Professional Documents

Culture Documents

Depletion Test GGT Test Procedure For H2S in WBM and OBM

Depletion Test GGT Test Procedure For H2S in WBM and OBM

Uploaded by

mahdiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Depletion Test GGT Test Procedure For H2S in WBM and OBM

Depletion Test GGT Test Procedure For H2S in WBM and OBM

Uploaded by

mahdiCopyright:

Available Formats

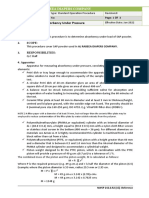

Depletion Test For H2S & GGT Test Procedures

:Note

PPB of Sourscave deplete → 213 PPM of H2S 1-

-PPB of Liquid Scavenger deplete → 150 PPM of H2S 1

If We Mixed to Active 5 PPB of Liquid Scav, so 5 x 150=750 PPM -

We Must consider safe factor of excess PPM, consider its 250 so 250 +750=1000 PPM

If We Mixed to Active 5 PPB of Sourscav. So 5 x 213=1065 PPM

We Must consider safe factor of excess PPM, consider its 250 so 250 +1065=1315 PPM

.ex:(5 X 150)+250 / 34.14(Na2S Conc)=29.3 ml of Sod. Sulphite-

-ex:(5 x 213)+250 / 34.14(Na2S Conc)=38.5 ml of Sod. Sulphite.

A-Depletion Test Procedures (WBM)

.Batch mixing 350 ml of Mud + Calculated Vol of Na2S for 10 min -

.Perform Api Filter Press from Batch Mixer-

.in chamber 1 put 20 cc of D/W + 5 drops Octyle defoamer+ 2 cc filtrate -

close the GGT Kit top cap manually with all screws -

Open both ends of dragger tube using specified breaker and insert dragger tube to -

.GGT, connect rubber hose to the tube

.Finally inject 10 cc of Sulphoric acid 5 N to same chamber 1 using Syringe -

use CO2 cartridge to apply pressure gradually till the flowmeter ball will be in the -

middle and maintain same till end of the test(until no more black colour is formed in

.the dragger tube or till CO2 gas is finished

:Results

if we exp low H2S so use the Low Range dr.Tube (its factor =0.12) -

#Dragger tube Reading x Tube Factor(0.12) / Ml of Sample =….PPM H2S

-if we exp High H2S so use the High Range dr.Tube (its factor =1500)

Dragger tube Reading x Tube Factor(1500) / Ml of Sample=….PPM H2S #

So The Resulted PPM-250 (Safe Factor)=…..PPM

So PPM / 150 if Liquid or 213 if Powder used )= …PPB of Scavenger

,depleted

Saudi Aramco: Company General Use

Depletion Test For H2S & GGT Test Procedures

If the result is +ve PPB it means that our scavenger is depleted by this -

value and we need to add this amount of scavenger more to deplete

.100% of H2S

If the result is -ve PPB it means that we have extra PPB of Scavenger in -

.the

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

B-Depletion Test Procedures(OBM):

.Batch mixing 350 ml of Mud + Calculated Vol of Na2S for 10 min -

In chamber 1 put 20 cc of D/W + 5 drops Octyle defoamer+ 2 cc Of OBM from Batch -

Mixer +10 ml isopropyl + 20 ml Citric acid + 10 ml Xylene (1:2:1 ratio )

.close the GGT Kit top cap manually with all screws -

Put all GGT Kit over Magnetic Stirrer to Face Chamber 1 to Stir sample

Open both ends of dragger tube using specified breaker and insert dragger tube to -

.GGT, connect rubber hose to the tube

.Finally inject 10 cc of Sulphoric acid 5 N to same chamber 1 -

Use CO2 cartridge to apply pressure gradually till the flowmeter ball will be in the -

middle and maintain same till end of the test (until no more black colour is formed in

.the dragger tube or till CO2 gas is finished

:Results

if we exp low H2S so use the Low Range dr.Tube (its factor =0.12) -

#Dragger tube Reading x Tube Factor(0.12) / Ml of Sample =….PPM H2S

-if we exp High H2S so use the High Range dr.Tube (its factor =1500)

