Professional Documents

Culture Documents

Ex Wps Train 01

Ex Wps Train 01

Uploaded by

aidil30Copyright:

Available Formats

You might also like

- Igcse Physics All FormulasDocument4 pagesIgcse Physics All FormulasRichie Harvy82% (17)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Sop For Motor Changing JobDocument10 pagesSop For Motor Changing JobT S Virdi50% (2)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Document2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS 1Document1 pageWPS 1janardan.sfeNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 pagesWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

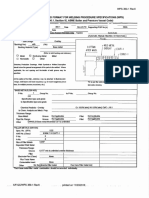

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

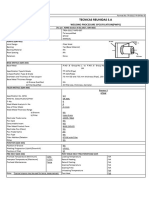

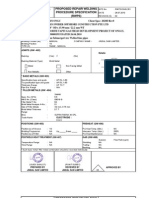

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSf silva-No ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- WPS FormatDocument3 pagesWPS Formatvivek bhangaleNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Sample WPS Format PDFDocument1 pageSample WPS Format PDFait.koufiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Operators Address Deep Gas Drilling Challenges: Expandable TubularsDocument4 pagesOperators Address Deep Gas Drilling Challenges: Expandable TubularsTrieu Nguyen100% (1)

- Curtain Wall ShadingDocument8 pagesCurtain Wall ShadingNajeela BanuNo ratings yet

- Diagnosis and Testing Engine Cooling 1.6 Duratec 16V Ti VCTDocument13 pagesDiagnosis and Testing Engine Cooling 1.6 Duratec 16V Ti VCTIsmael LopezNo ratings yet

- MEC-A4-125B EnglishDocument2 pagesMEC-A4-125B Englishdragos manoleNo ratings yet

- DFGHJDocument18 pagesDFGHJsmsm7000No ratings yet

- 99 9-5 2.3T Head Gasket Replacement - SaabCentral ForumsDocument3 pages99 9-5 2.3T Head Gasket Replacement - SaabCentral ForumsDerrick ChongNo ratings yet

- Scion GC Series: The Gas Chromatographerhs Choice For SeparationsDocument12 pagesScion GC Series: The Gas Chromatographerhs Choice For SeparationsLABSSSSSNo ratings yet

- De Cuong On Tap Anh 6 HK2 Nam 22 23Document8 pagesDe Cuong On Tap Anh 6 HK2 Nam 22 23Minh NguyenNo ratings yet

- 14.7.4 Matimba-Spitskop 2 400kV Loop-In and Out Transmission Line Specification Rev0 PDFDocument112 pages14.7.4 Matimba-Spitskop 2 400kV Loop-In and Out Transmission Line Specification Rev0 PDFmilosevicsasa11100% (1)

- Industrial Iot Based Condition Monitoring For Wind Energy Conversion SystemDocument12 pagesIndustrial Iot Based Condition Monitoring For Wind Energy Conversion SystemdikyNo ratings yet

- eArt-Calculating Overpressure From BLEVE ExplosionsDocument6 pageseArt-Calculating Overpressure From BLEVE ExplosionsJurizal Julian LuthanNo ratings yet

- Pokhara University Applied Mechanics - I Question PapersDocument4 pagesPokhara University Applied Mechanics - I Question PapersBuddhisagar BastolaNo ratings yet

- Spinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedDocument8 pagesSpinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedPadmanaban PasuvalingamNo ratings yet

- Power System Protection 25Document235 pagesPower System Protection 25mishra.satyam9874100% (1)

- Fischer Tropsch Reaction MechanismDocument9 pagesFischer Tropsch Reaction MechanismMarcus NguyễnNo ratings yet

- Arson InvestigationDocument128 pagesArson InvestigationOflodor Abmac50% (2)

- IIEE ANC RME Forum 2015Document231 pagesIIEE ANC RME Forum 2015Ray RodriguezNo ratings yet

- 375B - 385B IV 12 PG A4 Broch PDFDocument7 pages375B - 385B IV 12 PG A4 Broch PDFManuel VenturaNo ratings yet

- Flexible Connectors Catalogue 2016Document10 pagesFlexible Connectors Catalogue 2016FARIDNo ratings yet

- Biogas DigesterDocument35 pagesBiogas DigesterXylester Kenn FabreNo ratings yet

- 1 s2.0 S0306261911004636 MainDocument12 pages1 s2.0 S0306261911004636 Mainsb aliNo ratings yet

