradc Subc 02 (Survey Work)Document1 pageRMDJV Pj74 Hiradc Subc 02 (Survey Work)myn maliQue100% (1)

- Risk Assessment - BanDocument8 pagesRisk Assessment - Bankarthikeyan subramanianNo ratings yet

- Method Statement For Anti Termite TreatmentDocument7 pagesMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Rmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)Document2 pagesRmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)myn maliQueNo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- R.A For Cleaning Sanitary Tanks (Underground)Document2 pagesR.A For Cleaning Sanitary Tanks (Underground)JemoNo ratings yet

- DRP001-OUF-InC-GMD-Z-000-046-Rev.S3-Code 4 TRA For Blasting, Painting & Field Touch Up of Storage TankDocument24 pagesDRP001-OUF-InC-GMD-Z-000-046-Rev.S3-Code 4 TRA For Blasting, Painting & Field Touch Up of Storage Tankrodman823No ratings yet

- Confined Space EntryDocument4 pagesConfined Space Entrykwame fosterNo ratings yet

- 07 - Risk ReductionxDocument20 pages07 - Risk ReductionxAdriana HubleaNo ratings yet

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- 4.risk Assessment For PPM-Water HeaterDocument2 pages4.risk Assessment For PPM-Water HeaterManzur AhmadNo ratings yet

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- Risk Management Report: Type Make Model Chassis / VinDocument18 pagesRisk Management Report: Type Make Model Chassis / Vin2266kffhwdNo ratings yet

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- Planning of Lifting Operations Sigma 3 CosaltDocument115 pagesPlanning of Lifting Operations Sigma 3 Cosaltmohamed fahs100% (2)

- Drp001-Ouf-Inc-Gmd-Z-000-060-O2. C4Document16 pagesDrp001-Ouf-Inc-Gmd-Z-000-060-O2. C4rodman823No ratings yet

- Triple Height Area. Triple Height Area: Inadequate Communication of Task Planning and PreparationDocument5 pagesTriple Height Area. Triple Height Area: Inadequate Communication of Task Planning and PreparationMobin Thomas AbrahamNo ratings yet

- Integrated Control and Safety System (ICSS) Site Acceptance Test ProcedureDocument42 pagesIntegrated Control and Safety System (ICSS) Site Acceptance Test ProcedureFatholla SalehiNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- AB8-ELE-54-HMO - Raw Water Pump Pullout For InspectionDocument2 pagesAB8-ELE-54-HMO - Raw Water Pump Pullout For Inspectionvikrant911No ratings yet

- Drp001-Ouf-Inc-Gmd-Z-000-038-S1. Code 4Document26 pagesDrp001-Ouf-Inc-Gmd-Z-000-038-S1. Code 4rodman823No ratings yet

- Risk Assessment For Scaffolding Works Rev. 1Document15 pagesRisk Assessment For Scaffolding Works Rev. 1muhammad.younisNo ratings yet

- Part Number Vendor Name Part Description Vendor Code: Name Dept Phone Ext Name Dept Phone ExtDocument11 pagesPart Number Vendor Name Part Description Vendor Code: Name Dept Phone Ext Name Dept Phone Extisolong100% (1)

- Risk AssessmentDocument5 pagesRisk Assessmentsudeesh kumar100% (1)

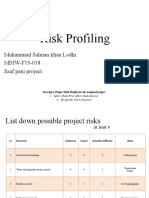

- Risk Profiling: Muhammad Salman Khan Lodhi MBIW-F19-018 Saaf Pani ProjectDocument5 pagesRisk Profiling: Muhammad Salman Khan Lodhi MBIW-F19-018 Saaf Pani ProjectSalman LodhiNo ratings yet

- FPSO Inherently Safe Design ReportSCM TC110 128 018 01Document82 pagesFPSO Inherently Safe Design ReportSCM TC110 128 018 01Faridah feedausNo ratings yet

- Risk Assement For Piling PDFDocument81 pagesRisk Assement For Piling PDFnagesh1234No ratings yet

