Professional Documents

Culture Documents

FPSO Cargo Liquid Handling Net

FPSO Cargo Liquid Handling Net

Uploaded by

Francisco CuevasCopyright:

Available Formats

You might also like

- Report On MiniprojectDocument28 pagesReport On Miniprojectrohith gombe100% (1)

- Test Automation Estimate Template: Automation Type Project NameDocument6 pagesTest Automation Estimate Template: Automation Type Project NameSantosh Prasad UlpiNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- How FPSO WorksDocument15 pagesHow FPSO WorksMajeed Rumani100% (3)

- DS 720 SDocument2 pagesDS 720 SIvan DumontNo ratings yet

- CST 8110 Quiz AnswersDocument8 pagesCST 8110 Quiz AnswershenNo ratings yet

- S&OP Wallace PresentationDocument91 pagesS&OP Wallace PresentationAutomation Boonlue100% (2)

- Slops Tanks WaterDocument6 pagesSlops Tanks WaterVasileios PantouvakisNo ratings yet

- LNG Receiving Terminals: BY CH - Satvika 16021A2545Document24 pagesLNG Receiving Terminals: BY CH - Satvika 16021A2545Ram Charan Konidela100% (1)

- OffShore Vessel GlossaryDocument21 pagesOffShore Vessel Glossarydaniel8iosif_178% (9)

- Liquid Bulk TerminalDocument21 pagesLiquid Bulk TerminalPaola Baleta Medina100% (1)

- FPSO-Bow Mounted vs. Aft MountedDocument79 pagesFPSO-Bow Mounted vs. Aft Mountedcxb07164100% (3)

- What Is Bilge and Ballast System?Document3 pagesWhat Is Bilge and Ballast System?Emirson CentinoNo ratings yet

- What Is Bilge and Ballast System?Document3 pagesWhat Is Bilge and Ballast System?Emirson CentinoNo ratings yet

- Largest Property Portal: LPG Handling Other Gas Products Fire & Safety Emergency ResponseDocument4 pagesLargest Property Portal: LPG Handling Other Gas Products Fire & Safety Emergency ResponsePrasad RaviproluNo ratings yet

- Itmconf Cccar2022 03019Document5 pagesItmconf Cccar2022 03019Sumya Ben mahmoudNo ratings yet

- Slop Tank Design For Improved Load-On-TopDocument6 pagesSlop Tank Design For Improved Load-On-Topscm_2628No ratings yet

- Framo Cargo Pumping Systems BrochureDocument32 pagesFramo Cargo Pumping Systems BrochureFfej-Jeff DizonNo ratings yet

- SISPER BAB 7 Sistem Pelayanan Di Kapal 2019Document124 pagesSISPER BAB 7 Sistem Pelayanan Di Kapal 2019Exi ShineNo ratings yet

- IG SysDocument59 pagesIG SysSergioi Indurain100% (1)

- Bilge Systems - Pumping and Piping Arrangements For Modern Cargo ShipsDocument5 pagesBilge Systems - Pumping and Piping Arrangements For Modern Cargo ShipsharimecNo ratings yet

- Rema Offshore CatalogueDocument44 pagesRema Offshore Cataloguemehdi6409100% (1)

- Design and Construction of LNG RegasificDocument12 pagesDesign and Construction of LNG RegasificOusseini SidibeNo ratings yet

- Design of COW MachineDocument27 pagesDesign of COW MachineATT2016100% (1)

- Oil Tanker Cargo WorkDocument12 pagesOil Tanker Cargo WorkAshutosh Singh100% (4)

- OUTDATED-AQUARIUS EC Case Study 082012 Hi ResDocument2 pagesOUTDATED-AQUARIUS EC Case Study 082012 Hi ResÇağlayan TopNo ratings yet

- Cargo Handling 5Document21 pagesCargo Handling 5LilCent MmanuelNo ratings yet

- B - 9.11.2. Bulk Transfer Operations in PortDocument2 pagesB - 9.11.2. Bulk Transfer Operations in PortCesar Augusto Arias CastroNo ratings yet

- Basic Training For Oil and Chemical Tanker Cargo Operations (Btoctco)Document113 pagesBasic Training For Oil and Chemical Tanker Cargo Operations (Btoctco)Ashok Y100% (2)

- CSV Oil Transfer Procedures 2.0Document49 pagesCSV Oil Transfer Procedures 2.0heath.a.hulinNo ratings yet

- Under Water Activity GuideDocument9 pagesUnder Water Activity GuideKentDemeterioNo ratings yet

- Bilge Pumping SystemsDocument2 pagesBilge Pumping SystemsKhaing26No ratings yet

- HPC-02 Catalyst HandlingDocument7 pagesHPC-02 Catalyst HandlingCarolina Cortes VazquezNo ratings yet

- Floating Cranes UkDocument14 pagesFloating Cranes Ukrajumj66No ratings yet

- An Oil TankerDocument30 pagesAn Oil TankerNIKHIL JASWAL100% (4)

