Professional Documents

Culture Documents

b53 3271 Emboutillage para Argentina y Brasil

b53 3271 Emboutillage para Argentina y Brasil

Uploaded by

GT-LUCAS BARCIOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

b53 3271 Emboutillage para Argentina y Brasil

b53 3271 Emboutillage para Argentina y Brasil

Uploaded by

GT-LUCAS BARCICopyright:

Available Formats

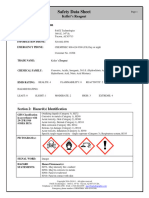

PSA PEUGEOT - CITROËN

Metallic materials

B53 3271

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT

STAMPED IN BRASIL AND ARGENTINA

Page 1/9

No use restriction

This standard is published by the PSA Standards Department (DRD/DAPF/RHN/NCF)

For any question, contact us at the next address: normespsa@mpsa.com.

This standard is available in the Intranet NORMES and on the B2B gate.

In the event of litigation, only the French version of this standard is taken.

FOREWORD

This document, as an experimental standard, is applicable and submitted for observations for a duration of

3 months. If no comments are received by 10/05/2015 at the address: normespsa@mpsa.com the content of this

document shall be confirmed.

Drafted by Checked by Approved by

Ludovic AUGÉ Douglas BARROSO Arnaud SALESSE

DRD/DCHM/PMXP/MCPV DAML/DSIL/MITV/ICHM DRD/DCHM/PMXP/MCPV

Date Signature Date Signature Date Signature

13/02/2015 - 13/02/2015 - 13/02/2015 -

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 2/9

RECORDS

Index Date Nature of the modifications

FOR BRASILIAN AND ARGENTINA PLANT THIS SPECIFICATION

OR 13/01/2015

STIPULATE LOCAL ADAPTATION

PARTICIPANTS

The following persons took part in the drafting and/or checking of this norm:

DAML/DSIL/MITV/ICHM Douglas BARROSO

DAML/DSIL/MITV/ICHM Clistian IRINEU DE PAĨVA

DRD/DAPF/RHN/NCF Mathieu HENRIQUES (SEGULA company for PSA PEUGEOT CITROEN)

Xavier DE CHEZELLES

CONTENTS

1. OBJECT AND FIELD OF APPLICATION 3

2. DOCUMENTARY REFERENTIAL 3

2.1. REFERENCE DOCUMENTS 3

2.1.1. Norms 3

2.1.2. Regulations 3

2.1.3. Other documents 3

2.2. APPLICABLE DOCUMENTS 4

2.2.1. Norms 4

2.2.2. Regulations 4

2.2.3. Other documents 4

2.3. EXPRESSIONS ON DOCUMENTS 4

3. TERMINOLOGY 5

3.1. DÉFINITIONS 5

3.2. ACRONYMS 5

4.3. CHEMICAL COMPOSITION 7

4.4. MECHANICAL PROPERTIES 8

4.5. CHARACTERISTIC OF THE DELIVERY CONDITION 9

4.6. ROUGHNESS 9

5. CHARACTERISTIC OF THE REFERENCE CONDITION 9

6. CHARACTERISTIC OF THE DELIVERY CONDITION 9

7. DELIVERED GRADES 9

APPENDIX TITLE 9

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 3/9

1.OBJECT AND FIELD OF APPLICATION

The present specification is only for use in South America. No parts for use in Europe, Asia, nor Russia must be

designed according to this specification. This document only specifies properties that have been changed from the

worldwide specification. These must be taken from the following documents:

It must be supplemented by the following documents:

B53 3020, B53 3050, B53 3055, B53 3059, B53 3070, B53 3072, B53 3210, B53 3220 (cf details 2.1.1).

