Professional Documents

Culture Documents

VibrationTrainingActivityBooklet CatII Mobius

VibrationTrainingActivityBooklet CatII Mobius

Uploaded by

Nelver Daniel Sánchez BarbaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

VibrationTrainingActivityBooklet CatII Mobius

VibrationTrainingActivityBooklet CatII Mobius

Uploaded by

Nelver Daniel Sánchez BarbaCopyright:

Available Formats

Vibration Training

Activity Booklet

-- CATEGORY II --

Page 1 of 49 Mobius Institute Activity Booklet

TABLE OF CONTENTS

TABLE OF CONTENTS.........................................................................................................2

MAINTENANCE PRACTICES.................................................................................................3

VIBRATION FUNDAMENTALS...............................................................................................5

VIBRATION FUNDAMENTALS: AVD.......................................................................................7

VIBRATION FUNDAMENTALS: PHASE...................................................................................9

VIBRATION FUNDAMENTALS: SPECTRA..............................................................................11

VIBRATION FORCING FREQUENCIES..................................................................................13

UNDERSTANDING SIGNALS..............................................................................................18

DATA COLLECTION: TRANSDUCER SELECTION....................................................................22

DATA COLLECTION: SENSOR LOCATION & MOUNTING.........................................................26

DATA COLLECTION: RECOGNIZING BAD DATA....................................................................28

DATA COLLECTION: PHASE...............................................................................................29

SIGNAL PROCESSING.......................................................................................................30

WINDOWING..................................................................................................................33

AVERAGING....................................................................................................................34

DIAGNOSING MACHINE FAULTS........................................................................................36

DIAGNOSING IMBALANCE.................................................................................................39

DIAGNOSING ECCENTRICITY............................................................................................41

DIAGNOSING MISALIGNMENT...........................................................................................41

DIAGNOSING BENT SHAFT...............................................................................................43

DIAGNOSING LOOSENESS................................................................................................43

DIAGNOSING RESONANCE................................................................................................44

DIAGNOSING BEARING FAULTS.........................................................................................44

DIAGNOSING ELECTRIC MOTORS......................................................................................46

Page 2 of 49 Mobius Institute Activity Booklet

GEARBOX ANALYSIS........................................................................................................48

BELTS............................................................................................................................49

MAINTENANCE PRACTICES

[1] Predictive maintenance involves scheduled maintenance, based on long-term expected risk of failure.

A. True

B. False

[2] Proactive maintenance...

A. is only implemented when you have a lull in maintenance activity.

B. involves precision balancing and alignment.

C. negates the need for condition monitoring.

D. is something that sounds great, but nobody actually does it.

[3] Condition monitoring is the same as predictive maintenance

A. True

B. False

[4] All machines should be a part of a condition monitoring program.

A. True

B. False

[5] When we simply react to machine failures, we are practicing...

A. Breakdown maintenance

B. Preventive maintenance

C. Predictive maintenance

[6] Preventive maintenance often results in unnecessary overhauls.

A. True

B. False

[7] Which maintenance philosophy can actually reduce plant reliability compared with doing nothing?

A. Breakdown maintenance

B. Predictive maintenance

C. Preventive maintenance

D. Proactive maintenance

Page 3 of 49 Mobius Institute Activity Booklet

[8] Which maintenance philosophy includes laser alignment & precision balancing as key elements?

A. Breakdown maintenance

B. Predictive maintenance

C. Preventive maintenance

D. Proactive maintenance

[9] Which maintenance philosophy is also known as condition based maintenance?

A. Breakdown maintenance

B. Predictive maintenance

C. Preventive maintenance

D. Proactive maintenance

[10] Which maintenance philosophy can result in the highest commercial loss?

A. Breakdown maintenance

B. Predictive maintenance

C. Preventive maintenance

D. Proactive maintenance

[11] Which maintenance philosophy would result in lower spare parts cost?

A. Breakdown maintenance

B. Predictive maintenance

C. Preventive maintenance

[12] Why do we perform condition monitoring and predictive maintenance?

A. To reduce the production and maintenance costs.

B. So that we understand the current health of our machinery.

C. Because visiting the machine reveals key information.

D. All of the above

[13] What is 'secondary damage'?

A. The damage done to a machine when failure occurs.

B. The downtime to the machine.

C. The reduction of product quality due to high vibration.

[14] Does condition monitoring by itself increase reliability?

A. No it does not.

B. Yes it does.

Page 4 of 49 Mobius Institute Activity Booklet

VIBRATION FUNDAMENTALS

[1] The RMS level is...

A. Half the peak level

B. Twice the peak level

C. 0.707 times the peak level (for a pure sinusoid)

D. Half the peak-to-peak level

[2] Circle the RMS level on this chart.

[3] True or False: The peak-peak level is always twice the peak level.

A. True

B. False

[4] Write down the relationship between frequency and period:

___Frequency = 1 / Period____________________________

Page 5 of 49 Mobius Institute Activity Booklet

[5] Compute the frequency of the sine wave below? 5 Hz

[6] Is the rms level of this vibration signal equal to 0.707 times the peak level?

A. Yes

B. No

Page 6 of 49 Mobius Institute Activity Booklet

VIBRATION FUNDAMENTALS: AVD

[1] The measurement that relates to the position of the shaft in the journal/sleeve bearing is...

A. Displacement

B. Velocity

C. Acceleration

[2] What is a “proximity probe” used to measure?

A. Displacement

B. Velocity

C. Acceleration

[3] The measurement that relates to the rate of change of the vertical movement of the shaft in the bearing

is...

A. Displacement

B. Velocity

C. Acceleration

[4] The measurement that is proportional to the rate of change of velocity is...

A. Displacement

B. Velocity

C. Acceleration

[5] The measurement that is proportional to the stress of the shaft on the bearing is...

A. Displacement

B. Velocity

C. Acceleration

[6] The measurement that is proportional to the fatigue experienced by the shaft and bearing is...

A. Displacement

B. Velocity

C. Acceleration

[7] The measurement that is proportional to the force of the shaft on the bearing is...

A. Displacement

B. Velocity

C. Acceleration

Page 7 of 49 Mobius Institute Activity Booklet

[8] The measurement units that are most sensitive to low frequency vibration from low speed machines

is...

A. Displacement

B. Velocity

C. Acceleration

[9] Which two vibration measures are 180 degrees out of phase?

A. Displacement and Acceleration

B. Velocity and Acceleration

C. Displacement and Velocity

D. All of the above

[10] A spectrum has a peak at 100 Hz of 5 mm/sec rms. Calculate the corresponding vibration levels in the

units listed below:

5 / 25.4 / 0.707 = 0.278 in/sec pk

5 x (100 x 60) / 93712 = 0.32 G’s rms

27009 x 5 / (100 x 60) = 22.5 Microns (um) pk-pk

[11] It is understood that vibration severity is proportional to the velocity value. Which of the following

vibration levels is the most severe? (They were all recorded at the running-speed peak of a 1485 RPM

motor.)

A. 10 mm/sec rms

B. 0.51 in/sec pk 0.51 x 25.4 x 0.707 = 9.16 mm/sec rms

C. 120 um pk-pk 120 x 1485 / 27009 = 6.6 mm/sec rms

D. 0.12 g’s rms 0.12 x 93712 / 1485 = 7.57 mm/sec rms

Page 8 of 49 Mobius Institute Activity Booklet

VIBRATION FUNDAMENTALS: PHASE

[1] Phase is measured in units of...