- Appendix A. Equipment Modification Design Study Summary AND Implementation of Equipment ModificationsDocument23 pagesAppendix A. Equipment Modification Design Study Summary AND Implementation of Equipment ModificationsZahir KhiraNo ratings yet

- PPR 3-18-1 - Clarification On Regulation 36 of MARPOL Annex I For Categorizing Offshore Terminal (Singl... (OCIMF)Document7 pagesPPR 3-18-1 - Clarification On Regulation 36 of MARPOL Annex I For Categorizing Offshore Terminal (Singl... (OCIMF)Levan NarakidzeNo ratings yet

- Dictionary of Marine TechnologyDocument13 pagesDictionary of Marine TechnologySurya YuwardanaNo ratings yet

- Decommissioningand Inspectionof Ammonia Storage TankDocument11 pagesDecommissioningand Inspectionof Ammonia Storage TankVrbank KrabNo ratings yet

- Spe 3349 MsDocument8 pagesSpe 3349 MswillNo ratings yet

- What Is Cofferdam On ShipsDocument6 pagesWhat Is Cofferdam On ShipsGiorgi KandelakiNo ratings yet

- Hazard Identification and Assessment ForDocument4 pagesHazard Identification and Assessment Forzn8f477bv4No ratings yet

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- Structural Design of Drydock Frontage Dredging SystemDocument37 pagesStructural Design of Drydock Frontage Dredging SystemSasi PraveenNo ratings yet

- Oil and GasDocument16 pagesOil and GaspietrofracassiNo ratings yet

- Compiled byDocument8 pagesCompiled byJaner James Jamera JalecoNo ratings yet

- VOC Recovery Leaflet 09 - 2012 ENGDocument2 pagesVOC Recovery Leaflet 09 - 2012 ENGd.sologubovNo ratings yet

- Bilge Pump - SOLAS Regulations For Merchant ShipsDocument2 pagesBilge Pump - SOLAS Regulations For Merchant ShipssimNo ratings yet

- Workover Operations PDFDocument13 pagesWorkover Operations PDFterusunduhNo ratings yet

- Oil & Gas HandbookDocument170 pagesOil & Gas HandbookRagh100% (11)

- CH 04 Fittings On Ballast & Other TanksDocument10 pagesCH 04 Fittings On Ballast & Other TanksAmit PandeyNo ratings yet

- Bilge and Ballast Systems For General Cargo ShipsDocument5 pagesBilge and Ballast Systems For General Cargo ShipsAngielo U. ComiaNo ratings yet

- Offshore Engineering For Structural EngineersDocument43 pagesOffshore Engineering For Structural Engineerskunlef91% (11)

- FERASDocument55 pagesFERASFeras SalmanNo ratings yet

- Collision ValveDocument7 pagesCollision ValveInan AkdoganNo ratings yet

- Cargo Conditioning, Reliquefaction and Boil-Off Control Requirement For A Liquefied Gas CarrierDocument7 pagesCargo Conditioning, Reliquefaction and Boil-Off Control Requirement For A Liquefied Gas Carrierarlucky5459No ratings yet

- LPG PracticeDocument91 pagesLPG PracticeКирилл Винокуров100% (14)

- Stern Tube Oil Pollution - FactsDocument28 pagesStern Tube Oil Pollution - Factsswapneel_kulkarni100% (2)

- The Ultimate Guide To Cargo Operations For TankersDocument87 pagesThe Ultimate Guide To Cargo Operations For TankersAndis OrravsNo ratings yet

- DSV RoyalIHCSeven Atlantic HSBDocument6 pagesDSV RoyalIHCSeven Atlantic HSBJorge Ricardo AlcivarNo ratings yet

- Offshore StructureDocument8 pagesOffshore StructureTHANGAVELU SIVAKUMARNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Speech Emotions Recognition Using Machine LearningDocument5 pagesSpeech Emotions Recognition Using Machine LearningAditya KumarNo ratings yet

- Datasheet-HD330 20190627Document2 pagesDatasheet-HD330 20190627Marcelo FerroNo ratings yet

- Strengths and Weaknesses of Railway TransportDocument41 pagesStrengths and Weaknesses of Railway Transportbakute12367% (3)

- Mediaandinformationliteracymil Visualinformationandmediapart3 170910121157Document33 pagesMediaandinformationliteracymil Visualinformationandmediapart3 170910121157Anonymous xagGSIdNo ratings yet

- Openvpn Guide Over HttpsDocument18 pagesOpenvpn Guide Over HttpsJust IoNo ratings yet

- Managing Assets and Asset Information in Maximo TRMDocument30 pagesManaging Assets and Asset Information in Maximo TRMratna dwiNo ratings yet