2.DOCUMENTARY REFERENTIAL

2.1.REFERENCE DOCUMENTS

2.1.1.NORMS

2.1.1.1. INTERNAL NORMS

B53 3020 STEEL FLAT PRODUCTS DESIGNATIONS – SYMBOLS

B53 3050 FLAT PRODUCTS IN STEEL SUPPLYING GENERAL REQUIREMENTS

B53 3055 STEEL OR ALUMINIUM FLAT PRODUCTS HOT OR COLD ROLLED METALLURGICAL

REQUIREMENTS – TESTS

B53 3059 STEEL FLAT PRODUCTS FOR STAMPING - SURFACE STATE

B53 3070 FLAT PRODUCTS HOT OR COLD ROLLED SPECIFIC TECHNICAL REQUIREMENTS

B53 3072 STEEL FLAT PRODUCTS HOT OR COLD ROLLED DIMENSIONAL SPECIFICATIONS

B53 3210 STEEL FLAT PRODUCTS HOT AND COLD ROLLED ZINC ELECTROPLATED

B53 3220 STEEL FLAT PRODUCTS HOT OR COLD ROLLED CONTINUOUSLY GALVANISED

2.1.1.2. EXTERNAL NORMS

NF EN ISO 643 STEELS - MICROGRAPHIC DETERMINATION OF THE APPARENT GRAIN SIZE

NF A04-106 IRON AND STEEL; METHODS OF DETERMINATION OF RATE OF NON METALLIC

INCLUSIONS IN WROUGTH STEEL

STEELS - MICROGRAPHIC DETERMINATION OF THE APPARENT GRAIN SIZE

NF EN 10 325 STEEL - DETERMINATION OF YIELD STRENGTH INCREASE BY THE EFFECT OF

HEAT TREATMENT (BAKE-HARDENING-INDEX)

NF EN 10 346 LOW-CARBON STEEL FLAT PRODUCTS CONTINUOUSLY COATED BY HOT

IMMERSION - TECHNICAL REQUIREMENTS OF SUPPLYING

2.1.2.REGULATIONS

CE 2000/53 CONVEY UNUSABLE

2.1.3.OTHER DOCUMENTS

Not applicable.

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 4/9

2.2.APPLICABLE DOCUMENTS

2.2.1.NORMS

2.2.1.1.INTERNAL NORMS

B18 0121 DEFINITION OF MASSES, LOAD CONDITIONS WEIGHING CONDITIONS OF VEHICLES

IN CATEGORIES M1 (PC) AND N1 (CV) HOMOLOGATED AFTER 11/2012 (according to

UE/1230/2012)

B20 0110 SUPPLIES FOR PURCHASED PRODUCTS - GENERAL RECOMMANDATIONS

B20 0200 RECYCLING AND ENVIRONMENT - ELV REGULATION - GREEN MATERIALS -

REGULATIONS ON CHEMICALS (REACH…)

2.2.1.2.EXTERNAL NORMS

Not applicable.

2.2.2.REGULATIONS

Not applicable.

2.2.3.OTHER DOCUMENTS

Not applicable.

2.3.EXPRESSIONS ON DOCUMENTS

The material is defined in the following form:

Sheet.

Grade.

N° of this specification indicated between brackets.

Nominal thickness delivered in millimeter (mm).

Coating if necessary.

Reference of the coating norm.

Aspect in case of Z aspect .

Example: Sheet DP590 PSA B53 3250 (last update in French only) th: 1.17 mm G10/10 PSA B53 3220

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 5/9

3.TERMINOLOGY

A dictionary (glossary) of the main terms and their definitions used within the activities of the R&D can be consulted

in-house via the DESP or by clicking on the following link: SCPO_MGPJ07_0116.

3.1.DEFINITIONS

For the requirements of this norm, the following term is defined:

BAKE HARDENING Increase in the yield point following a deformation, simulating an operation of stamping, and

(BH) EFFECT an ageing by heat treatment, simulating baking in the painting furnaces.

3.2.ACRONYMS

For the requirements of this norm, the following acronyms are defined:

BH Bake Hardening.

4. PROPERTIES OF THE PRODUCTS AT DELIVERY

4.1. GENERAL INFORMATION

No defect shall be identified during using. They are auto-annealed, pickled, oiled (cf B53 3050) and specific

roughness can be required (cf B53 3059). They must respect the generic requirements indicated in the standards

B53 3070 and B53 3072.