- PompaDocument71 pagesPompa3C10Iqbal Miftachul FalahNo ratings yet

- Stone Columns (SC) : Senoro GAS Development Project Luwuk, Central Sulawesi - IndonesiaDocument2 pagesStone Columns (SC) : Senoro GAS Development Project Luwuk, Central Sulawesi - IndonesiaMuhardi MNo ratings yet

- Petrol and Diesel Prices in IndiaDocument11 pagesPetrol and Diesel Prices in IndiaAnonymous V9Yo41No ratings yet

- WCL Chandrapur FinalDocument30 pagesWCL Chandrapur FinalVikram SinghNo ratings yet

- ENT7151 EPWA-DTTJ (06-Apr-2020) #1Document7 pagesENT7151 EPWA-DTTJ (06-Apr-2020) #1Awiatorzy WielcyNo ratings yet

- Physics KarateDocument6 pagesPhysics KaratehriziNo ratings yet

- Line Distance Protection IED REL 670Document47 pagesLine Distance Protection IED REL 670kass_ecs100% (1)

Ex Wps Train 01

Ex Wps Train 01

Uploaded by

aidil30Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ex Wps Train 01

Ex Wps Train 01

Uploaded by

aidil30Copyright:

Available Formats

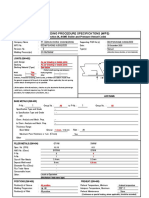

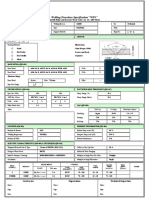

WELDING PROCEDURE SPECIFICATION (WPS)

(See QW-200.1, Section IX, ASME Bolier and Pressure Vessel Code - Edition 2019)

Company Name : By : -

Welding Procedure Specification No. : Date :

1

Supporting PQR No. (s) : Date :

Revision No. : 0 Date :

Welding Process(es) : Type :

(Automatic, Manual, Machine, or Semi-Automatic)

JOINT (QW-402) Details Joint :

Joint Design :

Root Spacing :

Backing : Yes No

Backing Matrial (Type) : N/A

(Refer to both backing and retainers)

Metal Nonfusing metal

Nonmetal Other

Sketches, Production Drawings, Weld Symbols, or Written Description should show the

general arrangement of the parts to be welded. Where applicable, the detail of weld groove

may be specified.

[At the option of the manufacturers, sketches may be attached to illustrate joint design, weld

layers, and bead sequence (e.g., for notch toughness procedures, for multiple process procedures,

etc.)].

*BASE METALS (QW-403)

P-No. : Group No. : P-No. : Group No. :

OR

Specification and type/grade or UNS Number :

to specification and type/grade or UNS Number :

OR

Chem. Analysis and Mech. Prop. :

to Chem. Analysis and Mech. Prop. :

Thickness Range :

Base Metal : Groove :

1

Maximum Pass Thickness ≤ /2 in. (13 mm) : (Yes) (No)

Other : -

*FILLER METALS (QW-404)

Process

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Filler Metals Product Form

Supplemental Filler Metal

Weld Metal

Thickeness Range

Groove

Fillet

Electrode-Flux (Class)

Flux Type

Consumable Trade Name

Consumable Insert

Other

* Each base metal-filler metal combination should be recorded individually.

WPS No. : 0 Rev. : 0

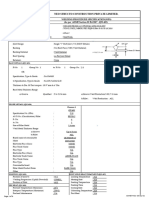

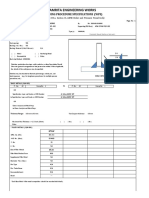

POSITION (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position (s) of Groove : Temperature Range :

Welding Progression : Up Down Time Range :

Position (s) of Fillet : Other :

Other : -

PREHEAT (QW-406) GAS (QW-408)

Preheat Temperature, Minimum : Precent Composition

Interpass Temperature, Maximum : Gas(es) (Mixture) Flow Rate

Preheat Maintenance : Shielding

Other : Trailing

(Continous or special heating, where applicable, should be recorded) Backing

Other

ELECTRICAL CHARECTERISTIC (QW-409)

Filler Metal

Wire Feed Other (e.g., Remarks,

Energy or Travel Speed

Welding Current Type Speed Coments, Hot Wire

Weld Pass Amps (Range) Power Volts (Range) (Range)

Process Class Diameter and Polarity (Range) Addition, Technique,

(Range) (mm/min)

mm/min Torch Angle, etc.,)

Root

Hot

Fill

Cap

Amps and volts, or power or energy range, should be recorded for each electrode size, position, and thickness, etc.