A. seconds

B. RPM

C. degrees

[2] What is the phase relationship between the following two signals?

A. In phase

B. 180 degrees out of phase

C. 90 degrees out of phase

[3] If two signals are in-phase...

A. they reach their maximums (peaks) at the same time

B. one will reach its peak when the other is zero

C. one will reach its minimum when the other reaches its maximum

[4] If two signals are 180 degrees out-of-phase...

A. they reach their maximums (peaks) at the same time

B. one will reach its peak when the other is zero

C. one will reach its minimum when the other reaches its maximum

Page 9 of 49 Mobius Institute Activity Booklet

[5] If signal 1 leads signal 2...

A. signal 1 is higher in amplitude than signal 2

B. signal 1 finishes before signal 2

C. signal 1 reaches its peak BEFORE signal 2 reaches its peak

D. signal 1 reaches its peak AFTER signal 2 reaches its peak

[6] Does signal A lead or lag signal B? LEAD

Page 10 of 49 Mobius Institute Activity Booklet

VIBRATION FUNDAMENTALS: SPECTRA

[1] If the spectrum is dominated by one very large peak...

A. it is time to stay clear of the machine!

B. the waveform is probably quite sinusoidal

C. the machine is out of balance

[2] If a waveform is a pure sine wave (a single frequency), how many peaks will be in the spectrum?

A. Just one

B. Two

C. Cannot tell from this information

[3] Which statement is true?

A. Orders of running speed are measured in units of 'X'.

B. CPM and Orders are the same when dealing with 2-pole motors.

C. Orders are only used for variable speed machines.

[4] If the running speed of a machine is 100 CPM, and there is peak at “8X”, calculate the frequency of

that peak: ___800______ CPM

[5] If the 10X peak is at 2500 CPM, the running speed of the machine is __250____ CPM

[6] Sketch: Draw a 2 Hz sine wave with an amplitude of 1 mm/sec. Draw the corresponding spectrum on the

chart below in mm/sec rms. Annotate the y-axis (show the min and max value on the graph scale.)

Page 11 of 49 Mobius Institute Activity Booklet

[7] What is the amplitude of the peak in the spectrum you have sketched (state the units)?

_____0.707 mm/sec rms___________

[8] The following “order normalized” spectrum came from a motor driving a pump at 1485 RPM via a

flexible coupling. Calculate the frequency of the peak at 6X: ____ 8910 _______ CPM

[9] Circle A, B, C, and/or D next to each of the following regions of the spectrum:

Synchronous A B C D

Sub-Synchronous A B C D

Non-Synchronous A B C D

Page 12 of 49 Mobius Institute Activity Booklet

VIBRATION FORCING FREQUENCIES

Chart courtesy DLI Engineering (ABB)

Page 13 of 49 Mobius Institute Activity Booklet

[1] If the following compressor ran at 1485 CPM, and there are 12 vanes on the impeller, calculate the

compressor vane-pass rate: ___ 12 x 1485 = 17,820 _____ CPM

[2] If the following fan had 10 blades, and the motor RPM was 1485, calculate the fan blade-pass forcing

frequency ___10 x 1485 = 14,850_____ CPM

[3] If there were 10 vanes on the following compressor, and the compressor vane rate was 29,700 CPM,

calculate the RPM of the compressor __29700 / 10 = 2,970_____ CPM

Page 14 of 49 Mobius Institute Activity Booklet

[4] If the pulley on this motor had a 100 mm diameter, and the pulley on the pump had a

350 mm diameter, and the motor speed was 2970 RPM, calculate the speed

of the pump: ___2970 x 100 / 350 = 848.6_____ CPM

[5] If the pulley on the 1460 RPM motor had a diameter of 200 mm, and the pulley on the fan had a 120

mm diameter, and the length of the belt is 1500 mm, and there were 10 blades on the fan, calculate

the following frequencies:

Fan shaft speed: ___1460 x 200 / 120 = 2,433.3___________ CPM

Belt rate frequency: __611.6_________ CPM

Fan blade pass rate: ___1460 x 200 / 120 x 10 = 24,333.3________ CPM

Note: Look in the Reference Guide for the formula for the belt rate frequency (sheave = pulley)

Page 15 of 49 Mobius Institute Activity Booklet

[6] If a compressor was driven by a gearbox with a 1:2 ratio, and the motor speed was 1500 CPM,

calculate the compressor speed: __1500 x 2 = 3000______ CPM

[7] If a compressor was driven by a gearbox with a 1:2 ratio, and the compressor speed was 1200 CPM,

calculate the motor speed ___1200 / 2 = 600_____ CPM

[8] If the motor speed was 1480 RPM, and the input gear of the gearbox had 39 teeth, and the pinion had

15 teeth, and the compressor had 12 vanes, provide the following details:

Gearmesh frequency: ___1480 x 39 = 57,720 _________ CPM

Compressor speed: ___1480 x 39 / 15 = 3,848 _________ CPM

Compressor vane pass rate: __3848 x 12 = 46,176 __________ CPM

[9] If a gearbox was quoted as having the speed ratios 1:8, which statement is true? **

A. If the output speed was 8000 CPM, the input speed must be 1000 CPM.

B. If the intermediate shaft turned at 1000 CPM, the motor turns at 3000 CPM.

C. If the input shaft turns at 8000 CPM, the output shaft turns at 1000 CPM.

Page 16 of 49 Mobius Institute Activity Booklet

D. It is a double reduction gearbox.

[10] The two-stage gearbox below has the number of teeth on each gear and pinion as shown. From this

information, and the fact that the motor speed is 1450 RPM, calculate the following information:

Stage one gearmesh frequency: ___ 1450 x 24 = 34,800 __________ CPM

Speed of intermediate shaft: ____1450 x 24 / 76 = 458___________ CPM

Stage two gearmesh frequency: ___1450 x 24 / 76 x 32 = 14,653_______ CPM

Speed of output shaft: ____1450 x 24 / 76 x 32 / 89 = 165______ CPM

[11] If a bearing on a motor running at 1485 CPM had 8 balls, what would be the approximate BPFI and BPFO

frequencies?

BPFO ____0.4 x 8 x 1485 = 4752 ___ CPM BPFI ___ 0.6 x 8 x 1485 = 7128 ____ CPM

[12] A belt driven machine had a 100 mm diameter pulley on the motor and 300 mm diameter pulley on the

driven unit. The motor had a SKF 6203 bearing, and the driven unit had an FAG 6305 bearing.

Calculate the following fault frequencies; assume the motor speed is 2988 CPM:

Speed of the driven unit: ___2988 x 100 / 300 = 996 ________ CPM

SKF 6203 BPFI __2988 x 4.945 = 14,776 _________ CPM

FAG 6305 BPFO___2988 x 100 / 300 x 2.573 = 2,563 ______ CPM

Note: Use the Reference Center or iTeachMachineFaults to look up the bearing frequencies.

Page 17 of 49 Mobius Institute Activity Booklet

UNDERSTANDING SIGNALS

[1] Sketch: Imagine a machine that generates a 2 Hz signal of 2 mm/sec and a second 2 Hz signal of 1

mm/sec. There is 0 degrees phase angle between the two signals.

