Professional Documents

Culture Documents

Cabin

Cabin

Uploaded by

PeetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cabin

Cabin

Uploaded by

PeetCopyright:

Available Formats

T11 rev2 10.

06 MY

Cabin Cabin 1

Sandvik Mining and Construction

Cabin 2

T11 rev2 10.06 MY

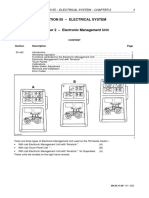

Instrument panel

Warning lights

Circuit breakers

remote strip

Control system display Emergency stop

Parking brake button

Ignition key

Air condition system Manual/ remote

controls key switch

Sandvik Mining and Construction

Cabin 3

T11 rev2 10.06 MY

Instrument panel

1. Alternator not charging

2. Circuit breaker open in the Rear connection box 15. Bucket counter

3. Engine air filter clogged (Weighting system,optional)

4. Brake circuit high pressure filter clogged 16. Boom floating (optional)

5. Transmission filter clogged 17. Ride control

6. Circuit breaker open in the instrument panel

7. Hydraulic return filter clogged

8. Brake circuit return filter clogged

1 2 3 4 5 15 16 17

6 7 8

18 19 20 21 22

9 10 11 12 13 14

9. Front lights 18. SEO

10. Rear light 19. Brake test

11. High/low lights 20. Brake release pump test

12. Indicator lights 21. Emergency steering test

13. Manual/ auto gear 22. Wiper timer

14. Lock-up on

Sandvik Mining and Construction

Cabin 4

T11 rev2 10.06 MY

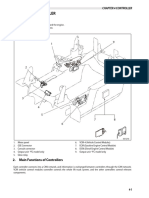

Joysticks

Windscreen

DeClutch wipers

Seat turn left

Seat turn Right

Horn

R

N Switch

Higher gear F

Bucket shaking

Lower gear

Ejector bucket

(optional)

Sandvik Mining and Construction

Cabin 5

T11 rev2 10.06 MY

Functional description of components

Steering joystick S149

The machine can be steered with the steering joystick on the left-hand side that is connected first to the Chair

module and from there through the can bus connected to the middle module where the steering outputs are

located. Two separate Pulse Width

Modulation (PWM) steering signals (turning left and turning right) and a feedback signal are used for steering

the machine. The Pulse Width Modulation (PWM) steering signal works so that the further youmove the

steering joystick from the middle position, the faster the steering movement is.

The steering can also be controlled with the display module’s forced functions window.

Boom and bucket joystick S148

Two different Pulse Width Modulation (PWM) control signals are used for controlling: movement up and

movement down. The PWMcontrol signal works so that the further you move the control joystick from the

middle position, the faster the control movement is.

The bucket is controlled according to the same principle as the boom (up and down with two PWM control

signals). Choose the movement direction for bucket control according to the instructions in Chapter Boom /

Bucket hydraulics ”Switching the control directions of the control joystick.” The bucket can also be controlled

with the displaymodule’s forced

functions window.

There is a limit switch for both directions on the boom and bucket joystick. The data from

the analog input and the direction limit switch must not conflict. Only one direction limit switch can be active at

a time. In case there is a conflict, the steering does not function.

Sandvik Mining and Construction

Cabin 6

T11 rev2 10.06 MY

Functional description of components

Throttle pedal

You can control engine revolutions with the throttle pedal that is connected to the chair module. The request for

revolution count is sent to the engine ECM through the SAE J1939 bus, through which the information on actual

engine revolutions returns to the control system. When the machine is started, the system controls the throttle

into idle running revolutions.

The position of the throttle pedal controls the engine RPM. During automatic gear

changing, the gear system controls engine revolutions and the position of the throttle pedal does not affect

engine revolutions (formore information, seeChapter 6. ”Controlling gearing”).

Safety interlocks

The system prevents engine revolutions control if the signal from the throttle pedal is above or below the

allowed value.