4.2. METALLURGICAL CHARACTERISTICS.

The microscopic examination must reveal:

A nonribboned frame with homogeneous grains in their form and size,

a metal without blister, nor important inclusion; the dirtiest scope charged in non-deformable inclusions should not

exceed for each type of inclusion figure 2 of scale JERNKONTONRET in accordance with the norm NF A04-106.

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 6/9

4.2.1. STRUCTURES

To describe the structures of each grades family, the following definitions must be taking into account:

Bake-hardening steel: BH steel

Steel that demonstrates an increase in proof strength following heating in the region of 170 °C for 20 min

Nota: These steels have a good suitability for cold forming and present a high resistance to plastic straining (which

is increased on finished parts during heat treatment) and a good dent resistance.

Complex-phase steel: CP steel

Steel with a ferritic/bainitic matrix containing small amounts of martensite, retained austenite and/or perlite

where an extreme grain refinement is caused by retarded recrystallisation or precipitation of micro-alloying elements

Dual-phase steel: DP steel

Steel with a ferritic matrix containing a martensitic second phase present in the form of islands and eventually

bainite as a complementary phase

Nota: According to their high tensile strength levels, dual phase steels show a low yield strength ratio and a high

work hardening rate.

Ferritic-bainitic steel: FB steel

Steel containing bainite or strengthened bainite in a matrix consisting of ferrite and/or strengthened ferrite

Nota: The strengthening of the matrix is caused by a high density of dislocations, by grain refinement and

precipitation of micro-alloying elements.

Interstitial free steel: IF steel

Steel whose composition is controlled to achieve improved r- and n-values

Nota: These steels have both, a high mechanical strength and an excellent suitability for cold forming, due to their

solid solution hardening and interstitial free microstructure.

Low alloy / micro-alloyed steel: High Strength Low Alloyed (HSLA) steel

Steel containing one or more of alloys Nb, Ti and V to achieve required proof strength levels

Nota: Combined precipitation and grain refinement hardening modes allow reaching a high mechanical resistance

while reducing the content of alloying elements.

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 7/9

4.3.CHEMICAL COMPOSITION

This list of chemical elements is exhaustive. Any other element must not be present in chemical composition

without the agreement of the Materials & Processes Department.

The chemical composition is expressed in volumic %.