Draw the resultant time waveform and spectrum in mm/sec rms. Annotate the y-axis (show the min

and max value on the graph scale.)

(Notice the graph scale is 400 Hz, not 10 Hz)

Page 18 of 49 Mobius Institute Activity Booklet

[2] Question: What is the amplitude of the peak in the spectrum you have sketched (state the units)?

__ 2.121 mm/sec rms (3 x 0.707) _________________

[3] Sketch: Now imagine that the two signals were 180 degrees out of phase with each other. Draw the

resultant time waveform and spectrum in mm/sec rms. Annotate the y-axis (show the min and max

value on the graph scale.)

[4] Question: What is the amplitude of the peak in the spectrum you have sketched (state the units)?

___0.707 mm/sec rms (the two signals subtract) _________________

Page 19 of 49 Mobius Institute Activity Booklet

[5] Odd harmonics can best be described as...

A. Harmonics that are not evenly spaced.

B. Harmonics that everyone tries to avoid.

C. Harmonics at 1X, 3X, 5X, 7X, 9X, etc.

D. Harmonics at 3X, 7X, 11X, etc.

[6] A square wave signal will produce what kind of spectrum?

A. Quite an attractive spectrum.

B. A square looking spectrum.

C. A spectrum with peaks at 1X, 2X, 3X, 4X, 5X, etc.

D. A spectrum with peaks at 1X, 3X, 5X, etc.

[7] A clipped or ‘distorted’ signal will produce...

A. Half-order harmonics.

B. A series of harmonics: 1X, 2X, 3X, 4X, etc.

C. Odd harmonics.

D. Even harmonics.

[8] A transient may produce...

A. Half-order or other sub-harmonics.

B. A series of harmonics: 1X, 2X, 3X, 4X, etc.

C. Odd harmonics.

D. Even harmonics.

[9] Sub-harmonics can best be described as...

A. Same as normal harmonics, but half the size.

B. A series of evenly spaced peaks in the spectrum, starting at 0 CPM.

C. A series of fractional harmonics, for example ½X, ¼X.

[10] Amplitude Modulation can best be described as...

A. The periodic change in the frequency of a signal.

B. The sound a radio makes when it is not correctly tuned.

C. The periodic change in the amplitude of a signal

D. Harmonics that don't look quite right.

[11] If amplitude modulation is occurring you will likely see...

A. A series of evenly spaced peaks in the spectrum, centered around a single peak.

B. A series of harmonics, beginning at the carrier frequency.

C. Odd harmonics.

Page 20 of 49 Mobius Institute Activity Booklet

[12] If a signal of 200 Hz was changing in amplitude at a rate of 20 Hz, you would see...

A. A peak at 200 Hz, 400 Hz, 600 Hz, etc.

B. A peak at 200 Hz and 20 Hz.

C. Peaks at 180 Hz, 200 Hz and 220 Hz.

[13] The term 'beating' can best be described as...

A. What you do to your head when you can't solve a problem.

B. The throbbing sound you hear after you have been beating your head.

C. Two signals of similar frequency that mix together, moving in and out of phase with each other;

resulting in a ‘throbbing’ sound.

D. The phenomenon experienced where a shroud comes loose and rattles.

[14] Describe what you would hear if an electric motor generated signals at 99 Hz and 100 Hz

___1 Hz beat – a throbbing sound with a period of 1 second ______________________

__________________________________________________________________________

__________________________________________________________________________

Page 21 of 49 Mobius Institute Activity Booklet

DATA COLLECTION: TRANSDUCER SELECTION

[1] What is most important?

A. The size of your sensor.

B. Test repeatability.

C. The speed of the measurement.

D. The accuracy of your measurement.

[2] True or False: I can use the same sensor for all of my vibration tests.

A. True

B. False

[3] Which measure would use for low speed machines (if you were interested in the lower frequencies)?

A. Displacement

B. Velocity

C. Acceleration

[4] Which measure would use for high speed machines and higher frequencies?

A. Displacement

B. Velocity

C. Acceleration

[5] To convert from acceleration to velocity you need to...

A. Integrate the signal

B. Differentiate the signal

C. Multiply by the square root of 2

[6] True or False: Integration causes a change in phase of the measurement.

A. True

B. False

[7] When you integrate the signal (accel-vel) what happens to low frequency (<160 Hz) signals?

A. They are increased in amplitude

B. They are reduced in amplitude

C. The amplitude is not affected

[8] Why do we need a high pass filter?

A. To filter out noise in the signal which is caused by machine 'rumble'

B. To filter out electrical noise

Page 22 of 49 Mobius Institute Activity Booklet

C. To filter out the low frequency signals that are amplified during the integration process

Page 23 of 49 Mobius Institute Activity Booklet

[9] What type of sensor measures the relative movement between the shaft and bearing?

A. Displacement non-contact eddy current probe

B. Velocity sensor

C. Accelerometer

[10] What type of sensor involves a magnet and a coil?

A. Displacement non-contact eddy current probe

B. Velocity transducers

C. Accelerometer

[11] What is the difference between a charge-mode accelerometer and 'ICP' accelerometers?

A. Charge mode accelerometers require an external amplifier

B. The frequency response of an ICP accelerometer is far greater

C. ICP accelerometers are better suited to high-temperature applications

[12] A triaxial accelerometer is...

A. the sensor you use when you first wish to try axial measurements

B. an accelerometer that can measure three times as fast

C. an accelerometer package that combines three orthogonally mounted single-axis

accelerometers

[13] Which transducer is best suited to a machine tool application with very low vibration?

A. 10 mV/g

B. 100 mV/g

C. 1000 mV/g

[14] What would happen if you used a 10 mV/g sensor on the quiet machine tool?

A. The machine tool would appear to vibrate much more than it actually did

B. The voltage output would be small, and the amplitude resolution of data would be

unacceptable

C. The sensor would 'saturate' and the vibration data would be poor

[15] What would happen if you used a 1000 mV/g accelerometer on a noisy rock crusher?

A. Sparks would fly from the transducer leads

B. The data collector would overload and may be damaged

C. The sensor would 'saturate' and the vibration data would be poor

[16] True or False: The frequency response is the same regardless of the sensitivity.

A. True

Page 24 of 49 Mobius Institute Activity Booklet

B. False

Page 25 of 49 Mobius Institute Activity Booklet

DATA COLLECTION: SENSOR LOCATION & MOUNTING

[1] What is the most important factor in selecting the location for the sensor?

A. Good, clean contact with the machine

B. Located on a bearing house with a good mechanical transmission path

C. Good, safe access to the mounting location

D. All of the above

[2] What is the mechanical transmission path?

A. The path you take around the machines to perform the data collection route

B. The path the vibration takes between the source of vibration and the sensor

C. The vibration measured when testing gearboxes, fluid couplings and other transmission

components

[3] If you cannot access a suitable test location for the sensor you should...

A. find another machine to monitor - that one is too hard.

B. buy a longer 'stinger' so that you can reach in to the best location.

C. mount the sensor anywhere that it vibrates - it is better than nothing.

D. permanently mount a sensor, and connect it to a junction box.

[4] Circle the best transducer mounting point from the available options: A B C D

[5] Why should you not use 'stingers' (hand held probes) when collecting routine vibration data?

