Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

11 viewsINSTRUCTIONAL BLUEPRINTcore

INSTRUCTIONAL BLUEPRINTcore

Uploaded by

Larra Phaye Amante AquelThis document outlines the qualifications and skills required for dressmaking. It includes 3 levels of objectives: 1) Prepare cut parts, 2) Prepare sewing machine for operation, and 3) Sew and assemble garment parts. The key skills required are proper sewing machine operations, threading procedures, basic sewing techniques, identifying workplace hazards, and applying safety precautions. Garment parts must be assembled and sewn according to instructions and specifications, with accurate sewing of pieces like sleeves, collars, and pockets.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You might also like

- Nebosh: Know - Workplace Health and Safety Principles (International)Document18 pagesNebosh: Know - Workplace Health and Safety Principles (International)ARJUN79% (14)

- Beginners Guide To Blackwork by Lesley Wilkins2 PDFDocument63 pagesBeginners Guide To Blackwork by Lesley Wilkins2 PDFSCP100% (4)

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- CassavaDocument4 pagesCassavaLarra Phaye Amante AquelNo ratings yet

- Instructional WatermelonnnDocument3 pagesInstructional WatermelonnnLarra Phaye Amante AquelNo ratings yet

- TCF GuideDocument25 pagesTCF GuideAlicia ForbesNo ratings yet

- Tic04 A1Document3 pagesTic04 A1Annabel Aureada PallesNo ratings yet

- Model Curriculum: Machine Maintenance Mechanic: Sewing MachineDocument20 pagesModel Curriculum: Machine Maintenance Mechanic: Sewing MachinekishoreNo ratings yet

- Diagram Roles in Aviation.Document2 pagesDiagram Roles in Aviation.Leanneth zharick Sierra CartagenaNo ratings yet

- Instructional KasabakikDocument2 pagesInstructional KasabakikLarra Phaye Amante AquelNo ratings yet

- New Hires/Replacements/Promotions: 1. Job Justification - From 1 Fabruary, 2016 TO 1 December, 2018 BackgroundDocument3 pagesNew Hires/Replacements/Promotions: 1. Job Justification - From 1 Fabruary, 2016 TO 1 December, 2018 BackgroundPiplu DasNo ratings yet

- Auto Component Assy FitterDocument8 pagesAuto Component Assy FitterAshwin KalapurakkalNo ratings yet

- Sample Competency MatrixDocument3 pagesSample Competency MatrixEdleo MaghopoyNo ratings yet

- Competency Enhancement V6Document6 pagesCompetency Enhancement V6venkat raNo ratings yet

- Technical Specifications Renishaw Probing PDFDocument72 pagesTechnical Specifications Renishaw Probing PDFmarianhainarosieNo ratings yet

- Preset For ProductionDocument3 pagesPreset For ProductionreynancsNo ratings yet

- Location Dependency of Positioning Error in A 3-Axes CNC Milling MachineDocument6 pagesLocation Dependency of Positioning Error in A 3-Axes CNC Milling MachineIrfan RfcNo ratings yet

- MC Sewing Machine Operator PDFDocument19 pagesMC Sewing Machine Operator PDFS KannagiNo ratings yet

- Analyse and Design Purl (Links/links) Structures and PatternsDocument4 pagesAnalyse and Design Purl (Links/links) Structures and PatternsAnonymous zd5HPB5No ratings yet

- Introduction To Drilling Machine AlignmentDocument10 pagesIntroduction To Drilling Machine AlignmentPruthviraj KukadeNo ratings yet

- Foundations of TLE Activity 1Document1 pageFoundations of TLE Activity 1Sally BaranganNo ratings yet

- CNC Lathe Machine Technician and ProgrammerDocument16 pagesCNC Lathe Machine Technician and ProgrammermanjuNo ratings yet

- 01-SmartROC D65 - CompressorDocument23 pages01-SmartROC D65 - CompressorElvis Jaen FernandezNo ratings yet

- 4747676299.1 en-US - FlexiROC T40 - CRI - Track FrameDocument32 pages4747676299.1 en-US - FlexiROC T40 - CRI - Track Framecarlos barreraNo ratings yet

- 7216524555.2 en - US - SmartROC D65 - CRI - Feed Angle Sensor (Inclinometer)Document20 pages7216524555.2 en - US - SmartROC D65 - CRI - Feed Angle Sensor (Inclinometer)carlos barreraNo ratings yet

