Professional Documents

Culture Documents

واجهة

واجهة

Uploaded by

Abdullah MustafaCopyright:

Available Formats

You might also like

- QSI PartsDocument76 pagesQSI PartsAdrian CantaragiuNo ratings yet

- Sheet MetalDocument8 pagesSheet MetalPrabir Kumar Pati100% (1)

- Design and Fabrication of Four Way Hacksaw MachineDocument22 pagesDesign and Fabrication of Four Way Hacksaw MachineDinesh KumarNo ratings yet

- The Overall Process of GunmakingDocument4 pagesThe Overall Process of GunmakingAshit Raj100% (1)

- Design of Steel Structures by Prof Damodar Maity PDFDocument793 pagesDesign of Steel Structures by Prof Damodar Maity PDFlakshminarayanstr100% (6)

- SID1Document18 pagesSID1Siddharth Srinivasan100% (1)

- BlankingDocument4 pagesBlankingk.prasadNo ratings yet

- Chapter 1 TO 5Document49 pagesChapter 1 TO 5nagisafurukawa122333No ratings yet

- IC Learning Series 2013 - Sheet Metal FabricationDocument19 pagesIC Learning Series 2013 - Sheet Metal FabricationnskumarmNo ratings yet

- Cutting Tool Applications: by George Schneider, Jr. CmfgeDocument9 pagesCutting Tool Applications: by George Schneider, Jr. CmfgeInfernuzNo ratings yet

- BCM 2Document34 pagesBCM 2rupanandaNo ratings yet

- Power PlantDocument39 pagesPower PlantSketcher Sumit GuptaNo ratings yet

- Aluminum Extrusion ThesisDocument4 pagesAluminum Extrusion Thesisvictorialeonlittlerock100% (2)

- Rolling & Extrusion Case StudyDocument20 pagesRolling & Extrusion Case StudyMahmoud KassabNo ratings yet

- Manufacturing Processes LabDocument6 pagesManufacturing Processes Labkhizeraftab1018No ratings yet

- Fact Sheet: METAL REMOVAL/CUTTINGDocument4 pagesFact Sheet: METAL REMOVAL/CUTTINGAl EnggNo ratings yet

- Design Study of Progressive Tool DesignDocument34 pagesDesign Study of Progressive Tool Designsudheer9289% (9)

- Pressure Die-CastingDocument12 pagesPressure Die-CastingAyush PandeyNo ratings yet

- BCMEDocument35 pagesBCMErupanandaNo ratings yet

- SWEPDocument11 pagesSWEPRizzleNo ratings yet

- Transmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaDocument19 pagesTransmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaPanchitou OuuNo ratings yet

- Design and Simulation of Different Progressive ToolsDocument8 pagesDesign and Simulation of Different Progressive ToolsAnnaNo ratings yet

- Abebe BeyeneDocument21 pagesAbebe Beyenedawit solomonNo ratings yet

- Flow Forming of Tubes A Review PDFDocument11 pagesFlow Forming of Tubes A Review PDFKaustubh Joshi100% (1)

- Sheet Cutting PDFDocument10 pagesSheet Cutting PDFkolla satishNo ratings yet

- Industrial ShedDocument13 pagesIndustrial ShedDivya KrishnaNo ratings yet

- Invicta Metal Stamping CatalogueDocument12 pagesInvicta Metal Stamping CatalogueVbNo ratings yet

- Sheetmetal IntroductionDocument9 pagesSheetmetal IntroductionVinay BalineniNo ratings yet

- Workshop Ex-1,2,3,4Document37 pagesWorkshop Ex-1,2,3,4Naim Mahmud RahadNo ratings yet

- Automated Pneumatic Sheet Metal Cutting MachineDocument9 pagesAutomated Pneumatic Sheet Metal Cutting MachineRushikesh Patil100% (1)

- Fabrication of Sheet Metal CuttingDocument14 pagesFabrication of Sheet Metal Cuttingkolla satishNo ratings yet

- Pneumatic Cutter SynopsisDocument10 pagesPneumatic Cutter SynopsisGurhans Pal SinghNo ratings yet

- Manufacturing Process of An Automobile ComponentDocument29 pagesManufacturing Process of An Automobile ComponentShiva BharathNo ratings yet

- Sandvik Part - 1 PDFDocument38 pagesSandvik Part - 1 PDFEliel AbadNo ratings yet