___ Poor high frequency response. Poor repeatability. ____________________________

______________________________________________________________________________

_____________________________________________________________________

Page 26 of 49 Mobius Institute Activity Booklet

______________________________________________________________________________

[6] What is repeatability?

A. The ability to perform the route in the same time every time

B. The ability to perform a test in exactly the same way every time

C. The ability to perform very accurate measurements

D. All of the above

[7] Which is the best method of mounting a sensor (the best frequency response)?

A. Stinger, or probe tip

B. Flat magnetic mount

C. Two-pole magnetic mount

D. Stud mount

[8] What are the benefits of mounting (or target) pads?

A. They show exactly where the sensor should be mounted

B. They provide a flat surface for the sensor

C. They are easy to clean (to remove debris)

D. All of the above

Page 27 of 49 Mobius Institute Activity Booklet

DATA COLLECTION: RECOGNIZING BAD DATA

[1] Describe the ‘ski-slope’ phenomenon: what does it look like, why does it occur (make at least three

suggestions), and what should you do if you see it during data collection?

__A mound in the spectrum that starts high at “0 Hz” and ramps down in amplitude________

______________________________________________________________________________

__Mechanical shock, thermal shock, ICP has not settled after being powered on, __________

__data collector electronics have not settled after a setting change, electrical/wiring fault, etc. __

_____________________________________________________________________

______________________________________________________________________________

_____________________________________________________________________

______________________________________________________________________________

______________________________________________________________________________

_____________________________________________________________________

______________________________________________________________________________

[2] When considering the vibration sensor, what is the settling time?

A. A setting on my data collector I have never understood

B. The time it takes the sensor to convert the entire vibration pattern.

C. The time it takes for the transducer to generate a stable output.

Page 28 of 49 Mobius Institute Activity Booklet

DATA COLLECTION: PHASE

[1] What should you do if you are comparing two phase measurements in the axial direction of the

machine?

___ Correct for transducer direction – add/subtract 180 if one transducer is pointing ________

____ in opposite direction. _______________________________________________________

[2] Name three methods used to collect phase readings:

_ Strobe, tachometer, two channel data collector (two accelerometers for cross channel phase) _

______________________________________________________________________________

_____________________________________________________________________

[3] Absolute phase is...

A. the phase difference between a point and an arbitrary reference.

B. the phase difference between two points on the machine

[4] What type of phase measurement is used when balancing?

A. Absolute phase

B. Relative phase

[5] What type of phase measurement is used when diagnosing typical machine faults?

A. Absolute phase

B. Relative phase

[6] True or False: A strobe should be used as a phase reference when balancing.

A. True

B. False

Page 29 of 49 Mobius Institute Activity Booklet

SIGNAL PROCESSING

Useful information:

T = Time required to collect the waveform

Ts = Time between each sample

Fs = Sampling rate = Samples per second

N = Number of samples (1024, 2048, 4096, etc.)

Window factor = 1 (no window/uniform/rectangular) or 1.5 (Hanning window)

Separating frequency ≥ 2 x Bandwidth ≥ 2 x Resolution * Window Factor

Required spectral lines ≥ 2 x Window factor x Fmax / Separating frequency

Accuracy of frequency (at peak) = ± ½ x Resolution

Page 30 of 49 Mobius Institute Activity Booklet

[1] If the first graph is the spectrum of the raw, unfiltered signal coming from the transducer, and that

signal was put through a filter such that the spectrum in the lower graph was the result, what sort of

filter must have been used?

__ Low pass _________________________________________

[2] What happens to the Fmax if you sample more quickly?

A. The Fmax increases

B. The Fmax is reduced

C. They are independent - there would be no change to the Fmax

[3] If a cyclical signal, which reaches its peak every second, was sampled every second, what would the

waveform look like?

A. A straight/flat line

B. It would be a sine wave, with a frequency of 1 Hz

C. Triangular, as it went from the top of one cycle to the bottom of the next

[4] What is the Nyquist Criterion?

A. The rule that states that there must be a sufficiently high Fmax in order view closely spaced

frequencies

B. The sampling rate must be greater than two times the highest frequency of interest

C. The sampling rate must be 2.56 times the highest frequency

[5] For the same Fmax, if you increase the number of lines of resolution...

A. The measurement will take longer to acquire

B. The test time will not change

C. The measurement will take less time to acquire

Page 31 of 49 Mobius Institute Activity Booklet

[6] Why shouldn't you collect data with the greatest possible Fmax (and just 800 lines)?

A. Because the test will take longer

B. Because the resolution becomes worse

C. Because you will need a special transducer

D. All of the above

[7] Why shouldn't you always collect the highest resolution measurement possible?

A. The test takes longer

B. The data takes more room in the database

C. The data takes longer to unload from the data collector

D. All of the above

[8] If there are 1024 samples in the time waveform, the FFT calculation will generate...

A. 2048 amplitude values

B. 400 amplitude values

C. 512 amplitude values

[9] If a spectrum had 1600 lines of resolution, how many samples were in the time record?

A. 1024 samples

B. 2048 samples

C. 4096 samples

[10] If the record length is 10 seconds, and there were 1024 samples, what is the Fmax?

___1024 / (2.56 x 10) = 40 Hz______________

[11] If the Fmax is 10,000 Hz and you have a 1600 line spectrum, how long does it take to sample the

vibration signal if you have one average only?

____1600 / 10000 = 4096 / (2.56 x 10000) = 0.16 seconds_________

[12] If the Fmax is 120 Hz and you have a 3200 line spectrum, how long does it take to sample the vibration

signal if you have 10 averages (no overlap)?

____10 x 3200 / 120 = 10 x 8192 / (2.56 x 120) = 266.67 seconds __________

[13] If I expect that a machine will generate key vibration signals of 100 Hz and 100.50 Hz, suggest an Fmax

setting and corresponding lines of resolution setting so that I can resolve these two frequencies

(assume that a Hanning window will be used):

___1600 lines and 200 Hz ________________

Page 32 of 49 Mobius Institute Activity Booklet

[14] If a spectrum had a peak at 250 Hz, and the spectrum had 800 lines and Fmax = 800 Hz, and the

window was turned off, which of the following is true about the actual source of vibration?

A. 250 ±0.5 Hz

B. 250 ±1 Hz

C. 250 ±1.5 Hz

D. 250 ±2 Hz

WINDOWING

[1] We experience leakage because:

A. The signal does not begin and end at zero in the time record – it is “finite”.

B. There are errors in the FFT calculation.

C. Time waveforms can often have a lot of noise.

[2] The window most commonly used in machinery vibration analysis is:

A. Hanning

B. Flat top

C. Exponential

D. Uniform/Rectangular/No window

[3] The window most commonly used for bump tests is:

A. Hanning

B. Flat top

C. Exponential

D. Uniform/Rectangular/No window

[4] The window that gives greatest frequency accuracy is:

A. Hanning

B. Flat top

C. Exponential

D. Uniform/Rectangular/No window

[5] The window that gives greatest amplitude accuracy is:

A. Hanning

B. Flat top

C. Exponential

D. Uniform

[6] The primary reason for windowing the time waveform is:

Page 33 of 49 Mobius Institute Activity Booklet

A. To increase frequency accuracy.

B. To improve amplitude accuracy.

C. To correct the leakage phenomenon.

AVERAGING

[1] How many averages should you normally use when using linear averaging with an Fmax of 10,000 Hz?

