Professional Documents

Culture Documents

Lontar Operation Discrepancy-I&c

Lontar Operation Discrepancy-I&c

Uploaded by

Ikbal SBOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lontar Operation Discrepancy-I&c

Lontar Operation Discrepancy-I&c

Uploaded by

Ikbal SBCopyright:

Available Formats

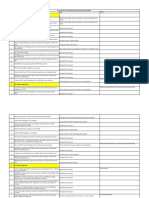

LONTAR OPERATIONAL DISCREPANCY

S.NO SYSTEM DESCRIPTION OF PROBLEM DEPARTMENT TO CHECK ISSUE DATE REPAIRED DATE

1 CPP Magnetic Level Acid Day Tank not reading correctly and stuck at 0.6m I&C

2 CWP CWP B HPU not get closed limit due to still > 2 % I&C

3 Condenser waterbox 2 inlet temperature bad reading I&C

4 Condenser Conductivity Analyzer Bad Reading I&C

Condenser

5 Outlet Waterbox Several time not at setting position after stop 1 CWP, pressure>215 kpa and get Vibration High I&C

6 Waterbox 1 Backwash inlet MOV sometime closed feedback disappear I&C

TWS A&B will stop if we stop 2nd CWP due to Low suction pressure of wash pump.

7 TWS The cwp discharge pressure will drop to <100 kpa during shutdown of 2nd cwp. DCS, Electric, I&C

Suction of screen wash pump coming from cwp discharge

8 CEP CEP B temp Transmitter Bad Reading I&C

9 IDF B Temp Transmitter Bad Reading Motor DE Temperature I&C

IDF

10 IDF Damper Seal Air Heater ampere reading neeed to check, we got over range I&C

11 Fly Ash Dryer A Always Trip Electric, I&C

Fly Ash

ESP Fly Ash Transport 12 OUT CA VLV often get open fault and close fault,

12 I&C

therefore sequence of fly ash transport not work properly.

13 Service Air Compressor C get Alarm 1st stage discharge temperature I&C

Compressor

14 Instrument Air Dryer A Problem/fault due to refrigerant pressure I&C, Mechanic

15 Mill Mill A,C,D still have reading the flow even draft system already shutdown. I&C

16 Vacuum Pump Vacuum pump downstream Switch always active so the sequence not proper and always running manual method. I&C

Flash Tank DR Loop Seal Level always got low level.

17 Need to check but it was no access I&C

Condensate System

18 Flash Tank Level Transmitter and gauge several time not same the reading I&C

19 Deaerator Inlet Condensate flow tranmistter 1&2 showing reading >50tph while CEP Stop I&C

20 Boiler HRA LHS Wall Metal Temperature 2 alaways higher reading value during normal operationand always got high temperature alarm. I&C

21 MDBFP MDBFP mechanical seal water several time got H alarm due to tramsitter installed before cooler I&C

22 MOV Attemperator sometimes get Torque Close Alarm when auto closed after maintain steam temperature I&C

23 Aux.Boiler MOV Blowdown Drum Conductivity after shutdown aux boiler always cannot closed by command DCS, I&C

24 Local Level Blowdown Aux Boiler not working, so cannot maintain level blowdown as a design. I&C

25 Caustic Day Tank level often got spike reading/ different value with local I&C

26 CMU MBE Acid and Caustic concentration different reading between local and HMI I&C

27 Catridge filter DP H sometimes active even flow still oke and actual cartridge filter not to dirty I&C

28 Electrochlorination Transmitter Flow of Blower ECP not reading correctly I&C

3. Magnetic Level Acid Day Tank not reading correctly and stuck at 0.6m

1.CWP B HPU not get closed limit due to still > 2 %

You might also like

- Alberta Learners Practice Q&A-1005Document14 pagesAlberta Learners Practice Q&A-1005mekonenhabtemariam100% (1)

- Switching Power Supply Design: A Concise Practical HandbookFrom EverandSwitching Power Supply Design: A Concise Practical HandbookNo ratings yet

- 2-2-14 Tier 4i Engine Troubleshooting Cheat SheetDocument8 pages2-2-14 Tier 4i Engine Troubleshooting Cheat SheetKevine Khaled100% (3)

- Pittsburgh (Harbor Freight) 92649 A-C Manifold Gauge Set Quick ReferenceDocument4 pagesPittsburgh (Harbor Freight) 92649 A-C Manifold Gauge Set Quick ReferenceRick McGuire0% (1)