GRADES C Mn Si P S Al Ti Nb Ti+Nb V Cr Mo B N Cr+Mo

LaF, HDG Ci min 0,02 0,10

max 0,12 0,60 0,50 0,10 0,045 0,30

LaF, HDG Ei min 0,08 0,015

max 0,12 0,70 0,50 0,10 0,045 0,30

LaF, HDG ESi min 0,05 0,015

max 0,12 0,60 0,50 0,10 0,045 0,30

Mild steels

LaF, HDG SESi min 0,015

max 0,12 0,60 0,50 0,10 0,045 0,30

TaQ, HDG 1Ci min

max 0,12 0,60 0,045 0,045

TaQ, HDG 3Ci min

max 0,08 0,40 0,030 0,030

LaF, HDG E180BHi min

Bake

max 0,10 0,70 0,50 0,06 0,03 0,100 0,12 0,09

hardening

LaF, HDG E220BHi min

steels

max 0,10 0,90 0,50 0,08 0,03 0,100 0,12 0,09

LaF, HDG P220i min 0,10 0,01 0,015

ReP

max 0,08 0,90 0,50 0,08 0,03 0,100 0,12 0,09

& Isotropic

LaF, HDG P260i min 0,20 0,01 0,015

Steels

max 0,11 1,30 0,50 0,10 0,03 0,100 0,12 0,09

LaF, HDG E275Di min 0,02 0,10 0,015

max 0,11 1,00 0,50 0,03 0,03 0,100 0,15 0,09

LaF, HDG E335Di min 0,02 0,20 0,015 0,02

max 0,12 1,10 0,50 0,03 0,03 0,15 0,09

LaF, HDG E390Di min 0,015

HSLA max 0,12 1,40 0,50 0,03 0,03 0,15 0,09

steels TaQ, HDG HD380LAi min 0,015

max 0,12 1,30 0,35 0,025 0,015 0,20 0,12 0,20 0,12

TaQ, HDG HE445Di min 0,015

max 0,12 1,60 0,35 0,025 0,015 0,15 0,09 0,20 0,12

TaQ, HDG HE490Di min 0,015

max 0,12 1,50 0,35 0,025 0,015 0,20 0,12 0,20 0,12

LaF, HDG DP450i min

max 0,14 2,00 0,80 0,080 0,015 2,000 0,15 0,15 0,15 0,20

Multiphase

LaF, HDG DP600i min

Dual Phase

max 0,17 2,20 0,80 0,08 0,02 2,000 0,15 0,15 0,15 0,20 1,00 1,00 0,01 1,00

steels

LaF, HDG DP780i min

max 0,18 2,50 0,80 0,08 0,02 2,000 0,15 0,15 0,15 0,20 1,00 1,00 0,01 1,00

Multiphase LaF, HDG FB45i min 0,015

Ferrite max 0,18 1,20 0,50 0,03 0,01 0,08 0,08 0,08 0,15 0,30 0,30 0,01 0,30

Bainite LaF, HDG FB60i min 0,015

Steels max 0,20 1,80 0,50 0,03 0,01 0,15 0,15 0,15 0,15 0,30 0,30 0,01 0,30

Boron LaF, HDG PHS 1500i min 0,19 1,50 0,010 0,02 0,00

steel max 0,27 2,50 0,50 0,03 0,01 0,06 0,50 0,01 0,02

% Mn % Si %Cr % Mo %V

C éq %C

Carbon equivalent: 6 5

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 8/9

4.4.MECHANICAL PROPERTIES

The mechanical properties are guaranteed 6 months starting from the delivery of the product to PSA. Trials

conditions are defined in the standard B53 3055.

GRADES Rp Rm A% Ag% r n BH

min 120,00 260,00 26,00

LaF, HDG Ci

max 300,00 420,00

min 120,00 260,00 34,00 1,30 0,16

LaF, HDG Ei

max 240,00 360,00

Mild steels

min 140,00 270,00 36,00 1,60 0,18

LaF, HDG ESi

max 200,00 340,00

min 140,00 270,00 40,00 1,90 0,21

LaF, HDG SESi

max 180,00 330,00

min 170,00 24,00

TaQ, HDG 1Ci

max 360,00 440,00

min 170,00 29,00

TaQ, HDG 3Ci

max 330,00 400,00

min

& Isotropic hardening

180,00 290,00 34,00 1,50 0,16 35,00

LaF, HDG E180BHi

steels

Bake

max 260,00 360,00

min 220,00 320,00 32,00 1,20 0,15 32,00

LaF, HDG E220BHi

max 300,00 400,00

min 200,00 340,00 31,00 1,30 0,15

LaF, HDG P220i

Steels

max 300,00 420,00

ReP

min 240,00 360,00 28,00 1,10 0,12

LaF, HDG P260i

max 340,00 440,00

min 260,00 350,00 23,00

LaF, HDG E275Di

max 380,00 480,00

min 320,00 410,00 21,00

LaF, HDG E335Di

max 440,00 520,00

min 380,00 440,00 19,00

LaF, HDG E390Di

HSLA steels

max 480,00 560,00

min 300,00 380,00 26,00

TaQ, HDG HD300LAi

max 430,00 500,00

HD380LAi min 380,00 460,00 23,00

TaQ, HDG

HE390D max 530,00 600,00

min 420,00 520,00 22,00

TaQ, HDG HE445Di

max 540,00 650,00

min 500,00 560,00 18,00

TaQ, HDG HE490Di

max 620,00 700,00

min 260,00 450,00 27,00 0,16 30,00

LaF, HDG DP450i

Multiphase

Dual Phase

max 340,00

steels

min 340,00 580,00 18,00 0,14 30,00

LaF, HDG DP600i

max 460,00

min 420,00 780,00 14,00 30,00

LaF, HDG DP780i

max 560,00

min 320,00 440,00 22,00

TaQ, HDG FB45i

Bainite

Ferrite

Steels

max 440,00

min 440,00 560,00 14,00

TaQ, HDG FB60i

max 640,00

OR INTERNAL USE (C1)