- Lightning Safe Structure Verification Form - 8347580Document6 pagesLightning Safe Structure Verification Form - 8347580Henry ArrvalNo ratings yet

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQueNo ratings yet

- MS Bunker Leak TestDocument9 pagesMS Bunker Leak Testaden72No ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- 077907J001 070 VALVE D312 0001 - Reva PDFDocument3 pages077907J001 070 VALVE D312 0001 - Reva PDFSAKHIRAMNo ratings yet

- HSE Audit TemplateDocument28 pagesHSE Audit Templatemohroy21No ratings yet

- AB8-ELE-75-HMO - Generator Dismantling For 5 Yearly MaintenanaceDocument2 pagesAB8-ELE-75-HMO - Generator Dismantling For 5 Yearly Maintenanacevikrant911No ratings yet

- MSCI ESG Research - Bruno RauisDocument15 pagesMSCI ESG Research - Bruno RauisValerio ScaccoNo ratings yet

- Project Costing - Final AssignmentDocument25 pagesProject Costing - Final AssignmentJohn KalarNo ratings yet

- Saudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeDocument11 pagesSaudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- 1-Risk Assessment For Hot Work ParmitDocument4 pages1-Risk Assessment For Hot Work Parmitsudeesh kumarNo ratings yet

- Hse Key Performance Indicator Contractor 2018Document9 pagesHse Key Performance Indicator Contractor 2018Bayu JatmikoNo ratings yet

- Type Approval: Offshore Container Lifting OperationDocument28 pagesType Approval: Offshore Container Lifting OperationregisreginhoNo ratings yet

- Aragon AragonOS Smart Contract Security Audit Report Halborn FinalDocument29 pagesAragon AragonOS Smart Contract Security Audit Report Halborn FinalFrancisco GomesNo ratings yet

- Risk Management ProcedureDocument10 pagesRisk Management ProcedurehapisstendeNo ratings yet

- Adac Asgtc 2018 Ra 07 Hot WorkDocument3 pagesAdac Asgtc 2018 Ra 07 Hot Workabubakrelsaid90No ratings yet

- Mobilization Risk AssessmentDocument53 pagesMobilization Risk AssessmentRAMY ABOU AL DAHABNo ratings yet

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- A 12.5-ENOB 10-kS/s Redundant SAR ADC in 65nm CMOS: Dai Zhang, Member, IEEE, and Atila Alvandpour, Senior Member, IEEEDocument5 pagesA 12.5-ENOB 10-kS/s Redundant SAR ADC in 65nm CMOS: Dai Zhang, Member, IEEE, and Atila Alvandpour, Senior Member, IEEESilpa VelagaletiNo ratings yet

- Special Considerations For Special Populations: Chapter ObjectivesDocument46 pagesSpecial Considerations For Special Populations: Chapter ObjectivesClaudia F de la ArceNo ratings yet

- Matrix-Theorist and Their ViewsDocument5 pagesMatrix-Theorist and Their Viewsrebekah laydaNo ratings yet

- Diamond Turn MachiningDocument73 pagesDiamond Turn Machiningsangeet khuleNo ratings yet

- Chapter 11 - Inferences About Population Variances: Session 15 Chi-Square DistributionDocument6 pagesChapter 11 - Inferences About Population Variances: Session 15 Chi-Square DistributionNitish NairNo ratings yet

- 2 Chocolate Reading TasksDocument2 pages2 Chocolate Reading TasksBussayapuch Nusang TKNo ratings yet

- Olympic 10 2018Document13 pagesOlympic 10 2018Bảo TrâmNo ratings yet

- Seven, SeeDocument39 pagesSeven, SeeShybe Elrik100% (1)

- Performance Assessment Tools: Marilou S. FerrerDocument16 pagesPerformance Assessment Tools: Marilou S. FerrerAlyssa AlbertoNo ratings yet

- Strap or Cantilever Footings ExampleDocument11 pagesStrap or Cantilever Footings ExamplehNo ratings yet