- Machine Vision System For Inspecting Flank Wear On Cutting ToolsDocument5 pagesMachine Vision System For Inspecting Flank Wear On Cutting ToolsRaghuNo ratings yet

- Design For AssemblyDocument11 pagesDesign For AssemblyMalay ShahNo ratings yet

- The ISO 11783 Standard and Its Use in Precision Agriculture EquipmentDocument9 pagesThe ISO 11783 Standard and Its Use in Precision Agriculture EquipmentHoa Binh TranNo ratings yet

- Moduldokumentation HydraulicsDocument66 pagesModuldokumentation HydraulicsJordi El MariachetNo ratings yet

- Why CSS? Why CSS?: Computer System Servicing Computer System ServicingDocument1 pageWhy CSS? Why CSS?: Computer System Servicing Computer System ServicingStiffany R. NercuitNo ratings yet

- CM Tle 8 Q3Document2 pagesCM Tle 8 Q3Anday Par LizaNo ratings yet

- JD Manager - Twisting MaintenanceDocument1 pageJD Manager - Twisting MaintenanceCraig MartinNo ratings yet

- General Concept of Preventive MaintenanceDocument11 pagesGeneral Concept of Preventive MaintenanceSayed NagyNo ratings yet

- Fitter Syllabus Sem 1Document18 pagesFitter Syllabus Sem 1krunal07786No ratings yet

- MC Sewing Machine OperatorDocument19 pagesMC Sewing Machine OperatorAvi Raj100% (1)

- 1 - Chapter OneDocument35 pages1 - Chapter Onemirahaem5No ratings yet

- Apparel Analysisfor Layout Planningin Sewing SectionDocument8 pagesApparel Analysisfor Layout Planningin Sewing SectionITM Teck Soft.No ratings yet

- Apparel Analysis For Layout Planning in Sewing SectionDocument8 pagesApparel Analysis For Layout Planning in Sewing SectionNadarajNo ratings yet

- BA DuraMax REV 3 0 Online en PDFDocument235 pagesBA DuraMax REV 3 0 Online en PDFbeto206123100% (1)

- Aircraft Assembly 2021Document8 pagesAircraft Assembly 2021SNL tvNo ratings yet

- TrueDocument57 pagesTrueEbisa DuressaNo ratings yet

- Apparel Analysis For Layout Planning in Sewing Section: ArticleDocument8 pagesApparel Analysis For Layout Planning in Sewing Section: ArticleGaurav kumarNo ratings yet

- Apparel Analysis For Layout Planning in Sewing SectionDocument8 pagesApparel Analysis For Layout Planning in Sewing SectionNure MohammadNo ratings yet

- Production and ManufacturingDocument80 pagesProduction and ManufacturingcgcbackupakNo ratings yet

- Competency Profile (CP) : Sub Sector After Sales Job Area Automotive After Sales Service Level TWODocument40 pagesCompetency Profile (CP) : Sub Sector After Sales Job Area Automotive After Sales Service Level TWONORISHAM BIN A RAHIMNo ratings yet

- On Job Training 1 GokulDocument10 pagesOn Job Training 1 GokulSanjayNo ratings yet

- Fundamentos de Inspección y Reacondicionamiento de Plataformas de PerforaciónDocument23 pagesFundamentos de Inspección y Reacondicionamiento de Plataformas de PerforaciónABRAHAM NERY LLORENTY ROJASNo ratings yet

- Drilling Rig Inspection and Workover FundamentalsDocument23 pagesDrilling Rig Inspection and Workover Fundamentalslearn offshore drillingNo ratings yet

- Model Curriculum Fitter NSQF Level 1Document6 pagesModel Curriculum Fitter NSQF Level 1Shitosh DilluNo ratings yet

- MTK 1032 Mechanical CuttingDocument17 pagesMTK 1032 Mechanical CuttingMR FIKRINo ratings yet

- Cora - INSTRUCTIONAL-DESIGN-TEMPLATEDocument4 pagesCora - INSTRUCTIONAL-DESIGN-TEMPLATECorazon CaldozaNo ratings yet

- Electrical Maintenance MapDocument4 pagesElectrical Maintenance MapScribdTranslationsNo ratings yet

