Professional Documents

Culture Documents

Umeguard HS 6174 20100430R

Umeguard HS 6174 20100430R

Uploaded by

rhannie garciaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Umeguard HS 6174 20100430R

Umeguard HS 6174 20100430R

Uploaded by

rhannie garciaCopyright:

Available Formats

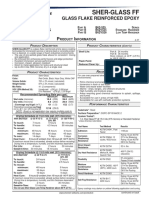

UMEGUARD HS

Product Data Sheet No. 6174

Product Information Regulatory Information

Generic Type Flash Point

Two component surface tolerant modified epoxy o

Base : 33.5 C

o

Hardener : 100 C

Description

High build, high solids modified epoxy resin Specific Gravity ( Mixed ) : 1.40 + 0.05 g / ml

maintenance coating as surface tolerant type primer ( ISO 2811 )

and topcoat V.O.C. as supplied : 150 g / litre

( Calculated from the formula with Light grey colour product )

Colour & Appearance UN Class / Packing Group : Base : 3 / II

Light grey, Black, Reddish brown, as specified Matt

Hardener : ―

Solids by Volume ( % ) 82 + 2 UN Shipping No. : 1263

Features Packaging & Handling Information

- Minimize surface preparation works

- May be applied over most aged anti-corrosive coating Packaging : 2 packs

systems Base Pack ( Liquid enamel )

- Various subsequent coats are applicable Hardener Pack ( Liquid semi-clear )

- Excellent resistance for petroleum products, water,

salt water, and selected chemicals Package size may vary from country to country according

- Excellent physical properties such as toughness, to local requirements

impact and abrasion resistance

- Easy application Storage Condition

- Must be in accordance with national regulation.

Recommended Use - Keep well ventilated space.

As a rust inhibiting epoxy maintenance coating for - Keep away from source of heat and ignition.

various plants, steel structures, tank externals, and o

Temperature : 5 - 50 C

bridges.

Humidity o

: 0 - 90 % RH

Shelf Life at 25 C : 12 months

Subject to re-inspection

Disposal of Package

Dispose in separate closed metal container in accordance

with all applicable regulations.

Practical Information

100 ( 91.5 ) : 9.2 ( 8.5 ) ( by weight )

Mixing Ratio Base : Hardener =

88 : 12 ( by volume )

Dry Film Thickness 100 - 200 microns

Wet Film Thickness 122 - 244 microns

2

0.122 - 0.244 litre / m

Theoretical Coverage 2

8.2 - 4.1 m / litre

Temperature 10 oC 20 oC 30 oC

Drying Time Surface Dry ( ISO 1517 ) 12 hrs. 6 hrs. 3 hrs.

( at D.F.T. 200 microns ) Hard Dry ( ISO 9117 ) 24 hrs. 12 hrs. 8 hrs.

Minimum 24 hrs. 12 hrs. 8 hrs.

Overcoating Interval

To self Overcoating 7 days 7 days 5 days

( at D.F.T. 200 microns ) Maximum

To Preferable Subsequent Coats (*) (*) (*)

Induction Time - - -

Pot Life ( ISO 9514 ) 5 hrs. 4 hrs. 3 hrs.

( * ) Consult Chugoku Marine Paints for further details.

Protective Coatings Issue Date : 30 April 2010 UMEGUARD HS

Page 1 of 2 No. 6174

UMEGUARD HS No. 6174

Surface Preparation

General

Surface to be painted must be clean ( free from rust, dust, oil, grease, etc. ) and dry.

All welds should be relatively smooth without sharp edges and free of weld slag and spatter. All scale must be removed

by power tool or spot blast cleaning.

Steel Surface

ISO ( 8501 - 1 ) St 2 or St 3 is acceptable. SSPC - SP11 is recommended.

1

Abrasive blast cleaning to ISO ( 8501 - 1 ) Sa 2 /2 and anchor profile of 40 - 50 microns are recommended for the highest

performance.

Aged Coated Surface

UMEGUARD HS may be coated over most aged anti-corrosive coating systems ( polyurethane, epoxy, chlorinated

rubber, alkyd, etc.). All loose coatings must be removed. Glossy surfaces should be abraded. Consult Chugoku Marine

Paints for further details.

Application

o

Temperature Min. 10 C

Humidity Max. 85% RH

Thinner EPOXY THINNER A

Mixing Material is supplied in two components as a unit. Always mix a complete unit in the

proportions supplied. Once the unit has been mixed, it must be used within the pot

life as specified.

