Professional Documents

Culture Documents

Specifications 2

Specifications 2

Uploaded by

Instrument CandidatesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Specifications 2

Specifications 2

Uploaded by

Instrument CandidatesCopyright:

Available Formats

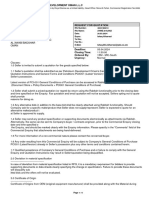

Rev : 01 SPECIFICATIONS Page 1 of 2

Heavy Power Equipment Plant, Enquiry No. & Dt.: M2/12/6000001631/VKT; DT: 25.08.2012

Due Date :

Bharat Heavy Electricals Limited, Supplier's Ref.:

Ramachandrapuram -502032, Andhra Pradesh, INDIA. Date :

Specification cum Compliance Certificate for FIBER GLASS FLOW NOZZLES

Note:-

1. The 'Offered' Column and where applicable, the 'Deviations' & 'Remarks' Column of this format shall be filled in by the Vendor and submitted along with the offer. Inadequate / incomplete,

ambiguous or unsustainable information against any of the clauses of the specifications / requirements shall be treated as non-compliance.

2. The offer and all documents enclosed with offer should be in English language only.

Name & Address of the supplier: Name & Address of the Indian Agent:

Telephone No. Telephone No.

Fax No. Fax No.

e-mail : e-mail :

Scope: Supply of FIBER GLASS FLOW NOZZLES complying with specification as below.

SPECIFIED / TO BE

SNO DESCRIPTION FOR BHEL REQUIREMENT

CONFIRMED BY OFFERED DEVIATIONS REMARKS

1.0 REFERENCE LIST / QUALIFYING CONDITIONS :

1.1 Only those vendors, who have supplied at least one Equipment/ part of Vendor to confirm and

equipment/structure made of Fiber Glass of size bigger than 1000 mm with give details.

dimensional accuracies equal to or better than ± 0.50 mm in the past ten years

(On the date of opening of tender) and such equipment is presently working

satisfactorily for more than one year after commissioning (On the date of

opening of tender) should quote. However,if such equipment has been

supplied to BHEL, then such equipment should be presently working

satisfactorily for more than six months after its commissioning and acceptance

(On the date of opening of tender) in BHELshould quote. The following

information should be submitted by the vendor about the companies where

such machines have been supplied. This is required from all the vendors for

qualification of their offer.

1.2 Name of the customer / company where such equipment is supplied. Vendor to provide details

1.3 Complete postal address of the customer Vendor to provide details

1.4 Month and Year of supply. Vendor to provide details

1.5 Size & Dimensional accuracy of equipment. Vendor to provide details

1.6 Evidance of supply of such equipment. Vendor to provide details

Rev : 01 SPECIFICATIONS Page 2 of 2

SPECIFIED / TO BE

SNO DESCRIPTION FOR BHEL REQUIREMENT

CONFIRMED BY OFFERED DEVIATIONS REMARKS

1.7 BHEL Reserves the right to verify the information provided by the vendor. In Vendor to confirm

case the information provided by the vendor is found to be false / in-correct,

the offer shall be rejected.

2.0 DESCRIPTION

2.1 Purpose: The proposed fibre glass flow nozzle will be used for Inlet air flow

measurement in Gas Turbines.

3.0 DETAIL SPECIFICATION OF FLOW NOZZLE :

3.1 CAPACITY & SIZE :

3.1.1 Material As specified in drawing

3.1.2 Applicable drawing 2-36408-00001

3.1.3 Air Flow 20 - 136 Kg/sec

3.1.4 Working Condition

3.1.4.1 Temperature 50°C Max.

3.1.4.2 Humidity 100% Max.

3.1.4.3 Pressure 700-760 mm of Hg

3.2 QUANTITY REQUIRED

3.2.1 Variant 00 of Throat diameter 762 mm, Material Code GT9751002010 06 (Six)

3.2.2 Variant 02 of Throat diameter 1006 mm, Material Code GT9751002036 05 (Five)

3.3 QUALITY ASSURANCE

3.3.1 All dimensional checks of the nozzles shall be witnessed by BHEL Vendor to confirm.

representative. Supplier shall arrange all necessary tools/instruments of

required accuracy for carrying out dimensional checks.

3.3.2 Supplier shall make necessary tempelate for checking curvature surface. Vendor to confirm.

3.3.3 Test report containing dimensional and curvature surface report of each nozzle Vendor to confirm

shall be submitted to BHEL

3.3.4 Each nozzle shall be parmanently marked uniquely for identifcation purpose Vendor to confirm

3.3.5 Nozzle shall withstand environemntal condition without change in shape and Vendor to confirm

3.3.6 size

Nozzle shall not deform when it is mounted on its flange and fully tightend. Vendor to confirm

Any deformation detected after erection on the flange, supplier shall rectify

the nozzles at free of cost.