- VLAN BasicsDocument18 pagesVLAN Basicssatyvan2003No ratings yet

- Con Rod TorqueDocument3 pagesCon Rod TorqueJerson T. AltovarNo ratings yet

- Presentation TCSDocument15 pagesPresentation TCSDibyajyoti MohantyNo ratings yet

- AUTOSAR SWS CANTransportLayerDocument96 pagesAUTOSAR SWS CANTransportLayerdinhquangcdtbkNo ratings yet

- Handbook - Warranty CoverageDocument10 pagesHandbook - Warranty Coveragedeepaknagar981No ratings yet

- If You Want To Save The Environment Imperatives Esl WorksheetDocument2 pagesIf You Want To Save The Environment Imperatives Esl WorksheetIya TemiNo ratings yet

- Strong PasswordDocument2 pagesStrong PasswordluciangeNo ratings yet

- DrdoDocument21 pagesDrdoANMOLNo ratings yet

- Voltage Frequency Control and SynchronizationDocument24 pagesVoltage Frequency Control and SynchronizationKashan Ali100% (2)

- Design Patterns in ReactDocument17 pagesDesign Patterns in ReactMohtasim KhanNo ratings yet

- MikroTik Loop Protect PDFDocument8 pagesMikroTik Loop Protect PDFHendra LinNo ratings yet

- Block Diagram Supply 37"Document37 pagesBlock Diagram Supply 37"OMARY MWAKAJE100% (1)

- Vf160 Owners ManualDocument154 pagesVf160 Owners ManualQiuvoNo ratings yet

- 3D Formats White PaperDocument24 pages3D Formats White PaperRobin WeiNo ratings yet

- Mobius Institute Vibration Brochure AlliedDocument12 pagesMobius Institute Vibration Brochure AlliedIslam BirgeNo ratings yet

- AERO Q307 Article4Document6 pagesAERO Q307 Article4AhmddhbNo ratings yet

- SPAD346Document178 pagesSPAD346ysohail78No ratings yet

- PLMH Notes PDFDocument78 pagesPLMH Notes PDFRossi AghdaNo ratings yet

- Aimcat 1705Document38 pagesAimcat 1705Swastik MahapatraNo ratings yet

FPSO Cargo Liquid Handling Net

FPSO Cargo Liquid Handling Net

Uploaded by

Francisco CuevasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FPSO Cargo Liquid Handling Net

FPSO Cargo Liquid Handling Net

Uploaded by

Francisco CuevasCopyright:

Available Formats

LEISTRITZ PUMPEN GMBH

Leistritz Screw Pumps & Systems

Cargo and

Liquid

Handling

tanker_2011.indd 1 26.07.12 13:23

Leistritz Screw Pumps and Systems

Leistritz Pumpen GmbH

Leistritz Pumpen GmbH with its headquarters in Nuremberg/Germany has been producing Screw Pumps since

1924. The first Leistritz Screw Pump was developed by Paul Leistritz as Main Lube Oil Pump for bearings of Steam

Turbine Generator Sets.

With the worldwide largest product range of Twin, Triple and Five Screw Pumps, Leistritz offers today complete

pump packages for a variety of applications.

Latest technology in combination with strictly controlled quality is the basis for the globally recognized efficiency

and reliability of Leistritz Screw Pumps.

The testing of the pumps through all well known classification societies as ABS, BV, DNV, GL, LRS, RINA and others

is made on Leistritz test fields to generate contribution to international shipping safety and maritime regulation.

Asphalt Carrier Chemical and Oil Tanker

Pages 4-5 Pages 6-7

tanker_2011.indd 2 26.07.12 13:23

Cargo and Liquid Handling

FPSO FPSO

r Leistritz Cargo Control

Dehydrating System Produced Water

Page 8 Page 9 Pages 10-11

Tankers for Oil, Refined Products, Chemicals and Asphalt

The transport of liquid cargos at sea is done by different types of tankers depend-

ing on the nature of the cargo and how it can be transferred and off-loaded safely

and efficiently. The pumps required have to be selected for most efficient opera-

tions taking into account pumping rate at different viscosities, stripping of tanks

and flow lines and offering the best environmental together with safe service.

The reliability of Leistritz Screw Pumps provides the optimum pumping solution for

most types of liquid cargo.

FPSO and Produced Water

The offshore oil and gas industry uses Floating Production, Storage and Off-load-

ing (FPSO) vessels in order to process and store gas or oil until it can be unloaded

onto tankers or forwarded through a pipeline. FPSOs are very flexible and cost ef-

fective since they can also be used in deepwater locations without installing long-

distance seabed pipelines.

During oil production not only crude oil is pumped but also produced water. The

main elements of produced water are dispersed oil, chemicals resulting from treat-

ment, salts and radioactive elements from minerals and heavy metals. For that

reason all medium wetted parts of the Leistritz Screw Pumps are built of special

materials in order to prevent pitting corrosion.

