Professional Documents

Culture Documents

Audit KRA

Audit KRA

Uploaded by

tre coolOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Audit KRA

Audit KRA

Uploaded by

tre coolCopyright:

Available Formats

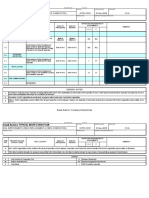

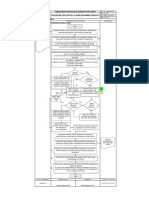

KCRC Quality Improvement Activity Signature

KLTD

Target Activity

FY18 Analysis by Defect phenomenon

1) Leakage

2) Performance issue KCRC

Engine Long block assembly process video quality cross audit

2023/**/**

Plant name: KI

a) Reusability

b) Assembly

c) Sub assy Auditors : KRA

d) Test Error

e) Machining

Process 1 Process 2 Process3

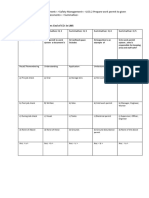

Safety 監査側のコメント Audi 納期 対策内容に対する監査側のコメン

Good or Video 被監査側の対策内容 Au 担当 技術 スタッフ 品保 quality 備考

No. process or Video play time Type Photo tor’s comment 参考資料 Reference material 班⾧ Team leader Schedule/ 改善した写真 Improved photo トAuditors comments on

Caution number ditee measures Person in Charge Technical staff assurance Remarks

Quality Due date countermeasures

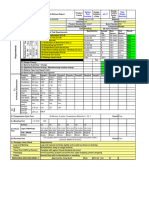

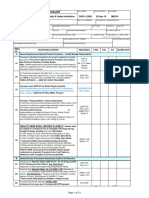

コネクティングロッドをウエスで清掃し Air blow process

ているが、エアブローしていない。 implemented ,now air blown

sample Caution c No.1 00:01:23 The connecting rod is wiped - with air gun Anand Krishna OK OK 08 April 2022 Good Completed

with a cloth, but there is no エアブロープロセスが追加され、エア

air blow work process. ガンでエアブローされました。

Placement of cleaner was

not proper (from video no 1

Dibuatkan tempat khusus di

1 Caution b Safety No.1 00:05:07 until no 3). Potential fall Andri Agung OK OK 26 June 2023

trolley tools Assembly

down if accidentally

touched.

Proses pengecheckan

After install bushing, didn’t lubang bushing sudah di

check the holes lakukan menggunakan flash

2 Caution b Quality No.2 00:05:52 concentricity. Potential the light dan hanya saja tidak Andri Agung OK OK 26 June 2023

lubrication hole was not terlampir dalam video sudah

center. tercantum di check sheet

Assembly.

Tool guide for install

Bushing of FIP Drive was Tools still good condition.

Safety &

3 Caution b No.3 00:02:44 loosen (fall down). Potential And for installation Andri Agung OK OK 26 June 2023

Quality

the bushing was not align & bushingcan be used

the tool was damage.

tool install bushing

Tool storage too far from

diletakkan di trolley terlebih

4 Caution b Safety No.5 00:01:10 workpiece. It's better to use Andri Agung OK OK 27 June 2023

dahulu agar tidak jauh dari

movable tool trolley.

tempat kerja

Verification marking sudah

No verification marking dilakukan sebelum proses

5 Caution b Quality No.5 00:01:17 Andri Agung OK OK 27 June 2023

after tightening torque tightening torque sesuai

dengan basic assembly

Proses pemberian plug di

Loctite applied on cylinder

lakukan plug bagian ujung

block (plug hole), not on

dan menggunakan kuas

6 Caution b Quality No.5 00:04:21 plug surface. Potential the Andri Agung OK OK 27 June 2023

agar tidak berlebihan

loctite pushed in during plug

locktitenya. sesuai basic

installation.

assembly .

Stand assembly di

Manpower hand position tambahkan special base

7 Caution b Safety No.5 00:08:36 when hitting tool was not sesuai dengan ketinggian. Andri Agung OK OK 26 June 2023

ergonomics Pemasangan menjadi lebih

ergonomi.