Pulsing Current : - Heat Input (max.)

Tungsten Electrode Size and Type : -

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW (FCAW) : N/A

(Spray Arc, Short Circuiting Arc, etc.)

Other :

TECHNIQUE (QW-410)

String or Weave Bead :

Orifice, Nozzle, or Gas Cup Size :

Initial and Interpass Cleaning (Brushing, Grinding, etc.) :

Methode of Back Gouging :

Oscilation :

Contact Tube to Work Distance :

Multiple or Single Pass (Per Side) :

Multiple or Single Electrode :

Peening :

other :

Prepared & Approve by,

WELDING ENGINEER

You might also like

- Igcse Physics All FormulasDocument4 pagesIgcse Physics All FormulasRichie Harvy82% (17)

- 37507022-WPS-PQR-SS-316 LDocument5 pages37507022-WPS-PQR-SS-316 LVarun Malhotra100% (6)

- Sop For Motor Changing JobDocument10 pagesSop For Motor Changing JobT S Virdi50% (2)

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weigh Systems Pvt. LTDHussein MohamedNo ratings yet

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - Plat SteDocument6 pagesWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps - Asme Ix - Gtaw - PipaDocument5 pagesWps - Asme Ix - Gtaw - PipaMuhammad Fitransyah Syamsuar PutraNo ratings yet

- Wps Blank Form 2sheetDocument4 pagesWps Blank Form 2sheetdidi sudiNo ratings yet

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 pagesWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriNo ratings yet

- Welding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2Document2 pagesWelding Procedure Specifications (WPS) : Universitas Negeri Yogyakarta Hanifan Nugroho - B2RahmadiNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- WPS & WPQR (Asme Section IX)Document7 pagesWPS & WPQR (Asme Section IX)Rizaldy PhoenksNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- WPS 1Document1 pageWPS 1janardan.sfeNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- Wps FormatDocument2 pagesWps FormatParminder SinghNo ratings yet

- Ejemplo Prueba 991003Document2 pagesEjemplo Prueba 991003MARIO ALBANo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- 347 310 WPSDocument2 pages347 310 WPSBIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 pagesWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiNo ratings yet

- QW-482 Suggested Format For Welding ProcDocument2 pagesQW-482 Suggested Format For Welding Procsachin0% (1)

- WPS 360-1 Rev0 PDFDocument14 pagesWPS 360-1 Rev0 PDFAhmed GomaaNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)pradeep4545No ratings yet

- Qw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Document2 pagesQw-483 Procedure Qualification Records (PQR: Groove Design of Test Coupon Base Metals (Qw-403) Filler Metals (Qw-404)Parminder SinghNo ratings yet

- Wps Train 01 (AIDIL)Document2 pagesWps Train 01 (AIDIL)aidil30No ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pages3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738No ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 pagesForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- QW-482 (WPS) GTAW 4MM FilletDocument4 pagesQW-482 (WPS) GTAW 4MM FilletBalkishan DyavanapellyNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSsbmmlaNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Sample Editable WPSDocument2 pagesSample Editable WPSf silva-No ratings yet

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 pagesWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanNo ratings yet

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 pagesAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyNo ratings yet

- Wps For Steel RodsDocument5 pagesWps For Steel RodsHamid MansouriNo ratings yet

- Wps FormatDocument2 pagesWps FormatMeghan GhoneNo ratings yet

- WPS&PQR FormsDocument4 pagesWPS&PQR FormsArab WeldersNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- WPS 1310Document2 pagesWPS 1310paulNo ratings yet

- Welding Procedure Specification (WPS) : Page: 1/1Document5 pagesWelding Procedure Specification (WPS) : Page: 1/1Walid BdeirNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- WPS FormatDocument3 pagesWPS Formatvivek bhangaleNo ratings yet

- First: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesDocument3 pagesFirst: Qw-482 Welding Procedure Specification (WPS) For General Contracs and SuppliesAhmed AbdoNo ratings yet

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- WPSDocument6 pagesWPSYASH BARDHAN SinghNo ratings yet

- Rev 2 - Proposed Repair WPSDocument2 pagesRev 2 - Proposed Repair WPSRakesh Patel75% (4)

- Sample WPS Format PDFDocument1 pageSample WPS Format PDFait.koufiNo ratings yet