Leistritz Screw Pumps are responsible for boosting the produced water into a hydro

cyclone where the remaining oil and sand will be extracted.

tanker_2011.indd 3 26.07.12 13:23

Asphalt Carrier

Dry Installation Submerged Installation

simplified illustration

Asphalt Heat Exchanger A Slop Tank (installed at port side)

B Slop Tank (installed at port side)

Filling Line Leistritz Sealing System

C Connecting Manifold

Discharge Pipe Line Leistritz Variable Frequency Converter D Connecting Manifold

Suction Pipe Line Leistritz Cargohandling Pump E Cargo Tank

Valve Dry Installation F Cargo Tank

1

G Cargo Tank

Check Valve 2 Submerged Installation

H Cargo Tank

Dry Installation

1.1 Leistritz Screw Pumps as Cargo Pumps for Asphalt Carrier

The cargo (asphalt) had been loaded into the tanks of the asphalt carrier at the tank terminal before

transport. Leistritz Screw Pumps are used mainly for unloading the cargo from the asphalt carrier at the arrival port.

Control of the trim and list of the ship can be done by transferring the cargo from tank to tank on board.

The Leistritz Screw Pumps (cargo pumps) will also be utilized as circulation pumps to keep the cargo

temperature or property under control during transportation of the highly viscous cargo. Arrangement with gas

tight bulkhead additionally available.

1.2 Stripping Pump

There is no seperate stripping pump installed on the asphalt carrier. The work of cargo and line stripping

will be done through the cargo pump as well.

1.3 Slop Tanks

The slop tanks are designed to collect any cargo rests after tank cleaning from the connecting manifolds or

pipes on the deck and spills.

4

tanker_2011.indd 4 26.07.12 13:23

Cargo Pumps in Dry Installation

or Vertical Submerged as

Deep Well Asphalt Cargo Pump

Cargo Loading and Unloading Pump L4 Side view with safety valve

Ex-Zone Non-Ex-Zone

Submerged Installation

2 Leistritz Screw Pumps as Deep Well Asphalt Cargo Pump

For unloading of the cargo products, Leistritz Screw Pumps can also be arranged as vertical submerged pump

inside the tank of the asphalt carrier. Cargo of all viscosities – from kerosene to asphalt – can be unloaded and

effectively stripped from tanks and suction lines. The pumps are designed as five-screw (or two-screw), single

flow pumps for high-capacity unloading and stripping. Drives are suitable as electrical- or hydraulic motor.

Top picture: Vertical “in-tank installation” of L5NT-Pumps

Right picture: Pump and assembly

5

tanker_2011.indd 5 26.07.12 13:23

Chemical and Oil Tanker

F

H

simplified illustration

Unloading Pipe Line 1 Cargo Pump A Cargo Tank Blending station

Unloading Pipe Line 2 Stripping Pump B Cargo Tank

Unloading Pipe Line C Cargo Tank

Unloading Pipe Line D Cargo Tanker & Slop Tank G Blender

Valve E Manifold H Hose Crane

F Manifold

tanker_2011.indd 6 26.07.12 13:23

Crude Oil, Fuel Oil (Diesel, HFO, Gasoil etc.)

Product Oil, Chemical and Molasses

Pumping System Additions

1 Cargo Pump

All different fluids from low viscosity diesel oil to high viscosity crude oil

or molasses are handled with Leistritz Screw Pumps. The design prin-

ciple and operation of these pumps ensure a very low noise level and

almost pulsation free discharge.

1 Cargo Pump L4N

2 Stripping Pump

All different fluids from diesel oil to crude oil or molasses are handled

with Leistritz Screw Pumps. Good suction ability and capability to empty

the tank, manifolds and lines.

2 Stripping Pump L4N

Special Applications: Bunkering Tanker

Leistritz Screw Pumps can handle the wide changes of the viscosity in

bunkering refueller tanker equipped with blending station.

Viscosity ranges from 1 to 2000 cSt are possible without additional hea-

ting system.

Frequency Converter Cabinet

Pumping System adders available

With the use of frequency controlled motors and nearly linear relation

of speed and flow rate can be adjusted easily by changing the speed

of the pump. Frequency convertor with air cooling or water cooling are

available.

For changes of the viscosity and temperature, Leistritz offers a PLC to

automatically adjust the speed of the pump.

As alternative, Leistritz Screw Pumps can be driven by hydraulic motors.

Gastight Bulkhead Seal

For pump room installation Leistritz offers a gastight bulkhead penet-

ration seal (with type approval) allowing the motor to be installed in a

non-hazardous area.

Available materials for pump casings are cast iron, nodular cast iron, cast

steel, bronze and stainless steel for handing all different kind of fluids.

Control apparatus mounted in Cargo room

tanker_2011.indd 7 26.07.12 13:23

FPSO - Dehydrating

Selection of material for wetted parts of Leistritz Screw Pumps for Produced Water Treatments

Chloride Content of Water

description chloride content (PPM x 1000)

freshwater +/- 1 1.4462

saline water 1-25

seawater 25-50

salty water <50

1.4435

In order to select the optimal pump material, it is ne-

cessary to know the chloride content of the produced

water.