- Ringkas NossDocument37 pagesRingkas Nossayein azliNo ratings yet

- University Institute of Engineering Department of Ait - CseDocument14 pagesUniversity Institute of Engineering Department of Ait - Cseayushworkspace279No ratings yet

- DLL Week 1 2 Q2Document8 pagesDLL Week 1 2 Q2Danica Rosabele Templo DionisioNo ratings yet

- Skills Framework For Precision Engineering Technical Skills and Competencies (TSC) Reference DocumentDocument2 pagesSkills Framework For Precision Engineering Technical Skills and Competencies (TSC) Reference Documentjeremytoh89No ratings yet

- Genie zx135/70 Operator ManualDocument71 pagesGenie zx135/70 Operator ManualAbdurrahim TomarNo ratings yet

- Medical Device MaintenanceDocument24 pagesMedical Device MaintenanceFayez Abu Al SaoudNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- MFS Web 16oDocument16 pagesMFS Web 16oSaid RoukbiNo ratings yet

- GMKDocument7 pagesGMKNKay AndroidNo ratings yet

- Cutting ParametersDocument7 pagesCutting ParametersAtelier MethodologieNo ratings yet

- Example of A Business Model Canvas Coconut Treat StandDocument2 pagesExample of A Business Model Canvas Coconut Treat StandSabrena FennaNo ratings yet

- Lpo Birds NestDocument6 pagesLpo Birds Nestapi-265791946No ratings yet

- Chapter 8 - Memory Storage Devices Question AnswersDocument4 pagesChapter 8 - Memory Storage Devices Question AnswersAditya MalhotraNo ratings yet

- Objectivity in Journalism (Williams & Stroud, 2020)Document4 pagesObjectivity in Journalism (Williams & Stroud, 2020)Dexter CaroNo ratings yet

- English File: Answer KeyDocument4 pagesEnglish File: Answer KeyEvelyn BoccioNo ratings yet

- Welcome To Good Shepherd Chapel: Thirty-Third Sunday in Ordinary TimeDocument4 pagesWelcome To Good Shepherd Chapel: Thirty-Third Sunday in Ordinary Timesaintmichaelpar7090No ratings yet

- Get Best Long Coat Green Apple ShampooDocument1 pageGet Best Long Coat Green Apple ShampooBhawna SinghNo ratings yet

- Canon 8.02Document1 pageCanon 8.02Vin LacsieNo ratings yet

- Knowledge L3/E Comprehension L4/D Application L5/C Analysis L6/B Synthesis L7/A Evaluation L8/ADocument2 pagesKnowledge L3/E Comprehension L4/D Application L5/C Analysis L6/B Synthesis L7/A Evaluation L8/AWaltWritmanNo ratings yet

- Operating, Maintenance & Parts Manual: Rated LoadsDocument48 pagesOperating, Maintenance & Parts Manual: Rated LoadsAmanNo ratings yet

- House of ConcreteDocument9 pagesHouse of ConcreteArkyadeep ChowdhuryNo ratings yet

- Project Management A Systems Approach To Planning Scheduling and Controlling 10Th Edition Kerzner Test Bank Full Chapter PDFDocument24 pagesProject Management A Systems Approach To Planning Scheduling and Controlling 10Th Edition Kerzner Test Bank Full Chapter PDFGeorgeAndersonkqmr100% (13)

- Gratuity Eligibility For Less Than 5 Yrs. (4yrs.240days)Document8 pagesGratuity Eligibility For Less Than 5 Yrs. (4yrs.240days)DILLIP KUMAR MAHAPATRA0% (1)

- Statements of Financial Position As at 31 December 2009 and 2010Document3 pagesStatements of Financial Position As at 31 December 2009 and 2010mohitgaba19No ratings yet

- Islamic Economics and The Islamic Sub EconomyDocument18 pagesIslamic Economics and The Islamic Sub EconomyNoerma Madjid Riyadi100% (1)

- KMPDocument2 pagesKMPPrajeesh KrishnanNo ratings yet

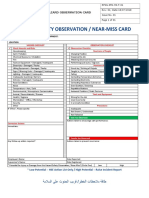

- RPSG-IMS-HS-F - 01 - Hazard Observation CardDocument2 pagesRPSG-IMS-HS-F - 01 - Hazard Observation CardRocky BisNo ratings yet