Door switch S147

The door switch S147 has two sets of contacts; NO= Normal open and NC= normal closed. The system

interprets the door to be closed only when the NO-output has no voltage but the NC output has voltage. The

system interprets the door to be open, if the switch outputs have the same status (either open or closed) and if

there is no voltage in either the NO-output or the NC output. If both of the door switch outputs are

simultaneously open or closed for more than the time period set with the parameter, it is an error condition and

an alarm will be given.

Brake pedal

Function of the component is presented in chapter brake system.

Sandvik Mining and Construction

Cabin 7

T11 rev2 10.06 MY

Window washer and wiper

Front and rear wipers are controlled by on/off switch on the instrument panel. This switch is connected to the

Control System Chair module.

If there is an intermittent wiper feature also, controlled by a potentiometer on the´instrument panel. Turn front

and rear wipers on using the on/off switch. Rotate potentiometer for full or suitable intermittent timing to suit

conditions.

There is also a windowwasher/wiper control button located on the right--hand side control joystick. When

pressing the button, the window washer starts and after an interval the wiper starts. When the button is

released, the window washer will stop and after window is wiped the wiper will stop also. The intermittent timer

does not affect the wipers; the wiping is continuous.

Side screen wiper is controlled by on/off switch on the instrument panel. Side screen

washers are controlled by a button on the instrument panel. Press the button to wash.

Sandvik Mining and Construction

Cabin 8

T11 rev2 10.06 MY

Heating and air conditioning system

System description

The vent air temperature is adjusted using switch S309

(regulator R20). the air conditioning is switched on / off by

using switch S17. When the air conditioning is switched on

and the temperature rises above the set limit (thermostat

A391 closes the electrical circuit), solenoid valveY319 of the

compressor is energised and air conditioning device A308

operates at full power.When the temperature drops belowthe

set limit (thermostat A391 opens the electrical circuit),

solenoid valve Y319 is de-energised and air conditioning

device A308 stops

Sandvik Mining and Construction

Cabin 9

T11 rev2 10.06 MY

Heating and air conditioning system

Air conditioning device A308

Hydraulic oil flow, controlled by valve Y319, rotates the

air conditioning compressor that aims to keep the cabin

temperature at the set value.

Solenoid valve Y319

When the valve coil is de-energised, the hydraulic flow

is open, this allows the hydraulic flow to bypass the

compressor and the air conditioning is not operational.

If the valve coil is energised, the hydraulic flow is

closed. In this case, the hydraulic flow is forced to the

compressor and airconditioning is operational.

Thermostat A391

Thermostat A391 switches the control of solenoid valve Y319 on /

off depending on the cabin temperature and the set limit value. The

solenoid valve coil Y319 becomes energized if the pressure switch

S326 on high pressure side or switch S309 on low pressure side do

not prevent this.

See Air conditioner Service manual for

further information.

Sandvik Mining and Construction

Cabin 10

T11 rev2 10.06 MY

Diagnostics window for throttle pedal

The top of the window shows the status of the safety lockings

that affect functions. If the symbol is black, the safety locking is

activated. In other words, the function is allowed when all the

symbols are grey. Safety lockings from left to right:

• Emergency stop must not be active

• Engine must be running

Diagnostics data from left to right:

• The field next to the throttle pedal symbol shows the voltage

(0...4,5V) that comes to the pedal module.

• The field below the module symbol shows the revolution count

that the module has requested from the engine (the value that

goes to the J1939 bus).

• The tachometer tells the engine’s revolution, this information

comes from the engina through the J1939 bus to the middle

module.

The information window shows the minimum and maximum

voltages calibrated for the throttle pedal

Note! Calibration requires service password.

Sandvik Mining and Construction

Cabin 11

T11 rev2 10.06 MY

Throttle pedal calibration

(requires service password)

The bar on the left-hand side of the Pedal Calibration window shows

the voltage values of the pedal’s extreme positions (pedal up and pedal

down).

The new voltage values for the pedal positions are calibrated In the

fields on the right-hand side of the window. The calibration is performed

by pressing the pedal down and then releasing it. The new voltage

values will be updated in the fields on the window. Save the calibration

by pressing the Calib button. When the calibration is finished, a

message appears at the bottom of the window.