Preferable Preceding Coats EPICON series, GALBON series, CERABOND 2000, NZ PRIMER S, etc…

Preferable Subsequent Coats EPICON series, UNYMARINE series, FLUOREX UNDERCOAT EP, etc…

For Airless Spray - Tip No. GRACO 623 et al.

- Paint Output Pressure 14.7 - 17.7 MPa ( g )

- Spray - gun Speed 60 - 80 cm / sec.

- Viscosity 1.5 - 2.0 Pa・s

- Thinning 0 - 10 % by volume

For Brush / Roller Brush Suitable Typically 75 microns can be achieved.

- Thinning 0 - 5 % by volume

- All blast cleaned surfaces should be coated normally within 4 hours and before rust bloom occurs.

- Patch or stripe coat for sharp edges, bolts, or crevice should be applied by brush at first.

- Two coats system is recommended for tank internal lining to avoid pinholes and holidays.

- Before subsequent coat application, all chalks ( if existed ) and any contaminations should be removed.

- Sufficient ventilation is required for confined space to remove solvent vapour during application and drying.

- Wear the suitable protection gears such as glasses, gloves and fresh indrawn to breathing on workers.

Safety

This product should be used only by professional applicators. Consult the current Chugoku Marine Paints Material

Safety Data Sheets. Follow all local or national health, safety and environmental regulations. Observe all safety labels

on packaging and containers. Take precautions against possible risks of fire or explosions as well as protection of the

environment. Apply only at ventilated areas. Handle with care.

Disclaimer

This data sheet contains the best and latest of our knowledge on the date of issue on laboratory testing and practical

application experience, and subject to change without notice. Since the paints are used under unexpected

circumstances in some cases, guarantee can not be given except on the quality of those paints themselves.

- Generally epoxies including this product will be chalking, yellowing, and discolouring on exposure to sunlight.

- Consult Chugoku Marine Paints as for accepted cargo products.

- This product coating is not suitable for water immersion.

Please visit Chugoku Marine Paints, Ltd. Worldwide Network.

http://www.cmp.co.jp/

Protective Coatings Issue Date : 30 April 2010 UMEGUARD HS

Page 2 of 2 No. 6174

You might also like

- 521+technical Data Sheet V-6Document2 pages521+technical Data Sheet V-6TeenTeen GaMingNo ratings yet

- Bannoh 1500 5084 20100622FDocument2 pagesBannoh 1500 5084 20100622FHung NguyenNo ratings yet

- DuraplateDocument4 pagesDuraplatelovaldes62No ratings yet

- Belzona 1121: Product Specification SheetDocument2 pagesBelzona 1121: Product Specification SheetQuy RomNo ratings yet

- Protective & Marine Coatings: Heavy Duty Block FillerDocument4 pagesProtective & Marine Coatings: Heavy Duty Block FillerAna CabreraNo ratings yet

- 101foam MingkoDocument1 page101foam MingkoJaime PeñabrañaNo ratings yet

- DOWSIL™ 1-2620 Dispersion RTV Elastoplastic Conformal CoatingDocument3 pagesDOWSIL™ 1-2620 Dispersion RTV Elastoplastic Conformal CoatingGreat StuffNo ratings yet

- Marathon XHBDocument5 pagesMarathon XHBakbarNo ratings yet

- TDS LF-371 - Dec22Document2 pagesTDS LF-371 - Dec22ofershochetNo ratings yet

- Steel Shield 1200Document2 pagesSteel Shield 1200Moin AltafNo ratings yet

- HereShield TDSDocument5 pagesHereShield TDSMahdi BagheriNo ratings yet

- Durebild HSE: High Build Two Pack Epoxy CoatingDocument3 pagesDurebild HSE: High Build Two Pack Epoxy CoatinglivefreakNo ratings yet

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Chemxseal 32 18 Fire Stop SealantDocument20 pagesChemxseal 32 18 Fire Stop SealantAbdel Mongy AhmedNo ratings yet

- Polyfoam SS 50Document2 pagesPolyfoam SS 50Navid HashemiNo ratings yet

- Pds Epilux 218 Hs VocDocument2 pagesPds Epilux 218 Hs VocmuthukumarNo ratings yet

- Nitocote ET402: Coal Tar Extended Epoxy Resin CoatingDocument4 pagesNitocote ET402: Coal Tar Extended Epoxy Resin CoatingSabyasachi BangalNo ratings yet

- Jotamastic Plus: Technical Data SheetDocument5 pagesJotamastic Plus: Technical Data SheetRamlialianNo ratings yet

