Professional Documents

Culture Documents

Loss On Heating

Loss On Heating

Uploaded by

alialwasity1914Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loss On Heating

Loss On Heating

Uploaded by

alialwasity1914Copyright:

Available Formats

Aim:

To determine the loss of volatiles present in asphaltic bitumen on

heating.

Significance:

Bitumen is commonly used as a binder in pavements. When it is

exposed to the atmosphere, the volatiles present in it evaporates and

bitumen hardens.

In the loss of heating of bitumen, the bitumen specimen is subjected

to an accelerated ageing process under the conditions specified by the

standard.

By carrying out penetration test at the start and finish of the test, the

amount by which bitumen hardens can be known.

Important Terms:

Loss on Heating: The loss of volatiles like oil except water on heating

the bituminous material to standard temperature and under

predetermined conditions is termed as a loss on heating.

Principle:

The practical works on the below principle:

The volatile materials evaporate when they are subjected to high

temperatures. Bitumen is heated to about 163 ° C so that the volatile

materials are evaporated.

Apparatus for Loss of Heating of Bitumen

Test:

The apparatus used while conducting loss on heating test of bitumen is

described below:

1. Hot Air Oven:

2. Perforated Metal Shelf:

It is made up of aluminum and placed in the center of the oven. It is

suspended by means of a vertical shaft which is rotated at the rate of

5-6 rev/min. Its diameter is about 250 mm.

3. Container:

Container

It is a cylindrical pan made up of either metal or glass, cylindrical in

shape and has a flat bottom. Its internal diameter is 55 mm and its

internal depth is 35 mm.

4. Thermometer or Temperature Indicator and Controller:

To measure the temperature of water in the ductility apparatus. It

should be graduated in Celcius. The temperature range should be from

155-170 °C. it is supported on the shaft of the perforated shelf so that

it can be kept in a vertical position. Distance between the top of the

contraction chamber and the bottom of bulb of the thermometer ≯ 41

mm.

5. Weighing Balance:

It should be accurate to 0.1 grams.

6. Other accessory equipment required for conducting Loss

on Bitumen Test are as follows:

• Asbestos gloves

• Penetrometer and water bath

• Container to mix bitumen of about 225 gram

• Hotplate

Materials:

• Bituminous material to be tested

Precaution:

The following precautions should be taken while performing the loss on

a heating test of bitumen to obtain accurate results:

• The loss on a heating test of bitumen should be conducted

in duplicate

• If there is presence of water in the sample, it should be

tested in that composition only

• The temperature of the oven should be strictly maintained

to 163 °C

• Hot air oven, analytical balance, penetrometer and water

bath should be calibrated in a while

• Water content of the sample should be determined in

accordance with IS 1211: 1978 as the method of

determination of water content specified

• If the sample shows evidence of loss by foaming, that

sample should not be considered but rejected

Procedure for Loss on Heating Test of

Bitumen:

1. Agitate the bituminous material by stirring as received so

that a complete mixture is obtained. Heat the sample above

its softening point, if necessary.

2. Heat the containers at 100-110 °C for about 30 minutes in

the oven and then allow them to cool at room temperature

and measure the weight of the empty containers.

3. Take a portion of the well-mixed material for testing in a

container and allow it to cool. Prepare at least 2 such

specimens.

4. Weigh the sample along with the container to the nearest

0.1 gram and subtract the weight of the container to obtain

the weight of the sample- W1. The weight of the sample

filled in the container is 50.0 ± 0.5 grams.

5. If penetration values are to be compared too, then pour the

sample in the penetrometer cup also. Find out the

penetration value as specified in IS: 1203- 1978.

6. Set the temperature of the oven to 163 ± 1 °C.

7. Place the container with the sample on the perforated shelf

placed centrally and close the oven.

8. Maintain the temperature to 163 ± 1 °C for 5 hours after

the oven has achieved the specified temperature. The

duration for which the sample is placed in the oven should

not be more than 5 hours and 15 minutes.

9. Switch on the motor switch to allow the perforated plate to

rotate at a rate of 5-6 rev/min.

10. Allow the sample in the containers to cool at room

temperature.

11. Weight the sample to the nearest 0.1 gram- W2.

12. Determine the water content for the sample as done

in the determination of water content test in accordance

with IS

13. Calculate the weight loss of volatile materials because

of heating from the above-observed values.

14. Arrange the containers on the perforated shelf and

turn on the oven for 5 minutes at the specified

temperature.