A. 2 averages

B. 5-10 averages

C. 50 averages

[2] The most commonly used averaging method used for routine data collection is:

A. Time synchronous averaging

B. Linear averaging

C. Peak-hold averaging

[3] True or False: Linear averaging works by averaging the time waveform.

A. True

B. False

[4] True or False: Linear averaging removes noise from the spectrum

A. True

B. False

[5] When performing a bump test, which averaging method should you use?

A. Time synchronous averaging

B. Linear averaging

C. Peak-hold averaging

D. Free run averaging

Page 34 of 49 Mobius Institute Activity Booklet

[6] How many averages should you normally use when using time synchronous averaging?

A. 4-6 averages

B. 10 averages

C. 20 averages

D. 100 averages (or more)

[7] True or False: Time synchronous averaging removes noise from the waveform

A. True

B. False

Page 35 of 49 Mobius Institute Activity Booklet

DIAGNOSING MACHINE FAULTS

[1] A 'synchronous frequency' is...

A. an odd multiple of the running speed frequency.

B. less than the running speed frequency.

C. an integer multiple of the running speed.

D. a non-integer multiple of the running speed.

[2] A 'sub-synchronous frequency' is...

A. an odd multiple of the running speed frequency.

B. less than the running speed frequency.

C. an integer multiple of the running speed.

D. a non-integer multiple of the running speed.

[3] A 'non-synchronous frequency' is...

A. an odd multiple of the running speed frequency.

B. less than the running speed frequency.

C. an integer multiple of the running speed.

D. a non-integer multiple of the running speed.

Page 36 of 49 Mobius Institute Activity Booklet

[4] What is wrong with this machine? Please briefly explain why you have come to this

conclusion. (Note that the L and R phase readings are axial readings taken on the left and the

right of the shaft. The axial phase readings have been adjusted – as if they were all taken in the

same direction.)

___ The levels are very high at 1X in vertical and horizontal – so it is imbalance _________

___ Also notice the 90 degrees phase difference between vertical and horizontal_________

Page 37 of 49 Mobius Institute Activity Booklet

[5] What is wrong with this machine? Please briefly explain why you have come to this

conclusion.

___ Axial is high at 1X on both sides of the coupling), and there is a 180 degrees phase difference

across the coupling in the axial direction. Therefore there is angular misalignment. The 1X and

2X is strong on the motor, so there could be some offset misalignment – but it is predominantly

angular. __________________________________________________________________

_____________________________________________________________________________

Page 38 of 49 Mobius Institute Activity Booklet

DIAGNOSING IMBALANCE

[1] If a machine (not overhung) is out of balance, the spectrum will have...

A. peaks at 1X, 2X, and 3X.

B. a high peak at 1X in the axial direction.

C. a high peak at 1X in the vertical and horizontal direction.

D. a high peak at 2X.

[2] If an overhung machine is out of balance, the spectrum will have...

A. peaks at 1X, 2X, and 3X.

B. a high peak at 1X in the axial direction.

C. a high peak at 1X in the vertical, horizontal and axial directions.

D. a high peak at 2X.

[3] If a vertical machine is out of balance, the spectrum will have...

A. peaks at 1X, 2X, and 3X.

B. a high peak at 1X in the axial direction.

C. a high peak at 1X in the radial (horizontal) directions.

D. a high peak at 2X.

[4] The amplitude of the 1X peak due to imbalance is proportional to...

A. the amount of lubricant in the bearings.

B. the load on the machine.

C. the speed of the machine.

D. the square of the speed of the machine.

[5] If a machine is out of balance, the velocity waveform will...

A. not contain any useful information.

B. have numerous pulses.

C. look quite flat.

D. be mostly sinusoidal (look somewhat like a sine wave).

[6] With static imbalance...

A. the two ends of the machine in the vertical direction will be in phase.

B. the two ends of the machine in the vertical direction will be out of phase.

[7] With couple imbalance...

A. the two ends of the machine in the vertical direction will be in phase.

B. the two ends of the machine in the vertical direction will be 180 deg out of phase.

Page 39 of 49 Mobius Institute Activity Booklet

[8] Select a common cause of imbalance.

A. Uneven dirt build-up, corrosion or erosion

B. Machining errors.

C. Missing balance weights.

D. All statements are true.

[9] If I have a large 24 Hz (1440 RPM) motor-pump with a peak at running speed of

3.0 mm/sec rms (and the fault was suspected to be imbalance), according to the chart below, what is

the severity of this condition? (Slight)

Key for vibration limits:

Limits are for “normal” machines operating from 1500 RPM to 3600 RPM

Reduce limits by 4 dB (multiply limits by 0.63) for slower machines

Increase limits by 4 dB (multiply limits by 1.6) for large and/or higher speed machines

Increase limits by 8 dB (multiply limits by 2.5) for reciprocating machines.

1X Vibration Level Diagnosis Repair Priority

in/sec pk mm/s rms VdB (US)

<0.134 <2.5 <108 Slight Imbalance No Recommendation

0.134-0.28 2.5-5.0 108 – 114 Moderate Imbalance Desirable

0.28 – 0.88 5 – 15.8 114 – 124 Serious Imbalance Important

>0.88 >15.8 >124 Extreme Imbalance Mandatory

Page 40 of 49 Mobius Institute Activity Booklet

DIAGNOSING ECCENTRICITY

[1] If a sheave/pulley or rotor is eccentric, the spectrum will have...

A. peaks at 1X, 2X, and 3X.

B. a high peak at 1X in the axial direction.

C. a high peak at 1X in the radial directions.

D. a high peak at 2X.

DIAGNOSING MISALIGNMENT

[1] If a machine has angular misalignment, in the axial direction the spectrum will have...

A. peaks at 1X, 2X, 3X, 4X, etc.

B. a high amplitude peak at 1X.

C. high amplitude peaks at 1X and 2X.

D. a high peak at 2X only.

[2] If a machine has angular misalignment, in the radial directions the spectrum will have...

A. peaks at 1X, 2X, 3X, 4X, etc.

B. a high amplitude peak at 1X and a moderate 2X peak.

C. moderate-high amplitude peaks at 1X and 2X.

D. a high peak at 2X only.

[3] Describe the phase relationship across the coupling when angular misalignment exists.

A. In-phase in the radial direction, and out-of-phase in the axial direction.

B. Out-of-phase in the radial and axial directions.

C. In-phase in the axial direction and out-of-phase in the radial directions.

D. In-phase in the radial and axial directions.

[4] If a machine has parallel misalignment, in the axial direction the spectrum will have...

A. peaks at 1X, 2X, 3X, 4X, etc.

B. a moderate amplitude peak at 1X and a high 2X peak.

C. moderate amplitude peaks at 1X and 2X.

D. a high peak at 2X only.

Page 41 of 49 Mobius Institute Activity Booklet

[5] If a machine has parallel misalignment, in the radial directions the spectrum will have...

A. peaks at 1X, 2X, 3X, 4X, etc.

B. a moderate-high amplitude peak at 1X and a high 2X peak.

C. moderate amplitude peaks at 1X and 2X.

D. a high peak at 2X only.

[6] Describe the phase relationship across the coupling when parallel misalignment exists.