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Operators Address Deep Gas Drilling Challenges: Expandable TubularsDocument4 pagesOperators Address Deep Gas Drilling Challenges: Expandable TubularsTrieu Nguyen100% (1)

- Curtain Wall ShadingDocument8 pagesCurtain Wall ShadingNajeela BanuNo ratings yet

- Diagnosis and Testing Engine Cooling 1.6 Duratec 16V Ti VCTDocument13 pagesDiagnosis and Testing Engine Cooling 1.6 Duratec 16V Ti VCTIsmael LopezNo ratings yet

- MEC-A4-125B EnglishDocument2 pagesMEC-A4-125B Englishdragos manoleNo ratings yet

- DFGHJDocument18 pagesDFGHJsmsm7000No ratings yet

- 99 9-5 2.3T Head Gasket Replacement - SaabCentral ForumsDocument3 pages99 9-5 2.3T Head Gasket Replacement - SaabCentral ForumsDerrick ChongNo ratings yet

- Scion GC Series: The Gas Chromatographerhs Choice For SeparationsDocument12 pagesScion GC Series: The Gas Chromatographerhs Choice For SeparationsLABSSSSSNo ratings yet

- De Cuong On Tap Anh 6 HK2 Nam 22 23Document8 pagesDe Cuong On Tap Anh 6 HK2 Nam 22 23Minh NguyenNo ratings yet

- 14.7.4 Matimba-Spitskop 2 400kV Loop-In and Out Transmission Line Specification Rev0 PDFDocument112 pages14.7.4 Matimba-Spitskop 2 400kV Loop-In and Out Transmission Line Specification Rev0 PDFmilosevicsasa11100% (1)

- Industrial Iot Based Condition Monitoring For Wind Energy Conversion SystemDocument12 pagesIndustrial Iot Based Condition Monitoring For Wind Energy Conversion SystemdikyNo ratings yet

- eArt-Calculating Overpressure From BLEVE ExplosionsDocument6 pageseArt-Calculating Overpressure From BLEVE ExplosionsJurizal Julian LuthanNo ratings yet

- Pokhara University Applied Mechanics - I Question PapersDocument4 pagesPokhara University Applied Mechanics - I Question PapersBuddhisagar BastolaNo ratings yet

- Spinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedDocument8 pagesSpinning Section Trutzschler: ITMA 2019 New Machinery / New Innovations DisplayedPadmanaban PasuvalingamNo ratings yet

- Power System Protection 25Document235 pagesPower System Protection 25mishra.satyam9874100% (1)

- Fischer Tropsch Reaction MechanismDocument9 pagesFischer Tropsch Reaction MechanismMarcus NguyễnNo ratings yet

- Arson InvestigationDocument128 pagesArson InvestigationOflodor Abmac50% (2)

- IIEE ANC RME Forum 2015Document231 pagesIIEE ANC RME Forum 2015Ray RodriguezNo ratings yet

- 375B - 385B IV 12 PG A4 Broch PDFDocument7 pages375B - 385B IV 12 PG A4 Broch PDFManuel VenturaNo ratings yet

- Flexible Connectors Catalogue 2016Document10 pagesFlexible Connectors Catalogue 2016FARIDNo ratings yet

- Biogas DigesterDocument35 pagesBiogas DigesterXylester Kenn FabreNo ratings yet

- 1 s2.0 S0306261911004636 MainDocument12 pages1 s2.0 S0306261911004636 Mainsb aliNo ratings yet

- PompaDocument71 pagesPompa3C10Iqbal Miftachul FalahNo ratings yet

- Stone Columns (SC) : Senoro GAS Development Project Luwuk, Central Sulawesi - IndonesiaDocument2 pagesStone Columns (SC) : Senoro GAS Development Project Luwuk, Central Sulawesi - IndonesiaMuhardi MNo ratings yet

- Petrol and Diesel Prices in IndiaDocument11 pagesPetrol and Diesel Prices in IndiaAnonymous V9Yo41No ratings yet

- WCL Chandrapur FinalDocument30 pagesWCL Chandrapur FinalVikram SinghNo ratings yet

- ENT7151 EPWA-DTTJ (06-Apr-2020) #1Document7 pagesENT7151 EPWA-DTTJ (06-Apr-2020) #1Awiatorzy WielcyNo ratings yet

- Physics KarateDocument6 pagesPhysics KaratehriziNo ratings yet

- Line Distance Protection IED REL 670Document47 pagesLine Distance Protection IED REL 670kass_ecs100% (1)