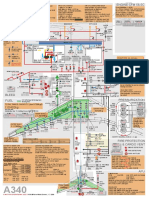

- A340 Air Fuel EngineDocument1 pageA340 Air Fuel EngineDAVID FAJARDO PUERTO100% (1)

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- (APA Handbooks in Psychology) Bracken, Bruce A. - Geisinger, Kurt F. - APA Handbook of Testing and Assessment in Psychology - Vol. 3-American Psychological Association (2013) PDFDocument702 pages(APA Handbooks in Psychology) Bracken, Bruce A. - Geisinger, Kurt F. - APA Handbook of Testing and Assessment in Psychology - Vol. 3-American Psychological Association (2013) PDFHerecome DatgurlNo ratings yet

- Refrigerator Service Manual: Models: DC440, DC451, DC490 DE441, DE451, DE461, DE490 MRFT415, MRFT440, MRFT460Document15 pagesRefrigerator Service Manual: Models: DC440, DC451, DC490 DE441, DE451, DE461, DE490 MRFT415, MRFT440, MRFT460Itseed CorcaNo ratings yet

- Shine Kaizen TeamDocument35 pagesShine Kaizen TeamHemant PatilNo ratings yet

- 150 KV Circuit Breaker: Kupang Gas Engine Power Plant (Peaker) 40 MW 150 KV Switchard Site Test ReportDocument6 pages150 KV Circuit Breaker: Kupang Gas Engine Power Plant (Peaker) 40 MW 150 KV Switchard Site Test ReportrioNo ratings yet

- NT Change A-C PWB OIDocument8 pagesNT Change A-C PWB OIerpataNo ratings yet

- Manual Chillers20 NewDocument14 pagesManual Chillers20 NewMinh NguyễnNo ratings yet

- AuditDocument3 pagesAuditswapnil majeeNo ratings yet

- BE-Ch11-Capacitor Charging & DischargingDocument20 pagesBE-Ch11-Capacitor Charging & DischargingMaxNo ratings yet

- Water Wash CHECKLISTDocument5 pagesWater Wash CHECKLISTAbdelaziz EldeebNo ratings yet

- Defects 07.03.2023Document2 pagesDefects 07.03.2023Jitendra HarchandaniNo ratings yet

- 3vin210719d4036 ADocument25 pages3vin210719d4036 Aiwant2chatwithuNo ratings yet

- Turbine Punch Point Closeout Status-For HURLDocument7 pagesTurbine Punch Point Closeout Status-For HURLpriyajit sahooNo ratings yet

- Trouble Shooting & Ventilation Guide: For Marine and Truck DC/DE RefrigeratorsDocument19 pagesTrouble Shooting & Ventilation Guide: For Marine and Truck DC/DE RefrigeratorsAnaelle ApollonNo ratings yet

- 5.TROUBLESHOOTING (Overttde Operation) : Erter Shutdown Code CodeDocument11 pages5.TROUBLESHOOTING (Overttde Operation) : Erter Shutdown Code CodeQuy HoangNo ratings yet

- Startup Flow Chart PDFDocument1 pageStartup Flow Chart PDFNukul KumarNo ratings yet

- Arp Malita Plant PLS CheckDocument25 pagesArp Malita Plant PLS CheckIan B. YtomNo ratings yet

- Current TransformerDocument10 pagesCurrent TransformerShady NasrNo ratings yet

- NEC Table 310 Calculo Conductor Rayos X y Caida de VoltajeDocument2 pagesNEC Table 310 Calculo Conductor Rayos X y Caida de VoltajeChristianM.LeandroYauriNo ratings yet

- To Be An Efficient Power Producer Delivering Consistent Value To StakeholdersDocument104 pagesTo Be An Efficient Power Producer Delivering Consistent Value To StakeholdersPratap PandaNo ratings yet

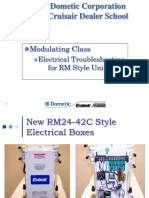

- 3 - RM Electrical TroubleshootingDocument26 pages3 - RM Electrical TroubleshootingAlexandre SilvaNo ratings yet

- Cb2pcing enDocument6 pagesCb2pcing enLuis JesusNo ratings yet

- Multi Test PanelDocument11 pagesMulti Test PanelRAKESHNo ratings yet

- Gujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2Document5 pagesGujarat Transformers PVT - Ltd. E-Mail Copy: As Per IS 1180 - Level-2THANGAVEL PNo ratings yet