4.0 PACKING

4.1 Rigid packing shall be provided for nozzles to avoid any damage in transit. Vendor to offer &

confirm

You might also like

- Bharat Heavy Electricals Limited: Tiruchirappalli - 620014, Materials Management / Capital EquipmentDocument12 pagesBharat Heavy Electricals Limited: Tiruchirappalli - 620014, Materials Management / Capital Equipmentsantoshkumar gurmeNo ratings yet

- Section 3 - Enq 14e0101 1406182266Document5 pagesSection 3 - Enq 14e0101 1406182266jitender.singh29No ratings yet

- Tech - Spec - 2024 03 30 11 09 16Document7 pagesTech - Spec - 2024 03 30 11 09 16sufiyanahmed1611No ratings yet

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Document5 pagesBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16No ratings yet

- PQ-0046959 Rev. 1Document2 pagesPQ-0046959 Rev. 1Divino Edgar LacambraNo ratings yet

- 5156 - High Mast LightDocument23 pages5156 - High Mast LightPEER ZAKIR HUSSAINNo ratings yet

- Technical Specification For GasketsDocument10 pagesTechnical Specification For GasketsRahul GangulyNo ratings yet

- Hydro Test Stations A) With Test Pressure of 500 KG/CM (G) B) With Test Pressure of 400 KG/CM (G)Document25 pagesHydro Test Stations A) With Test Pressure of 500 KG/CM (G) B) With Test Pressure of 400 KG/CM (G)muthuinchristNo ratings yet

- Tech PDFDocument12 pagesTech PDFShailendra SinghNo ratings yet

- PQ 0047296Document2 pagesPQ 0047296Divino Edgar LacambraNo ratings yet

- AM - OTH0230.2020 - PG Rueger - Approved - 27-01-2021Document10 pagesAM - OTH0230.2020 - PG Rueger - Approved - 27-01-2021Yong Lin Albon TiongNo ratings yet

- 160KW 415V Induction MotorDocument2 pages160KW 415V Induction MotorManisha KharwarNo ratings yet

- Technical Specification For PipesDocument13 pagesTechnical Specification For PipesRahul GangulyNo ratings yet

- Bid Document Bid Details: Air Conditioner (2 Pieces)Document3 pagesBid Document Bid Details: Air Conditioner (2 Pieces)Madheshwer Yadav100% (1)

- CONTOH Final Spec - Cooling Water Pump For NBTDocument8 pagesCONTOH Final Spec - Cooling Water Pump For NBTSoegiantoro SoegiantoroNo ratings yet

- PQ 0047293Document2 pagesPQ 0047293Divino Edgar LacambraNo ratings yet

- E7190261 Earthing SystemDocument2 pagesE7190261 Earthing SystemKAVITANo ratings yet

- PQ 0047213Document2 pagesPQ 0047213Divino Edgar LacambraNo ratings yet

- Technical Specification For FlangesDocument13 pagesTechnical Specification For FlangesRahul GangulyNo ratings yet

- EPI Machine Specification New 2016 A2024Document145 pagesEPI Machine Specification New 2016 A2024biresheyit9No ratings yet

- Tender Documents - 2022 06 25 17 03 54Document37 pagesTender Documents - 2022 06 25 17 03 54Metropolitan IndustriesNo ratings yet

- Page 1 of 7Document7 pagesPage 1 of 7SoniyaNo ratings yet

- Technical Specification For FastenersDocument8 pagesTechnical Specification For FastenersRahul GangulyNo ratings yet

- Petroleum Development Oman L.L.CDocument6 pagesPetroleum Development Oman L.L.Cvishnu RajNo ratings yet

- 24 - 400 - 220 - KV - SS HW PDFDocument28 pages24 - 400 - 220 - KV - SS HW PDFgaurang1111No ratings yet

- Spiral Wound Gasket: Bharat Heavy Electricals Limited Tiruchirappalli-620 014Document54 pagesSpiral Wound Gasket: Bharat Heavy Electricals Limited Tiruchirappalli-620 014Ramalingam PrabhakaranNo ratings yet

- Tender Documents - 2Document25 pagesTender Documents - 2Junior EngineerNo ratings yet

- Meghalaya Energy Corpration Limited Meghalaya Energy Corpration Limited Meghalaya Energy Corpration LimitedDocument20 pagesMeghalaya Energy Corpration Limited Meghalaya Energy Corpration Limited Meghalaya Energy Corpration Limitedarjun kumarNo ratings yet

- PQ 0045895Document2 pagesPQ 0045895juandlc3368No ratings yet

- Duct Inspection ChecklistDocument3 pagesDuct Inspection ChecklistHaymanot Baynesagn100% (1)