A. In-phase in the radial direction, and out-of-phase in the axial direction.

B. Out-of-phase in the radial and axial directions.

C. In-phase in the axial direction and out-of-phase in the radial directions.

D. In-phase in the radial and axial directions.

[7] Select a common cause of misalignment.

A. Inaccurate assembly of components.

B. Relative position of components changing after assembly.

C. Distortion due to forces exerted by piping.

D. All of the above.

[8] It is important to correct a misalignment conditions because...

A. the high vibration level can create resonant conditions.

B. you will void the coupling warranty.

C. misaligned machines can create pipe-strain.

D. high vibration level (increases stresses) can damage bearings and cause premature failure.

[9] Why are imbalance faults on overhung machines misdiagnosed as misalignment faults?

A. Because it is hard to correctly align overhung machines.

B. Because both conditions result in 1X vibration in the axial direction.

C. Because both conditions result in 2X vibration in the axial direction.

D. Gee, I don't know!

Page 42 of 49 Mobius Institute Activity Booklet

DIAGNOSING BENT SHAFT

[1] Why is a bent shaft misdiagnosed as an angular misalignment fault?

A. Because bent shafts cause the coupling to be misaligned.

B. Because both conditions result in 1X vibration in the axial direction.

C. Because both conditions result in 2X vibration in the axial direction.

[2] If a shaft is bent, what will be the phase relationship when measured at either end of the machine?

A. In-phase in the vertical direction, but out-of-phase in the horizontal direction.

B. In-phase when measured axially.

C. Out-of-phase when measured axially.

D. Phase is not a useful tool for diagnosing a bent shaft.

DIAGNOSING LOOSENESS

[1] Name one of the causes of rotating looseness.

A. Motor not bolted down securely.

B. Loose cowling or other metallic structure.

C. Wear within a rolling element bearing.

D. Pedestal bearing not bolted down sufficiently.

[2] If you witnessed a series of 1X harmonics, which would you suspect?

A. Rotating looseness.

B. Structural looseness (foundation flexibility).

C. Pedestal bearing looseness.

D. All of the above

[3] If you witnessed a 1X peak in the vertical direction, and a much stronger 1X peak in the horizontal

direction, which would you suspect?

A. Rotating looseness.

B. Non-rotating looseness.

C. Structural looseness (foundation flexibility).

D. Pedestal bearing looseness.

[4] If you witnessed a 1X, 2X, and 3X peak, which would you suspect?

A. Rotating looseness.

B. Non-rotating looseness.

C. Structural looseness (foundation flexibility).

D. Pedestal bearing looseness.

Page 43 of 49 Mobius Institute Activity Booklet

[5] Can phase be used to detect rotating looseness?

A. Yes, there is a 180 degree phase difference between vertical and horizontal.

B. No, phase does not tell you anything.

C. Yes, the lack of a phase relationship helps you to distinguish looseness from misalignment and

other fault conditions.

DIAGNOSING RESONANCE

[1] If a region of a spectrum with increased amplitude was determined to be generated by a resonance,

what will happen to the frequency of that region if the machine speed is changed?

A. The frequency of the region will also change

B. The frequency of the region will remain constant

[2] If the running speed of the machine was changed so that it now coincided with a natural frequency,

how would the vibration amplitude change?

A. It will remain unchanged

B. It will increase if the machine was out-of-balance and the machine speed was decreased.

C. It will decrease in amplitude due to the resonance

D. It will increase in amplitude due to the resonance

[3] A bump test is...

A. a way to seek revenge on annoying machines.

B. a way to identify the natural frequencies.

C. a way to tell if your colleague is awake.

D. a way to change the dynamics of the machine.

DIAGNOSING BEARING FAULTS

[1] What percentage of bearings reach their design lifetime?

A. Approximately 10%

B. Approximately 50%

C. Approximately 90%

[2] Order normalizing a graph is useful because...

A. I forget what order normalizing is...

B. it highlights which peaks are integer and non-integer multiples of running speed

Page 44 of 49 Mobius Institute Activity Booklet

C. it is confusing to relate the frequency in Hz or CPM to forcing frequencies

[3] True or false: Bearing forcing frequency calculations are 100% accurate.

A. False

B. True

[4] True or false: BPO is normally higher in frequency than BPI.

A. False

B. True

[5] If we knew that BPO was 3.2X and BPI was 4.8X, how many balls are there?

A. There must be 8 balls (3.2 + 4.8 = 8)

B. There must be 10 balls (2 + 8 = 10)

C. There must be 7 balls (3 + 4 = 7)

[6] If you detected changes in vibration from a bearing at ultrasonic frequencies (and you don’t see

anything in other parts of the spectrum)...

A. you should change the bearings at your next opportunity.

B. you should keep dogs away from the machine - it may hurt their ears.

C. you should continue monitoring for additional signs of wear.

[7] A logarithmic graph scale helps with bearing analysis because...

A. it is easier to determine relative amplitude.

B. it is easier to see higher frequencies.

C. it is easier to see low amplitude peaks, like harmonics and sidebands

D. it is easier to determine which peaks are non-synchronous.

[8] You should first consider replacing the bearings when...

A. you first detect an ultrasonic frequency

B. when you see an increase in amplitude at the bearing forcing frequencies

C. when you see strong harmonics and sidebands of the bearing forcing frequencies

D. when the bearing is glowing red and the screaming can be heard three buildings away

[9] Why do we use a high pass filter in a demodulation/enveloping circuit?

A. To amplify the useful low frequency signals

B. To amplify all of the high amplitude high frequency signals

C. To remove the high amplitude, low frequency signals

Page 45 of 49 Mobius Institute Activity Booklet

DIAGNOSING ELECTRIC MOTORS

[1] In countries with a 50 Hz line frequency, if the machine turns at just under 3000 RPM, how many poles

must the motor have?

A. Two-poles

B. Four-poles

[2] The slip frequency is...

A. The actual speed of the motor

B. Another term for the synchronous speed.

C. The difference between the actual speed and the synchronous speed

D. The number of times per second that the squirrel slips inside the cage

Page 46 of 49 Mobius Institute Activity Booklet

[3] An eccentric stator (with a stationary differential air gap) will produce...

A. a high 1X peak at the motor running speed

B. increased amplitude at twice line frequency

C. harmonics of 1X with pole-pass sidebands

[4] Select a cause for an eccentric stator.

A. Purchasing from “Jim-Bob's Used Stators” instead of your normal source

B. Over-lubrication, which increases the slip

C. Soft foot

D. Loose holding-down bolts

[5] An eccentric rotor (with a rotating differential air gap) will produce...

A. a high 1X peak at the motor running speed

B. a peak at the rotor bar frequency with twice line-frequency sidebands

C. increased amplitude at 1X vibration and twice line frequency, with pole-pass sidebands

D. harmonics of 1X with pole-pass sidebands

[6] The pole-pass frequency is...

A. the number of poles times the motor running speed

B. the difference between the number of poles and the synchronous speed

C. the same as the line frequency (50 or 60 Hz)

D. the slip frequency times the number of poles

[7] A cracked rotor bar will produce...

A. a high 1X peak at the motor running speed

B. a peak at the rotor bar frequency with twice line-frequency sidebands

C. increased amplitude at twice line frequency, with pole-pass sidebands

D. harmonics of 1X with pole-pass sidebands around each harmonic

Page 47 of 49 Mobius Institute Activity Booklet

[8] The 'beating' phenomenon can indicate...