Dragger tube Reading x Tube Factor(1500) / Ml of Sample=….PPM H2S #

So The Resulted PPM-250 (Safe Factor)=…..PPM

So PPM / 150 if Liquid or 213 if Powder used )= …PPB of Scavenger

,depleted

If the result is +ve PPB it means that our scavenger is depleted by this -

value and we need to add this amount of scavenger more to deplete

.100% of H2S

If the result is -ve PPB it means that we have extra PPB of Scavenger in -

.the

.…………………………………………………………………………………………

Saudi Aramco: Company General Use

Depletion Test For H2S & GGT Test Procedures

Example:

If we did a test using the High Range Dragger Tube and its reading= 1.5,

and we added 5 PPB of Milguard to the active system previously, cc of

Sample used =2 cc.

-First We Must consider safe factor of excess PPM ex:250 ppm

Result:

1 X 1500 / 2 = 750 PPM-250=500 PPM / 150 (Liquid scav)= 3.3 PPB of

Milguard is required more to be added to deplete 100 % H2S.

,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,

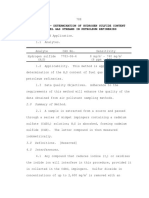

C-Sulfides test in OBM using GGT.

SULFIDES (GGT Test in details)

.This procedure is used to measure the active soluble sulfides concentration in an oil-base mud

Equipment

.Complete Garrett Gas Train (GGT) .11

.H2S Dräger tubes (low range and high range) .12

.Flowmeter .13

.Flexible tubing made of Latex rubber or Tygon (plastic or equivalent) .14

.Magnetic stirrer .15

.Magnetic stirring bar (1⁄4 in. x 1 in. [6.3 x 25.4 mm]) .16

.Hypodermic syringe: 10-mL glass or plastic .17

.molar citric acid/isopropyl alcohol/demulsifier solution 2 .18

.a. 420 g (C6H8O7H2O) citric acid dissolved into 1,000mL deionized water

b. To this solution add 25 mL of Dowell W-35 demulsifier from Fann Instrument or equivalent

.(an asphalt dispersant chemical)

.c. To this solution add 200 mL of isopropyl alcohol

.Defoamer: octanol (CAS # 111-87-5) .19

.mL graduated cylinder-25 .10

.Carrier gas — CO2 cartridges,or preferably, nitrogen. Do Not use N2O .11

Sample injection tube: 6-in. (15.2-mm) long PTFE (Teflon or equivalent) .12

.needle or equivalent

Procedure

Saudi Aramco: Company General Use

Depletion Test For H2S & GGT Test Procedures

Start with a clean, dry Garrett Gas Train.1 .1

Modify the Garrett Gas Train by inserting the sample injection tube through the rubber septum so .2

that the bottom end of the dip tube is approximately 1⁄2 in. (12.7mm) from the bottom of chamber 1.

The dip tube is used so that the mud

.sample can be injected directly into the citric acid solution

Arrange the magnetic stirrer and stirring bar (in chamber 1) so that .13

.the bar will rotate freely

.Install CO2 cartridge .14

.Add 20 mL of 2 molar citric acid/ isopropyl/demulsifier solution to chamber 1 .15

.Add 10 drops of octanol defoamer to chamber 1 .16

Break tips of H2S Dräger tube and insert into the Garrett Gas Train holder on the extreme right .17

side. The arrow indicating the gas flow should be pointing down. Place

.an O-ring on the Dräger tube

Insert the flowmeter in the other holder with the air flow arrow pointing up. Place an O-ring on .18

.the flowmeter

.Install the top of the Garrett Gas Train and tighten all screws to seal .19

.Adjust the dispersion tube so that the tube is positioned above the liquid level .10

Connect the rubber hose from the regulator to the dispersion tube. Connect the rubber hose .11

.from chamber 3 to the Dräger tube

.DO NOT START GAS

Draw into the syringe the whole mud sample volume plus 0.5 mL of excess mud. The excess .12