- Module-3: Cutting Tool Materials, Geometry and Surface FinishDocument18 pagesModule-3: Cutting Tool Materials, Geometry and Surface FinishYashas KattemaneNo ratings yet

- Forging PDF NotesDocument51 pagesForging PDF Notesaman prasadNo ratings yet

- Al Die CastingDocument11 pagesAl Die CastingMallesh Munje100% (1)

- Adigrat University: College of Engineering and TechnologyDocument15 pagesAdigrat University: College of Engineering and TechnologyHadush TeklayNo ratings yet

- 555555555555Document15 pages555555555555Hadush TeklayNo ratings yet

- Strain Studies IN Sheet Metal StampingDocument3 pagesStrain Studies IN Sheet Metal StampingPotluri NagasaitejNo ratings yet

- Chapter 1Document45 pagesChapter 1idris_ali_7No ratings yet

- Sheet Metal Design GuidelinesDocument17 pagesSheet Metal Design GuidelinesOmar YoushimatzNo ratings yet

- Pneumatic Sheet Metal Cutting Machine: K.Krantikumar K.V.S.S.Saikiran Jakkoju Sathish, M.TechDocument9 pagesPneumatic Sheet Metal Cutting Machine: K.Krantikumar K.V.S.S.Saikiran Jakkoju Sathish, M.TechSiva RajNo ratings yet

- Topic 3-Tool and DieDocument16 pagesTopic 3-Tool and DiegepigavinceNo ratings yet

- 43-Sheet Metal Punching MachineDocument25 pages43-Sheet Metal Punching MachinesathishNo ratings yet

- Cnc-12 Protp Oi78Document25 pagesCnc-12 Protp Oi78Carlos ArenasNo ratings yet

- Metal Stamping and Fabricating OperationsDocument23 pagesMetal Stamping and Fabricating OperationsAnonymous wtK1AZBi100% (1)

- Manufacturing Process Value Chain.Document8 pagesManufacturing Process Value Chain.Nouman wahidNo ratings yet

- Metal Fabrication - WikipediaDocument4 pagesMetal Fabrication - WikipediaSanthan SalaiNo ratings yet

- Cutting Tool MaterialsDocument5 pagesCutting Tool MaterialsMichael MeltzNo ratings yet

- Turret PunchingDocument9 pagesTurret PunchingMukulNo ratings yet

- MIE 375 Final ReportDocument8 pagesMIE 375 Final Reportjohn jonesNo ratings yet

- Manufacturing Technology - MachiningDocument61 pagesManufacturing Technology - Machiningviverefelice100% (1)

- Rosacay Task Sheet !!Document10 pagesRosacay Task Sheet !!Sherren Marie NalaNo ratings yet

- Beveling PDFDocument29 pagesBeveling PDFTechnology SinghNo ratings yet

- ColdRolledSteel PDFDocument32 pagesColdRolledSteel PDFeduardomacieldelimaNo ratings yet

- Sheet Metal Design1Document57 pagesSheet Metal Design1Mohamed ZeinNo ratings yet

- Sheet Metal DesignDocument13 pagesSheet Metal Designsivakumar subramanianNo ratings yet

- What Is The Difference Between Open Fire and Stock Fire in Forge?Document3 pagesWhat Is The Difference Between Open Fire and Stock Fire in Forge?HaftamuNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- RefrencessDocument3 pagesRefrencessAbdullah MustafaNo ratings yet

- المحاضرة الثالثةDocument16 pagesالمحاضرة الثالثةAbdullah MustafaNo ratings yet

- واجهةDocument1 pageواجهةAbdullah MustafaNo ratings yet

- Q3Document1 pageQ3Abdullah MustafaNo ratings yet

- واجهةDocument2 pagesواجهةAbdullah MustafaNo ratings yet

- Catalogo Tosaca 1216Document16 pagesCatalogo Tosaca 1216isa.cuenta.26No ratings yet

- Guidelines No. 3 Sewage Treatment System BookDocument88 pagesGuidelines No. 3 Sewage Treatment System BookK4No ratings yet

- CDHF SVN01A en InstallationDocument88 pagesCDHF SVN01A en InstallationEmerson PenaforteNo ratings yet

