Professional Documents

Culture Documents

Unit 01 Fundamentals of Machine Design (Question Bank)

Unit 01 Fundamentals of Machine Design (Question Bank)

Uploaded by

satyamchgl2010Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Unit 01 Fundamentals of Machine Design (Question Bank)

Unit 01 Fundamentals of Machine Design (Question Bank)

Uploaded by

satyamchgl2010Copyright:

Available Formats

Fundamentals of machine design Machine Design- I| 1-2

Unit- 01 Fundamentals of machine design

T1] Describe various steps involved in the design of a machine element (Give

general design procedure for a machine component). Discuss what working

drawing is.

T2] Distinguish between static and dynamic load giving suitable examples.

T3] What is factor of safety? Why it is used in machine design (why it is

considered while designing the machine element?)? How is it selected?

T4] Discuss the guidelines for the selection of quantitative values of ‘factor of

safety’.

T5] How will you classify engineering material? For each category of

classification, give at least two materials, falling in that category.

T6] How material is selected while designing a machine element?

T7] Summarize material selection procedure adopted for designing a machine

element.

T8] Explain in brief factors govern the selection of material for mechanical

component.

T9] Explain the various factors influencing the selection of material for a

particular application.

T10] Name different theories of failure. Define any three.

T11] Enlist different theories of elastic failure giving area of its application.

T12] Illustrate the use of theory of failure for brittle material.

T13] State the major alloying elements added to steel and their influence on

properties of steel.

T14] What do you understand by following designations of materials?

a. FG350 c. 20Mn2

b. 40C8 d. 40Cr1Mo28

FG350 indicates a grey cast iron with ultimate tensile strength 350 N/𝑚𝑚2

40C8 indicates a plain carbon steel with 0.4% carbon and 0.8% manganese

20Mn2 indicates alloy steel having average 0.2% carbon and average 2%

manganese

R. V. BMMANKATTI (MECHANICAL ENG. DEPT.) SGMCOE, Mahagaon

Fundamentals of machine design Machine Design- I| 2-2

40Cr1Mo28 indicates alloy steel having average 0.4% carbon, 0.25%

chromium, and 0.28% molybdenum

T15] Suggest with justification the suitable material for the following:

a. Ball bearing, roller bearing

b. Machine bed (Lathe machine bed)

c. Dairy equipment

d. Surgical instrument

e. Large flywheel

f. Helical spring

g. Leaf spring in automobile

h. Side stand spring of bike

i. Lathe tail-stock

j. Water bottle

k. Helmet (Two wheeler)

l. Engine parts: Connecting rod, piston, gasket, crank shaft

m. Automotive cylinder block

n. Keys for fastening

o. Flange for coupling

p. Blade of house- hold knife

q. Turbine blade

r. Gears

s. Worm and worm gear

t. Boiler water tubes

u. Machine tool spindle

v. V- belt

R. V. BMMANKATTI (MECHANICAL ENG. DEPT.) SGMCOE, Mahagaon

You might also like

- ASTM A194-A194M-20aDocument12 pagesASTM A194-A194M-20aViviana Leon100% (8)

- Astm C478Document8 pagesAstm C478Nelson Hernandez100% (2)

- Electrode Selection Excel ChartDocument2 pagesElectrode Selection Excel ChartMahesh Kumar100% (2)

- Me 2252Document3 pagesMe 2252cbeprabhugmailNo ratings yet

- Production Technology SyllabusDocument9 pagesProduction Technology SyllabusPankaj SharmaNo ratings yet

- International Journal of Engineering Research and DevelopmentDocument8 pagesInternational Journal of Engineering Research and DevelopmentIJERDNo ratings yet

- Milestone No. 01 - CAE LABDocument9 pagesMilestone No. 01 - CAE LABMuhammad Junaid Rajput FatimaNo ratings yet

- Machine Tools Assignments 1 N 2Document3 pagesMachine Tools Assignments 1 N 2Sunkeswaram Deva PrasadNo ratings yet