- Power Station Pumps-Condensate Extraction Pumps & Circulating Water PumpsDocument30 pagesPower Station Pumps-Condensate Extraction Pumps & Circulating Water PumpsSakthi MuruganNo ratings yet

- TL494 Linear Integrated Circuit: Voltage Mode PWM Control CircuitDocument7 pagesTL494 Linear Integrated Circuit: Voltage Mode PWM Control CircuitIsrael GonzalesNo ratings yet

- P 1464Document8 pagesP 1464Yargen GonzalezNo ratings yet

- Centrifugal Compressor Surge & ControlDocument32 pagesCentrifugal Compressor Surge & Controlejzuppelli8036No ratings yet

- Module 4Document7 pagesModule 4valoto4868No ratings yet

- Description On DosingDocument2 pagesDescription On DosingAbu Bakar HamadaNo ratings yet

- CI Comments@Air CompressorDocument1 pageCI Comments@Air CompressorAWANISH KUMARNo ratings yet

- L I Máy NénDocument5 pagesL I Máy NénDoan TruongNo ratings yet

- Remy Technical Bulletin 4 17Document4 pagesRemy Technical Bulletin 4 17miguel100% (1)

- VCB Installation & Wiring DiagramDocument91 pagesVCB Installation & Wiring DiagramAGM E&C Narayanganj PBS-2No ratings yet

- Fault Tree AnalysisDocument36 pagesFault Tree AnalysisAMOL RASTOGI 19BCM0012No ratings yet

- Q - One Check ListDocument1 pageQ - One Check Listmoualla.m.alasaadNo ratings yet

- Error Code Full CodeDocument71 pagesError Code Full CodeOrlydon Tagaan100% (1)

- MS 264Document6 pagesMS 264viky0979No ratings yet

- Controls & Instrumentation FOR 660 MW Supercritical Unit at TirodaDocument23 pagesControls & Instrumentation FOR 660 MW Supercritical Unit at TirodaSteve WanNo ratings yet

- Log ChillerDocument4 pagesLog ChillerJoe JordisonNo ratings yet

- DS EGC General Catalogue Industrial Products Ed3 English Spectronic SPDocument90 pagesDS EGC General Catalogue Industrial Products Ed3 English Spectronic SPjjelectronicNo ratings yet

- Hokkim Control & Protection RelaysDocument2 pagesHokkim Control & Protection RelaysAhmad Radzi Sabtu100% (2)

- R59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMDocument22 pagesR59770032 01 LiquidcoolingrefurbishmentDP100 DP90 XLMRamon Bochaca SandiumengeNo ratings yet

- Transformer Failure DetailsDocument6 pagesTransformer Failure DetailsSantosh BagadeNo ratings yet

- Comp.a Troubleshooting Report 1-12-2023Document4 pagesComp.a Troubleshooting Report 1-12-2023hamadaNo ratings yet

- Tulsa Gas Technologies India Pvt. LTD: Data Sheet For 37 KW CNG Booster CompressorDocument6 pagesTulsa Gas Technologies India Pvt. LTD: Data Sheet For 37 KW CNG Booster Compressorsumit kumarNo ratings yet

- 16OBDG03 Engine Diagnostics PDFDocument991 pages16OBDG03 Engine Diagnostics PDFManuel Gomez MartinezNo ratings yet

- DC Sistem 110Document13 pagesDC Sistem 110anggaNo ratings yet

- Condensate Cycle SystemDocument26 pagesCondensate Cycle SystemBhumit Sagathiya100% (4)

- 2-FM Electrical TroubleshootingDocument38 pages2-FM Electrical TroubleshootingAlexandre SilvaNo ratings yet

- CN3703 ConsonanceDocument11 pagesCN3703 ConsonancetvworldccNo ratings yet

- Controls & Instrumentation FOR 660 MW Supercritical Unit at TirodaDocument23 pagesControls & Instrumentation FOR 660 MW Supercritical Unit at TirodaAakash kumar Shrivastava100% (1)

- (ED) .Stabilize T To 1e-5 Deg With Linear-DC-feedbackDocument6 pages(ED) .Stabilize T To 1e-5 Deg With Linear-DC-feedbackf826401No ratings yet

- Parameter Setting TIMDocument7 pagesParameter Setting TIMTirta NoegrahaNo ratings yet

- Circuit Breaker Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Document3 pagesCircuit Breaker Test: Power Supply To Plot P18 at Zayed Military City D108337 SWH38A1Jayaprakash M PNo ratings yet