- J-SF24 Sand FilterDocument8 pagesJ-SF24 Sand Filterelle diemNo ratings yet

- ASPHALT CONCRETE Lecture NoteDocument11 pagesASPHALT CONCRETE Lecture Notekalana mihirangaNo ratings yet

- Huda Gurgaon Recycle: Civil Works 11% Transportation 2%Document19 pagesHuda Gurgaon Recycle: Civil Works 11% Transportation 2%rvsingh17No ratings yet

- MDV D80T2VN1 Ba5 PDFDocument2 pagesMDV D80T2VN1 Ba5 PDFJuan Carlos Soto OrihuelaNo ratings yet

- Material Properties of TDADocument11 pagesMaterial Properties of TDAMahmoud. HlelaiNo ratings yet

- StepocDocument6 pagesStepocRobert WhiteNo ratings yet

- MWYY Defect - E&M (JRP 20200113)Document23 pagesMWYY Defect - E&M (JRP 20200113)yiuloi997023No ratings yet

- 2021 - B Nespor Et Al. - Development of Rapid Set Mortar For AdditiveDocument15 pages2021 - B Nespor Et Al. - Development of Rapid Set Mortar For AdditiveChaman Modi 20310015No ratings yet

- No Fine Mix DesignDocument8 pagesNo Fine Mix DesignSANJAY TNo ratings yet

- Planning Guide Hans en Pole BuildingsDocument8 pagesPlanning Guide Hans en Pole BuildingsSandy MundrickNo ratings yet

- Mixed Use DevelopmentDocument7 pagesMixed Use DevelopmentIsabella BeatrixNo ratings yet

- 0m134e GP15 Compressor MaintenanceDocument40 pages0m134e GP15 Compressor MaintenancepradojuanNo ratings yet

- Check List Piping Project Start Kick-Off Meeting DiscussionDocument5 pagesCheck List Piping Project Start Kick-Off Meeting DiscussionAnonymous PsafDWSiOoNo ratings yet

- Heat Recovery Units RangeDocument35 pagesHeat Recovery Units RangeGabetsos KaraflidisNo ratings yet

- Door & Window ScheduleDocument1 pageDoor & Window ScheduleJubaerul IslamNo ratings yet

- Crane Safety Standards - RegulationsDocument22 pagesCrane Safety Standards - RegulationsSai Shankar LakshminarayananNo ratings yet

- Concure PI: Membrane Concrete Curing Compound UsesDocument2 pagesConcure PI: Membrane Concrete Curing Compound UsesTechnicalproducts 02 Indo Riau PerkasaNo ratings yet

- REN E SG 10 LS 000 0007 - System Turnover Package List (Construction)Document10 pagesREN E SG 10 LS 000 0007 - System Turnover Package List (Construction)Smith SuwanNo ratings yet

- E DBL 008 Ol SteelceramicDocument4 pagesE DBL 008 Ol SteelceramicCostas AggelidisNo ratings yet

- 40 SQM Structural PlanDocument5 pages40 SQM Structural PlanCharles SiaNo ratings yet

- 2UZ-FE Timing Belt Water Pump Guide 11-14Document4 pages2UZ-FE Timing Belt Water Pump Guide 11-14Guillermo AguileraNo ratings yet

- Corporate Presentation R7Document73 pagesCorporate Presentation R7manishbhingareNo ratings yet

- Living Hinge DesignDocument9 pagesLiving Hinge Designom.mauryaNo ratings yet

- CE2011 - Structural Analysis IDocument10 pagesCE2011 - Structural Analysis IRashmiNo ratings yet

- Some - Considerations - in - The - Stability - Analysis - of - Upstream DamsDocument18 pagesSome - Considerations - in - The - Stability - Analysis - of - Upstream DamsAhmedNo ratings yet

واجهة

واجهة

Uploaded by

Abdullah MustafaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

واجهة

واجهة

Uploaded by

Abdullah MustafaCopyright:

Available Formats

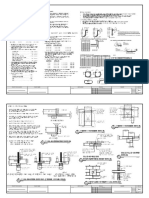

University of Technology

Production Engineering and

Metallurgy

Production

Department

محمد فاخر عبد الصاحب: االسم

الرابع: الصف

تصميم القوالب – عملي: المادة

punch and die : العنوان

; punch and die

Punch and die is a type of cutting tool equipment used in

punching and forging work, which is a metal forming process

that requires high heat. This process needs a 'punch' as a pusher

on the cutting workpiece, and the die is a secondary object that

.the punch pushes in

Blanking

Manufacturers use blanking to punch pieces in specific shapes

from sheets or strips of raw material. The punched-out piece is

called the “blank,” hence the term “blanking.” Blanking is most

often performed with tools made from hardened steel or carbide,

which work on metals like aluminum, carbon steel, stainless

steel, and even plastic.