PSA PEUGEOT - CITROËN

PRODUCT SPECIFICATION FOR FLAT ROLLED PRODUCT B53 3271 9/9

GRADES Rp Rm A% Ag% r N BH

min 300,00 550,00 10,00

Boron

steel

LaF, HDG

PHS 1500i max 600,00 750,00

4.5.CHARACTERISTIC OF THE DELIVERY CONDITION

If a coating is required, its characteristics must respect PSA specification B53 3220 for hot-dip galvanizing and

PSA specification B53 3210 for electroplating.

For the parts of mechanical - suspension, wheels, steering (wishbones, wells, REAR crosspieces…) imperatively

protected by an anti-corrosive painting, 1 to 2 light defects is tolerated on the faces of the part. By defect, it is

supposed there is a lack of localized coating. The lowest dimension of the defect must remain lower than 2 mm.

The length of the defect is not limited as much as its width remains lower than 2 mm.

4.6.ROUGHNESS

Due to welding, stamping & painting issues restrictions are the following:

Grades family Min Max

Mild steel, BH steel, ReP and 1 µm 2 µm

isotropic steel

5.CHARACTERISTIC OF THE REFERENCE CONDITION

Not applicable.

6.CHARACTERISTIC OF THE DELIVERY CONDITION

Not applicable.

7.DELIVERED GRADES

Not applicable.

APPENDIX TITLE

Not applicable.

OR INTERNAL USE (C1)

You might also like

- WSS M99P1111 ADocument3 pagesWSS M99P1111 Ajose luis100% (1)

- Fiat52605 02Document6 pagesFiat52605 02LucaNo ratings yet

- MBN 10494-6 2016-03Document22 pagesMBN 10494-6 2016-03cmorabitoNo ratings yet

- BS Iso 10631-2013Document24 pagesBS Iso 10631-2013GT-LUCAS BARCI0% (1)

- BS en 26704-1991 (1999) Iso 6704-1982Document12 pagesBS en 26704-1991 (1999) Iso 6704-1982GT-LUCAS BARCINo ratings yet

- Harmonized Document: Fluids Resistance To VariousDocument8 pagesHarmonized Document: Fluids Resistance To VariousJuliano Depetris100% (1)

- N67F CM-ZN-2 - 5001.110.016 - NormDocument22 pagesN67F CM-ZN-2 - 5001.110.016 - Normgokul100% (1)

- 4701000EN - Cap. 7.1.2Document6 pages4701000EN - Cap. 7.1.2Carlos LanzillottoNo ratings yet

- Cathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsDocument5 pagesCathodic Electrocoating of Body Skin Parts Made From Aluminum Semi-Finished ProductsMaryana c100% (1)

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesDocument5 pagesNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliNo ratings yet

- DBL 4023 2012-08Document7 pagesDBL 4023 2012-08Fernando MartínNo ratings yet

- BN - 586437-115 - Acr 04Document15 pagesBN - 586437-115 - Acr 04oslat100% (1)

- SteelDocument44 pagesSteelDevendra SinghNo ratings yet

- Paint Coatings Resistance To Dry Abrasion Method With Abrasive MaterialDocument8 pagesPaint Coatings Resistance To Dry Abrasion Method With Abrasive Materialclaudio5475No ratings yet