On the window, the dead band of the pedal means the movement

range you can press the pedal down before it starts accelerating.

It is only possible to perform the calibration when the upper and lower

values of the bar are between the set default dead band values. If

calibration is not possible, a warning message appears at the bottom of

the window. The warning message will be removed when it is possible

to perform calibration.

Sandvik Mining and Construction

Cabin 12

T11 rev2 10.06 MY

Testing the door switch

The Button test window 4 is used for testing the door switch functions . The two buttons to the right of the door

symbol indicate the status change when the door is opened. The Door switch test symbol is in the Info window.

Sandvik Mining and Construction

Cabin 13

T11 rev2 10.06 MY

Testing the buttons

This window is used for testing the functioning of the window

washer, window wiper and drizzle switch potentiometer.

When you press the button that activates the function, the

picture of a button on the right--hand side of the symbol

becomes black. The bar next to the drizzle switch symbol

becomes darker according to the voltage from the

potentiometer.When the potentiometer is in its extreme

position to the right, the whole bar is dark.

The information windows show the button tests:

- Window wiper

- Window washer

- Intermitent switch potentiometer (Window wiper timer)

Sandvik Mining and Construction

T11 rev2 10.06 MY

Forced functions Cabin 14

(requires service password)

Forced functions windows are used to control the machine’s different

functions by using the display module’s buttons instead of the

machine’s control buttons. A forced functions window can replace

a broken control actuator; for example, if the steering joystick is

broken, the machine can be driven for service using a forced

functions window.

Test functions may cause unexpected movements

of the machine. Always be sure when test functions

is done there is no-one beside the machine and the

machine has enough free space.

Sandvik Mining and Construction

Cabin 15

T11 rev2 10.06 MY

Forcing the throttle

The window is used for forcing the following functions: boom control, bucket control, throttle, gearing, machine

control, and starting/stopping the engine and braking (only machines with five modules).

Choose the functions to be forced on the right--hand side column (Off = function not forced, On = function

forced). On the left--hand side column, set the value according to which the function is forced.

Forcing the throttle:

1. Select Throttle Control as the function to be forced.

2. Set a forcing value for the throttle. The forcing values range

between 0...100 %.

3. Start the forcing by pressing and holding the SENDbutton.

The forcing stays active until you release the button.

A forced function controls engine revolutions regardless of the

situation, only emergency stop prevents the controlling. The

forcing window allows throttle control even when the engine is

not running.

NOTE! Pressing the SEND button forces all the functions that

are selected to be forced. If you force multiple functions

simultaneously, make sure that the forcing values are logical.

Sandvik Mining and Construction

Cabin 16

T11 rev2 10.06 MY

Forcing the door switch

(requires service password)

Force the door switch status (open /closed) by using the

Door switch forcing window (Door).

1. Set a forcing value for the door switch control. Close =

close the door,Open = open the door.

2. Start the forcing by pressing the SEND button.

3. The forcing function will remain active until leaving the

window. The forcing function controls the door in all

situations. Using the door switch forcing function will leave a

alarm message on the alarm log.

Sandvik Mining and Construction

You might also like

- Isuzu N-Series 4JJ1 Engine Control System Lg4jjed-We - 4jj1 Euro 5 With DPDDocument379 pagesIsuzu N-Series 4JJ1 Engine Control System Lg4jjed-We - 4jj1 Euro 5 With DPDMircea Gilca93% (58)

- Isuzu DmaxDocument320 pagesIsuzu DmaxJacke Villalba92% (13)

- FIAT KOBELCO-e145w Electrical System PDFDocument70 pagesFIAT KOBELCO-e145w Electrical System PDFDragan67% (6)

- Section 4 F GB CASEDocument32 pagesSection 4 F GB CASEAhmed Kamal100% (5)

- Mechatro Hand Book Geospec PDFDocument76 pagesMechatro Hand Book Geospec PDFtaufiqharto100% (6)

- TBR at Aw03-72leDocument19 pagesTBR at Aw03-72lehayyeuanh_duchimotla84% (19)

- Manual Akpp BTR M11 PDFDocument26 pagesManual Akpp BTR M11 PDFОлег МарусинNo ratings yet