The influence on critical temperature for initiation of

pitting (CTP) for different rust-resistent steels in chlo-

ride solutions is mentioned in the adjoining diagram.

fresh water brakish/saline/salty water seawater/salty water

*ppm = parts per million (e.g. 1ppm = 1 part oil in 1 million parts water)

Electric Dehydrating System

From produced

water system

Electric

Dehydrator

To produced

water system

simplified illustration

Crude Oil Heat Exchanger 1 Leistritz Dehydrating Pump A Oil Well

Mixture of Water & Oil Filter 2 Leistritz Forwarding Pump B Settling Tank

Water (Oil more than 2000 ppm) C Storage Tank

Water (Oil less than 2000 ppm)

Oil (Water less than 0,5 % by volume)

tanker_2011.indd 8 26.07.12 13:23

FPSO - Produced Water

Produced Water System

4 5

Offshore

Plattform simplified illustration

Well Flow Stage Separator 3 Produced Water Pump A Produced Water Tank

Oily Water Electric Dehydrator 4 Electric Dehydrator Feed Pump B Crude Oil Tank

Crude Oil 5 Crude Oil Cargo/Shipping Pump

1 Leistritz Dehydrating Pump

One method used to separate water from oil in offshore oil fields is the principle of electrostatic separation.

Leistritz Dehydrating Pumps, series L4, are used for the supply of the electrostatic separator.

The water content of crude oil is a very important parameter that characterizes the grade or quality of the crude oil. In

general a water content (BSW) of 0,2 % to 0,5 % by volume is considered as acceptable.

The small water drops in crude oil are getting seperated in a strong electric field. Cathods and anods attract small

water drops in order to form bigger ones. This procedure enables an easily water separation from crude oil.

2 Leistritz Forwarding Pump

After the electrostatic separation Leistritz Triple Screw Pumps, series L3, are used for transferring oil from the settling

tank to the storage tank in the FPSO vessel.

3 Leistritz Produced Water Booster Pump

Formation water or produced water are usually produced along with oil

and gas from a well or well cluster. The produced water is separated

and treated to minimize the oil and solids content. Leistritz L4 Pumps are

used to boost high pressure produced water injection pumps for pressu-

re maintenance of the reservoirs.

3 Produced Water Pump L4NG

4 Leistritz Electric Dehydrator Feed Pump

As boosting equipment, Leistritz L4 Pumps will transfer oil from the first

stage separator to the electrostatic Dehydrator. Two Pumps shall run in

parallel, one standby. Leistritz L4 Pumps will be part of the process treat-

ment module (FPSO deck).

4 Electric Dehydrator Feed Pump L4

5 Leistritz Crude Oil Cargo/Shipping Pump

Leistritz L4 Pumps will transfer the crude oil from the crude oil tank to the

Oil Tanker. Low NPSH reqirements and reliable flow, free of turbulence

are the major advantage for Leistritz L4 Pumps.

9

5 Leistritz Crude Oil Cargo/Shipping Pump L4NG

tanker_2011.indd 9 26.07.12 13:23

Leistritz Cargo Control

Electro-hydraulic Control System

The Independent load control of cargo pumps and side thruster con-

nected to main close loop hydraulic system is generally arranged both Ex d/Ex de Ex d/Ex i

remotely and locally.

The Cargo Pumping System is controlled by a Programmable Logic Seal/Lube Oil Sy

Heating

Controller (PLC) installed inside the control panel. The PLC is pro- 4 x Flow switch

grammed by HHI and provides the logic for safe operation and easy

maintenance of the control system Seal Oil Pump 1 x Pressure Tran

The control panel contains a potentiometer and pressure gauge for 1 x Level Switch

each pump, for stepless independent load control. Electrical connec- Lube Oil Pump 2 x Temp. Transm

tions run between the control panel and a proportional valve/amplifier

located in a safe area, where the electronic control signals are trans-

Cooler

formed into hydraulic signals.

Only hydraulic pilot lines run between the proportional valve/amplifier

and the individual pumps. This control system can be interfaced to

any central ship computerizing system.

Control Panel

Start/ Stop

ESD

Speed up/down

Operator Panel

(optional )

10

tanker_2011.indd 10 26.07.12 13:23

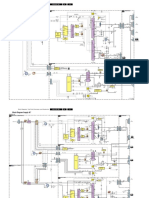

Leistritz Cargo Control

Ex-Zone

Ex d/Ex i Ex d/Ex e Ex d/Ex i Ex d/Ex de

Pump Motor

Seal/Lube Oil System Local Control

Panel

x Flow switch

Start, Stop,

x Pressure Transmitter ESD

x Level Switch

x Temp. Transmitter 2 x Bearing Temp. Transmitter

1 x Medium Temp. Transmitter

1 x Vibration Sensor

Junction Box

Ex d/Ex e

Non-Ex-Zone

PLC Based ( Cabinet )

VFD ( Cabinet )

Control Panel

Control Panel

Power Supply Power Supply

Customer Customer

simplified illustration

11

tanker_2011.indd 11 26.07.12 13:23

Leistritz Screw Pump Programm

Series Use for Leistritz Screw Maximal Performance Data

Pump Capacity Differential Viscosity Pumping

Pressure Temperature

L2 Low pressure duty, suit- 900 m3/h 16 bar 100,000 cSt 280°C

able for transport of light [3,960 gpm] [232 psi] [536°F]

abrasive and corrosive,

high or low viscous fluids

with poor or good lubricity.