- Modul EFB Unit 7Document18 pagesModul EFB Unit 7Muhammad IlhamNo ratings yet

- 04 What Is Easement Distinguish Easement From Usufruct 2 Can There Be A An - Course HeroDocument9 pages04 What Is Easement Distinguish Easement From Usufruct 2 Can There Be A An - Course HerojrstockholmNo ratings yet

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDocument1 pageIndian Income Tax Return Acknowledgement: Name of Premises/Building/Villagehealth with wealthNo ratings yet

- NutriSmart - Food Products Recommendation SystemDocument3 pagesNutriSmart - Food Products Recommendation SystemAnonymous izrFWiQNo ratings yet

- Practical Class 2 Text Artificial IntelligenceDocument3 pagesPractical Class 2 Text Artificial IntelligenceAlex VaskoNo ratings yet

- Wedding Venue List 1Document53 pagesWedding Venue List 1Vivek Kumar GuptaNo ratings yet

- SxzsaDocument15 pagesSxzsabadmash1988No ratings yet

- PD 477Document21 pagesPD 477Rak Nopel Taro100% (1)

- Handwritten Notes IP XII 2020 PYTHON - RPDocument37 pagesHandwritten Notes IP XII 2020 PYTHON - RPchaitanyanegi2004No ratings yet

- Annotated BibliographyDocument2 pagesAnnotated Bibliographyapi-314923435No ratings yet

- Factors Influencing Savings Mobilization by Commercial BanksDocument81 pagesFactors Influencing Savings Mobilization by Commercial BanksNicholas Gowon100% (7)

INSTRUCTIONAL BLUEPRINTcore

INSTRUCTIONAL BLUEPRINTcore

Uploaded by

Larra Phaye Amante Aquel0 ratings0% found this document useful (0 votes)

11 views3 pagesThis document outlines the qualifications and skills required for dressmaking. It includes 3 levels of objectives: 1) Prepare cut parts, 2) Prepare sewing machine for operation, and 3) Sew and assemble garment parts. The key skills required are proper sewing machine operations, threading procedures, basic sewing techniques, identifying workplace hazards, and applying safety precautions. Garment parts must be assembled and sewn according to instructions and specifications, with accurate sewing of pieces like sleeves, collars, and pockets.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the qualifications and skills required for dressmaking. It includes 3 levels of objectives: 1) Prepare cut parts, 2) Prepare sewing machine for operation, and 3) Sew and assemble garment parts. The key skills required are proper sewing machine operations, threading procedures, basic sewing techniques, identifying workplace hazards, and applying safety precautions. Garment parts must be assembled and sewn according to instructions and specifications, with accurate sewing of pieces like sleeves, collars, and pockets.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

0 ratings0% found this document useful (0 votes)

11 views3 pagesINSTRUCTIONAL BLUEPRINTcore

INSTRUCTIONAL BLUEPRINTcore

Uploaded by

Larra Phaye Amante AquelThis document outlines the qualifications and skills required for dressmaking. It includes 3 levels of objectives: 1) Prepare cut parts, 2) Prepare sewing machine for operation, and 3) Sew and assemble garment parts. The key skills required are proper sewing machine operations, threading procedures, basic sewing techniques, identifying workplace hazards, and applying safety precautions. Garment parts must be assembled and sewn according to instructions and specifications, with accurate sewing of pieces like sleeves, collars, and pockets.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

Download as docx, pdf, or txt

You are on page 1of 3

INSTRUCTIONAL BLUEPRINT(UC3-CORE)

UC: SEW CASUAL APPAREL QUALIFICATIONS:DRESSMAKING NCII

REQUIRED REQUIRED

KNOWLEDGE/UNDERPINNING SKILLS/UNDERPINNING

KNOWLEDGE SKILLS

LO.1PREPARE CUT PARTS

Types of sewing machines Discuss the features and Sewing machine operations Proper lubrication of

capabilities of machines the machine.

specifically design for embroidery

work.

Garments part Defined the different kinds of Threading procedures Applying the different

garments part. kinds of threading

Characteristics of fabrics,threads Discuss the properties of eco- Apply basic sewing Apply,develop and

and other materials used in basic friendly fabrics and their impact techniques improve the

garment assembly on sustainability in the fashion techniques for sewing.

industry

Parts sewing machine What are the types of sewing Carry out work in accordance Evaluate the process of

machines. with OH&S policies and identifying workplace

procedures hazards and

conducting risk

assessments to

prevent accidents and

injuries.