A. loose rotor bars

B. an eccentric slip ring

C. a bent or warped rotor

D. an eccentric stator

[9] Loose rotor bars will produce...

A. a high 1X peak at the motor running speed

B. a peak at the rotor bar frequency with twice line-frequency sidebands

C. increased amplitude at twice line frequency, with pole-pass sidebands

D. harmonics of 1X with pole-pass sidebands

[10] What is the 'rotor bar frequency'?

A. The number of rotor bars times the slip frequency

B. The slip frequency times the synchronous frequency

C. The number of rotor bars times the running speed

D. The number of rotor bars times the synchronous speed

GEARBOX ANALYSIS

[1] Gearmesh is calculated by...

A. Adding the number of teeth on each gear

B. Multiplying the number of teeth on the gear by the speed of that gear

C. Multiplying the number of teeth on the input shaft by the speed of the output shaft

[2] Why is time waveform analysis useful in analyzing vibration from gearboxes?

A. You can easily identify the shaft speed from the time waveform

B. You can see the pattern of wear on the teeth

C. You can detect damage to individual teeth

D. Time waveform analysis is good for all rotating components so it must be good for gearboxes

[3] The main benefit of time synchronous averaging is...

A. it removes all sources of vibration not synchronous with the tachometer signal

B. that it takes longer to perform this test, and I am paid by the hour

Page 48 of 49 Mobius Institute Activity Booklet

[4] What is the best tool for detecting cracked or broken gear teeth?

A. Motor current analysis

B. Perform thermographic analysis on the lubricant

C. A wrench and a large hammer

D. Time waveform analysis

BELTS

[1] The 'belt rate' forcing frequency is...

A. lower than the machine RPM

B. higher than the machine RPM

C. the same as the output RPM

[2] If a sheave/pulley is eccentric, the vibration pattern will produce...

A. a strong 1X component in the radial directions

B. a series of harmonics of the belt rate

C. a strong 1X component in the axial direction

D. strong 1X, 2X, and 3X peaks

[3] If a belt is worn or loose, the vibration pattern will produce...

A. a strong 1X component in the radial directions

B. a series of harmonics of the belt rate frequency

C. a strong 1X component in the axial direction

D. strong 1X, 2X, and 3X peaks

[4] If two sheaves/pulleys are not aligned correctly, the vibration pattern will produce...

A. a strong 1X component in the radial directions

B. a series of harmonics of the belt rate

C. a strong 1X component in the axial direction

D. strong 1X, 2X, and 3X peaks

[5] If a belt resonance coincides with the sheave/pulley RPM, the vibration pattern will produce...

A. a strong 1X component in the radial directions

B. a series of harmonics of the belt rate

C. a strong 1X component in the axial direction

D. strong 1X, 2X, and 3X peaks

Page 49 of 49 Mobius Institute Activity Booklet

You might also like

- CAT II Student Workbook v4.0 A4Document104 pagesCAT II Student Workbook v4.0 A4Mohamed Arafat100% (3)

- Cat IiDocument72 pagesCat Iizeroseya100% (3)

- Vibration Cat II Practise ExamDocument3 pagesVibration Cat II Practise Examalxmaas91% (11)

- Vibration Analysis Level 1Document3 pagesVibration Analysis Level 1mohanmani0267% (3)

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- JPS Reliability Bearing FailuresDocument14 pagesJPS Reliability Bearing FailuresAnonymous Bdt0OGh100% (1)

- STS - (3000K, 6000K) - H1 Smart Transformer Station User ManualDocument145 pagesSTS - (3000K, 6000K) - H1 Smart Transformer Station User ManualAntonio CanalesNo ratings yet

- Mobius CAT III Activity Book 170112 A4Document35 pagesMobius CAT III Activity Book 170112 A4Novindra PutraNo ratings yet

- Cat IiDocument71 pagesCat Iimustafa100% (13)

- Vibration Analysis - Iso Cat II Asnt Level II 1331196230Document3 pagesVibration Analysis - Iso Cat II Asnt Level II 1331196230tylerdurdaneNo ratings yet

- Vibration Chart CharloteDocument25 pagesVibration Chart Charloteantok09100% (1)

- Balancing Letter PDFDocument307 pagesBalancing Letter PDFCamilo Andres Quintero100% (6)

- Vibration Diagnostic ChartDocument49 pagesVibration Diagnostic Chartujepadounk100% (1)

- PeakvueDocument68 pagesPeakvueLe Thanh Hai100% (1)

- Case Study - Gearbox FailureDocument16 pagesCase Study - Gearbox FailureRateesh VenugopalanNo ratings yet

- Test (With Ans)Document25 pagesTest (With Ans)B V ManoharNo ratings yet

- Training Course IIIDocument188 pagesTraining Course IIIHosam Abd Elkhalek100% (2)

- Machinery Diagnostic PlotsDocument16 pagesMachinery Diagnostic Plotsfazzlie100% (1)

- Forsthoffer’s Component Condition MonitoringFrom EverandForsthoffer’s Component Condition MonitoringRating: 4 out of 5 stars4/5 (2)

- HDB3 ReportDocument98 pagesHDB3 ReportCornel CaceamacNo ratings yet

- Cuaderno Curso - CAT I Activity Book Spanish With CoverDocument34 pagesCuaderno Curso - CAT I Activity Book Spanish With CoverJose Raul Reyes Dominguez100% (1)

- VA II TrainingDocument393 pagesVA II Trainingjawadhussain195% (20)

- CAT II Activity Book v4.0 - Letter - Answer KeyDocument7 pagesCAT II Activity Book v4.0 - Letter - Answer Keyazay_saja100% (2)

- Predict-Mobius Training BrochureDocument7 pagesPredict-Mobius Training BrochurefaisalNo ratings yet

- PeakvueDocument68 pagesPeakvueChe Khairuddin100% (1)

- Vibration SeverityDocument19 pagesVibration Severityanon_900141394No ratings yet

- Phase Analysis: Part 1Document27 pagesPhase Analysis: Part 1Shawn RuhlNo ratings yet

- An Introduction To Time Waveform AnalysisDocument17 pagesAn Introduction To Time Waveform AnalysisBassemNo ratings yet

- Cat II Course PDFDocument153 pagesCat II Course PDFMohammad Zainullah Khan100% (2)

- Phase MeasurementDocument5 pagesPhase Measurementuak107080No ratings yet

- AnalysisDocument44 pagesAnalysisMounicaRasagyaPallaNo ratings yet

- ISO VA DocumentDocument20 pagesISO VA DocumentgsaiprasathNo ratings yet

- Vibration Adv 0402Document433 pagesVibration Adv 0402Sajid Rafique100% (7)

- Case Study - Bearing FailureDocument24 pagesCase Study - Bearing FailureRateesh Venugopalan100% (2)

- Advanced Vibration Analysis TechniquesDocument324 pagesAdvanced Vibration Analysis Techniquesharikrishnanpd3327100% (1)

- Autocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookDocument8 pagesAutocorrelation: 131 CAT IV Part 1 - Signal Processing SlidebookLe Thanh Hai100% (2)

- Low Freq. Meas & gSEDocument13 pagesLow Freq. Meas & gSEsatya_chaganti100% (1)