Cylinder liner was directly Proses pressing cylinder

pressed using push tool liner dilakukan

8 Caution b Quality No.7 00:07:20 without being pressed by menggunakan tangan Andri Agung OK OK 26 June 2023

hand to ensure the o-ring terlebih dahulu lalu di tekan

was seated properly dengan mesin press 130 bar

Proses protrusion liner

Protrusion liner was not sudah di lakukan dan diukur

9 Caution b Quality No.7 00:09:30 measured after install 4 titik selanjutnya sudah Andri Agung OK OK 28 June 2023

cylinder liner tercantum di check sheet

assembly

Oli di berikan pada main

Not applied oil lubricant on metal sebelum crank shaft

10 Caution b Quality No.8 00:09:35 main metal before install di pasang. Dan sudah Andri Agung OK OK 26 June 2023

Main Cap on Cylinder Block tercantum di check sheet

assembly

Dilakukan pengecheckan

Rotating torque was not rotating torque. Sesuai

11 Caution b Quality No.9 00:11:46 checked after main cap standart prosedure. Andri Agung OK OK 26 June 2023

tightening torque Tercantum di check sheet.

Check video

Main cap bolts were not

punched after 3rd step of Dilakukan punch marking

bolts tightening torque. The pada bolts setelah

12 Caution b Quality No.9 00:10:31 Andri Agung OK OK 26 June 2023

punch process applied after tightening torque. Check

conrod installment (video video

no.11). Potential missed.

Pengecheckan end play di

lakukan. Dorong

Final endplay measurement

menggunakan bar sebanyak

of Crankshaft was not

13 Caution b Quality No.9 00:11:41 3 kali untuk memastikan Andri Agung OK OK 26 June 2023

accurate (only 1 time to

end play pada crank shaft

shift the Crankshaft)

dan tercantum di check

sheet.

Protrusion liner

measurement only applied

on 1 point for every cylinder

Protusion linner di lakukan

liner. It's better to measure

14 Caution b Quality No.10 00:00:09 pengecheckan 4 posisi Andri Agung OK OK 26 June 2023

it in 4 position to ensure

check video

evenness of cylinder liner

surface to Cylinder block

surface.

Verification marking sudah

No verification marking

dilakukan sebelum proses

15 Caution b Quality No.12 00:06:21 after bolt tightening torque Andri Agung OK OK 26 June 2023

tightening torque sesuai

(piston cooling nozzle)

dengan basic assembly

Masking workpieces after

16 Good b Quality No.12 00:10:44 Andri Agung OK OK 26 June 2023

process

Apply special tool to install

17 Good b Quality No.13 00:05:07 Andri Agung OK OK 26 June 2023

camshaft

Trolley di geser agar

Confined space to install

pemasangan camshaft

Safety & Camshaft to Cylinder Block.

18 Caution b No.13 00:05:29 space lebih luas. dan Andri Agung OK OK 26 June 2023

Quality Potential the Camshaft

pemasangan menjadi lebih

collided with another object.

aman

Marking direction of

Verification marking sudah

mounting bolts of Oil Pump

dilakukan sebelum proses

19 Caution b Quality No.14 00:04:05 were not same and no Andri Agung OK OK 26 June 2023

tightening torque sesuai

verification marking after

dengan basic assembly

bolt tightening torque

Verification marking sudah

No verification marking

dilakukan sebelum proses

20 Caution b Quality No.15 00:03:48 after bolt tightening torque Andri Agung OK OK 26 June 2023

tightening torque sesuai

(timing gear)

dengan basic assembly

Apply oil on strainer to

21 Good b Quality No.16 00:07:52 Andri Agung OK OK 26 June 2023

prevent rust

Gunakan lock tite pada

ujubg blind plug

Not apply loctite during menggunakan kuas agar

22 Caution b Quality No.17 00:01:06 Andri Agung OK OK 26 June 2023

blind plug installment tidak berlebihan dan cara

pemasangan di lakukan

dengan benar.

Tool installer blind plug was Tools still good condition.