- H PDFDocument83 pagesH PDFvivianeNo ratings yet

- B65 4251 (Rev. D 2016.03) EN - SOUNDPROOFING ACOUSTIC ABSORBENTS SPECIFICATIONDocument25 pagesB65 4251 (Rev. D 2016.03) EN - SOUNDPROOFING ACOUSTIC ABSORBENTS SPECIFICATIONDiego CamargoNo ratings yet

- Unspecified Tolerances Plastic Parts: 1. ObjectDocument7 pagesUnspecified Tolerances Plastic Parts: 1. ObjectDiegoNo ratings yet

- B53 3325 - enDocument6 pagesB53 3325 - enSukant Ghosh100% (1)

- B62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDocument15 pagesB62 0030 (Rev. E 2008.03) EN - THERMOPLASTIC, THERMOSETTING MATERIALS, THERMOPLASTIC ELASTOMERS AND RUBBERS - SPECIFICATIONSDiego CamargoNo ratings yet

- M 3031 (2013-06)Document16 pagesM 3031 (2013-06)Hatada FelipeNo ratings yet

- Weldable Steel Flat Products Extra-Mild Hot Rolled Steels For Cold StampingDocument5 pagesWeldable Steel Flat Products Extra-Mild Hot Rolled Steels For Cold StampingLucasNo ratings yet

- MS.50002Document44 pagesMS.50002Adriano MagalhãesNo ratings yet

- DBL 8440 2018-11Document11 pagesDBL 8440 2018-11jyoti prakash singhNo ratings yet

- Mpaps G-20Document6 pagesMpaps G-20PANKAJ CHAUHANNo ratings yet

- Thermoplastic, Thermosetting, Thermoplastic Elastomer and Rubber Materials Classification and SpecificationDocument36 pagesThermoplastic, Thermosetting, Thermoplastic Elastomer and Rubber Materials Classification and SpecificationIsrael FidelesNo ratings yet

- NES-M2032 - 2021 - (ColdRoll-High Tensile)Document13 pagesNES-M2032 - 2021 - (ColdRoll-High Tensile)dpfloresNo ratings yet

- r12 3201 (Rev. e 2000.09) en - Mechanical Elements Connected To The Engine Fuel Tank Fuel LinesDocument3 pagesr12 3201 (Rev. e 2000.09) en - Mechanical Elements Connected To The Engine Fuel Tank Fuel LinesDiego CamargoNo ratings yet

- TL245 English 2004Document8 pagesTL245 English 2004Elliott RussellNo ratings yet

- Guia de Materiales - MatricesDocument11 pagesGuia de Materiales - MatricesGracielaNo ratings yet

- Structural Steels in Bar or Wire Form Grade Af 43: Psa Peugeot - CitroënDocument2 pagesStructural Steels in Bar or Wire Form Grade Af 43: Psa Peugeot - CitroënThiago Silva100% (1)

- D493027 en PDFDocument39 pagesD493027 en PDFJose ValenciaNo ratings yet

- En-PpDocument34 pagesEn-PpDan IlcaNo ratings yet

- VW 50019 PDFDocument4 pagesVW 50019 PDFSujay Nahalde100% (1)

- WSS-M2D507-B4 02d507b5 - ElastomerDocument6 pagesWSS-M2D507-B4 02d507b5 - ElastomerFrancesco VignaliNo ratings yet

- WSS M1a347 (Hsla)Document14 pagesWSS M1a347 (Hsla)Enrique Maya VisuetNo ratings yet

- TMS6900Document14 pagesTMS6900Josue Garcia QuiniNo ratings yet

- Acrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedDocument7 pagesAcrylonitrile Butadiene Styrene - UV Stabilized and General Purpose, Heat StabilizedJefferson CruzNo ratings yet

- Flexibility: ASTM D-1737-89Document1 pageFlexibility: ASTM D-1737-89s_omeone4usNo ratings yet

- Psa D 271571 2003Document9 pagesPsa D 271571 2003KasraNo ratings yet

- GMW14400 Apr - 2016Document20 pagesGMW14400 Apr - 2016Joel MedellinNo ratings yet