- The Study About The Discrimination of LGBTQIA+ Grade 11 and 12 Students in ACLC College of MeycauayanDocument65 pagesThe Study About The Discrimination of LGBTQIA+ Grade 11 and 12 Students in ACLC College of MeycauayanTatin Mendones BurgosNo ratings yet

- S - A - Retailer's Impact Woolworth CaseDocument8 pagesS - A - Retailer's Impact Woolworth CaseKonrad GłowackiNo ratings yet

- 6-OTC107601 OptiX NG WDM Network Design ISSUE1.14Document80 pages6-OTC107601 OptiX NG WDM Network Design ISSUE1.14HachidSofianeNo ratings yet

- Introduction To Science Technology and SocietyDocument23 pagesIntroduction To Science Technology and SocietyFatima AbayonNo ratings yet

- Tpg23 08 NSW Government Guide To Cost Benefit Analysis 202304Document116 pagesTpg23 08 NSW Government Guide To Cost Benefit Analysis 202304Hassan ElmiNo ratings yet

- Concept Map General EssayDocument2 pagesConcept Map General EssayAtun Mojado xdNo ratings yet

- Artifacts of The Wastelands (MuFut)Document16 pagesArtifacts of The Wastelands (MuFut)Mike Mitchell100% (1)

- Lta-35 Mtp-1 Facp Vendor CutsheetsDocument63 pagesLta-35 Mtp-1 Facp Vendor Cutsheetsinfo.faizanizamNo ratings yet

- Compendex 2013 Source List 4 Aptil 2013Document333 pagesCompendex 2013 Source List 4 Aptil 2013Zelalem MengistuNo ratings yet

- HGP Year End Report 2021-2022 NewDocument169 pagesHGP Year End Report 2021-2022 Newangelica sungaNo ratings yet

- Read About Lightning and ThunderDocument2 pagesRead About Lightning and ThunderTino SalabsabNo ratings yet

- Guelen, Jeanne ThereseDocument2 pagesGuelen, Jeanne ThereseJay GeeNo ratings yet

- Best Practices in Donor RecognitionDocument5 pagesBest Practices in Donor RecognitiongNo ratings yet

- Single Phase TransformerDocument29 pagesSingle Phase Transformerkaran nirmala gajanan shindeNo ratings yet

- Hypothesis & TypesDocument3 pagesHypothesis & Typesaxa3811No ratings yet

- Srivastava Et Al 2023 Estimating Relative Tax Efficiency For Selected States in India An Error Correction ApproachDocument27 pagesSrivastava Et Al 2023 Estimating Relative Tax Efficiency For Selected States in India An Error Correction ApproachsushilNo ratings yet

Dry Dock Checklist by Intertanko

Dry Dock Checklist by Intertanko

Uploaded by

abbasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dry Dock Checklist by Intertanko

Dry Dock Checklist by Intertanko

Uploaded by

abbasCopyright:

Available Formats

Standard Dry-Dock Check List

&

Risk assessment

Dragos Rauta

INTERTANKO

2019 Tripartite Meeting

18 October 2019

Tokyo

Leading the way; Making a difference

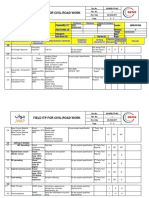

Vessel Name:

Vessel Type:

IMO Number:

Class (including Notations):

Repair (Build) yard:

Repair commencement (steel cutting) date:

Delivery date:

Criticality

VIQ #7

Item per Completed Verified Exposure

# item Timing Remarks

category by by Index

No.

(CEI)

Leading the way; Making a difference

DONE BY TIMING VERIFIED BY

yard PDT: prior dock trials Class

crew rank DDT: during dock trials Fleet superintendent

class DST: during sea trials Master

workshop PS: prior sailing Chief Engineer

service engineer

Leading the way; Making a difference

Criticality

VIQ #7 Verified

Item per category Completed by Timing REMARKS Exposure Index

item No. by

(CEI)

1 General Information

2. Certification and

2

Documentation

New Certificates / Test

Records / Receipts issued

2.1 2 PDT 1

during DD period verified to

be onboard.