Safety &

23 Caution b No.17 00:01:11 bad condition on hitted And for installation blind Andri Agung OK OK 26 June 2023

Quality

surface area plug can be used

General cleaning parts

24 Good b Quality All All Andri Agung OK OK 26 June 2023

before assembly process

Perform Yosh Check during

25 Good b Quality All All Andri Agung OK OK 26 June 2023

final check process

You might also like

- Dimensional Inspection ProcedureDocument3 pagesDimensional Inspection ProcedureWalter Unabia Rendon100% (5)

- FW Pipe Support Drawings PDFDocument231 pagesFW Pipe Support Drawings PDFJoby George100% (1)

- Itp Electrical CheweeDocument2 pagesItp Electrical CheweeRonnel Dean LimNo ratings yet

- HSE Procedure PDFDocument186 pagesHSE Procedure PDFAndreas Schlager100% (4)

- Diaphragm Seal Filling GuideDocument14 pagesDiaphragm Seal Filling GuideKrishnaraj DhavalaNo ratings yet

- System Routing Workbench of Catia V5Document189 pagesSystem Routing Workbench of Catia V5rasgeetsinghNo ratings yet

- Boc India Limited: Cryogenic Nitrogen Plant Bharat Oman Refineries Ltd. Engineers India Ltd. BOC India Ltd. Bina (M.P.)Document6 pagesBoc India Limited: Cryogenic Nitrogen Plant Bharat Oman Refineries Ltd. Engineers India Ltd. BOC India Ltd. Bina (M.P.)aceengineering08No ratings yet

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- Itp FormatDocument8 pagesItp FormatAhmed KassemNo ratings yet

- Book 1Document2 pagesBook 1srinivasu.k2009No ratings yet

- 1Document4 pages1DanielNo ratings yet

- 1Document4 pages1DanielNo ratings yet

- Gpe-Fat OverviewDocument5 pagesGpe-Fat Overviewn.hartonoNo ratings yet

- Temporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaDocument7 pagesTemporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaJosua Ferry ManurungNo ratings yet

- 1.SRO-QPITP - Mechanical WorksDocument2 pages1.SRO-QPITP - Mechanical Worksachusanachu100% (1)

- Inspection and Test Plan 2 PDF FreeDocument3 pagesInspection and Test Plan 2 PDF FreeaefNo ratings yet

- Appendix 3 - SH-QAC-PI-007 Work Defects RectificationDocument2 pagesAppendix 3 - SH-QAC-PI-007 Work Defects Rectificationcheongminglong00No ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 31-Nov-2018 CivilTariqMalik0% (1)

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- Pressure Vessel ITP Rev 0Document10 pagesPressure Vessel ITP Rev 0SLC HosurNo ratings yet

- QCR W 2012Document2 pagesQCR W 2012Madhan KannanNo ratings yet

- Inspection and Test Plan 2Document3 pagesInspection and Test Plan 2EdNo ratings yet

- Vedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Document4 pagesVedanta Aluminium Plant Ltd. Quality Assurance Plan For Buildinng Construction Job (Rev-00)Sasanka SekharNo ratings yet

- TWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodDocument11 pagesTWJO-ITP-EMB-0003 Reva ITP For Retaining Wall RRR MethodBangkit SamosirNo ratings yet

- Inspection & Test PlanDocument1 pageInspection & Test PlanDanielNo ratings yet

- Inspection & Test PlanDocument1 pageInspection & Test PlanDanielNo ratings yet

- WQM - CGL48-QA-WQM-010 Draft (1) - RemovedDocument11 pagesWQM - CGL48-QA-WQM-010 Draft (1) - RemovedVijay Allimuthu AvathipalayamNo ratings yet

- Saudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilDocument10 pagesSaudi Aramco Typical Inspection Plan: Soil Improvement (Vibro Replacement & Vibro Compaction) 30-Oct-17 CivilJagdishNo ratings yet

- Limpieza Uso OxigenoDocument1 pageLimpieza Uso OxigenoHugo Alberto Tena LeònNo ratings yet

- SP-C12.5-325-2250PB (Po 16977)Document1 pageSP-C12.5-325-2250PB (Po 16977)Osmar Adolfo Davila SoriaNo ratings yet

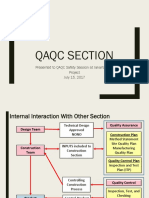

- Qaqc Section: Presented To QAQC Safety Session at Jakarta MRT Project July 15, 2017Document17 pagesQaqc Section: Presented To QAQC Safety Session at Jakarta MRT Project July 15, 2017Wildan Al BaihaqiNo ratings yet

- Sop of Garment TechnologistDocument9 pagesSop of Garment TechnologistMUDASSAR AFZAL100% (1)