- D271389 F' PDFDocument13 pagesD271389 F' PDFReza AbdolahiNo ratings yet

- DBL 7381 2015-05Document17 pagesDBL 7381 2015-05cmorabitoNo ratings yet

- Iso898 2Document19 pagesIso898 2Ricardo VitorianoNo ratings yet

- GMW16536 Sealer-In Welded Struct Aug2011Document9 pagesGMW16536 Sealer-In Welded Struct Aug2011Taofiq AbiolaNo ratings yet

- JSA JIS G 3135 - Cold-Reduced HighDocument19 pagesJSA JIS G 3135 - Cold-Reduced Highnavid100% (1)

- Engineering Material Specification: Printed Copies Are UncontrolledDocument8 pagesEngineering Material Specification: Printed Copies Are UncontrolledaldairlopesNo ratings yet

- Standard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesDocument16 pagesStandard: Normalisation Renault Automobiles Service 60201 Section Normes Et Cahiers Des ChargesRicardo VitorianoNo ratings yet

- C15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesDocument2 pagesC15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesPaulo Henrique NascimentoNo ratings yet

- M0140 (2014-N) NES: Salt Spray TestingDocument11 pagesM0140 (2014-N) NES: Salt Spray TestingBea RiveraNo ratings yet

- Coating Systems For Customised, Special Versions: January 2004Document14 pagesCoating Systems For Customised, Special Versions: January 2004Akmal NizametdinovNo ratings yet

- AbsDocument17 pagesAbsDrurajNo ratings yet

- Bes MSDocument1 pageBes MSasdNo ratings yet

- A 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFDocument7 pagesA 1008 - A 1008M - 02 Qtewmdgtmdjfmq - PDFTiến Lượng NguyễnNo ratings yet

- DIN EN 10130 (Parte 1-2)Document14 pagesDIN EN 10130 (Parte 1-2)aldairlopesNo ratings yet

- VW 011 03Document22 pagesVW 011 03Alexandre UrquizaNo ratings yet

- FiatDocument10 pagesFiatrgi178100% (1)

- Salt Spray ReportDocument1 pageSalt Spray ReportaslamNo ratings yet

- WSS M1P94 ADocument9 pagesWSS M1P94 AAleks SenaNo ratings yet

- Standard STD 121-0003Document9 pagesStandard STD 121-0003RobertoNo ratings yet

- Minimum Performance Requirements For Decorative Chromium Plated Plastic PartsDocument20 pagesMinimum Performance Requirements For Decorative Chromium Plated Plastic PartsJefferson CruzNo ratings yet

- MBN10231 Eng+2008-09Document12 pagesMBN10231 Eng+2008-09gültekin gökNo ratings yet

- Worldwide Engineering Standards: General Specification HVAC & PT Cooling GMW15866Document11 pagesWorldwide Engineering Standards: General Specification HVAC & PT Cooling GMW15866Akmal NizametdinovNo ratings yet

- Psa B15 3320 B enDocument13 pagesPsa B15 3320 B enhkatzerNo ratings yet

- KellersDocument13 pagesKellersGT-LUCAS BARCINo ratings yet

- Scope: Official Test Method - 1981 REVISED - 1989 REVISED - 1997 © 1997 TAPPIDocument6 pagesScope: Official Test Method - 1981 REVISED - 1989 REVISED - 1997 © 1997 TAPPIGT-LUCAS BARCINo ratings yet

- BS en Iso 6553-2017Document14 pagesBS en Iso 6553-2017GT-LUCAS BARCINo ratings yet

- Sae J 2045 2012-11-01Document16 pagesSae J 2045 2012-11-01GT-LUCAS BARCI100% (1)

- Sae J2045Document2 pagesSae J2045GT-LUCAS BARCINo ratings yet

- Sugar HandlingDocument4 pagesSugar Handlingrbrbs7100% (1)