- Khanna 2015Document29 pagesKhanna 2015nishanth124acharyaNo ratings yet

- Bmm4243 (Mt2) - TutorialDocument3 pagesBmm4243 (Mt2) - TutorialNajip TalibinNo ratings yet

- Dome 6TH Sem. SP - 09Document7 pagesDome 6TH Sem. SP - 09neelesh singhNo ratings yet

- WWW - Manaresults.Co - In: Design of Machine Members - IiDocument8 pagesWWW - Manaresults.Co - In: Design of Machine Members - IigopichandallakaNo ratings yet

- Tribological Properties of Aluminium Metal Matrix Composites (Aa7075 Reinforced With Titanium Carbide (Tic) Particles)Document14 pagesTribological Properties of Aluminium Metal Matrix Composites (Aa7075 Reinforced With Titanium Carbide (Tic) Particles)whatisnameNo ratings yet

- Me6004 QB RejinpaulDocument5 pagesMe6004 QB Rejinpaulashoku24007No ratings yet

- AAAAAAAAAAAAAADocument16 pagesAAAAAAAAAAAAAASriramulu JaichandarNo ratings yet

- Manufacturing Engineering Guide BookDocument2 pagesManufacturing Engineering Guide BookGiridharan SharmaNo ratings yet

- Cutting Parameters and Analysis by Fea Simulation ofDocument12 pagesCutting Parameters and Analysis by Fea Simulation ofmont21No ratings yet

- Procedure Machine Tool Gear Box - 21Document8 pagesProcedure Machine Tool Gear Box - 21Prasad GhogareNo ratings yet

- 7 TransformadorDocument27 pages7 TransformadorMarkovic Ávila MartínezNo ratings yet

- MEL311Document281 pagesMEL311Shiri ShaNo ratings yet

- Deber 4Document8 pagesDeber 4jmgavilanesNo ratings yet

- About I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018Document8 pagesAbout I-Beam Versus H-Beam Connecting Rod Design Using Inventor Autodesk 2018npatil_10No ratings yet

- Machine Element WikipediaDocument12 pagesMachine Element WikipediaFERNANDEZ, RELLY ANDREWNo ratings yet

- The International Journal of Engineering and Science (The IJES)Document6 pagesThe International Journal of Engineering and Science (The IJES)theijes100% (1)

- Design and Manufacturing of A Non-Standard Chain Parts For A Scraper Chain Conveyor - A Case StudyDocument7 pagesDesign and Manufacturing of A Non-Standard Chain Parts For A Scraper Chain Conveyor - A Case StudyMohammed GamilNo ratings yet

- Indian Institute of Packagin1Document3 pagesIndian Institute of Packagin1aghosh704No ratings yet

- Investigation On Mechanical Properties of Welded Aluminium Joints of AA 8011 Using Friction Stir WeldingDocument7 pagesInvestigation On Mechanical Properties of Welded Aluminium Joints of AA 8011 Using Friction Stir WeldingŜħîvěńdra SinghNo ratings yet

- Ucmp-Question Bank - NewDocument4 pagesUcmp-Question Bank - New9966197483No ratings yet

- Engineering Failure Analysis: Lucjan Witek, Marek Orkisz, Piotr Wygonik, Daniel N. Musili, Tadeusz KowalskiDocument10 pagesEngineering Failure Analysis: Lucjan Witek, Marek Orkisz, Piotr Wygonik, Daniel N. Musili, Tadeusz KowalskiGholamreza MahmoodiNo ratings yet

- Design of Machine Members-II Feb 2022Document3 pagesDesign of Machine Members-II Feb 2022Anand KedhariNo ratings yet

- Structure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleDocument4 pagesStructure Analysis of Cast Iron For Dry Clutch of Amphibious VehicleseventhsensegroupNo ratings yet

- Design of Liner Puller PresentationDocument29 pagesDesign of Liner Puller PresentationKirubel MogesNo ratings yet

- Experimental Investigation of Process Parameters in Orthogonal Machining of Ti6Al4V With Tic Coated PCBN Inserts - A Finite Element AnalysisDocument8 pagesExperimental Investigation of Process Parameters in Orthogonal Machining of Ti6Al4V With Tic Coated PCBN Inserts - A Finite Element AnalysisAzaath AzuNo ratings yet