- TM CARGOdc PDFDocument49 pagesTM CARGOdc PDFEriflonaNo ratings yet

- 09 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Caja - Automatica - 1f0efc15ddDocument74 pages09 - SsangYong-Korando - 2012 - EN - US - Manual - de - Taller - Caja - Automatica - 1f0efc15ddMateus FumuassucaNo ratings yet

- TUCSON (JM) 2008 G 2.7 DOHC Transfer System: Transfer System Transfer Case Assembly Flow Diagram (M5GF1)Document37 pagesTUCSON (JM) 2008 G 2.7 DOHC Transfer System: Transfer System Transfer Case Assembly Flow Diagram (M5GF1)robin machadoNo ratings yet

- CT100-NT05 Service Manual PDFDocument93 pagesCT100-NT05 Service Manual PDFDwane DuncanNo ratings yet

- Diagrama Sigurante QashqaiDocument9 pagesDiagrama Sigurante QashqaiCristian Dobre100% (1)

- Section 4003 Electronic Instrument ClusterDocument30 pagesSection 4003 Electronic Instrument Clusterlungu mihaiNo ratings yet

- Lab-Report On DC Power Supply PDFDocument4 pagesLab-Report On DC Power Supply PDFakongo gordon80% (5)

- Chapter 12-Electrical SystemDocument38 pagesChapter 12-Electrical SystemNikkikumar MaisuriyaNo ratings yet

- Gen7 Level 1-Operator ControlsDocument22 pagesGen7 Level 1-Operator ControlsDrago LugonjaNo ratings yet

- Wdg4, p4 ElectricalDocument74 pagesWdg4, p4 ElectricalHanuma ReddyNo ratings yet

- PTFE1223 13MY MIRAGE TH J Spec Part2 Revised1Document89 pagesPTFE1223 13MY MIRAGE TH J Spec Part2 Revised1Genevieve Diaz MorenoNo ratings yet

- Controls and Instruments NH CHEX TIER3Document50 pagesControls and Instruments NH CHEX TIER3GeorgiNo ratings yet

- Fuse Box Diagram Nissan Frontier (D40 2005-2014)Document1 pageFuse Box Diagram Nissan Frontier (D40 2005-2014)Salman JoNo ratings yet

- Main BodyDocument16 pagesMain Bodyarum nadaNo ratings yet

- General Information: Automatic Transaxle (M11)Document26 pagesGeneral Information: Automatic Transaxle (M11)Yordano PerezNo ratings yet

- Electrical Rev.2B 20120814ACDocument50 pagesElectrical Rev.2B 20120814ACAugusto OliveiraNo ratings yet

- Service Training 2530D 35DN 9V v1.2Document157 pagesService Training 2530D 35DN 9V v1.2Gogu Ilie0% (1)

- 4runner: Quick Reference GuideDocument40 pages4runner: Quick Reference GuideXavier GutiérrezNo ratings yet

- Hybrid Regenerative Braking Systems PDFDocument97 pagesHybrid Regenerative Braking Systems PDFCRISTIANO PRUSCHNo ratings yet

- Componentes Tractor John Deere 5090 ENDocument18 pagesComponentes Tractor John Deere 5090 ENdiego valenciaNo ratings yet

- Brake Switch B HighDocument2 pagesBrake Switch B HighDannyDDannyDNo ratings yet

- User Manual Manual de Usuario Manuel de L'UtilisateurDocument15 pagesUser Manual Manual de Usuario Manuel de L'Utilisateuro.j.dumbo0No ratings yet

- AC 665-1040-039 - en (Crane Operator's Cab)Document18 pagesAC 665-1040-039 - en (Crane Operator's Cab)Arslan AhmedNo ratings yet

- Case Construction Backhoe Loader Tier3Document19 pagesCase Construction Backhoe Loader Tier3Nick E100% (2)

- HHP Locomotive Compartments and Parts Location: DTTC/GTLDocument233 pagesHHP Locomotive Compartments and Parts Location: DTTC/GTLarjunsai100% (1)