.mud compensates for the hold-up volume inside the injection tube

Insert the syringe into the dip tube, and using a rubber band, secure the syringe plunger to the .13

dip tube. This will prevent the citric acid-defoamer mixture from traveling up the dip tube when

.pressure is applied

Gently flow gas through the dispersion tube for 10 to 15 sec to purge air from the GGT. .14

Regulate the flow of gas to avoid frothing of the solution in chamber 1. Check for leaks and for

.proper operation of the flowmeter

Turn on the magnetic stirrer. Adjust speed so that a vortex is formed. Carefully lower the .15

.dispersion tube into the liquid to a point just above the stirring bar

Lower the injection tube so that the bottom is slightly below the dispersion .16

.tube. This will allow the oil mud to be injected into the vortex

Slowly inject a measured amount‡ (see Table 6 on page 3.35) of oil-base mud into chamber 1 .17

through the injection tube. Increase the speed of the stirring bar to improve dispersion and to

prevent oil mud from sticking to the walls. Continue to

.stir for 1 min

Saudi Aramco: Company General Use

Depletion Test For H2S & GGT Test Procedures

Use a rubber band to secure the plunger of the syringe in place. Restart gas flow. Adjust the .18

rate so that the flowmeter shows between 200 and 400 mL/min by keeping the flowmeter ball

.between the red marks on the flowmeter

Observe changes in appearance of the Dräger tube. Note and record the maximum distinct .19

darkened length (in units marked on the tube) before the front starts to “feather” or smear. Continue

.flowing for a total of 15 min, a second gas cartridge may be required

Clean the GGT immediately after use to minimize deterioration of the plastic. Clean the .20

chambers and passages with warm water and a mild detergent. Wash the dispersion tube and

injection tube with an organic solvent such as acetone and then with water. Occasionally, the

dispersion tube may require soaking in an acid to remove calcium carbonate deposits. The organic

solvents can crack the lucite body of the GGT. Using the sample volume, the Dräger tube darkened

.length, and the Dräger tube factor, calculate sulfides in the sample

GGT sulfides (mg/L) = (darkened length x tube factor sample volume (mL)) / sample

volume (mL)

Simply:

Consider all test procedures and rigging up instruction as above

1. Put magnetic stirrer small size and string bar in chamber#1and add:

a. 20 ml of Citric acid

b. 10 drops of defoamer

2. Install the top of GGT and tighten all screws to seal from gas leaking.

3. Connect the rubber hose from regulator to the dispersion tube, connect the

rubber hose from chamber 3 to dragger tube

4. Break the tips of H2S Dragger tube and insert into the GGT holder and the arrow

should point down.

5. Gently flow gas for 10 seconds to purge air from the GGT.

6. Connect the dragger tube to the rubber hose from chamber 3.

7. Turn on magnetic stirrer to adjust speed of stirring bar to adjust speed that a

vortex is formed.

8. Lower the injection tube so that the bottom is slightly below the dispersion tube.

9. Slowly inject 2ml of OBM sample and increase the speed of stirring bar to

improve dispersion – for 1 minutes.

10. Restart gas flow for 15 minutes and regulate it so the ball can float between the

two red lines.

11. Observe the changes in appearance of the Drager tube and record the darkened

length and the Drägger tube factor, calculate sulfides in the sample.

GGT sulfides (mg/L) = (darkened length x tube factor sample volume (mL)) /

sample volume (mL)

12-Clean the GGT immediately after use to minimize deterioration of the plastic.

Clean the chambers and passages with warm water and a mild detergent. Wash

the dispersion tube and injection tube with an organic solvent such as acetone

and then with water. Occasionally, the dispersion tube may require soaking in an

Saudi Aramco: Company General Use

Depletion Test For H2S & GGT Test Procedures

acid to remove calcium carbonate deposits. The organic solvents can crack the

Lucite body of the GGT.