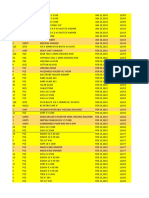

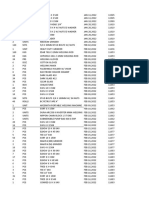

- Sherglass FFDocument4 pagesSherglass FFJhose BonillaNo ratings yet

- Polyfoam SS45Document71 pagesPolyfoam SS45BavishNo ratings yet

- Vitralit 1650 English Tds Panacol AdhesiveDocument4 pagesVitralit 1650 English Tds Panacol Adhesivetito3007No ratings yet

- Hi-Pon 200Ht Cui: Product DescriptionDocument4 pagesHi-Pon 200Ht Cui: Product DescriptionGatra Bagus PrakosoNo ratings yet

- Apcodur Ehb 500-VocDocument2 pagesApcodur Ehb 500-VocMoin AltafNo ratings yet

- Soft Natural Rubber Lining: Technical Data SheetDocument2 pagesSoft Natural Rubber Lining: Technical Data SheetArmanda SiryogiawanNo ratings yet

- MyPDF 3Document2 pagesMyPDF 3nikenNo ratings yet

- Varnishes For Electric EquipmentsDocument2 pagesVarnishes For Electric EquipmentsAnonymous KeBaAOY3T100% (1)

- TDS For Rubber Lining 1056HTDocument2 pagesTDS For Rubber Lining 1056HTYao WangNo ratings yet

- TDS 44902 Tankguard NCV N Euk GBDocument5 pagesTDS 44902 Tankguard NCV N Euk GBzattie89No ratings yet

- Aquashield Cool Roof - TDSDocument2 pagesAquashield Cool Roof - TDSAnoop ShankarNo ratings yet

- Pds Epilux 218 VocDocument2 pagesPds Epilux 218 VocmuthukumarNo ratings yet

- Belzona 1121 InstrustionsDocument2 pagesBelzona 1121 Instrustionssh4kesNo ratings yet

- Brochure TDS RedisetLQ 1106Document1 pageBrochure TDS RedisetLQ 1106Iwan ShofyanNo ratings yet

- Macropoxy 240Document2 pagesMacropoxy 240nellyNo ratings yet

- Penguard WF BrochureDocument2 pagesPenguard WF BrochurehersonNo ratings yet

- TDS 2920 Penguard Express ZP Eng USDocument5 pagesTDS 2920 Penguard Express ZP Eng USnatig samedovNo ratings yet

- Epofine 404 - Finehard 2404Document3 pagesEpofine 404 - Finehard 2404Karishma PrabhuNo ratings yet

- Loctite Stycast 2651MM Cat 9 TDS 1Document2 pagesLoctite Stycast 2651MM Cat 9 TDS 1steffan.henryNo ratings yet

- Jotamastic Plus - TDS.engDocument5 pagesJotamastic Plus - TDS.engJayasurya PaluriNo ratings yet

- Cardolite NX 2016Document2 pagesCardolite NX 2016Lê TiếnNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- Sigma Marine Coatings Manual - Part8Document2 pagesSigma Marine Coatings Manual - Part8EngTamerNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- TDS LF-361Document2 pagesTDS LF-361ofershochetNo ratings yet

- Enydyne c40-8161ct TdsDocument2 pagesEnydyne c40-8161ct TdsakosirhockzNo ratings yet

- Cote LDocument1 pageCote Lalvarado.hdez05No ratings yet

- Technical Data Sheet: Silcoset 151 1 Part Adhesive SealantDocument2 pagesTechnical Data Sheet: Silcoset 151 1 Part Adhesive SealantArun VaideeswaranNo ratings yet

- WWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinDocument2 pagesWWW - Techsil.co - Uk: Stainless Steel Putty Product BulletinVinodKandukuriNo ratings yet

- TDS Penguard Midcoat M20 (Midcoat)Document5 pagesTDS Penguard Midcoat M20 (Midcoat)rndsb.aopNo ratings yet

- Dura-Plate UHS: Protective & Marine CoatingsDocument2 pagesDura-Plate UHS: Protective & Marine CoatingsABIMAELNo ratings yet

- Rust O Cap PDFDocument1 pageRust O Cap PDFTitus PraveenNo ratings yet

- Epilux 58 M.I.O.: Product DescriptionDocument2 pagesEpilux 58 M.I.O.: Product DescriptionMoin AltafNo ratings yet

- Product Data Sheet: Topaz Matt Emulsion 588MEDocument2 pagesProduct Data Sheet: Topaz Matt Emulsion 588MEJoseph DarwinNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 HardenerVaibhav AnuseNo ratings yet