- 3900 - Trane Ccud 104Document6 pages3900 - Trane Ccud 104HoàngViệtAnhNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reproducible Discipleship Making Process PDFDocument12 pagesReproducible Discipleship Making Process PDFJohn Fieck100% (2)

- Airlines Reservation SynopsisDocument49 pagesAirlines Reservation SynopsisSagar NNo ratings yet

- Wages Structure in India Under The Minimum Wages Act 1948Document61 pagesWages Structure in India Under The Minimum Wages Act 1948Karan Bhutani100% (4)

- Lecture4 PDFDocument26 pagesLecture4 PDFLaura HumăNo ratings yet

- Threat Assessment ReportDocument31 pagesThreat Assessment Reportapi-388018238100% (1)

- Conectores y DiagramasDocument6 pagesConectores y Diagramasrodrigo michelNo ratings yet

- Direct & Indirect SpeechDocument29 pagesDirect & Indirect SpeechHumanist English ManNo ratings yet

- I (-02t,-1m - : - .8m-R-18m-M - 8A) :-+$-3 # - 1&) +-0bo# K! !!!: Milarapa's Guru Yoga and Tsok Offering !Document34 pagesI (-02t,-1m - : - .8m-R-18m-M - 8A) :-+$-3 # - 1&) +-0bo# K! !!!: Milarapa's Guru Yoga and Tsok Offering !Kaleb Singh100% (1)

- New Research Proporsal 16-10-2022 MukutaDocument14 pagesNew Research Proporsal 16-10-2022 MukutaNelson Kdm NellyNo ratings yet

- Hotel CaliforniaDocument3 pagesHotel CaliforniaAnton BaronkinNo ratings yet

- The Particle Theory ModelDocument1 pageThe Particle Theory ModelThenmolle RamanathanNo ratings yet

- Dua-e-Nudba Translated by Naba Cultural OrganizationDocument31 pagesDua-e-Nudba Translated by Naba Cultural OrganizationWhizbeeNo ratings yet

- Draft LC Payment OkDocument4 pagesDraft LC Payment OkMarvel IsmeNo ratings yet

- T24-Jbase Editor Tips TricksDocument3 pagesT24-Jbase Editor Tips TricksHeng PutheaNo ratings yet

- Aircraft Design Project Designing A Competitor Fighter AircraftDocument45 pagesAircraft Design Project Designing A Competitor Fighter AircraftKarthick. GNo ratings yet

- English Language 2001 WAEC Past Questions - MyschoolDocument1 pageEnglish Language 2001 WAEC Past Questions - Myschooldosumuahmod47No ratings yet

- Micro Focus Cobol Survey Itl 2015 Report PTDocument22 pagesMicro Focus Cobol Survey Itl 2015 Report PTprojrev2No ratings yet

- Food in MoroccoDocument3 pagesFood in Moroccoapi-348760740100% (1)

- Cabagnot Vs CSCDocument10 pagesCabagnot Vs CSCKcompacionNo ratings yet

- 01 Drillmec Company Profile E78913cf d70c 465b 911a Ab1b009160baDocument13 pages01 Drillmec Company Profile E78913cf d70c 465b 911a Ab1b009160baDaniel Marulituah SinagaNo ratings yet

- Lesson 5: Targeting Job Search: Mobilize Your NetworkDocument20 pagesLesson 5: Targeting Job Search: Mobilize Your NetworkJohn Raven Monte100% (1)

- Application & Technical Manual 02 Structural SteelDocument65 pagesApplication & Technical Manual 02 Structural SteelTian NgNo ratings yet

- PCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Document51 pagesPCW Guidelines For Developing and Implementing Gender Responsive Programs and Projects 1993Randell ManjarresNo ratings yet

- L2 - ABFA1163 FA II (Student)Document4 pagesL2 - ABFA1163 FA II (Student)Xue YikNo ratings yet

- Vietnam 11 Intro PDFDocument113 pagesVietnam 11 Intro PDFIlhin HarrisNo ratings yet

- Home Brew Mart Homework SeriesDocument6 pagesHome Brew Mart Homework Seriesh48j8gwb100% (1)

- 1111Document9 pages1111trungtroangNo ratings yet

- ARTS 725-734, 748-749 Donation REVIEW23Document11 pagesARTS 725-734, 748-749 Donation REVIEW23Vikki AmorioNo ratings yet