L3N Low pressure duty, suit- 700 m3/h 16 bar 15,000 cSt 180°C

able for transport of non [3,100 gpm] [232 psi] [356°F]

abrasive lubricating fluids.

L3M Medium pressure duty, 300 m3/h 80 bar 10,000 cSt 280°C

suitable for transport of [1,320 gpm] [1,160 psi] [536°F]

non abrasive lubricating

fluids.

L3H High pressure duty, suit- 200 m3/h 160 bar 10,000 cSt 280°C

able for transport of non [880 gpm] [2,320 psi] [536°F]

abrasive lubricating fluids.

L3V/U Ultra high pressure duty 180 m3/h 280 bar 1,000 cSt 280°C

suitable for transport of [792 gpm] [4,060 psi] [536°F]

light abrasive and corro-

sive, high or low viscous

fluids with poor or good

lubricity.

L4 Low, medium and high 5,000 m3/h 150 bar 150,000 cSt 350°C

pressure duty, suitable [22,000 gpm] [2,175 psi] [662°F]

for transport of abrasive/

non abrasive, corrosive/

non corrosive, lubricat-

ing/non lubricating, high

or low viscous fluids.

L5 Low pressure duty, suit- 1,700 m3/h 10 bar 100,000 cSt 280°C

able for transport of light [7,500 gpm] [145 psi] [536°F]

abrasive and corrosive,

high or low viscous fluids

with poor or good lubricity.

1.2 - 44 e 07/12 2‘ tü

LEISTRITZ PUMPEN GMBH LEISTRITZ ITALIA SRL LEISTRITZ CORPORATION

Markgrafenstrasse 29-39 Via dei Fontanili, 26 165 Chestnut Street

D-90459 Nuremberg I-20141 Milan USA-Allendale, NJ 07401

Germany Italy USA

Phone: +49 (0)911/4306 - 0 Phone: +39 02 84477 451 Phone: +1 201 934 8262

Fax: +49 (0)911/4306 - 490 +39 02 84477 505 Fax: +1 201 934 8266

E-Mail: pumps@leistritz.com Fax: +39 02 84477 444 E-Mail: staff@leistritzcorp.com

12 Internet: www.leistritz.com E-Mail: pompeitalia@leistritz.com

tanker_2011.indd 12 26.07.12 13:23

You might also like

- Report On MiniprojectDocument28 pagesReport On Miniprojectrohith gombe100% (1)

- Test Automation Estimate Template: Automation Type Project NameDocument6 pagesTest Automation Estimate Template: Automation Type Project NameSantosh Prasad UlpiNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- How FPSO WorksDocument15 pagesHow FPSO WorksMajeed Rumani100% (3)

- DS 720 SDocument2 pagesDS 720 SIvan DumontNo ratings yet

- CST 8110 Quiz AnswersDocument8 pagesCST 8110 Quiz AnswershenNo ratings yet

- S&OP Wallace PresentationDocument91 pagesS&OP Wallace PresentationAutomation Boonlue100% (2)

- Slops Tanks WaterDocument6 pagesSlops Tanks WaterVasileios PantouvakisNo ratings yet

- LNG Receiving Terminals: BY CH - Satvika 16021A2545Document24 pagesLNG Receiving Terminals: BY CH - Satvika 16021A2545Ram Charan Konidela100% (1)

- OffShore Vessel GlossaryDocument21 pagesOffShore Vessel Glossarydaniel8iosif_178% (9)

- Liquid Bulk TerminalDocument21 pagesLiquid Bulk TerminalPaola Baleta Medina100% (1)

- FPSO-Bow Mounted vs. Aft MountedDocument79 pagesFPSO-Bow Mounted vs. Aft Mountedcxb07164100% (3)

- What Is Bilge and Ballast System?Document3 pagesWhat Is Bilge and Ballast System?Emirson CentinoNo ratings yet

- What Is Bilge and Ballast System?Document3 pagesWhat Is Bilge and Ballast System?Emirson CentinoNo ratings yet

- Largest Property Portal: LPG Handling Other Gas Products Fire & Safety Emergency ResponseDocument4 pagesLargest Property Portal: LPG Handling Other Gas Products Fire & Safety Emergency ResponsePrasad RaviproluNo ratings yet