- Dsi 6 Speed Auto TransaxleDocument24 pagesDsi 6 Speed Auto TransaxleKada Ben youcefNo ratings yet

- Electrics: Section C Section CDocument39 pagesElectrics: Section C Section CRicardo CostaNo ratings yet

- FM2.3 - Drill and DriveDocument16 pagesFM2.3 - Drill and DrivePranav JoshiNo ratings yet

- Valvetronic ServomotorDocument1 pageValvetronic ServomotorIgor PinheiroNo ratings yet

- Ficha Pulsar 220 FsDocument11 pagesFicha Pulsar 220 FsWalter SaguiNo ratings yet

- 06 Scion TCDocument11 pages06 Scion TCPSC RFQNo ratings yet

- 1 G4P4 Elec Parts EmdDocument72 pages1 G4P4 Elec Parts EmdSAI KRISHNAN LNo ratings yet

- 16 Su Brazil-Kd WMDocument88 pages16 Su Brazil-Kd WMGustavo Sostenes Rodrigues Nunes100% (1)

- Mitsubishi MSCA12YV ManualDocument32 pagesMitsubishi MSCA12YV Manualsansegundo79No ratings yet

- Section 55 - Electrical System - Chapter 2Document10 pagesSection 55 - Electrical System - Chapter 2Cristian SterieNo ratings yet

- Maintenance Manual AC DC EMU (Siemens) - Draft For Comments From RailwaysDocument293 pagesMaintenance Manual AC DC EMU (Siemens) - Draft For Comments From RailwaysTA CWMNo ratings yet

- Error Code FD50NT ControllerDocument86 pagesError Code FD50NT ControllerDeni Moch IchsanNo ratings yet

- En 01.318 - RM 70go! 2.0 Short Manual Start v1Document22 pagesEn 01.318 - RM 70go! 2.0 Short Manual Start v1andrew stablesNo ratings yet

- 132kv Grid Station FNF, SheikhupuraDocument18 pages132kv Grid Station FNF, Sheikhupurasyed waheedNo ratings yet

- Isuzu Cambio PDFDocument340 pagesIsuzu Cambio PDFjordi garcia0% (1)

- En40c-1030 ADocument16 pagesEn40c-1030 AIgnacio Jesus Prado MellaNo ratings yet

- 02 02 TRansmissionDocument51 pages02 02 TRansmissionKhaerul Ade WiyatnoNo ratings yet

- Section 55 - Electrical System - Chapter 4Document12 pagesSection 55 - Electrical System - Chapter 4Cristian SterieNo ratings yet

- Section 55 - Electrical System - Chapter 4Document12 pagesSection 55 - Electrical System - Chapter 4Cristian SterieNo ratings yet

- E4nb71 PDFDocument99 pagesE4nb71 PDFtambache69100% (1)

- 22B Automated Manual TransmissionDocument10 pages22B Automated Manual TransmissionmanhNo ratings yet

- Case Construction Backhoe Loader Tier3Document18 pagesCase Construction Backhoe Loader Tier3Nick E100% (1)

- Service Training Manual: AutolearnDocument33 pagesService Training Manual: AutolearnBasukiNo ratings yet

- GROUP 8 TRANSMISSION (Up To #0978) : 1. StructureDocument14 pagesGROUP 8 TRANSMISSION (Up To #0978) : 1. StructureVladimir ParamonovNo ratings yet

- Pda Mechatro - Handbook 070226Document40 pagesPda Mechatro - Handbook 070226Paul Galvez100% (6)

- Starter Relay CircuitDocument5 pagesStarter Relay CircuitDaniel Mamani ParedezNo ratings yet

- Steering Column Telescope Position Sensor-Circuit Short ToDocument6 pagesSteering Column Telescope Position Sensor-Circuit Short Torafale30No ratings yet

- Manual Do Proprietario NH190Document153 pagesManual Do Proprietario NH190Francisco S. AlmeidaNo ratings yet