- AzimaDLI Severity Chart 2013 PDFDocument1 pageAzimaDLI Severity Chart 2013 PDFEswin Paico de la Cruz100% (1)

- VIBS Modal Overview 021703 MACLDocument55 pagesVIBS Modal Overview 021703 MACLBakkiya RajNo ratings yet

- Detect Machinery Faults by Using Peak VueDocument13 pagesDetect Machinery Faults by Using Peak VueHarold Alconz100% (2)

- Vertical Motor Case History Shurafa IIR Rotate 2012Document4 pagesVertical Motor Case History Shurafa IIR Rotate 2012aal_shurafa100% (2)

- Vib - Peakvue As Part ofDocument15 pagesVib - Peakvue As Part ofHatem Abdelrahman100% (3)

- ISO 18436 Category IVDocument2 pagesISO 18436 Category IVzona amrullohNo ratings yet

- Vibration Reference GuideDocument2 pagesVibration Reference GuideErez Matana100% (1)

- Orbits and SCL PresentationDocument18 pagesOrbits and SCL PresentationChad Hunt100% (4)

- Detection of Ski Slopes in Vibration SpectrumsDocument7 pagesDetection of Ski Slopes in Vibration SpectrumsjeyaselvanmNo ratings yet

- Introduction To Vibration Analysis Program - Bnetly NevadaDocument52 pagesIntroduction To Vibration Analysis Program - Bnetly NevadaSam100% (5)

- Cat II Cover A4 250912Document4 pagesCat II Cover A4 250912Shahbaz KhanNo ratings yet

- AMPLITUDE MODULATION Versus BEATSDocument5 pagesAMPLITUDE MODULATION Versus BEATSHaitham YoussefNo ratings yet

- ISO 18436 Category III Vibration Analyst TrainingDocument4 pagesISO 18436 Category III Vibration Analyst TrainingDean LofallNo ratings yet

- Vibration Report For The Vapor Compressor of Desalination Unit B (59ML04B-MJ01)Document8 pagesVibration Report For The Vapor Compressor of Desalination Unit B (59ML04B-MJ01)FadooollNo ratings yet

- CHAPTER 6 Resonance and Critical Speed TestingDocument31 pagesCHAPTER 6 Resonance and Critical Speed TestingHosam Abd Elkhalek75% (4)

- Vibration Adv 0402 PDFDocument433 pagesVibration Adv 0402 PDFChintan Raval100% (2)

- AMS Machinery Manager Test DriveDocument39 pagesAMS Machinery Manager Test DriverharaksiNo ratings yet

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionFrom EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNo ratings yet

- Case Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerFrom EverandCase Histories in Vibration Analysis and Metal Fatigue for the Practicing EngineerRating: 4.5 out of 5 stars4.5/5 (3)

- Mechanical Vibrations and Condition MonitoringFrom EverandMechanical Vibrations and Condition MonitoringRating: 5 out of 5 stars5/5 (1)

- Examen Vibraciones Nivel IIDocument41 pagesExamen Vibraciones Nivel IIJim Morrison67% (3)

- Maintenance MCQDocument5 pagesMaintenance MCQRitesh BoraseNo ratings yet

- DCQ Assessment Questionnaire Subjective Question Position: NDT InspectorDocument5 pagesDCQ Assessment Questionnaire Subjective Question Position: NDT InspectoramirrulasyrafNo ratings yet

- E3000 GB 3406Document100 pagesE3000 GB 3406lsilverNo ratings yet

- Ako D14123Document4 pagesAko D14123Toader MarcuNo ratings yet

- Basic Linear Amplifiers by Sm0vpoDocument8 pagesBasic Linear Amplifiers by Sm0vpoChris GozzardNo ratings yet

- Akg c3000b Condenser Microphone SM PDFDocument3 pagesAkg c3000b Condenser Microphone SM PDFРубен БогдаянNo ratings yet

- 10 FM ReceiverDocument9 pages10 FM ReceiverMohamed shabanaNo ratings yet

- An Attic Coaxial-Cable Trap Dipole For 10, 15, 20, 30, 40, and 80 MetersDocument10 pagesAn Attic Coaxial-Cable Trap Dipole For 10, 15, 20, 30, 40, and 80 MetersJeff100% (1)

- Cps1200-2200eilcd Manual enDocument2 pagesCps1200-2200eilcd Manual enMujtaba AbbasNo ratings yet

- 82740a Catalogue Lift LowDocument128 pages82740a Catalogue Lift LowBreno Gonçalves Porto de OliveiraNo ratings yet

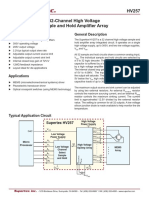

- HV257DB2 SupertexDocument13 pagesHV257DB2 SupertexJuan MartinezNo ratings yet

- 1100w Sharp 1 CF MicrowaveDocument36 pages1100w Sharp 1 CF Microwavewissam.alnaser6332100% (1)

- Document Version: 1.5 Image Version: V1.0: Lorawan Soil Moisture & Ec Sensor User ManualDocument31 pagesDocument Version: 1.5 Image Version: V1.0: Lorawan Soil Moisture & Ec Sensor User ManualGusti Made Arya WijayaNo ratings yet

- Jog CircuitsDocument3 pagesJog CircuitsReysean Ive Jhon MadaliNo ratings yet

- Chint NM8N MCCB Catalog - 2023 - ENDocument98 pagesChint NM8N MCCB Catalog - 2023 - ENMuhammad AzriNo ratings yet

- Service Manual: DP AlchemyDocument96 pagesService Manual: DP Alchemyeeyyee GsNo ratings yet

- 35 DS01 1600 C - JM - 1600cellDocument2 pages35 DS01 1600 C - JM - 1600cellAngel MorenoNo ratings yet

- Brushless Exciters For Turbine GeneratorsDocument8 pagesBrushless Exciters For Turbine GeneratorsEM wing, D&E, NEEPCO, GuwahatiNo ratings yet

- DS Syscompact 2000 M Pro BAUR En-GbDocument2 pagesDS Syscompact 2000 M Pro BAUR En-Gbrupesh kumarNo ratings yet

- ECE3013 - Linear Integrated Circuits: Module-IiiDocument50 pagesECE3013 - Linear Integrated Circuits: Module-IiiWINORLOSENo ratings yet

- Ncert Solutions March2 For Cbse Class 7 Science Chapter 14Document6 pagesNcert Solutions March2 For Cbse Class 7 Science Chapter 14VimalaNo ratings yet

- Solar ConverterDocument2 pagesSolar Convertersukhvinder singhNo ratings yet

- Control ElectricoDocument7 pagesControl ElectricoEmer nelsonNo ratings yet

- Codici SDHDocument7 pagesCodici SDHkalwar98esNo ratings yet

- Ti-Rfid ProductsDocument10 pagesTi-Rfid ProductsKhoirul UmamNo ratings yet

- Module 5 - Counter Register Design and ALU Function - FDocument21 pagesModule 5 - Counter Register Design and ALU Function - FYvanne Esquia CuregNo ratings yet

- Arduino Circuits and Projects Guide - ElektorDocument15 pagesArduino Circuits and Projects Guide - ElektordeckerNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument12 pagesCambridge International Advanced Subsidiary and Advanced LevelMARSHALLNo ratings yet