- Proses Inspeksi SLO Pembangkit PDFDocument13 pagesProses Inspeksi SLO Pembangkit PDFAlfian Muhammad RezaNo ratings yet

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Construction Procedures and Internal Quality ControlDocument17 pagesConstruction Procedures and Internal Quality ControlbienndcNo ratings yet

- Section C - Preparation and Coating Audit TemplateDocument7 pagesSection C - Preparation and Coating Audit TemplateAnnNo ratings yet

- 0297 - Deluge SystemsDocument11 pages0297 - Deluge SystemsMohamed ElsayedNo ratings yet

- CHECK-LIST PL-01 Pipeline Material Selection Report - Fr.enDocument4 pagesCHECK-LIST PL-01 Pipeline Material Selection Report - Fr.enYousef SalahNo ratings yet

- True Blue Inspection-Test-Plan - Issued For ReviewDocument4 pagesTrue Blue Inspection-Test-Plan - Issued For ReviewJohn HartNo ratings yet

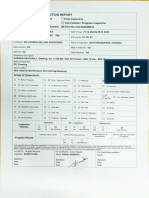

- Qeto Report - 00531Document2 pagesQeto Report - 00531Pinki Mitra DasNo ratings yet

- Contractor Approved Typical Inspection Plan: Classification - INTERNALDocument10 pagesContractor Approved Typical Inspection Plan: Classification - INTERNALMohamed Reda Hussein SengarNo ratings yet

- Satip A 000 01Document10 pagesSatip A 000 01Akansha SharmaNo ratings yet

- Quality Assurance PlanDocument3 pagesQuality Assurance PlanPEng. Tech. Alvince KoreroNo ratings yet

- Inspection and Testing Plan For ErectionDocument2 pagesInspection and Testing Plan For Erectionjerome pillienNo ratings yet

- Inspection and Test Plan: Contract NoDocument2 pagesInspection and Test Plan: Contract NoAhmed Samir SalimNo ratings yet

- 2 Pre & Post-Concreting Check List - FootingsDocument2 pages2 Pre & Post-Concreting Check List - Footingsgopi.bcimNo ratings yet

- BV PSPC Pres 03122012Document31 pagesBV PSPC Pres 03122012Ahmed Algunaid احمد الجنيدNo ratings yet

- Factory Acceptance TestDocument1 pageFactory Acceptance TestDaniel CamposNo ratings yet

- QAD Procedure - Control of Non-Conforming Products P2Document2 pagesQAD Procedure - Control of Non-Conforming Products P2sumanNo ratings yet

- Itp For Re-Slurry Tank - R-1Document8 pagesItp For Re-Slurry Tank - R-1Rejoy babyNo ratings yet

- Man Co4 Lo3 Lo3.2 AssessmentDocument2 pagesMan Co4 Lo3 Lo3.2 Assessmentyadavaadityaxc36No ratings yet

- Add BJC Logo: Manufacturing Process Plan (MPP)Document3 pagesAdd BJC Logo: Manufacturing Process Plan (MPP)Tee Klong RungNo ratings yet

- 05-Saadiyat Itp Backfilling InfrastructureDocument4 pages05-Saadiyat Itp Backfilling InfrastructuresoorajNo ratings yet

- Induction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesDocument5 pagesInduction Cap Sealing Machine Performance Qualification Report - Pharmaceutical UpdatesChetan Ganesh RautNo ratings yet

- SAIC-A-2022 Rev 6 Depressure PnematicDocument1 pageSAIC-A-2022 Rev 6 Depressure Pnematicpookkoya thangalNo ratings yet

- Satip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalDocument2 pagesSatip-A-000-01 Rev 8 Soil Improvement (Vibro Replacement - Vibro Compaction FinalTarek YehiaNo ratings yet

- Assessment Compliance Audit Action Catalogue: TESDA-OP-CO-06-F48 Rev - No.00-03/08/17Document2 pagesAssessment Compliance Audit Action Catalogue: TESDA-OP-CO-06-F48 Rev - No.00-03/08/17Neja DumapiasNo ratings yet

- QAP N2 Generator & N2 VesselDocument2 pagesQAP N2 Generator & N2 VesselVijay - Spantech EngineersNo ratings yet

- Pages From 03 - 20060401 - WPIFWNB - FDocument14 pagesPages From 03 - 20060401 - WPIFWNB - Fmakbul.kapoorNo ratings yet