- Araldite Epoxy Resin Cy 230 and Hy 951 HardenerDocument6 pagesAraldite Epoxy Resin Cy 230 and Hy 951 Hardenersonu50% (2)

- Jotun Malathon TDSDocument5 pagesJotun Malathon TDSBiju_PottayilNo ratings yet

- Jotamastic 80 MIODocument5 pagesJotamastic 80 MIOBiju_PottayilNo ratings yet

- Armorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsDocument4 pagesArmorseal 650 SL/RC: Armorseal Heavy Duty Floor CoatingsOswaldo SantoyoNo ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- CI-FDN-IPGC-2023-1613 IGT Luzon Terminal MBT and RW Geopier Layout and Section (01!14!24)Document4 pagesCI-FDN-IPGC-2023-1613 IGT Luzon Terminal MBT and RW Geopier Layout and Section (01!14!24)rhannie garciaNo ratings yet

- CI-FDN-IPGC-2023-1614 IGT Luzon Terminal Coordinates (01!14!24)Document16 pagesCI-FDN-IPGC-2023-1614 IGT Luzon Terminal Coordinates (01!14!24)rhannie garciaNo ratings yet

- SWAPDocument1 pageSWAPrhannie garciaNo ratings yet

- PL Plu Spi 2023 02 2317 Option2Document1 pagePL Plu Spi 2023 02 2317 Option2rhannie garciaNo ratings yet

- PL Plu Spi 2023 02 2317 Option1Document1 pagePL Plu Spi 2023 02 2317 Option1rhannie garciaNo ratings yet

- SCHEDULEDocument3 pagesSCHEDULErhannie garciaNo ratings yet

- SPI Mabini Electrical - As BuiltDocument24 pagesSPI Mabini Electrical - As Builtrhannie garciaNo ratings yet

- PerifenceDocument1 pagePerifencerhannie garciaNo ratings yet

- MS - TTLR Driveway Crack Repair UpdatedDocument12 pagesMS - TTLR Driveway Crack Repair Updatedrhannie garciaNo ratings yet

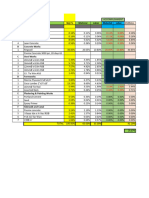

- Item Description WGT % Material Labor Material Labor 3Ml VST Foundation A EarthworksDocument1 pageItem Description WGT % Material Labor Material Labor 3Ml VST Foundation A Earthworksrhannie garciaNo ratings yet

- DELAYSDocument1 pageDELAYSrhannie garciaNo ratings yet

- NMPIDocument1 pageNMPIrhannie garciaNo ratings yet

- Excel Construction Project Management Templates Construction Documentation Tracker Template V1Document1 pageExcel Construction Project Management Templates Construction Documentation Tracker Template V1rhannie garciaNo ratings yet

- GantryDocument1 pageGantryrhannie garciaNo ratings yet

- Attachment #4 (Site Issues and Concerns) 062323Document1 pageAttachment #4 (Site Issues and Concerns) 062323rhannie garciaNo ratings yet

- Tema Spi MabiniDocument4 pagesTema Spi Mabinirhannie garciaNo ratings yet

- Me-Mom-Spi-2023-02-005 Mabini 02.28.23Document2 pagesMe-Mom-Spi-2023-02-005 Mabini 02.28.23rhannie garciaNo ratings yet

- WAR - Seaoil Mabini Phase III For SiteDocument2 pagesWAR - Seaoil Mabini Phase III For Siterhannie garciaNo ratings yet

- Borehole-15-1 (Preliminary)Document1 pageBorehole-15-1 (Preliminary)rhannie garciaNo ratings yet

- Consent Privacy Notice 2022Document3 pagesConsent Privacy Notice 2022rhannie garciaNo ratings yet

- Spi MabiniDocument16 pagesSpi Mabinirhannie garciaNo ratings yet

- PM-OP (SITS) Site Instruction To Subcontractor (1.0) 10Document2 pagesPM-OP (SITS) Site Instruction To Subcontractor (1.0) 10rhannie garciaNo ratings yet

- Weekly Accompishment Report Format WPR 002 (18 - 24) February 2023Document29 pagesWeekly Accompishment Report Format WPR 002 (18 - 24) February 2023rhannie garciaNo ratings yet

- SEAOIL ProjectDocument71 pagesSEAOIL Projectrhannie garciaNo ratings yet

- SPI MabiniDocument14 pagesSPI Mabinirhannie garciaNo ratings yet

- SodapdfDocument15 pagesSodapdfrhannie garciaNo ratings yet

- Manpower Mob StatusDocument5 pagesManpower Mob Statusrhannie garciaNo ratings yet