- Itmconf Cccar2022 03019Document5 pagesItmconf Cccar2022 03019Sumya Ben mahmoudNo ratings yet

- Slop Tank Design For Improved Load-On-TopDocument6 pagesSlop Tank Design For Improved Load-On-Topscm_2628No ratings yet

- Framo Cargo Pumping Systems BrochureDocument32 pagesFramo Cargo Pumping Systems BrochureFfej-Jeff DizonNo ratings yet

- SISPER BAB 7 Sistem Pelayanan Di Kapal 2019Document124 pagesSISPER BAB 7 Sistem Pelayanan Di Kapal 2019Exi ShineNo ratings yet

- IG SysDocument59 pagesIG SysSergioi Indurain100% (1)

- Bilge Systems - Pumping and Piping Arrangements For Modern Cargo ShipsDocument5 pagesBilge Systems - Pumping and Piping Arrangements For Modern Cargo ShipsharimecNo ratings yet

- Rema Offshore CatalogueDocument44 pagesRema Offshore Cataloguemehdi6409100% (1)

- Design and Construction of LNG RegasificDocument12 pagesDesign and Construction of LNG RegasificOusseini SidibeNo ratings yet

- Design of COW MachineDocument27 pagesDesign of COW MachineATT2016100% (1)

- Oil Tanker Cargo WorkDocument12 pagesOil Tanker Cargo WorkAshutosh Singh100% (4)

- OUTDATED-AQUARIUS EC Case Study 082012 Hi ResDocument2 pagesOUTDATED-AQUARIUS EC Case Study 082012 Hi ResÇağlayan TopNo ratings yet

- Cargo Handling 5Document21 pagesCargo Handling 5LilCent MmanuelNo ratings yet

- B - 9.11.2. Bulk Transfer Operations in PortDocument2 pagesB - 9.11.2. Bulk Transfer Operations in PortCesar Augusto Arias CastroNo ratings yet

- Basic Training For Oil and Chemical Tanker Cargo Operations (Btoctco)Document113 pagesBasic Training For Oil and Chemical Tanker Cargo Operations (Btoctco)Ashok Y100% (2)

- CSV Oil Transfer Procedures 2.0Document49 pagesCSV Oil Transfer Procedures 2.0heath.a.hulinNo ratings yet

- Under Water Activity GuideDocument9 pagesUnder Water Activity GuideKentDemeterioNo ratings yet

- Bilge Pumping SystemsDocument2 pagesBilge Pumping SystemsKhaing26No ratings yet

- HPC-02 Catalyst HandlingDocument7 pagesHPC-02 Catalyst HandlingCarolina Cortes VazquezNo ratings yet

- Floating Cranes UkDocument14 pagesFloating Cranes Ukrajumj66No ratings yet

- An Oil TankerDocument30 pagesAn Oil TankerNIKHIL JASWAL100% (4)

- Appendix A. Equipment Modification Design Study Summary AND Implementation of Equipment ModificationsDocument23 pagesAppendix A. Equipment Modification Design Study Summary AND Implementation of Equipment ModificationsZahir KhiraNo ratings yet

- PPR 3-18-1 - Clarification On Regulation 36 of MARPOL Annex I For Categorizing Offshore Terminal (Singl... (OCIMF)Document7 pagesPPR 3-18-1 - Clarification On Regulation 36 of MARPOL Annex I For Categorizing Offshore Terminal (Singl... (OCIMF)Levan NarakidzeNo ratings yet

- Dictionary of Marine TechnologyDocument13 pagesDictionary of Marine TechnologySurya YuwardanaNo ratings yet

- Decommissioningand Inspectionof Ammonia Storage TankDocument11 pagesDecommissioningand Inspectionof Ammonia Storage TankVrbank KrabNo ratings yet

- Spe 3349 MsDocument8 pagesSpe 3349 MswillNo ratings yet

- What Is Cofferdam On ShipsDocument6 pagesWhat Is Cofferdam On ShipsGiorgi KandelakiNo ratings yet

- Hazard Identification and Assessment ForDocument4 pagesHazard Identification and Assessment Forzn8f477bv4No ratings yet

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- Structural Design of Drydock Frontage Dredging SystemDocument37 pagesStructural Design of Drydock Frontage Dredging SystemSasi PraveenNo ratings yet

- Oil and GasDocument16 pagesOil and GaspietrofracassiNo ratings yet

- Compiled byDocument8 pagesCompiled byJaner James Jamera JalecoNo ratings yet

- VOC Recovery Leaflet 09 - 2012 ENGDocument2 pagesVOC Recovery Leaflet 09 - 2012 ENGd.sologubovNo ratings yet

- Bilge Pump - SOLAS Regulations For Merchant ShipsDocument2 pagesBilge Pump - SOLAS Regulations For Merchant ShipssimNo ratings yet