Blanking has many benefits, but manufacturers must take some

considerations into account before embarking on a full course of

metal blanking. Although this process is a quick and cost-

effective way to produce a large number of identical pieces, these

punched-out pieces may have burrs or cracks on the edges.

However, these drawbacks can be avoided by using high-quality

tools, and they can be corrected by post-processing the blanks.

Although blanking sounds simple, this basic option can

.accommodate many variations. A full overview continues below

The product be like this after a blanking process

Benefits of Blanking

Machinery used for blanking ranges from simple punches and

dies to sophisticated CNC machinery. Blanking equipment can

quickly be configured to end product specifications, and the

process itself takes little time per part as it involves simply

feeding the primary metal stock continuously into the blanking

machine.

Because of this, blanking can perform long production runs that

require little or no changes to the machinery or base material. The

straightforward process also allows you to construct materials to

strict tolerances with little part-to-part variation, and technology

has become so sophisticated that it can build multiple geometries

using a single process.

Furthermore, because the primary metal stock can be reused,

blanking can help manufacturing firms reduce their material

waste. Due to these benefits, blanking is commonly used to mass

produce components for industries such as aerospace and

automobile manufacturing. It’s also used for high-volume

fabrication of parts for common household appliances

Different Types of Blanking Methods

While the fundamentals of the blanking process are simple,

they have many variations, which we describe below:

1. Compound Die Stamping

This type of blanking is used to precisely manufacture complex

steel parts. In this process, workers or automated equipment feed

a steel strip through the stamping machine, which punches out a

blank every three seconds. This simple, precise, and fast

technique enables firms to produce steel components in bulk.

2. Continuous Strip Blanking

As implied by the name, continuous strip blanking continuously

feeds metal substrates through a machine. This allows punching

machines to produce uniform end products around the clock, with

each product having the same characteristics of those before and

after it. This process is a great way to develop coins, bottle caps,

and medallions.

3. Progressive Die Stamping

Progressive die stamping uses coiled strips of thin flat metal as its

base material. In this process, progressive die machines

sequentially stamp, trim, and bend workpieces to make the

finished parts, which exit the machine in conjoined strips. After

performing this task, the machine separates individual parts from

the strip, which results in the creation of several identical parts.

4. Square Sheared Blanking

Square sheared blanking is a fine process that uses specialized

clamping tools to produce square-edged and contoured blanks.

This process is a great way to create panels, casings, and any

other component that requires a uniform square shape.

1. Cutoff

This process combines metal cutting and metal blanking

procedures to create highly specialized blanks. When cutoff

blanking, manufacturers blank metal sheets and then cut the

metal at the sheets, allowing the production of long, flat pieces

Best Materials to Use When Blanking

performs blanking on carbon steel, stainless steel, and aluminum.

Each material brings unique properties to the process, which we

explore below.

1. Carbon Steel

Metalworkers use carbon steel to make industrial equipment and

household tools like knives because of this material’s exceptional

strength and hardness. Carbon steel’s hardness varies depending

on the amount of carbon present within it, and the higher the

carbon content, the harder the alloy is.

Carbon content in carbon steel ranges from 0.8% to 2.11%, and

the typical value is about 1.5%. Carbon steel is more cost

effective than other materials of comparable hardness, thus

making it a popular raw material to use as a substrate.

2. Stainless Steel

Stainless steel has low carbon content but a large amount of

chromium, which ranges from 10% to 30% of the final material.

This chromium content makes stainless steel highly resistant to

corrosion and heat.

Stainless steel may also incorporate other metals like aluminum,

copper, and titanium to enhance various attributes, and even

nonmetals like phosphorous and sulfur can be used to improve

resistance to certain types of corrosive substances. Stainless steel

is thus a versatile alloy that can take on a variety of uses

depending on its composition.