Machine problem or faults Checking for the machine’s Interpret and apply defined Applying the accurate

condition procedures procedures

Types of sleeves How to cut and draft pattern for Apply safety precautions Conducting the safety

sleeves. relevant to the task precautions for the

task.

Types of collar Identifying the different kinds of Cut parts are prepared in Preparing the cut parts

collar accordance with the specified according to their

garment design/style specific style.

Types of pocket Attaching the pocket in the right Cut parts are pressed in Pressing of the cut

position accordance with fabric parts with

specifications specifications

Cut parts are pinned together Pinning the cut parts

in accordance with garment with garment design in

design or style their accordance.

Accessories and accents are Essential accessories

prepared in accordance with and accents are well

garment design or style prepared.

LO.2 PREPARE SEWING MACHINE FOR OPERATION

Machine parts are cleaned Machine parts are well

and lubricated in accordance cleaned and lubricated

with company’s requirements and having proper

And manufacturer’s cleaning treatment.

and lubricating instructions

Machines are set-up and Proper adjusting of the

adjusted in accordance with machines and its work

work specifications specifications.

Machines are threaded in Apply the proper

accordance with procedures threading in the

machine using the

accurate procedures.

Machine is started and Safety implications and

stopped in accordance with best practices for

manufacturer’s and starting and stopping

company’s requirements of the machine.

Speed of machines and work Proper controlling of

handling are controlled in the speed in the

accordance with company’s machine with

procedure company’s procedure.

Minor machine problem or Identify the proper

fault is identified and repaired procedure when we

in accordance with repair a machine

manufacturer’s manual problem or fault.

Machine operation is Proper monitoring of

monitored as per procedures the machine situation.

Company’s health and safety Following the the

policies and procedures are policies and

followed as per standard procedures in the

operating procedures(SOPs) machine .

LO3. SEW AND ASSEMBLE GARMENT PARTS

Garment parts are assembled Proper assembling of

in accordance with garment the garments part

assembly instructions and according to the

pattern specifications instructions and

pattern specifications.

Garments are sewn in Standard procedures

conformance with sewing in sewing a garments

standard procedures and pieces.

company’s time frame

Sleeves,collars and pockets Proper sewing of the

are identified and sewn sleeves,collars and

according to customers pockets according to

specification the customers

specification.

Pocket flaps are sewn with Applying the proper

clean corners and no raw sewing of the pocket

edges flaps with no raw

edges.

Zipper is sewn without Following of the

puckered according to sewing proper sewing

instructions instruction for zipper.

Seams edges are finished Finishing the seam

in accordance with job edges in accordance.

requirements

Waistband width are Applying yhe

evenly sewn from end to standard sewing for

end according to standard the waistband

operating procedures width.

LO4. ALTER COMPLETED GARMENT

Alterations/modifications are Modifying garments

done in accordance with the to fit client

clients specifications preferences.

Final fitting is conducted to Conducting a final

ensure client’s satisfaction fitting to ensure the

clients satisfaction.

Garment alteration is Techniques and

completed as per client’s strategies are well

satisfaction applied to the

garments .

You might also like

- Nebosh: Know - Workplace Health and Safety Principles (International)Document18 pagesNebosh: Know - Workplace Health and Safety Principles (International)ARJUN79% (14)

- Beginners Guide To Blackwork by Lesley Wilkins2 PDFDocument63 pagesBeginners Guide To Blackwork by Lesley Wilkins2 PDFSCP100% (4)

- CNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingFrom EverandCNC Machining Certification Exam Guide: Setup, Operation, and ProgrammingNo ratings yet

- CassavaDocument4 pagesCassavaLarra Phaye Amante AquelNo ratings yet

- Instructional WatermelonnnDocument3 pagesInstructional WatermelonnnLarra Phaye Amante AquelNo ratings yet

- TCF GuideDocument25 pagesTCF GuideAlicia ForbesNo ratings yet

- Tic04 A1Document3 pagesTic04 A1Annabel Aureada PallesNo ratings yet

- Model Curriculum: Machine Maintenance Mechanic: Sewing MachineDocument20 pagesModel Curriculum: Machine Maintenance Mechanic: Sewing MachinekishoreNo ratings yet