Saudi Aramco: Company General Use

You might also like

- Becoming A Critical Thinker: A User-Friendly Manual, 6/eDocument35 pagesBecoming A Critical Thinker: A User-Friendly Manual, 6/emicklo36% (11)

- Latin America Payments Solution: November 2018Document19 pagesLatin America Payments Solution: November 2018Jairo MartinezNo ratings yet

- UOP 981-14 Trace Nitrogen in Liquid Hydrocarbons by Oxidative Combustion With ChemiluminescenceDocument9 pagesUOP 981-14 Trace Nitrogen in Liquid Hydrocarbons by Oxidative Combustion With ChemiluminescenceRamakrishnan HariNo ratings yet

- Sulfitos Monier-Williams AOAC 990-28Document2 pagesSulfitos Monier-Williams AOAC 990-28Paula Catalina Marín Uribe50% (2)

- C++ MCQDocument23 pagesC++ MCQVishal ManeNo ratings yet

- 002.0 Surface Sampling TrainingDocument17 pages002.0 Surface Sampling TrainingNguyễnTrường100% (1)

- H2O Innovation Maple Membrane Training 2011 ENG PDFDocument31 pagesH2O Innovation Maple Membrane Training 2011 ENG PDFJamil Kaynu KamilNo ratings yet

- F1983005L Wiring DiagramJ97UDocument124 pagesF1983005L Wiring DiagramJ97Upermataakasha100% (2)

- Depletion Test & GGT Test Procedure For H2S in WBM and OBMDocument6 pagesDepletion Test & GGT Test Procedure For H2S in WBM and OBMHashim YahyaNo ratings yet

- Garret Gas TrainDocument6 pagesGarret Gas Trainlicheng6820No ratings yet

- Sample 03.62 Water System Validation - SOPDocument44 pagesSample 03.62 Water System Validation - SOPKenechukwu Igwagu100% (2)

- Lab Tech7Document16 pagesLab Tech7yasir aliNo ratings yet

- Amine Test ProcedureDocument2 pagesAmine Test ProcedureAvinash NegiNo ratings yet

- GSPC Gas Welcomes Training Program On Safe CNG Fuelling OperationDocument92 pagesGSPC Gas Welcomes Training Program On Safe CNG Fuelling OperationsonidarshNo ratings yet

- CO2 Gas Purity TesterDocument2 pagesCO2 Gas Purity TesterPrerak PatelNo ratings yet

- Aoac-990 28Document3 pagesAoac-990 28izobara33No ratings yet

- Hydrogen Sulfide ScavengingDocument3 pagesHydrogen Sulfide ScavengingAhmed MonirNo ratings yet

- Absorbency Under PressureDocument3 pagesAbsorbency Under PressureMOHAMED DawiNo ratings yet

- Method 11 PDFDocument28 pagesMethod 11 PDFMichael StevenNo ratings yet

- Pegasys Manual Inst Oper MantDocument12 pagesPegasys Manual Inst Oper MantDaniel LagosNo ratings yet

- h2s by TitrationDocument13 pagesh2s by TitrationMuhammad Amir AkhterNo ratings yet

- Metodo XenosepDocument12 pagesMetodo XenosepJenny Chavez AlarconNo ratings yet

- Lafferty 914105 IODocument4 pagesLafferty 914105 IORichard LesterNo ratings yet

- Espumas InglesDocument25 pagesEspumas InglesGustavo Alberto Alzamora DávalosNo ratings yet

- Enpe460 LabDocument12 pagesEnpe460 LabPraise KoobeeNo ratings yet

- Random Quetsion Abdullah AbdelsalamDocument13 pagesRandom Quetsion Abdullah AbdelsalamMoNo ratings yet

- Performing A Leak-Off TestDocument1 pagePerforming A Leak-Off TestemiljuchiacNo ratings yet

- Power Plants and Helium Mass SpectrometerDocument27 pagesPower Plants and Helium Mass Spectrometeradamos.georgiosNo ratings yet

- Random Question For InterviewDocument5 pagesRandom Question For InterviewMohamed HashemNo ratings yet

- Choke SizingDocument19 pagesChoke Sizingudokas50% (2)

- Trace Metals SamplingDocument4 pagesTrace Metals SamplingSidik PamungkasNo ratings yet