15. If the penetration test is also to be compared, then

mix the sample of the containers and keep the mixture on a

hotplate so that it remains in the liquid state. Pour the

mixture into a penetrometer cup and determine the

penetration value. The value will be less than the previous

one.

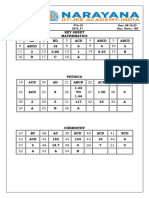

Observation:

Following observation is made as the loss on heating test of bitumen is

conducted:

The weight of the sample reduces on heating as the volatile materials

are evaporated.

Hence, the initial weight of the sample is more while the weight after

testing is reduced. The difference in weight is the loss of volatile

materials present in the bitumen.

You might also like

- Gravimetric Determination of Moisture and Phosphorus in Fertilizer SampleDocument6 pagesGravimetric Determination of Moisture and Phosphorus in Fertilizer SampleGelo Buligan100% (3)

- Thin Film OvenDocument4 pagesThin Film OvenAli Ib TarshaNo ratings yet

- Tfot Astm D 1754Document3 pagesTfot Astm D 1754Mansueta StefanusNo ratings yet

- Expt5 SolemneDocument11 pagesExpt5 SolemneArthur Christian SolemneNo ratings yet

- Experiment Name:: LaboratoryDocument10 pagesExperiment Name:: LaboratoryAhmad F AwwadNo ratings yet

- 2Document1 page2JOSE CANTERONo ratings yet

- Bitumen Testing MethodDocument35 pagesBitumen Testing MethodArun NesamNo ratings yet

- Aashto T-47Document3 pagesAashto T-47renzoNo ratings yet

- Specific Gravity and Softening Point of A Bitumen SampleDocument9 pagesSpecific Gravity and Softening Point of A Bitumen Samplemwaqas250No ratings yet

- Expt 4Document7 pagesExpt 4JV RatmanNo ratings yet

- Directly Into A Gas Without Passing Through The Liquid Phase. (1) in This Process, The StudentsDocument5 pagesDirectly Into A Gas Without Passing Through The Liquid Phase. (1) in This Process, The StudentsChelleNo ratings yet

- .Archivetemptest 2 - Softening Point of BitumenDocument6 pages.Archivetemptest 2 - Softening Point of BitumenSadon B AsyNo ratings yet

- Directly Into A Gas Without Passing Through The Liquid Phase. (1) in This Process, The StudentsDocument5 pagesDirectly Into A Gas Without Passing Through The Liquid Phase. (1) in This Process, The StudentsChelleNo ratings yet

- Calculating The Heat Transfer Between Wax and Water.: Lab ReportDocument4 pagesCalculating The Heat Transfer Between Wax and Water.: Lab Reportapi-406055813No ratings yet

- Specific Gravity of Fine Grained Soils - IS 2720Document20 pagesSpecific Gravity of Fine Grained Soils - IS 2720chandra chanduNo ratings yet

- Softening Point TestDocument3 pagesSoftening Point TestChristian Nicolaus MbiseNo ratings yet

- Flash & Fire Point Test of BitumenDocument8 pagesFlash & Fire Point Test of BitumenDakshraj RathodNo ratings yet

- تجربة 13Document7 pagesتجربة 13yousefhjeejNo ratings yet

- 1,2,9Document20 pages1,2,9Zekariyas AbushaNo ratings yet

- B.Sc. SEM IDocument4 pagesB.Sc. SEM IsameerNo ratings yet

- EXPERIMENT- 4Document2 pagesEXPERIMENT- 4Richa 101 dph 20No ratings yet

- Methodology NewDocument13 pagesMethodology NewWilliam J ThompsonNo ratings yet

- Melting PointDocument10 pagesMelting Pointapi-246263792No ratings yet

- D4429, CBRDocument22 pagesD4429, CBRসামিউল হাসান শান্তNo ratings yet

- Chem PracDocument35 pagesChem PracVilina Nayan BhayaniNo ratings yet

- Softening PointDocument10 pagesSoftening Pointபிரபாகரன் முனிசாமி100% (1)

- Lab Report Softeing Point G1Document7 pagesLab Report Softeing Point G1Zak HeroNo ratings yet

- Molar Mass of Volatile Liquid LabDocument5 pagesMolar Mass of Volatile Liquid LabJackNo ratings yet

- Ahmed KocherDocument16 pagesAhmed KocherAhmed KucherNo ratings yet

- Melting Point and Boiling Point ProcedureDocument5 pagesMelting Point and Boiling Point Proceduresamreen banuNo ratings yet