- Workover Operations PDFDocument13 pagesWorkover Operations PDFterusunduhNo ratings yet

- Oil & Gas HandbookDocument170 pagesOil & Gas HandbookRagh100% (11)

- CH 04 Fittings On Ballast & Other TanksDocument10 pagesCH 04 Fittings On Ballast & Other TanksAmit PandeyNo ratings yet

- Bilge and Ballast Systems For General Cargo ShipsDocument5 pagesBilge and Ballast Systems For General Cargo ShipsAngielo U. ComiaNo ratings yet

- Offshore Engineering For Structural EngineersDocument43 pagesOffshore Engineering For Structural Engineerskunlef91% (11)

- FERASDocument55 pagesFERASFeras SalmanNo ratings yet

- Collision ValveDocument7 pagesCollision ValveInan AkdoganNo ratings yet

- Cargo Conditioning, Reliquefaction and Boil-Off Control Requirement For A Liquefied Gas CarrierDocument7 pagesCargo Conditioning, Reliquefaction and Boil-Off Control Requirement For A Liquefied Gas Carrierarlucky5459No ratings yet

- LPG PracticeDocument91 pagesLPG PracticeКирилл Винокуров100% (14)

- Stern Tube Oil Pollution - FactsDocument28 pagesStern Tube Oil Pollution - Factsswapneel_kulkarni100% (2)

- The Ultimate Guide To Cargo Operations For TankersDocument87 pagesThe Ultimate Guide To Cargo Operations For TankersAndis OrravsNo ratings yet

- DSV RoyalIHCSeven Atlantic HSBDocument6 pagesDSV RoyalIHCSeven Atlantic HSBJorge Ricardo AlcivarNo ratings yet

- Offshore StructureDocument8 pagesOffshore StructureTHANGAVELU SIVAKUMARNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshFrom EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshNo ratings yet

- Speech Emotions Recognition Using Machine LearningDocument5 pagesSpeech Emotions Recognition Using Machine LearningAditya KumarNo ratings yet

- Datasheet-HD330 20190627Document2 pagesDatasheet-HD330 20190627Marcelo FerroNo ratings yet

- Strengths and Weaknesses of Railway TransportDocument41 pagesStrengths and Weaknesses of Railway Transportbakute12367% (3)

- Mediaandinformationliteracymil Visualinformationandmediapart3 170910121157Document33 pagesMediaandinformationliteracymil Visualinformationandmediapart3 170910121157Anonymous xagGSIdNo ratings yet

- Openvpn Guide Over HttpsDocument18 pagesOpenvpn Guide Over HttpsJust IoNo ratings yet

- Managing Assets and Asset Information in Maximo TRMDocument30 pagesManaging Assets and Asset Information in Maximo TRMratna dwiNo ratings yet

- VLAN BasicsDocument18 pagesVLAN Basicssatyvan2003No ratings yet

- Con Rod TorqueDocument3 pagesCon Rod TorqueJerson T. AltovarNo ratings yet

- Presentation TCSDocument15 pagesPresentation TCSDibyajyoti MohantyNo ratings yet

- AUTOSAR SWS CANTransportLayerDocument96 pagesAUTOSAR SWS CANTransportLayerdinhquangcdtbkNo ratings yet

- Handbook - Warranty CoverageDocument10 pagesHandbook - Warranty Coveragedeepaknagar981No ratings yet

- If You Want To Save The Environment Imperatives Esl WorksheetDocument2 pagesIf You Want To Save The Environment Imperatives Esl WorksheetIya TemiNo ratings yet

- Strong PasswordDocument2 pagesStrong PasswordluciangeNo ratings yet

- DrdoDocument21 pagesDrdoANMOLNo ratings yet

- Voltage Frequency Control and SynchronizationDocument24 pagesVoltage Frequency Control and SynchronizationKashan Ali100% (2)

- Design Patterns in ReactDocument17 pagesDesign Patterns in ReactMohtasim KhanNo ratings yet

- MikroTik Loop Protect PDFDocument8 pagesMikroTik Loop Protect PDFHendra LinNo ratings yet

- Block Diagram Supply 37"Document37 pagesBlock Diagram Supply 37"OMARY MWAKAJE100% (1)

- Vf160 Owners ManualDocument154 pagesVf160 Owners ManualQiuvoNo ratings yet

- 3D Formats White PaperDocument24 pages3D Formats White PaperRobin WeiNo ratings yet

- Mobius Institute Vibration Brochure AlliedDocument12 pagesMobius Institute Vibration Brochure AlliedIslam BirgeNo ratings yet

- AERO Q307 Article4Document6 pagesAERO Q307 Article4AhmddhbNo ratings yet

- SPAD346Document178 pagesSPAD346ysohail78No ratings yet

- PLMH Notes PDFDocument78 pagesPLMH Notes PDFRossi AghdaNo ratings yet

- Aimcat 1705Document38 pagesAimcat 1705Swastik MahapatraNo ratings yet