3. Aluminum

Aluminum’s softness and flexibility make it very suitable. In fact,

aluminum is the most common metal used to create industrial and

household products because of this material’s low cost, ease of

extraction, and properties like lightness, durability, and recycling

potential.

For these reasons, many applications in the automotive,

aerospace, energy, and packaging industries use aluminum in

large quantities. Aluminum is a very cost-effective way to

produce high volumes of components

.

:Sources

https://unipunch.com/system-capabilities/typical-work-done/

/ blanking

/https://www.ohiovalleymfg.com/blog/blanking

https://www.toptechdiamond.com/what-is-punch-and-die/

#:~:text=Punch%20and%20die%20is%20a,that%20the%20punch

.%20pushes%20in

You might also like

- QSI PartsDocument76 pagesQSI PartsAdrian CantaragiuNo ratings yet

- Sheet MetalDocument8 pagesSheet MetalPrabir Kumar Pati100% (1)

- Design and Fabrication of Four Way Hacksaw MachineDocument22 pagesDesign and Fabrication of Four Way Hacksaw MachineDinesh KumarNo ratings yet

- The Overall Process of GunmakingDocument4 pagesThe Overall Process of GunmakingAshit Raj100% (1)

- Design of Steel Structures by Prof Damodar Maity PDFDocument793 pagesDesign of Steel Structures by Prof Damodar Maity PDFlakshminarayanstr100% (6)

- SID1Document18 pagesSID1Siddharth Srinivasan100% (1)

- BlankingDocument4 pagesBlankingk.prasadNo ratings yet

- Chapter 1 TO 5Document49 pagesChapter 1 TO 5nagisafurukawa122333No ratings yet

- IC Learning Series 2013 - Sheet Metal FabricationDocument19 pagesIC Learning Series 2013 - Sheet Metal FabricationnskumarmNo ratings yet

- Cutting Tool Applications: by George Schneider, Jr. CmfgeDocument9 pagesCutting Tool Applications: by George Schneider, Jr. CmfgeInfernuzNo ratings yet

- BCM 2Document34 pagesBCM 2rupanandaNo ratings yet

- Power PlantDocument39 pagesPower PlantSketcher Sumit GuptaNo ratings yet

- Aluminum Extrusion ThesisDocument4 pagesAluminum Extrusion Thesisvictorialeonlittlerock100% (2)

- Rolling & Extrusion Case StudyDocument20 pagesRolling & Extrusion Case StudyMahmoud KassabNo ratings yet

- Manufacturing Processes LabDocument6 pagesManufacturing Processes Labkhizeraftab1018No ratings yet

- Fact Sheet: METAL REMOVAL/CUTTINGDocument4 pagesFact Sheet: METAL REMOVAL/CUTTINGAl EnggNo ratings yet

- Design Study of Progressive Tool DesignDocument34 pagesDesign Study of Progressive Tool Designsudheer9289% (9)

- Pressure Die-CastingDocument12 pagesPressure Die-CastingAyush PandeyNo ratings yet

- BCMEDocument35 pagesBCMErupanandaNo ratings yet

- SWEPDocument11 pagesSWEPRizzleNo ratings yet

- Transmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaDocument19 pagesTransmission Linkages: Universidad Autónoma Del Estado de México Facultad de IngenieríaPanchitou OuuNo ratings yet

- Design and Simulation of Different Progressive ToolsDocument8 pagesDesign and Simulation of Different Progressive ToolsAnnaNo ratings yet

- Abebe BeyeneDocument21 pagesAbebe Beyenedawit solomonNo ratings yet

- Flow Forming of Tubes A Review PDFDocument11 pagesFlow Forming of Tubes A Review PDFKaustubh Joshi100% (1)

- Sheet Cutting PDFDocument10 pagesSheet Cutting PDFkolla satishNo ratings yet

- Industrial ShedDocument13 pagesIndustrial ShedDivya KrishnaNo ratings yet

- Invicta Metal Stamping CatalogueDocument12 pagesInvicta Metal Stamping CatalogueVbNo ratings yet

- Sheetmetal IntroductionDocument9 pagesSheetmetal IntroductionVinay BalineniNo ratings yet

- Workshop Ex-1,2,3,4Document37 pagesWorkshop Ex-1,2,3,4Naim Mahmud RahadNo ratings yet