- Fab Order MabiniDocument4 pagesFab Order Mabinirhannie garciaNo ratings yet

- StormWater and AssetManagement ToolDocument9 pagesStormWater and AssetManagement ToolIsaac OtiNo ratings yet

- 42VSGS CatalogDocument4 pages42VSGS CatalogPattamon KhempilaNo ratings yet

- Microbiology An Introduction 12th Edition Tortora Test BankDocument36 pagesMicrobiology An Introduction 12th Edition Tortora Test Bankbegravebasnetvp8su100% (23)

- Five Rivers of SikkimDocument5 pagesFive Rivers of SikkimIT Support100% (1)

- Activities That Disrupt The Cycle in An Ecosystem and Importance of ForstDocument33 pagesActivities That Disrupt The Cycle in An Ecosystem and Importance of ForstMyschool Lag-asan100% (1)

- Injection Systems - Water Guide SpecificationDocument3 pagesInjection Systems - Water Guide SpecificationCarlos LagosNo ratings yet

- VITA SPA DX SERIES OWNERS ManualDocument12 pagesVITA SPA DX SERIES OWNERS ManualJackNo ratings yet

- Cleaning Pipette US WebDocument1 pageCleaning Pipette US WebKamil JNo ratings yet

- Plant Trees To Avoid FloodingDocument5 pagesPlant Trees To Avoid FloodingMunting TahananNo ratings yet

- MSDS 0106Document6 pagesMSDS 0106Kannan Sasidharan PillaiNo ratings yet

- Domina Plusb Premium Line Eng Rev5 OpDocument35 pagesDomina Plusb Premium Line Eng Rev5 OpSergiu Si Renata Bancos100% (1)

- Hec HMSDocument62 pagesHec HMSdstar13No ratings yet

- Dsce-19.2.2021-Critical Issues and Remedial Measures For Ground Water ManagementDocument8 pagesDsce-19.2.2021-Critical Issues and Remedial Measures For Ground Water Managementiamskg63891583No ratings yet

- An Overview of Alternative Raw Materials Used in Cement and ClinkerDocument19 pagesAn Overview of Alternative Raw Materials Used in Cement and ClinkerLucero MamaniNo ratings yet

- LWAASHJSPLANGULDocument5 pagesLWAASHJSPLANGULAmiy SrivastavaNo ratings yet

- Industrial WastewaterDocument32 pagesIndustrial WastewaterAldo Martinez100% (1)

- Problems On Channel ControlsDocument2 pagesProblems On Channel Controlswacotc2163No ratings yet

- Septic Tank DetailDocument1 pageSeptic Tank DetailJonniel De Guzman100% (3)

- Faculty of Engineering Online Final Examination: WarningDocument11 pagesFaculty of Engineering Online Final Examination: WarningJan Olaf Müller JohanssenNo ratings yet

- Final ESIA Report Uvuvi House 24th Jan 2022Document184 pagesFinal ESIA Report Uvuvi House 24th Jan 2022Ronnie WartNo ratings yet

- Constrution Manual Biodigester 1Document25 pagesConstrution Manual Biodigester 1Sudarno Utomo100% (1)

- ReportDocument21 pagesReportPawan BhakuniNo ratings yet

- Surface Preparation Methods For Common Substrate Materials: AppendixDocument24 pagesSurface Preparation Methods For Common Substrate Materials: AppendixMartin BonillaNo ratings yet

- A Production Chain: THE Link INDocument199 pagesA Production Chain: THE Link INThania LimacheNo ratings yet

- In Vitro Anticoccidial Antioxidant Activities and Cytotoxicity of Psidium Guajava Extracts PDFDocument11 pagesIn Vitro Anticoccidial Antioxidant Activities and Cytotoxicity of Psidium Guajava Extracts PDFBakhti GulNo ratings yet

- Use of Grade 25 Concrete in Design of Water Retaining Structures Based On Bs 8007 RecommendationsDocument8 pagesUse of Grade 25 Concrete in Design of Water Retaining Structures Based On Bs 8007 RecommendationsEngr Ishfaque TunioNo ratings yet

- Solar Water Heater Lab Guide FinalDocument14 pagesSolar Water Heater Lab Guide Finalerduobing100% (1)

- CH 3 Problems SolutionsDocument13 pagesCH 3 Problems SolutionsdwiyogasariNo ratings yet

- Fiitjee: Talent Reward Exam-2018Document49 pagesFiitjee: Talent Reward Exam-2018truenameNo ratings yet

- Philippines FreshwaterDocument11 pagesPhilippines FreshwaterBJ Allon Mallari100% (1)