- Laser Repair Hardfacing of Titanium Alloy Turbine: 2.experimentalDocument12 pagesLaser Repair Hardfacing of Titanium Alloy Turbine: 2.experimentalwsjouri2510No ratings yet

- OPTIMIZATION OF EDM PROCESS PARAMETERS ON ALUMINIUM ALLOY 6061/5% SiC COMPOSITEDocument4 pagesOPTIMIZATION OF EDM PROCESS PARAMETERS ON ALUMINIUM ALLOY 6061/5% SiC COMPOSITEIJORATNo ratings yet

- Question Bank - All UnitsDocument11 pagesQuestion Bank - All UnitsParamasivam Veerappan100% (1)

- Design Optimization and Analysis of An Automotive Manual Transmission Shaft Using Titanium Alloy (TI6AL4V)Document5 pagesDesign Optimization and Analysis of An Automotive Manual Transmission Shaft Using Titanium Alloy (TI6AL4V)hidaiNo ratings yet

- Cutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningDocument6 pagesCutting Temperature and Laser Beam Temperature Effects On Cutting Tool Deformation in Laser-Assisted MachiningrrameshsmitNo ratings yet

- TDF Flange Forming Machine-Opreation ManualDocument15 pagesTDF Flange Forming Machine-Opreation ManualIBRAHIM AL-SURAIHINo ratings yet

- Budak tmt07Document29 pagesBudak tmt07abdollahzadehNo ratings yet

- MT Question Bank PDFDocument9 pagesMT Question Bank PDFHarish RajaNo ratings yet

- Experiment p1 Metal Cutting ProcessDocument13 pagesExperiment p1 Metal Cutting Processvipin_shrivastava25No ratings yet

- Case Study On Advanced Manufacturing and Quality Control of Compressor BladesDocument5 pagesCase Study On Advanced Manufacturing and Quality Control of Compressor BladesL...nNo ratings yet

- Join Al Cu (Mumin Sahin) PDFDocument8 pagesJoin Al Cu (Mumin Sahin) PDFAgusWahyuWibowoNo ratings yet

- SMC Ti Separator FormingDocument6 pagesSMC Ti Separator FormingDullah AllyNo ratings yet

- Low Cost Automation For CNC Machining Center PDFDocument11 pagesLow Cost Automation For CNC Machining Center PDFgsudhanta1604No ratings yet

- Optimization of Turning Process Parameters by Using Grey-TaguchiDocument8 pagesOptimization of Turning Process Parameters by Using Grey-TaguchiDagim atnafuNo ratings yet

- Unconventional Machining ProcessesDocument6 pagesUnconventional Machining ProcessesMohan ManiNo ratings yet

- Chapter ForDocument10 pagesChapter Forajie LambertNo ratings yet

- Analysis of PistonDocument8 pagesAnalysis of PistonShahzad ahamadNo ratings yet

- Spur Gear Thermal AnalizDocument5 pagesSpur Gear Thermal AnalizkarayagizmuhammedNo ratings yet

- Paperpublished STM 2023-Versão3Document11 pagesPaperpublished STM 2023-Versão3Filipe PossamaiNo ratings yet

- TE 2008 Mechanical Qp2013Document56 pagesTE 2008 Mechanical Qp2013avinash119870% (1)

- Slip TestDocument3 pagesSlip TestSaravanan MathiNo ratings yet

- Optimization of CNC MachiningDocument3 pagesOptimization of CNC MachiningVIVA-TECH IJRINo ratings yet

- PRODUCTIONTECHNOLOGYDocument4 pagesPRODUCTIONTECHNOLOGYSamiullah MohammedNo ratings yet

- WWW - Manaresults.Co - In: Set - 1 Code No: RT32033Document8 pagesWWW - Manaresults.Co - In: Set - 1 Code No: RT32033Sai RamNo ratings yet

- Matecconf Mtem2019 03010Document6 pagesMatecconf Mtem2019 03010metal squad metal squadNo ratings yet