- Meltingpoint PDFDocument4 pagesMeltingpoint PDFShama Al-ShadidiNo ratings yet

- Flash and Fire Point TestDocument4 pagesFlash and Fire Point TestحسامNo ratings yet

- Q 535 Q 5Document23 pagesQ 535 Q 5JAN JERICHO MENTOYNo ratings yet

- Hydrate Lab: Never Place A Hot Crucible On A Balance! When Cool, Determine The Mass of The Crucible andDocument1 pageHydrate Lab: Never Place A Hot Crucible On A Balance! When Cool, Determine The Mass of The Crucible andmamazookeeprNo ratings yet

- Methods of Test For Pesticides and Their FormulationsDocument24 pagesMethods of Test For Pesticides and Their FormulationsMadhumitha katreddyNo ratings yet

- Heat Sterilization TechnologyDocument49 pagesHeat Sterilization TechnologyLeyvert De Jesus100% (1)

- Flash Point Test of BitumenDocument20 pagesFlash Point Test of BitumenMastani BajiraoNo ratings yet

- Training On Raw Material TestingDocument4 pagesTraining On Raw Material TestingElizabeth MaryNo ratings yet

- Miscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueDocument28 pagesMiscellaneous Determination & Tests: By: Dr. Shumaila ShafiqueShoaib Muhammad100% (1)

- Process Control in Fruit Canning, Milk Frezzing and Vegetable FreezingDocument37 pagesProcess Control in Fruit Canning, Milk Frezzing and Vegetable FreezingSharmina RituNo ratings yet

- Softening Point of BitumenDocument1 pageSoftening Point of BitumenAnonymous 59kjvq4OLBNo ratings yet

- Typ. Slow Firing Alkali BoiloutDocument3 pagesTyp. Slow Firing Alkali Boiloutsantoshkumarmishra2009100% (2)

- 11 - Practical Term 1Document6 pages11 - Practical Term 1OJASisLiveNo ratings yet

- Bomb CalorimeterDocument4 pagesBomb Calorimeteruserh1911100% (1)

- AP Chemistry - Specific Heat of A Metal LabDocument2 pagesAP Chemistry - Specific Heat of A Metal LabJonathan Chen0% (1)

- Softnes of BitumenDocument10 pagesSoftnes of BitumenSher AliNo ratings yet

- Criteria BDocument2 pagesCriteria BDavids Antonijs RitersNo ratings yet

- Flash and Fire PointDocument3 pagesFlash and Fire PointH.V.THENUWARANo ratings yet

- Screenshot 2023-11-25 at 14.33.40Document54 pagesScreenshot 2023-11-25 at 14.33.40Lana MajidNo ratings yet

- Melting Point: Experiment 1Document5 pagesMelting Point: Experiment 1abasoudaNo ratings yet

- Transport (LAB) Lec4 Sem 4thDocument17 pagesTransport (LAB) Lec4 Sem 4thMuhammad AsifNo ratings yet

- 001 WBT Version 3.0Document38 pages001 WBT Version 3.0IanDanielAyarzaSánchezNo ratings yet

- Experiment 6 (Calibration of Temperature Measuring Devices - A4)Document16 pagesExperiment 6 (Calibration of Temperature Measuring Devices - A4)Jamiel CatapangNo ratings yet

- Organic Chemistry Laboratory: Basra University College of Science and Technology Pharmacy DepartmentDocument12 pagesOrganic Chemistry Laboratory: Basra University College of Science and Technology Pharmacy DepartmentcrtgyhujikNo ratings yet

- DOC3165301205 9edDocument4 pagesDOC3165301205 9edAhmed JubaerNo ratings yet

- Theory of Boys CalorimeterDocument2 pagesTheory of Boys CalorimeterIzzah Ishak50% (4)

- Engineering Bulletin No 1: Boiler and Furnace TestingFrom EverandEngineering Bulletin No 1: Boiler and Furnace TestingRating: 4.5 out of 5 stars4.5/5 (2)

- Fowler's Household Helps: Over 300 Useful and Valuable Helps About the Home, Carefully Compiled and Arranged in Convenient Form for Frequent UseFrom EverandFowler's Household Helps: Over 300 Useful and Valuable Helps About the Home, Carefully Compiled and Arranged in Convenient Form for Frequent UseNo ratings yet

- Is.2974 Part 5Document9 pagesIs.2974 Part 5Swapnil ToraskarNo ratings yet

- Q173D (S) CPU/Q172D (S) CPU Motion Controller Programming Manual (Safety Observation)Document252 pagesQ173D (S) CPU/Q172D (S) CPU Motion Controller Programming Manual (Safety Observation)Anh Tuân LeNo ratings yet