- Diagram Roles in Aviation.Document2 pagesDiagram Roles in Aviation.Leanneth zharick Sierra CartagenaNo ratings yet

- Instructional KasabakikDocument2 pagesInstructional KasabakikLarra Phaye Amante AquelNo ratings yet

- New Hires/Replacements/Promotions: 1. Job Justification - From 1 Fabruary, 2016 TO 1 December, 2018 BackgroundDocument3 pagesNew Hires/Replacements/Promotions: 1. Job Justification - From 1 Fabruary, 2016 TO 1 December, 2018 BackgroundPiplu DasNo ratings yet

- Auto Component Assy FitterDocument8 pagesAuto Component Assy FitterAshwin KalapurakkalNo ratings yet

- Sample Competency MatrixDocument3 pagesSample Competency MatrixEdleo MaghopoyNo ratings yet

- Competency Enhancement V6Document6 pagesCompetency Enhancement V6venkat raNo ratings yet

- Technical Specifications Renishaw Probing PDFDocument72 pagesTechnical Specifications Renishaw Probing PDFmarianhainarosieNo ratings yet

- Preset For ProductionDocument3 pagesPreset For ProductionreynancsNo ratings yet

- Location Dependency of Positioning Error in A 3-Axes CNC Milling MachineDocument6 pagesLocation Dependency of Positioning Error in A 3-Axes CNC Milling MachineIrfan RfcNo ratings yet

- MC Sewing Machine Operator PDFDocument19 pagesMC Sewing Machine Operator PDFS KannagiNo ratings yet

- Analyse and Design Purl (Links/links) Structures and PatternsDocument4 pagesAnalyse and Design Purl (Links/links) Structures and PatternsAnonymous zd5HPB5No ratings yet

- Introduction To Drilling Machine AlignmentDocument10 pagesIntroduction To Drilling Machine AlignmentPruthviraj KukadeNo ratings yet

- Foundations of TLE Activity 1Document1 pageFoundations of TLE Activity 1Sally BaranganNo ratings yet

- CNC Lathe Machine Technician and ProgrammerDocument16 pagesCNC Lathe Machine Technician and ProgrammermanjuNo ratings yet

- 01-SmartROC D65 - CompressorDocument23 pages01-SmartROC D65 - CompressorElvis Jaen FernandezNo ratings yet

- 4747676299.1 en-US - FlexiROC T40 - CRI - Track FrameDocument32 pages4747676299.1 en-US - FlexiROC T40 - CRI - Track Framecarlos barreraNo ratings yet

- 7216524555.2 en - US - SmartROC D65 - CRI - Feed Angle Sensor (Inclinometer)Document20 pages7216524555.2 en - US - SmartROC D65 - CRI - Feed Angle Sensor (Inclinometer)carlos barreraNo ratings yet

- Machine Vision System For Inspecting Flank Wear On Cutting ToolsDocument5 pagesMachine Vision System For Inspecting Flank Wear On Cutting ToolsRaghuNo ratings yet

- Design For AssemblyDocument11 pagesDesign For AssemblyMalay ShahNo ratings yet

- The ISO 11783 Standard and Its Use in Precision Agriculture EquipmentDocument9 pagesThe ISO 11783 Standard and Its Use in Precision Agriculture EquipmentHoa Binh TranNo ratings yet

- Moduldokumentation HydraulicsDocument66 pagesModuldokumentation HydraulicsJordi El MariachetNo ratings yet

- Why CSS? Why CSS?: Computer System Servicing Computer System ServicingDocument1 pageWhy CSS? Why CSS?: Computer System Servicing Computer System ServicingStiffany R. NercuitNo ratings yet

- CM Tle 8 Q3Document2 pagesCM Tle 8 Q3Anday Par LizaNo ratings yet

- JD Manager - Twisting MaintenanceDocument1 pageJD Manager - Twisting MaintenanceCraig MartinNo ratings yet

- General Concept of Preventive MaintenanceDocument11 pagesGeneral Concept of Preventive MaintenanceSayed NagyNo ratings yet

- Fitter Syllabus Sem 1Document18 pagesFitter Syllabus Sem 1krunal07786No ratings yet

- MC Sewing Machine OperatorDocument19 pagesMC Sewing Machine OperatorAvi Raj100% (1)