Confirm Certificates /

Endorsements are correct

2.2 2 PDT 1

(forward copies to office

ASAP).

...... .............

Temporary notices, Navtex,

weather information received

4.13, 4.20,

4.6 and passage plan prepared. PS 3

4.17

ECDIS pre-departure check

list “Bridge-24” completed.

Leading the way; Making a difference

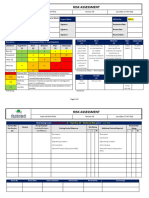

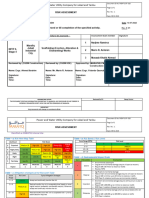

Code: F-SEE-28

SHIP ENERGY EFFICIENCY FORMS Issue No.: 3

Revision: 0

Vessel's Drydocking - Risk Code Date: 01/03/2018

RISK PRIORITY CODE

(C)

Risk (R) = Likelihood (L) x Consequence (C) CONSEQUENCE RATING

1-3:LOW Risk acceptable, can proceed with the task 1 2 3

Task can be scheduled, however reviewing of controls recommended

4-6:MEDIUM to reduce the risk rating

Commercial Pollution Safety

Cannot proceed with the task unless appropriate controls are taken to Damage to asset or Harm to the Human injury, health

7-12:HIGH reduce the risk financial damage environment damage or fatality

1 Very Unlikely Never occurred in the industry 1 2 3

LIKELIHOOD RATING

2 Unlikely Occurred in the industry 2 4 6

(L)

Occurred more than once in the

3 Likely industry 3 6 9

Occurred more than once in the

4 Very Likely industry & at least once in the 4 8 12

Company

Leading the way; Making a difference

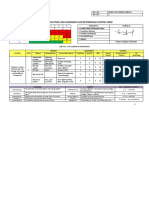

IDENTIFICATION OF HAZARD ASSESSMENT OF RISK * IMPLEMENTATION OF CONTROLS FINAL RISK

(FR)

(R)

(L1) (C) REFERENCE (L2) Final Risk Risk Level

HAZARD CAUSE RESULT Risk (L1xC) Risk Level ACTION

Likelihood Consequence DOCUMENT Likelihood (L2xC)

Certification & Documentation

2

New Certificates / Test Records / Receipts issued during Humman error/ negligence. Commercial implications in Verification prior sailing that all newly issued Dry dock check list

DD period not onboard. (VIQ. 2) vessel's trading. certificates are onboard, both by Master and

2.1 2 1 2 LOW attending superintendent. 1 1 LOW

Certificates / Endorsements not correct (copies not sent Humman error/ negligence. Commercial implications in Verification prior sailing that all newly issued Dry dock check list

to office ASAP). (VIQ. 2) vessel's trading. certificates are correct, both by Master and

2.2 2 1 2 LOW attending superintendent. 1 1 LOW

VGP requirements breached / documentation not in Required inspections/ Pollution/ Commercial Verification prior sailing that each VGP required -Dry dock check list

order. Class Statement of Facts not prepared. (VIQ. 2) maintenance not carried implications in vessel's form/ certificate/ statement have been issued in -Biofouling Management Plan/

out, reports for same not trading. good order, both by Master and attending Records

issued. Items overlooked/ superintendent. All required inspections have been

VESSEL'S DRYDOCKING

forgoten. carried out to the satisfaction of the attending class

2.3 2 2 4 MEDIUM surveyor. 1 2 LOW

Class 'Factual Statement' that the Special Survey has Required inspections/ Commercial implications in Verification prior sailing that relevant statement Dry dock check list

been completed and that the ESP (Executive Hull maintenance not carried vessel's trading. issued and final report is under preparation, both

Summary & Thickness Measurements) documentation is out, reports for same not by Master and attending superintendent.

2.4 under preparation by Class head office (will be issued in issued. Items overlooked/ 2 1 2 LOW 1 1 LOW

due course) not issued. (VIQ.2) forgoten.