- Reactions of Aldehydes and KetonesDocument12 pagesReactions of Aldehydes and KetonespramodpsmpharmNo ratings yet

- T700S Technical Data Sheet PDFDocument2 pagesT700S Technical Data Sheet PDFjairoNo ratings yet

- @bohring Bot 08-10-23 SR Iit Star Co Scmodel @heyitsyashxdDocument12 pages@bohring Bot 08-10-23 SR Iit Star Co Scmodel @heyitsyashxdDinesh BabuNo ratings yet

- 4-Math Module 4-TrigonometryDocument15 pages4-Math Module 4-TrigonometryHindrick JumawanNo ratings yet

- Construction and Building Materials: Bashar S. Mohammed, Musa AdamuDocument18 pagesConstruction and Building Materials: Bashar S. Mohammed, Musa AdamuMuaz Bin Ali ArafNo ratings yet

- CH1 Module1 DiodesDocument54 pagesCH1 Module1 DiodesParidhi kothariNo ratings yet

- 35-Guided-Missiles DrdoDocument25 pages35-Guided-Missiles DrdoYagjna Valkya50% (2)

- Chapter 23. Concrete Building Systems 21.11.08Document94 pagesChapter 23. Concrete Building Systems 21.11.08Hasanain GaltanNo ratings yet

- Chapter 3Document17 pagesChapter 3Mintesnot TadeleNo ratings yet

- Freyssibar enDocument12 pagesFreyssibar enDario MarcoraNo ratings yet

- Structural Components of A Road: Transportation Engineering - IDocument32 pagesStructural Components of A Road: Transportation Engineering - INasirNo ratings yet

- Module in Analytic Geometry and Conic SectionCalculus1Document64 pagesModule in Analytic Geometry and Conic SectionCalculus1JESSA GRACENo ratings yet

- SOP Hot Line Water Cleaning at 150 Tower Energize Line (Washing Insulator)Document5 pagesSOP Hot Line Water Cleaning at 150 Tower Energize Line (Washing Insulator)Prames WaraNo ratings yet

- 4th Quarter G-9 ScienceDocument5 pages4th Quarter G-9 Sciencemiriams academyNo ratings yet

- 1,740 Units: Choudhry Amin AhmedDocument2 pages1,740 Units: Choudhry Amin AhmedUroona MalikNo ratings yet

- Effects of MN Addition and Related Mn-Containing Dispersoids On The Hot Deformation Behavior of 6082 Aluminum AlloysDocument11 pagesEffects of MN Addition and Related Mn-Containing Dispersoids On The Hot Deformation Behavior of 6082 Aluminum AlloysPengxuan DongNo ratings yet

- Lecture 4Document29 pagesLecture 4ivonasofronievska26No ratings yet

- Nitowrap FRCDocument2 pagesNitowrap FRCMansoor AliNo ratings yet

- KoL Mekflu - 9Document104 pagesKoL Mekflu - 9Maha D NugrohoNo ratings yet

- Class 12 P Block Elements by Bharat PanchalDocument34 pagesClass 12 P Block Elements by Bharat PanchalHardik Gaur100% (2)

- LLLLLL,, TP: 9lROE NE MDocument21 pagesLLLLLL,, TP: 9lROE NE MLarvalNo ratings yet

- Principles of Solar Energy Storage: Oleg Dimitriev - Tsukasa Yoshida - He SunDocument13 pagesPrinciples of Solar Energy Storage: Oleg Dimitriev - Tsukasa Yoshida - He SunArpit Kumar MishraNo ratings yet

- Seminors Reading For Tomorrow1Document30 pagesSeminors Reading For Tomorrow1eantphone kyawNo ratings yet

- Classwork or Homework Investigating Diffusion in AirDocument2 pagesClasswork or Homework Investigating Diffusion in AirPranav BISUMBHERNo ratings yet

- Panasonic Manual SM - Cs-E18.21ckeDocument100 pagesPanasonic Manual SM - Cs-E18.21ckeaaNo ratings yet

- Ghacem 2019Document23 pagesGhacem 2019jojo youngNo ratings yet

- 15 1D Barrier ProblemsDocument23 pages15 1D Barrier ProblemsengshimaaNo ratings yet

- Early Streamer Emission (ESE) Lightning Protection SystemDocument8 pagesEarly Streamer Emission (ESE) Lightning Protection SystemRague MiueiNo ratings yet