- 302SOP & Safe Operating Procedure of Nitration Plant08.05.10Document12 pages302SOP & Safe Operating Procedure of Nitration Plant08.05.10Er Bali PandhareNo ratings yet

- Drilling Fluids Testing 2016-17Document28 pagesDrilling Fluids Testing 2016-17Tyo DekaNo ratings yet

- Calculation K ValueDocument12 pagesCalculation K ValueAshrafMostafaNo ratings yet

- Gardobond 159 M: Technical Service Data SheetDocument3 pagesGardobond 159 M: Technical Service Data SheetSamNo ratings yet

- FPPC335 Asphalt RejuvenationDocument7 pagesFPPC335 Asphalt RejuvenationGeeta JiraliNo ratings yet

- Mud: General Guidelines and Rules-Of-ThumbDocument2 pagesMud: General Guidelines and Rules-Of-ThumbtrikorodarmoNo ratings yet

- Name:: Ahmed Ayad KhalifaDocument11 pagesName:: Ahmed Ayad KhalifaAhmed AyadNo ratings yet

- General Procedure For Corrosion Testing in Higher Than 60 Bar - 870 Psi - of Co2 Pressure EnviromentsDocument3 pagesGeneral Procedure For Corrosion Testing in Higher Than 60 Bar - 870 Psi - of Co2 Pressure Enviromentsely wagnerNo ratings yet

- CavitationDocument5 pagesCavitationSaeed VuNo ratings yet

- Gastester G4125 InstructionsDocument20 pagesGastester G4125 InstructionsTom ToyeNo ratings yet

- UOP 826-81 Carbon Dioxide in Ammine SolutionDocument7 pagesUOP 826-81 Carbon Dioxide in Ammine SolutionMorteza Sepehran100% (1)

- Tire HydroinflationDocument13 pagesTire HydroinflationJosé Inés Bazán MotaNo ratings yet

- Drilling Fluid Programme For PetromineDocument35 pagesDrilling Fluid Programme For Petrominejoonak konwarNo ratings yet

- BC501-502 2015Document119 pagesBC501-502 2015CESARALARCON1No ratings yet

- MT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesDocument18 pagesMT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesFelipe Navarrete100% (1)

- 02.understanding Process Equipment For Operators & Engineers-50Document5 pages02.understanding Process Equipment For Operators & Engineers-50rahulNo ratings yet

- Macurco CM6-FCK UserManualDocument4 pagesMacurco CM6-FCK UserManualTrí NguyễnNo ratings yet

- UOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodDocument4 pagesUOP 9 Hydrogen Sulphide in Gases by The Tutweiller MethodmkmejavierNo ratings yet

- Liquid SamplingDocument7 pagesLiquid SamplingSrewaBenshebilNo ratings yet

- Aocs PDFDocument1 pageAocs PDFAnonymous OuNIMJRZNo ratings yet

- De Kati Dilute RDocument4 pagesDe Kati Dilute RPatricio Alarcon CastroNo ratings yet

- 03-Section 3A WBM TestingDocument44 pages03-Section 3A WBM TestingLazharNo ratings yet

- Fluids Field Testing ProceduresDocument7 pagesFluids Field Testing Procedurespajamas94117No ratings yet

- Baroid Fluids HandbookDocument8 pagesBaroid Fluids HandbookTamer Hesham AhmedNo ratings yet

- DP 3102013Document20 pagesDP 3102013lifemillion2847No ratings yet

- 13 3-8" Cementing Program ChecklistDocument2 pages13 3-8" Cementing Program ChecklistYougchu LuanNo ratings yet

- TEG Dehydration ProcessDocument20 pagesTEG Dehydration Processarraziy fauzanNo ratings yet

- Uop 987Document11 pagesUop 987pramod23septNo ratings yet

- Dew Point Detector TubeDocument1 pageDew Point Detector TubeTahir MehmoodNo ratings yet

- Pre Treatment TestDocument15 pagesPre Treatment TestMirza Tahir BaigNo ratings yet