- Saic L 2002Document13 pagesSaic L 2002chidambaramNo ratings yet

- Man Co4 Lo3 Lo3.2 AssessmentDocument2 pagesMan Co4 Lo3 Lo3.2 AssessmentAjit WaysalNo ratings yet

- How To Fill A NCR: Non-Conformance ReportDocument1 pageHow To Fill A NCR: Non-Conformance ReportThai Hai LyNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Annex C Robust Analysis: (Normative)Document1 pageAnnex C Robust Analysis: (Normative)tomychalil0% (1)

- Unit 3Document65 pagesUnit 3Arpan ChoudhuryNo ratings yet

- Physical Chemistry Competency ExamDocument2 pagesPhysical Chemistry Competency ExamRaymond YabutNo ratings yet

- Effect of Spray Rails and Wedges On The Performance of Semi-Displacement HullsDocument12 pagesEffect of Spray Rails and Wedges On The Performance of Semi-Displacement HullsAnggaGustamaNo ratings yet

- Iec 60076 14 2013Document124 pagesIec 60076 14 2013Osama AhmedNo ratings yet

- Unitrigmt6500 Dump PumpDocument11 pagesUnitrigmt6500 Dump PumpnikbeamNo ratings yet

- Panasonic Workio 1510Document394 pagesPanasonic Workio 1510Abderrahim HameurlaineNo ratings yet

- MicroSCADA System Config OverviewDocument14 pagesMicroSCADA System Config OverviewmihirandesilvaNo ratings yet

- 6HP19 21 ManualDocument66 pages6HP19 21 ManuallyutenkoeNo ratings yet

- Bibliography For AntennasDocument16 pagesBibliography For AntennasFrancisco ArrudaNo ratings yet

- Matlab Based Electromagnetics 1St Edition Notaros Solutions Manual Full Chapter PDFDocument23 pagesMatlab Based Electromagnetics 1St Edition Notaros Solutions Manual Full Chapter PDFkathylutzrogcbxditz100% (12)

- Poynting VectorDocument3 pagesPoynting Vectorpadmavathy2kNo ratings yet

- Paper SizeDocument19 pagesPaper SizeHeriberto TrejoNo ratings yet

- Outdoor Unit L: Ayout GuideDocument20 pagesOutdoor Unit L: Ayout Guideaditarian .pNo ratings yet

- Littelfuse Thyristor C106 D Datasheet PDFDocument5 pagesLittelfuse Thyristor C106 D Datasheet PDFExodia RaNo ratings yet

- Energy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneDocument25 pagesEnergy Conversion and Management: Gvidonas Labeckas, Stasys Slavinskas, Irena KanapkieneVỵ ĐặngNo ratings yet

- Edited - 04 Application - Well - Built - Residential - AwardsDocument6 pagesEdited - 04 Application - Well - Built - Residential - AwardsRabish ANo ratings yet

- VAL Team: Non-Return Valve RT25Document2 pagesVAL Team: Non-Return Valve RT25Octavio DavidNo ratings yet

- 50 Top Design of Masonry Structures Multiple Choice QuestionsDocument8 pages50 Top Design of Masonry Structures Multiple Choice Questionssaikiran1493No ratings yet

- Kali Linux 2 2013Document85 pagesKali Linux 2 2013SR DT100% (4)

- Kemlon Catalogs Duo-Seel K-25Document6 pagesKemlon Catalogs Duo-Seel K-25katastrofa2No ratings yet

- 01 Kros Ch01Document28 pages01 Kros Ch01Nikhil Gandhi0% (1)

- Steps of Making WPSDocument51 pagesSteps of Making WPSmohammadkhairy0% (2)

- Swivel Joints EngDocument24 pagesSwivel Joints Enghendry_hdwNo ratings yet

- Gmail - FWD - Mechanical National Conference - Udpdate in Website-RegardsDocument4 pagesGmail - FWD - Mechanical National Conference - Udpdate in Website-RegardsYUVA RAJA BNo ratings yet

- Engine MechanicalDocument42 pagesEngine MechanicalDavit OmegaNo ratings yet

- Electrical Engineering Question Paper-II: - Kirchoff's LossDocument25 pagesElectrical Engineering Question Paper-II: - Kirchoff's LossbasavarajNo ratings yet