- 5290 Landing ValveDocument11 pages5290 Landing ValveSachin KumarNo ratings yet

- Management Discussion and Analysis 2013-14: Rank Country 2013 2012 Change %Document26 pagesManagement Discussion and Analysis 2013-14: Rank Country 2013 2012 Change %galacticwormNo ratings yet

- Ferrous MetalsDocument37 pagesFerrous MetalsGidNo ratings yet

- Steel DesignDocument131 pagesSteel DesignAndrea RamirezNo ratings yet

- En 9Document2 pagesEn 9Swaran SinghNo ratings yet

- DATA SHEET Gas Atomized Powder For Additive ManufacturingDocument1 pageDATA SHEET Gas Atomized Powder For Additive ManufacturingdaffaNo ratings yet

- MF Ipl 2001 R Shop Drawing RebarDocument1 pageMF Ipl 2001 R Shop Drawing RebarMahmoud ShakerNo ratings yet

- Synopsis of Changes in Section VIII Div2 E2023Document140 pagesSynopsis of Changes in Section VIII Div2 E2023yathi sNo ratings yet

- Chemical Composition % of Steel 20Mncr5 (1.7147) : en 10084-2008Document39 pagesChemical Composition % of Steel 20Mncr5 (1.7147) : en 10084-2008Yokesh SamannanNo ratings yet

- Detail of The Type of Material ChosenDocument4 pagesDetail of The Type of Material Chosen000No ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure PreparationNokiabhre WijayaNo ratings yet

- Approved Steel Pipe Mills061016Document89 pagesApproved Steel Pipe Mills061016William DaslerNo ratings yet

- Investigation On Material Characteristics and Fatigue Crack Behavior of Thermite Welded Rail JointDocument16 pagesInvestigation On Material Characteristics and Fatigue Crack Behavior of Thermite Welded Rail JointDanilo Soares da MottaNo ratings yet

- WPS-43 - Gtaw & Smaw Tig + SmawDocument19 pagesWPS-43 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaNo ratings yet

- Branch Connection StandardDocument5 pagesBranch Connection StandardAdi OktaNo ratings yet

- SRS 128Document64 pagesSRS 128Maruan MuhammadNo ratings yet

- Offshore Mooring Steel Wire RopesDocument30 pagesOffshore Mooring Steel Wire RopesMark InnesNo ratings yet

- Heat Treatment ProcessesDocument7 pagesHeat Treatment ProcessesArjun H NambiarNo ratings yet

- Bhilai Steel Plant Pre Final ProjectDocument76 pagesBhilai Steel Plant Pre Final Projectnrathi87100% (2)

- Metals, Alloys & Extraction of MetalsDocument22 pagesMetals, Alloys & Extraction of MetalsbuffuigokuNo ratings yet

- Types of Welding ElectrodesDocument34 pagesTypes of Welding ElectrodesAileen May Caminero SumampaoNo ratings yet

- Elephant Lifting Catalog v48Document80 pagesElephant Lifting Catalog v48dsnsarmaNo ratings yet

- Flame Arrester CatalogueDocument16 pagesFlame Arrester CataloguebramantiyaNo ratings yet

- HMC Spec 002 - Welding and Fabrication of Structural Lifting AppliancesDocument29 pagesHMC Spec 002 - Welding and Fabrication of Structural Lifting AppliancesJohnnyNo ratings yet

- Material Science & Metallurgy 2131904: Heat Treatment ProcessesDocument47 pagesMaterial Science & Metallurgy 2131904: Heat Treatment ProcessesNyanda MadiliNo ratings yet

- 3.3 Piping Design Criteria Rev 2Document15 pages3.3 Piping Design Criteria Rev 2Maheswaran KurusamyNo ratings yet

- Glossary of Terms Used in Galvanizing of SteelDocument11 pagesGlossary of Terms Used in Galvanizing of SteelMaria Ines CastelluccioNo ratings yet

- Strap Clamp: Additional Custom Products AvailableDocument1 pageStrap Clamp: Additional Custom Products AvailableKashif MirzaNo ratings yet