- 1 - Chapter OneDocument35 pages1 - Chapter Onemirahaem5No ratings yet

- Apparel Analysisfor Layout Planningin Sewing SectionDocument8 pagesApparel Analysisfor Layout Planningin Sewing SectionITM Teck Soft.No ratings yet

- Apparel Analysis For Layout Planning in Sewing SectionDocument8 pagesApparel Analysis For Layout Planning in Sewing SectionNadarajNo ratings yet

- BA DuraMax REV 3 0 Online en PDFDocument235 pagesBA DuraMax REV 3 0 Online en PDFbeto206123100% (1)

- Aircraft Assembly 2021Document8 pagesAircraft Assembly 2021SNL tvNo ratings yet

- TrueDocument57 pagesTrueEbisa DuressaNo ratings yet

- Apparel Analysis For Layout Planning in Sewing Section: ArticleDocument8 pagesApparel Analysis For Layout Planning in Sewing Section: ArticleGaurav kumarNo ratings yet

- Apparel Analysis For Layout Planning in Sewing SectionDocument8 pagesApparel Analysis For Layout Planning in Sewing SectionNure MohammadNo ratings yet

- Production and ManufacturingDocument80 pagesProduction and ManufacturingcgcbackupakNo ratings yet

- Competency Profile (CP) : Sub Sector After Sales Job Area Automotive After Sales Service Level TWODocument40 pagesCompetency Profile (CP) : Sub Sector After Sales Job Area Automotive After Sales Service Level TWONORISHAM BIN A RAHIMNo ratings yet

- On Job Training 1 GokulDocument10 pagesOn Job Training 1 GokulSanjayNo ratings yet

- Fundamentos de Inspección y Reacondicionamiento de Plataformas de PerforaciónDocument23 pagesFundamentos de Inspección y Reacondicionamiento de Plataformas de PerforaciónABRAHAM NERY LLORENTY ROJASNo ratings yet

- Drilling Rig Inspection and Workover FundamentalsDocument23 pagesDrilling Rig Inspection and Workover Fundamentalslearn offshore drillingNo ratings yet

- Model Curriculum Fitter NSQF Level 1Document6 pagesModel Curriculum Fitter NSQF Level 1Shitosh DilluNo ratings yet

- MTK 1032 Mechanical CuttingDocument17 pagesMTK 1032 Mechanical CuttingMR FIKRINo ratings yet

- Cora - INSTRUCTIONAL-DESIGN-TEMPLATEDocument4 pagesCora - INSTRUCTIONAL-DESIGN-TEMPLATECorazon CaldozaNo ratings yet

- Electrical Maintenance MapDocument4 pagesElectrical Maintenance MapScribdTranslationsNo ratings yet

- Ringkas NossDocument37 pagesRingkas Nossayein azliNo ratings yet

- University Institute of Engineering Department of Ait - CseDocument14 pagesUniversity Institute of Engineering Department of Ait - Cseayushworkspace279No ratings yet

- DLL Week 1 2 Q2Document8 pagesDLL Week 1 2 Q2Danica Rosabele Templo DionisioNo ratings yet

- Skills Framework For Precision Engineering Technical Skills and Competencies (TSC) Reference DocumentDocument2 pagesSkills Framework For Precision Engineering Technical Skills and Competencies (TSC) Reference Documentjeremytoh89No ratings yet

- Genie zx135/70 Operator ManualDocument71 pagesGenie zx135/70 Operator ManualAbdurrahim TomarNo ratings yet

- Medical Device MaintenanceDocument24 pagesMedical Device MaintenanceFayez Abu Al SaoudNo ratings yet

- Continental Biscuits LTD: Job Description FormDocument2 pagesContinental Biscuits LTD: Job Description FormSaad mubeenNo ratings yet

- MFS Web 16oDocument16 pagesMFS Web 16oSaid RoukbiNo ratings yet

- GMKDocument7 pagesGMKNKay AndroidNo ratings yet

- Cutting ParametersDocument7 pagesCutting ParametersAtelier MethodologieNo ratings yet

- Example of A Business Model Canvas Coconut Treat StandDocument2 pagesExample of A Business Model Canvas Coconut Treat StandSabrena FennaNo ratings yet

- Lpo Birds NestDocument6 pagesLpo Birds Nestapi-265791946No ratings yet

- Chapter 8 - Memory Storage Devices Question AnswersDocument4 pagesChapter 8 - Memory Storage Devices Question AnswersAditya MalhotraNo ratings yet