- Automated Pneumatic Sheet Metal Cutting MachineDocument9 pagesAutomated Pneumatic Sheet Metal Cutting MachineRushikesh Patil100% (1)

- Fabrication of Sheet Metal CuttingDocument14 pagesFabrication of Sheet Metal Cuttingkolla satishNo ratings yet

- Pneumatic Cutter SynopsisDocument10 pagesPneumatic Cutter SynopsisGurhans Pal SinghNo ratings yet

- Manufacturing Process of An Automobile ComponentDocument29 pagesManufacturing Process of An Automobile ComponentShiva BharathNo ratings yet

- Sandvik Part - 1 PDFDocument38 pagesSandvik Part - 1 PDFEliel AbadNo ratings yet

- Module-3: Cutting Tool Materials, Geometry and Surface FinishDocument18 pagesModule-3: Cutting Tool Materials, Geometry and Surface FinishYashas KattemaneNo ratings yet

- Forging PDF NotesDocument51 pagesForging PDF Notesaman prasadNo ratings yet

- Al Die CastingDocument11 pagesAl Die CastingMallesh Munje100% (1)

- Adigrat University: College of Engineering and TechnologyDocument15 pagesAdigrat University: College of Engineering and TechnologyHadush TeklayNo ratings yet

- 555555555555Document15 pages555555555555Hadush TeklayNo ratings yet

- Strain Studies IN Sheet Metal StampingDocument3 pagesStrain Studies IN Sheet Metal StampingPotluri NagasaitejNo ratings yet

- Chapter 1Document45 pagesChapter 1idris_ali_7No ratings yet

- Sheet Metal Design GuidelinesDocument17 pagesSheet Metal Design GuidelinesOmar YoushimatzNo ratings yet

- Pneumatic Sheet Metal Cutting Machine: K.Krantikumar K.V.S.S.Saikiran Jakkoju Sathish, M.TechDocument9 pagesPneumatic Sheet Metal Cutting Machine: K.Krantikumar K.V.S.S.Saikiran Jakkoju Sathish, M.TechSiva RajNo ratings yet

- Topic 3-Tool and DieDocument16 pagesTopic 3-Tool and DiegepigavinceNo ratings yet

- 43-Sheet Metal Punching MachineDocument25 pages43-Sheet Metal Punching MachinesathishNo ratings yet

- Cnc-12 Protp Oi78Document25 pagesCnc-12 Protp Oi78Carlos ArenasNo ratings yet

- Metal Stamping and Fabricating OperationsDocument23 pagesMetal Stamping and Fabricating OperationsAnonymous wtK1AZBi100% (1)

- Manufacturing Process Value Chain.Document8 pagesManufacturing Process Value Chain.Nouman wahidNo ratings yet

- Metal Fabrication - WikipediaDocument4 pagesMetal Fabrication - WikipediaSanthan SalaiNo ratings yet

- Cutting Tool MaterialsDocument5 pagesCutting Tool MaterialsMichael MeltzNo ratings yet

- Turret PunchingDocument9 pagesTurret PunchingMukulNo ratings yet

- MIE 375 Final ReportDocument8 pagesMIE 375 Final Reportjohn jonesNo ratings yet

- Manufacturing Technology - MachiningDocument61 pagesManufacturing Technology - Machiningviverefelice100% (1)

- Rosacay Task Sheet !!Document10 pagesRosacay Task Sheet !!Sherren Marie NalaNo ratings yet

- Beveling PDFDocument29 pagesBeveling PDFTechnology SinghNo ratings yet

- ColdRolledSteel PDFDocument32 pagesColdRolledSteel PDFeduardomacieldelimaNo ratings yet

- Sheet Metal Design1Document57 pagesSheet Metal Design1Mohamed ZeinNo ratings yet

- Sheet Metal DesignDocument13 pagesSheet Metal Designsivakumar subramanianNo ratings yet

- What Is The Difference Between Open Fire and Stock Fire in Forge?Document3 pagesWhat Is The Difference Between Open Fire and Stock Fire in Forge?HaftamuNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- RefrencessDocument3 pagesRefrencessAbdullah MustafaNo ratings yet