Class factual statement for the pressure test of piping Leakage in way of piping. Pollution hazards. Pressure test of piping performed during cargo Dry dock check list

conducted not issued. (VIQ. 2, 8.3) Report not issued, item Commercial implications in tank washing operations prior docking; repairs (as/

overlooked/ forgoten. vessel's trading. if needed affected). Verification prior sailing that

relevant statement issued, both by Master and

2.5 2 2 4 MEDIUM 1 2 LOW

attending superintendent.

Class factual statement for the ETA structural support Defect in way of underdeck ETA equipment inoperative. Supporting structure is inspected by Class Dry dock check list

members. (VIQ. 2, 9.28) supporting structure. Safety issues. Commercial surveyor and attending superntendent. Verification Class checklist

Relevant inspections not implications in vessel's prior sailing that relevant statement issued, both by

2.6 carried out and/ or reports trading. 2 3 6 MEDIUM Master and attending superintendent. 1 3 LOW

missing.

Vessel drawings, Fire/ Safety/ Emergency plans used Humman error/ negligence. Safety hazards/ routine Items landed/ handed over to the shipyard's Landing forms/ onboard checklist

during drydock period missing. Special tools, and other maintenance implications. personnel documented in relevant landing forms.

ship property not returned on board. (VIQ. 2) Master/ Chief engineer frequently updated on

2.7 3 3 9 HIGH aoutstanding items during daily safety meetings. 1 3 LOW

Final check prior sailing is performed by ship's

crew.

Leading the way; Making a difference

CONCLUSIONS

Dry-Dock Check List is a Guidance

INTERTANKO Members invited to use it and many do

Advantage to use a standard Check List

Advantage to do a Risk Assessment on work /outcome of the

Dry-Dock activity

Initiative to attempt on reducing/eliminating post DD problems

Increase confidence on problem-free post Dry Dock operation

Maybe easier to be contracted for a “post Dry Dock first cargo”

Leading the way; Making a difference

dragos.rauta@Intertanko.com

Leading the way; Making a difference

You might also like

- RA Export 20230303-171712 (TEMPLATE-04 Haz) - ID230303164833 - Rev2023-03-03 - Cargo & Ballast Works - Ballast Water Treatment System FailureDocument3 pagesRA Export 20230303-171712 (TEMPLATE-04 Haz) - ID230303164833 - Rev2023-03-03 - Cargo & Ballast Works - Ballast Water Treatment System FailureHarman Sandhu100% (3)

- Risk Assessment - Confined Space. SESA-BFIM-RA-CS-001Document13 pagesRisk Assessment - Confined Space. SESA-BFIM-RA-CS-001Abdul Wasay100% (1)

- ITP - ROAD WORK-Rev-01Document4 pagesITP - ROAD WORK-Rev-01Ateeq Rahman100% (1)

- IEEE STD 1547.1 2020Document282 pagesIEEE STD 1547.1 2020Emre BENGINo ratings yet

- Social Welfare, Policies and Social ServicesDocument4 pagesSocial Welfare, Policies and Social ServicesRisa Jubilan100% (2)

- Math Teachers Guide 8 QUARTER 3Document66 pagesMath Teachers Guide 8 QUARTER 3Hazel Clemente Carreon68% (82)

- DryDock CompleteDocument24 pagesDryDock Completeashry_tarek100% (2)

- Bengaluru BDA RMP 2031 Volume - 3 - MasterPlanDocument PDFDocument214 pagesBengaluru BDA RMP 2031 Volume - 3 - MasterPlanDocument PDFAnkitaVerma100% (1)

- Intertanko Guidance Dry-Dock ChecklistDocument34 pagesIntertanko Guidance Dry-Dock ChecklistReda Hmr100% (3)

- Risk Assess Forklift DriverDocument12 pagesRisk Assess Forklift DriverNick KrugerNo ratings yet

- Engineer' Stamp: Contractor'S Stamp:: Issued For Approval Joel Pino R. D'Souza 16 Feb. 2020Document2 pagesEngineer' Stamp: Contractor'S Stamp:: Issued For Approval Joel Pino R. D'Souza 16 Feb. 2020dada khalandarNo ratings yet