- MT Paper 2nd Mid TermDocument2 pagesMT Paper 2nd Mid Termanil chaudharyNo ratings yet

- Metal Matrix Composites: A Modern Approach to ManufacturingFrom EverandMetal Matrix Composites: A Modern Approach to ManufacturingNo ratings yet

- SANDVIK - Steel Designation and Markings - STA-02-030EDocument4 pagesSANDVIK - Steel Designation and Markings - STA-02-030EPetr HavelNo ratings yet

- Case HardeningDocument17 pagesCase Hardeningmahi_mNo ratings yet

- ACI 364.10T-14 TechNoteDocument4 pagesACI 364.10T-14 TechNotedddNo ratings yet

- Question Bank For CAT IIDocument3 pagesQuestion Bank For CAT IIVicky GautamNo ratings yet

- 20050602014857.orion AlloysDocument25 pages20050602014857.orion AlloysdtweetyNo ratings yet

- MEP FinalDocument82 pagesMEP FinalKaushal KumarNo ratings yet

- WWW Successcds Net Cce Cbse Class Xii English The Rattrap HTMLDocument36 pagesWWW Successcds Net Cce Cbse Class Xii English The Rattrap HTMLLolo MutuNo ratings yet

- USm Nitjsr MFGDocument33 pagesUSm Nitjsr MFGshaliniNo ratings yet

- Piping QC PocketBook Navaneethan SundaramDocument25 pagesPiping QC PocketBook Navaneethan SundaramShanmuga Navaneethan100% (1)

- Ali Enterprise: Our Ref: DatedDocument4 pagesAli Enterprise: Our Ref: DatedSheedaNo ratings yet

- Elems 02Document101 pagesElems 02Reynald de VeraNo ratings yet

- Catalog PK AnchorDocument2 pagesCatalog PK AnchorkumuthaNo ratings yet

- Manufacturing of Speaker BasketsDocument19 pagesManufacturing of Speaker BasketsAmritsingh321100% (1)

- Mu2018 Article InfluencesOfHotStampingParametDocument11 pagesMu2018 Article InfluencesOfHotStampingParametAndress SsalomonnNo ratings yet

- Blowdown ValvesDocument13 pagesBlowdown ValvesShameer MajeedNo ratings yet

- Cimberio Valve CatalogueDocument16 pagesCimberio Valve CatalogueQuynh NguyenNo ratings yet

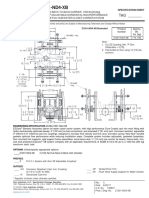

- Z1201-ND4-XB: Patent PendingDocument1 pageZ1201-ND4-XB: Patent PendingZineddine ALICHENo ratings yet

- Brass: Sales@columbiametals - Co.ukDocument2 pagesBrass: Sales@columbiametals - Co.ukAditya VernekarNo ratings yet

- Bombas Centífugas KSBDocument12 pagesBombas Centífugas KSBkarmencitaconk4035No ratings yet

- Specification Section S40: Structural SteelworkDocument24 pagesSpecification Section S40: Structural Steelworkkiet eelNo ratings yet

- Amte 128Document24 pagesAmte 128Jan Patrick VelosoNo ratings yet

- Thermocouple Colour CodesDocument2 pagesThermocouple Colour CodesmgkvprNo ratings yet

- Dura Seals Material Code Guide Dura Seals Material Code GuideDocument4 pagesDura Seals Material Code Guide Dura Seals Material Code GuideHendriM89No ratings yet

- Protective CoatingsDocument203 pagesProtective CoatingsGopalakrishnan KuppuswamyNo ratings yet

- Exhibit B-30 InsulationDocument7 pagesExhibit B-30 Insulationsethu1091No ratings yet

- Cham Samco and Sons Inc.: Tel: (+632) 243-1561 To 68 Fax: (+632) 241-9862 EmailDocument3 pagesCham Samco and Sons Inc.: Tel: (+632) 243-1561 To 68 Fax: (+632) 241-9862 EmailkkNo ratings yet

- Aircraft WeldingDocument3 pagesAircraft Weldingajrio1785No ratings yet