- Wulpi Figs 10Document33 pagesWulpi Figs 10PeetNo ratings yet

- Eland Torque Wheel HubDocument2 pagesEland Torque Wheel HubPeetNo ratings yet

- Wulpi Figs 4Document6 pagesWulpi Figs 4PeetNo ratings yet

- Wulpi Figs 2Document2 pagesWulpi Figs 2PeetNo ratings yet

- Rockwell Brake RHDocument5 pagesRockwell Brake RHPeetNo ratings yet

- PM B25L & B30L, 4X4 Mkii June 2003Document351 pagesPM B25L & B30L, 4X4 Mkii June 2003PeetNo ratings yet

- Bell B30L 4X4 Mkii - July 2002Document335 pagesBell B30L 4X4 Mkii - July 2002PeetNo ratings yet

- S09 Power TrainDocument54 pagesS09 Power TrainPeetNo ratings yet

- PM B25L 4x4 LP S.A.H.R. BRAKESDocument313 pagesPM B25L 4x4 LP S.A.H.R. BRAKESPeetNo ratings yet

- PC228USLC-3 Opps & Maint ManualDocument272 pagesPC228USLC-3 Opps & Maint ManualPeetNo ratings yet

- PC200-6a Opps & Maint ManualDocument240 pagesPC200-6a Opps & Maint ManualPeetNo ratings yet

- SteeringDocument21 pagesSteeringPeetNo ratings yet

- Section 4 - HydraulicsDocument30 pagesSection 4 - HydraulicsPeetNo ratings yet

- S06 Drilling ComponentsDocument14 pagesS06 Drilling ComponentsPeetNo ratings yet

- General Safety InstructionsDocument14 pagesGeneral Safety InstructionsPeetNo ratings yet

- Section 5 - ElectricalDocument10 pagesSection 5 - ElectricalPeetNo ratings yet

- HM300-2 Operation & MaintananceDocument331 pagesHM300-2 Operation & MaintanancePeetNo ratings yet

- Hm300-1opps&maint 1265Document267 pagesHm300-1opps&maint 1265PeetNo ratings yet

- Frame RelatedDocument51 pagesFrame RelatedPeetNo ratings yet

- Section 3 - PowertrainDocument50 pagesSection 3 - PowertrainPeetNo ratings yet

- Section 2 - EngineDocument20 pagesSection 2 - EnginePeetNo ratings yet

- Section 6 - Frame & Body PDFDocument19 pagesSection 6 - Frame & Body PDFPeetNo ratings yet

- HM300-2 Shop ManualDocument1,330 pagesHM300-2 Shop ManualPeetNo ratings yet

- HQR1112 Manual 13012017Document788 pagesHQR1112 Manual 13012017PeetNo ratings yet

- L1204C Plus - Section 3 - TransmissionDocument8 pagesL1204C Plus - Section 3 - TransmissionPeetNo ratings yet

- L1204C Plus - Section 1 - GeneralDocument30 pagesL1204C Plus - Section 1 - GeneralPeetNo ratings yet

- HM300-1 Shop ManualDocument1,027 pagesHM300-1 Shop ManualPeetNo ratings yet

- 1204C+ EngineDocument25 pages1204C+ EnginePeetNo ratings yet

- DH350 Maintenance Manual - Jul.16Document234 pagesDH350 Maintenance Manual - Jul.16PeetNo ratings yet

- L1204C Plus - Section 4 - PowertrainDocument60 pagesL1204C Plus - Section 4 - PowertrainPeetNo ratings yet

- Technical Specification ConceptPower DPA 10-250kVA-S2 EnglishDocument19 pagesTechnical Specification ConceptPower DPA 10-250kVA-S2 EnglishPutra Kandung WidyantoNo ratings yet

- MCQ's Chap 16aDocument5 pagesMCQ's Chap 16aArham MunirNo ratings yet

- Tabulation of Published Data On Electron Devices of The U.S.S.R. December 1976Document144 pagesTabulation of Published Data On Electron Devices of The U.S.S.R. December 1976Sam SatalofNo ratings yet

- 01 - Cms502-Esquema de Conexion PDFDocument35 pages01 - Cms502-Esquema de Conexion PDFJonas Mendibil PazNo ratings yet