- Duqm Refinery Company Approval Status: Subcontractor Document Review Cover SheetDocument14 pagesDuqm Refinery Company Approval Status: Subcontractor Document Review Cover SheetibrahimNo ratings yet

- Risk Assessment P3 Permanent Power Provision at IthraDocument2 pagesRisk Assessment P3 Permanent Power Provision at Ithraghazi4uNo ratings yet

- Hirarc SlideDocument19 pagesHirarc SlideKrishnan Mudaliar Bopalan100% (1)

- Mock Drill Report IA FAILUREDocument4 pagesMock Drill Report IA FAILURE00083583rfNo ratings yet

- RMDJV Pj74 Hiradc Subc 02 (Survey Work)Document1 pageRMDJV Pj74 Hiradc Subc 02 (Survey Work)myn maliQue100% (1)

- Risk Assessment - BanDocument8 pagesRisk Assessment - Bankarthikeyan subramanianNo ratings yet

- Method Statement For Anti Termite TreatmentDocument7 pagesMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Rmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)Document2 pagesRmdjv-pj74-Hiradc-subc 04 (Site Clearing & Earthwork)myn maliQueNo ratings yet

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- R.A For Cleaning Sanitary Tanks (Underground)Document2 pagesR.A For Cleaning Sanitary Tanks (Underground)JemoNo ratings yet

- DRP001-OUF-InC-GMD-Z-000-046-Rev.S3-Code 4 TRA For Blasting, Painting & Field Touch Up of Storage TankDocument24 pagesDRP001-OUF-InC-GMD-Z-000-046-Rev.S3-Code 4 TRA For Blasting, Painting & Field Touch Up of Storage Tankrodman823No ratings yet

- Confined Space EntryDocument4 pagesConfined Space Entrykwame fosterNo ratings yet

- 07 - Risk ReductionxDocument20 pages07 - Risk ReductionxAdriana HubleaNo ratings yet

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- 4.risk Assessment For PPM-Water HeaterDocument2 pages4.risk Assessment For PPM-Water HeaterManzur AhmadNo ratings yet

- 23) R A For Installation of Kerbstone and Paving BlocksDocument6 pages23) R A For Installation of Kerbstone and Paving Blocksabubakrelsaid90No ratings yet

- Risk Management Report: Type Make Model Chassis / VinDocument18 pagesRisk Management Report: Type Make Model Chassis / Vin2266kffhwdNo ratings yet

- DNV Hazid PDFDocument13 pagesDNV Hazid PDF홍인기100% (1)

- Planning of Lifting Operations Sigma 3 CosaltDocument115 pagesPlanning of Lifting Operations Sigma 3 Cosaltmohamed fahs100% (2)

- Drp001-Ouf-Inc-Gmd-Z-000-060-O2. C4Document16 pagesDrp001-Ouf-Inc-Gmd-Z-000-060-O2. C4rodman823No ratings yet

- Triple Height Area. Triple Height Area: Inadequate Communication of Task Planning and PreparationDocument5 pagesTriple Height Area. Triple Height Area: Inadequate Communication of Task Planning and PreparationMobin Thomas AbrahamNo ratings yet

- Integrated Control and Safety System (ICSS) Site Acceptance Test ProcedureDocument42 pagesIntegrated Control and Safety System (ICSS) Site Acceptance Test ProcedureFatholla SalehiNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaNo ratings yet

- AB8-ELE-54-HMO - Raw Water Pump Pullout For InspectionDocument2 pagesAB8-ELE-54-HMO - Raw Water Pump Pullout For Inspectionvikrant911No ratings yet

- Drp001-Ouf-Inc-Gmd-Z-000-038-S1. Code 4Document26 pagesDrp001-Ouf-Inc-Gmd-Z-000-038-S1. Code 4rodman823No ratings yet

- Risk Assessment For Scaffolding Works Rev. 1Document15 pagesRisk Assessment For Scaffolding Works Rev. 1muhammad.younisNo ratings yet