- Spectrophotometric Determination of Hydrogen SulfideDocument3 pagesSpectrophotometric Determination of Hydrogen SulfideVictor HugoNo ratings yet

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Böhler Er 70 S-2Document1 pageBöhler Er 70 S-2brayanNo ratings yet

- Checklist For Equipment Inspection Lifting Tools - TacklesDocument2 pagesChecklist For Equipment Inspection Lifting Tools - TacklesAsaf Ibn RasheedNo ratings yet

- SMU11C V100R021C10 Site Monitoring Unit User ManualDocument38 pagesSMU11C V100R021C10 Site Monitoring Unit User Manualmagdy elmasryNo ratings yet

- ANFIS by JANG 1993 PDFDocument21 pagesANFIS by JANG 1993 PDFm.shoaibNo ratings yet

- XALDocument5 pagesXALZidan ZaifNo ratings yet

- MTCP ETN Server EDocument3 pagesMTCP ETN Server EcardonPTNo ratings yet

- Properties of SteamDocument7 pagesProperties of SteamRavichandran GNo ratings yet

- 7-3 IP Board Part (SMPS Part) : 7 Block DiagramsDocument8 pages7-3 IP Board Part (SMPS Part) : 7 Block DiagramsSonu KumarNo ratings yet

- Gambella WASH Physical Construction BOQ - For WASH StaffDocument25 pagesGambella WASH Physical Construction BOQ - For WASH StaffDavid TabangNo ratings yet

- Softening-Point-Test OmedDocument12 pagesSoftening-Point-Test OmedOmar BokhareNo ratings yet

- ARM1176 Reference ManualDocument759 pagesARM1176 Reference ManualMelanie WallaceNo ratings yet

- Car's Disc Brake Picture: Firdaus Putra KuswoyoDocument5 pagesCar's Disc Brake Picture: Firdaus Putra KuswoyoFirdaus Kuswoyo100% (1)

- Full Stack Engineer - SploreDocument2 pagesFull Stack Engineer - SploreSujay VadavadagiNo ratings yet

- Linear Thinking Vs Lateral ThinkingDocument15 pagesLinear Thinking Vs Lateral ThinkingAyush JainNo ratings yet

- Customer Service Email:: Voice Type Multifunctional Gas Detector User's ManualDocument20 pagesCustomer Service Email:: Voice Type Multifunctional Gas Detector User's ManualIGNACIO ANDAURNo ratings yet

- TEMPLATE FOR REFLECTION Day 2Document2 pagesTEMPLATE FOR REFLECTION Day 2Noel BandaNo ratings yet

- Flare WordPress Theme - DocumentationDocument15 pagesFlare WordPress Theme - Documentationkenixe69No ratings yet

- Books Are Our Best Friends EssayDocument7 pagesBooks Are Our Best Friends Essayezkrg6k2100% (2)

- The Maharashtra Factories Rules 1963Document104 pagesThe Maharashtra Factories Rules 1963rasinv100% (1)

- Course Outline Integral Calculus UwindsorDocument3 pagesCourse Outline Integral Calculus UwindsorNemanja DjordjevicNo ratings yet

- bs1452 Grade 250Document2 pagesbs1452 Grade 250Syed Shoaib RazaNo ratings yet

- A Survey of Voltage Sags and Voltage Swells Phenomena in Power Quality ProblemsDocument5 pagesA Survey of Voltage Sags and Voltage Swells Phenomena in Power Quality ProblemsDwikiNo ratings yet

- Northwestern University, Inc: Laoag City, Ilocos NorteDocument3 pagesNorthwestern University, Inc: Laoag City, Ilocos NorteAlex MarcosNo ratings yet

- Raises Montessori Academe: Curriculum MapDocument8 pagesRaises Montessori Academe: Curriculum MapLara LealNo ratings yet

- Nyquist Plots For EDLCDocument13 pagesNyquist Plots For EDLCLoga NathanNo ratings yet

- Syllabus: Cambridge O Level Design and TechnologyDocument25 pagesSyllabus: Cambridge O Level Design and Technologymstudy123456No ratings yet