- Voltage Ratio and Magnetizing Current Tests by Kareem oDocument18 pagesVoltage Ratio and Magnetizing Current Tests by Kareem oKAREEM OLAWALENo ratings yet

- Product Data Sheet: Tesys K - Differential Thermal Overload Relays - 1.2... 1.8 A - Class 10ADocument3 pagesProduct Data Sheet: Tesys K - Differential Thermal Overload Relays - 1.2... 1.8 A - Class 10APop VasileNo ratings yet

- Siestorage Catalog enDocument28 pagesSiestorage Catalog ennguyenqlda0% (1)

- Quartz Crystal: 3 Pyroelectricity and PiezoelectricityDocument1 pageQuartz Crystal: 3 Pyroelectricity and PiezoelectricityNam KolyaNo ratings yet

- V80838 Murphy PowerView Wiring DiagramsDocument2 pagesV80838 Murphy PowerView Wiring DiagramsPaulPaucarCampos100% (1)

- Kelly Ke Bus Er ManualDocument16 pagesKelly Ke Bus Er Manualhmgp1975No ratings yet

- Nonlinear DevicesDocument604 pagesNonlinear Devicesmentally_illNo ratings yet

- Unit 6 Sciences Worksheets With Answers. Miriam Valle SillerasDocument4 pagesUnit 6 Sciences Worksheets With Answers. Miriam Valle SillerasRegina Maestro Gomez100% (1)

- Li-Ion Accu ChargerDocument3 pagesLi-Ion Accu ChargervdwuNo ratings yet

- HELITA General InformationDocument28 pagesHELITA General Informationicygears21No ratings yet

- Third Generation of ComputersDocument15 pagesThird Generation of ComputersHainah Kariza LeusNo ratings yet

- General Polar Pattern: SpecificationsDocument2 pagesGeneral Polar Pattern: SpecificationsEsteban Bonilla JiménezNo ratings yet

- Analysing Electric Field Distribution of HV Standard Capacitor Using Finite Element MethodDocument7 pagesAnalysing Electric Field Distribution of HV Standard Capacitor Using Finite Element MethodsreekanthaNo ratings yet

- Tinkercad Circuits Components (ALL)Document3 pagesTinkercad Circuits Components (ALL)bob100% (1)

- Delta Monitoring Solution: Quick, Simple, Reliable. Always Care About Your Needs !Document3 pagesDelta Monitoring Solution: Quick, Simple, Reliable. Always Care About Your Needs !vanhuong87No ratings yet

- WAB Series: Current Transformers For AC/DC Systems Used With Digital RCMA and RCMS Series DevicesDocument4 pagesWAB Series: Current Transformers For AC/DC Systems Used With Digital RCMA and RCMS Series DevicesCalin SebarchieviciNo ratings yet

- Design Exercise 4 Charge PumpDocument22 pagesDesign Exercise 4 Charge PumpTrần Tấn ĐạiNo ratings yet

- SN74LV541APWRDocument16 pagesSN74LV541APWRHassan MahdaviNo ratings yet

- Tesla Theory 1 PDFDocument257 pagesTesla Theory 1 PDFShiva Kumar50% (2)

- Semikron Skhi 24 R l6100039Document8 pagesSemikron Skhi 24 R l6100039omairyNo ratings yet

- M300Mj (A), M301Mj (A), M302Mj (A) & M300Dj (A) : Monitor Modules With Flashscan®Document4 pagesM300Mj (A), M301Mj (A), M302Mj (A) & M300Dj (A) : Monitor Modules With Flashscan®Robel MTNo ratings yet

- Panel Board Single LineDocument1 pagePanel Board Single Linekingjam dimacaling2019No ratings yet

- A 1 - 57-GHz RF Front-EndDocument8 pagesA 1 - 57-GHz RF Front-EndSreedevi MenonNo ratings yet

- REx316 PresentationDocument60 pagesREx316 PresentationIgnacio Lucas Avila ManganoNo ratings yet

- Electrical Substation Maintenance Inspection ChecklistDocument5 pagesElectrical Substation Maintenance Inspection ChecklistJitendraPachoriNo ratings yet