- المحاضرة الثالثةDocument16 pagesالمحاضرة الثالثةAbdullah MustafaNo ratings yet

- واجهةDocument1 pageواجهةAbdullah MustafaNo ratings yet

- Q3Document1 pageQ3Abdullah MustafaNo ratings yet

- واجهةDocument2 pagesواجهةAbdullah MustafaNo ratings yet

- Catalogo Tosaca 1216Document16 pagesCatalogo Tosaca 1216isa.cuenta.26No ratings yet

- Guidelines No. 3 Sewage Treatment System BookDocument88 pagesGuidelines No. 3 Sewage Treatment System BookK4No ratings yet

- CDHF SVN01A en InstallationDocument88 pagesCDHF SVN01A en InstallationEmerson PenaforteNo ratings yet

- J-SF24 Sand FilterDocument8 pagesJ-SF24 Sand Filterelle diemNo ratings yet

- ASPHALT CONCRETE Lecture NoteDocument11 pagesASPHALT CONCRETE Lecture Notekalana mihirangaNo ratings yet

- Huda Gurgaon Recycle: Civil Works 11% Transportation 2%Document19 pagesHuda Gurgaon Recycle: Civil Works 11% Transportation 2%rvsingh17No ratings yet

- MDV D80T2VN1 Ba5 PDFDocument2 pagesMDV D80T2VN1 Ba5 PDFJuan Carlos Soto OrihuelaNo ratings yet

- Material Properties of TDADocument11 pagesMaterial Properties of TDAMahmoud. HlelaiNo ratings yet

- StepocDocument6 pagesStepocRobert WhiteNo ratings yet

- MWYY Defect - E&M (JRP 20200113)Document23 pagesMWYY Defect - E&M (JRP 20200113)yiuloi997023No ratings yet

- 2021 - B Nespor Et Al. - Development of Rapid Set Mortar For AdditiveDocument15 pages2021 - B Nespor Et Al. - Development of Rapid Set Mortar For AdditiveChaman Modi 20310015No ratings yet

- No Fine Mix DesignDocument8 pagesNo Fine Mix DesignSANJAY TNo ratings yet

- Planning Guide Hans en Pole BuildingsDocument8 pagesPlanning Guide Hans en Pole BuildingsSandy MundrickNo ratings yet

- Mixed Use DevelopmentDocument7 pagesMixed Use DevelopmentIsabella BeatrixNo ratings yet

- 0m134e GP15 Compressor MaintenanceDocument40 pages0m134e GP15 Compressor MaintenancepradojuanNo ratings yet

- Check List Piping Project Start Kick-Off Meeting DiscussionDocument5 pagesCheck List Piping Project Start Kick-Off Meeting DiscussionAnonymous PsafDWSiOoNo ratings yet

- Heat Recovery Units RangeDocument35 pagesHeat Recovery Units RangeGabetsos KaraflidisNo ratings yet

- Door & Window ScheduleDocument1 pageDoor & Window ScheduleJubaerul IslamNo ratings yet

- Crane Safety Standards - RegulationsDocument22 pagesCrane Safety Standards - RegulationsSai Shankar LakshminarayananNo ratings yet

- Concure PI: Membrane Concrete Curing Compound UsesDocument2 pagesConcure PI: Membrane Concrete Curing Compound UsesTechnicalproducts 02 Indo Riau PerkasaNo ratings yet

- REN E SG 10 LS 000 0007 - System Turnover Package List (Construction)Document10 pagesREN E SG 10 LS 000 0007 - System Turnover Package List (Construction)Smith SuwanNo ratings yet

- E DBL 008 Ol SteelceramicDocument4 pagesE DBL 008 Ol SteelceramicCostas AggelidisNo ratings yet

- 40 SQM Structural PlanDocument5 pages40 SQM Structural PlanCharles SiaNo ratings yet

- 2UZ-FE Timing Belt Water Pump Guide 11-14Document4 pages2UZ-FE Timing Belt Water Pump Guide 11-14Guillermo AguileraNo ratings yet

- Corporate Presentation R7Document73 pagesCorporate Presentation R7manishbhingareNo ratings yet

- Living Hinge DesignDocument9 pagesLiving Hinge Designom.mauryaNo ratings yet

- CE2011 - Structural Analysis IDocument10 pagesCE2011 - Structural Analysis IRashmiNo ratings yet

- Some - Considerations - in - The - Stability - Analysis - of - Upstream DamsDocument18 pagesSome - Considerations - in - The - Stability - Analysis - of - Upstream DamsAhmedNo ratings yet