- Part Number Vendor Name Part Description Vendor Code: Name Dept Phone Ext Name Dept Phone ExtDocument11 pagesPart Number Vendor Name Part Description Vendor Code: Name Dept Phone Ext Name Dept Phone Extisolong100% (1)

- Risk AssessmentDocument5 pagesRisk Assessmentsudeesh kumar100% (1)

- Risk Profiling: Muhammad Salman Khan Lodhi MBIW-F19-018 Saaf Pani ProjectDocument5 pagesRisk Profiling: Muhammad Salman Khan Lodhi MBIW-F19-018 Saaf Pani ProjectSalman LodhiNo ratings yet

- FPSO Inherently Safe Design ReportSCM TC110 128 018 01Document82 pagesFPSO Inherently Safe Design ReportSCM TC110 128 018 01Faridah feedausNo ratings yet

- Risk Assement For Piling PDFDocument81 pagesRisk Assement For Piling PDFnagesh1234No ratings yet

- Lightning Safe Structure Verification Form - 8347580Document6 pagesLightning Safe Structure Verification Form - 8347580Henry ArrvalNo ratings yet

- Rmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)Document1 pageRmdjv-pj74-Hiradc-subc 05 (Setting Out Piling Point)myn maliQueNo ratings yet

- MS Bunker Leak TestDocument9 pagesMS Bunker Leak Testaden72No ratings yet

- 213 Laminating of GRPDocument11 pages213 Laminating of GRPgrantNo ratings yet

- 077907J001 070 VALVE D312 0001 - Reva PDFDocument3 pages077907J001 070 VALVE D312 0001 - Reva PDFSAKHIRAMNo ratings yet

- HSE Audit TemplateDocument28 pagesHSE Audit Templatemohroy21No ratings yet

- AB8-ELE-75-HMO - Generator Dismantling For 5 Yearly MaintenanaceDocument2 pagesAB8-ELE-75-HMO - Generator Dismantling For 5 Yearly Maintenanacevikrant911No ratings yet

- MSCI ESG Research - Bruno RauisDocument15 pagesMSCI ESG Research - Bruno RauisValerio ScaccoNo ratings yet

- Project Costing - Final AssignmentDocument25 pagesProject Costing - Final AssignmentJohn KalarNo ratings yet

- Saudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeDocument11 pagesSaudi Aramco Typical Inspection Plan: Radiographic Testing (RT) On IK Projects Satip-Nde-Rt-01 15-Nov-17 Mechanical - NdeSyed Mohammed Abdul Aleem SoofiyaniNo ratings yet

- 1-Risk Assessment For Hot Work ParmitDocument4 pages1-Risk Assessment For Hot Work Parmitsudeesh kumarNo ratings yet

- Hse Key Performance Indicator Contractor 2018Document9 pagesHse Key Performance Indicator Contractor 2018Bayu JatmikoNo ratings yet

- Type Approval: Offshore Container Lifting OperationDocument28 pagesType Approval: Offshore Container Lifting OperationregisreginhoNo ratings yet

- Aragon AragonOS Smart Contract Security Audit Report Halborn FinalDocument29 pagesAragon AragonOS Smart Contract Security Audit Report Halborn FinalFrancisco GomesNo ratings yet

- Risk Management ProcedureDocument10 pagesRisk Management ProcedurehapisstendeNo ratings yet

- Adac Asgtc 2018 Ra 07 Hot WorkDocument3 pagesAdac Asgtc 2018 Ra 07 Hot Workabubakrelsaid90No ratings yet

- Mobilization Risk AssessmentDocument53 pagesMobilization Risk AssessmentRAMY ABOU AL DAHABNo ratings yet

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- A 12.5-ENOB 10-kS/s Redundant SAR ADC in 65nm CMOS: Dai Zhang, Member, IEEE, and Atila Alvandpour, Senior Member, IEEEDocument5 pagesA 12.5-ENOB 10-kS/s Redundant SAR ADC in 65nm CMOS: Dai Zhang, Member, IEEE, and Atila Alvandpour, Senior Member, IEEESilpa VelagaletiNo ratings yet