- Objectivity in Journalism (Williams & Stroud, 2020)Document4 pagesObjectivity in Journalism (Williams & Stroud, 2020)Dexter CaroNo ratings yet

- English File: Answer KeyDocument4 pagesEnglish File: Answer KeyEvelyn BoccioNo ratings yet

- Welcome To Good Shepherd Chapel: Thirty-Third Sunday in Ordinary TimeDocument4 pagesWelcome To Good Shepherd Chapel: Thirty-Third Sunday in Ordinary Timesaintmichaelpar7090No ratings yet

- Get Best Long Coat Green Apple ShampooDocument1 pageGet Best Long Coat Green Apple ShampooBhawna SinghNo ratings yet

- Canon 8.02Document1 pageCanon 8.02Vin LacsieNo ratings yet

- Knowledge L3/E Comprehension L4/D Application L5/C Analysis L6/B Synthesis L7/A Evaluation L8/ADocument2 pagesKnowledge L3/E Comprehension L4/D Application L5/C Analysis L6/B Synthesis L7/A Evaluation L8/AWaltWritmanNo ratings yet

- Operating, Maintenance & Parts Manual: Rated LoadsDocument48 pagesOperating, Maintenance & Parts Manual: Rated LoadsAmanNo ratings yet

- House of ConcreteDocument9 pagesHouse of ConcreteArkyadeep ChowdhuryNo ratings yet

- Project Management A Systems Approach To Planning Scheduling and Controlling 10Th Edition Kerzner Test Bank Full Chapter PDFDocument24 pagesProject Management A Systems Approach To Planning Scheduling and Controlling 10Th Edition Kerzner Test Bank Full Chapter PDFGeorgeAndersonkqmr100% (13)

- Gratuity Eligibility For Less Than 5 Yrs. (4yrs.240days)Document8 pagesGratuity Eligibility For Less Than 5 Yrs. (4yrs.240days)DILLIP KUMAR MAHAPATRA0% (1)

- Statements of Financial Position As at 31 December 2009 and 2010Document3 pagesStatements of Financial Position As at 31 December 2009 and 2010mohitgaba19No ratings yet

- Islamic Economics and The Islamic Sub EconomyDocument18 pagesIslamic Economics and The Islamic Sub EconomyNoerma Madjid Riyadi100% (1)

- KMPDocument2 pagesKMPPrajeesh KrishnanNo ratings yet

- RPSG-IMS-HS-F - 01 - Hazard Observation CardDocument2 pagesRPSG-IMS-HS-F - 01 - Hazard Observation CardRocky BisNo ratings yet

- Modul EFB Unit 7Document18 pagesModul EFB Unit 7Muhammad IlhamNo ratings yet

- 04 What Is Easement Distinguish Easement From Usufruct 2 Can There Be A An - Course HeroDocument9 pages04 What Is Easement Distinguish Easement From Usufruct 2 Can There Be A An - Course HerojrstockholmNo ratings yet

- Indian Income Tax Return Acknowledgement: Name of Premises/Building/VillageDocument1 pageIndian Income Tax Return Acknowledgement: Name of Premises/Building/Villagehealth with wealthNo ratings yet

- NutriSmart - Food Products Recommendation SystemDocument3 pagesNutriSmart - Food Products Recommendation SystemAnonymous izrFWiQNo ratings yet

- Practical Class 2 Text Artificial IntelligenceDocument3 pagesPractical Class 2 Text Artificial IntelligenceAlex VaskoNo ratings yet

- Wedding Venue List 1Document53 pagesWedding Venue List 1Vivek Kumar GuptaNo ratings yet

- SxzsaDocument15 pagesSxzsabadmash1988No ratings yet

- PD 477Document21 pagesPD 477Rak Nopel Taro100% (1)

- Handwritten Notes IP XII 2020 PYTHON - RPDocument37 pagesHandwritten Notes IP XII 2020 PYTHON - RPchaitanyanegi2004No ratings yet

- Annotated BibliographyDocument2 pagesAnnotated Bibliographyapi-314923435No ratings yet

- Factors Influencing Savings Mobilization by Commercial BanksDocument81 pagesFactors Influencing Savings Mobilization by Commercial BanksNicholas Gowon100% (7)