- Special Considerations For Special Populations: Chapter ObjectivesDocument46 pagesSpecial Considerations For Special Populations: Chapter ObjectivesClaudia F de la ArceNo ratings yet

- Matrix-Theorist and Their ViewsDocument5 pagesMatrix-Theorist and Their Viewsrebekah laydaNo ratings yet

- Diamond Turn MachiningDocument73 pagesDiamond Turn Machiningsangeet khuleNo ratings yet

- Chapter 11 - Inferences About Population Variances: Session 15 Chi-Square DistributionDocument6 pagesChapter 11 - Inferences About Population Variances: Session 15 Chi-Square DistributionNitish NairNo ratings yet

- 2 Chocolate Reading TasksDocument2 pages2 Chocolate Reading TasksBussayapuch Nusang TKNo ratings yet

- Olympic 10 2018Document13 pagesOlympic 10 2018Bảo TrâmNo ratings yet

- Seven, SeeDocument39 pagesSeven, SeeShybe Elrik100% (1)

- Performance Assessment Tools: Marilou S. FerrerDocument16 pagesPerformance Assessment Tools: Marilou S. FerrerAlyssa AlbertoNo ratings yet

- Strap or Cantilever Footings ExampleDocument11 pagesStrap or Cantilever Footings ExamplehNo ratings yet

- The Study About The Discrimination of LGBTQIA+ Grade 11 and 12 Students in ACLC College of MeycauayanDocument65 pagesThe Study About The Discrimination of LGBTQIA+ Grade 11 and 12 Students in ACLC College of MeycauayanTatin Mendones BurgosNo ratings yet

- S - A - Retailer's Impact Woolworth CaseDocument8 pagesS - A - Retailer's Impact Woolworth CaseKonrad GłowackiNo ratings yet

- 6-OTC107601 OptiX NG WDM Network Design ISSUE1.14Document80 pages6-OTC107601 OptiX NG WDM Network Design ISSUE1.14HachidSofianeNo ratings yet

- Introduction To Science Technology and SocietyDocument23 pagesIntroduction To Science Technology and SocietyFatima AbayonNo ratings yet

- Tpg23 08 NSW Government Guide To Cost Benefit Analysis 202304Document116 pagesTpg23 08 NSW Government Guide To Cost Benefit Analysis 202304Hassan ElmiNo ratings yet

- Concept Map General EssayDocument2 pagesConcept Map General EssayAtun Mojado xdNo ratings yet

- Artifacts of The Wastelands (MuFut)Document16 pagesArtifacts of The Wastelands (MuFut)Mike Mitchell100% (1)

- Lta-35 Mtp-1 Facp Vendor CutsheetsDocument63 pagesLta-35 Mtp-1 Facp Vendor Cutsheetsinfo.faizanizamNo ratings yet

- Compendex 2013 Source List 4 Aptil 2013Document333 pagesCompendex 2013 Source List 4 Aptil 2013Zelalem MengistuNo ratings yet

- HGP Year End Report 2021-2022 NewDocument169 pagesHGP Year End Report 2021-2022 Newangelica sungaNo ratings yet

- Read About Lightning and ThunderDocument2 pagesRead About Lightning and ThunderTino SalabsabNo ratings yet

- Guelen, Jeanne ThereseDocument2 pagesGuelen, Jeanne ThereseJay GeeNo ratings yet

- Best Practices in Donor RecognitionDocument5 pagesBest Practices in Donor RecognitiongNo ratings yet

- Single Phase TransformerDocument29 pagesSingle Phase Transformerkaran nirmala gajanan shindeNo ratings yet

- Hypothesis & TypesDocument3 pagesHypothesis & Typesaxa3811No ratings yet

- Srivastava Et Al 2023 Estimating Relative Tax Efficiency For Selected States in India An Error Correction ApproachDocument27 pagesSrivastava Et Al 2023 Estimating Relative Tax Efficiency For Selected States in India An Error Correction ApproachsushilNo ratings yet