- Nit 5Document6 pagesNit 5Anonymous GfPSYi4nNo ratings yet

- 24 66 11 KV 5 MVA Transformer With Amendment PDFDocument100 pages24 66 11 KV 5 MVA Transformer With Amendment PDFNirmal mehtaNo ratings yet

- RFQ - Motorized Traveling ChuteDocument17 pagesRFQ - Motorized Traveling ChuteBasabRajNo ratings yet

- PQ 0047230Document2 pagesPQ 0047230Divino Edgar LacambraNo ratings yet

- Sprinkler Irrigation System TenderDocument6 pagesSprinkler Irrigation System TenderMahesh Savandappa0% (1)

- Bharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)Document7 pagesBharat Heavy Electricals Limited: Tiruchirappalli-620 014 Fuel Systems/PE (FB)bmanojkumar16No ratings yet

- MR ValvesDocument56 pagesMR ValvesIdris SiddiquiNo ratings yet

- GeM Bidding 2552191Document4 pagesGeM Bidding 2552191Sajid AkhterNo ratings yet

- Specifications For UG TapeDocument7 pagesSpecifications For UG TapeKok WaiNo ratings yet

- Transformer MR 6005Document8 pagesTransformer MR 6005Mohamed RafikNo ratings yet

- Bid DocumentDocument4 pagesBid DocumentabhayundaleNo ratings yet

- Technical Specification For FittingsDocument13 pagesTechnical Specification For FittingsRahul GangulyNo ratings yet

- PQ 0046966Document2 pagesPQ 0046966Divino Edgar LacambraNo ratings yet

- GeM Bidding 2581363Document5 pagesGeM Bidding 2581363Ketan KotechNo ratings yet

- PQ 0042938Document2 pagesPQ 0042938Divino Edgar LacambraNo ratings yet

- 1 SS MT 007Document34 pages1 SS MT 007SURAJ PRSADNo ratings yet

- PQ 0047229Document2 pagesPQ 0047229Divino Edgar LacambraNo ratings yet

- PQ 0047322Document2 pagesPQ 0047322Divino Edgar LacambraNo ratings yet

- GeM Bidding 2143371Document2 pagesGeM Bidding 2143371rseeni2710No ratings yet

- Binder1 - 2023 02 22 11 46 14Document16 pagesBinder1 - 2023 02 22 11 46 14Varun BatraNo ratings yet

- GeM Bidding 4020677Document6 pagesGeM Bidding 4020677Tumbin DilseNo ratings yet

- Enq en Val BSK 065 TotDocument32 pagesEnq en Val BSK 065 Totsaisrikanths5168No ratings yet

- HFY-GEN-CIV-SPC-0011 - B Specification For Platforms, Stairs, Ladders and Handrailings Code ADocument9 pagesHFY-GEN-CIV-SPC-0011 - B Specification For Platforms, Stairs, Ladders and Handrailings Code ATahir FadhilNo ratings yet

- PQ 0041663 4Document2 pagesPQ 0041663 4Divino Edgar LacambraNo ratings yet

- Arcelor Mittal Nippon Steel India (Am/Ns) Paradeep, Odisha Technical Specification FORDocument12 pagesArcelor Mittal Nippon Steel India (Am/Ns) Paradeep, Odisha Technical Specification FORBasabRajNo ratings yet

- Specification For Ductile Iron Pillar HydrantsDocument12 pagesSpecification For Ductile Iron Pillar HydrantsyogeswaranNo ratings yet

- Gem Bidding 3062365procurement Drone Accessoriesgd 67Document10 pagesGem Bidding 3062365procurement Drone Accessoriesgd 67amalNo ratings yet

- Specification For Power Transformers: Petroleum Development Oman L.L.CDocument20 pagesSpecification For Power Transformers: Petroleum Development Oman L.L.CAshraf MohammedNo ratings yet

- Tender 2Document43 pagesTender 2pbhat83No ratings yet

- Volume IA - 1088-89Document130 pagesVolume IA - 1088-89Instrument CandidatesNo ratings yet

- Annexure-I-Technical Specification WHRB 1Document16 pagesAnnexure-I-Technical Specification WHRB 1Instrument CandidatesNo ratings yet

- SCC - Raozan 400 MW - Rev00 1592303308Document13 pagesSCC - Raozan 400 MW - Rev00 1592303308Instrument CandidatesNo ratings yet

- Nit Flow Element Nozzle 1409747683Document6 pagesNit Flow Element Nozzle 1409747683Instrument CandidatesNo ratings yet

- Technical Spec Barh 2 Part 3 of 6 1564812856Document100 pagesTechnical Spec Barh 2 Part 3 of 6 1564812856Instrument CandidatesNo ratings yet

- 5SY61067 Datasheet enDocument4 pages5SY61067 Datasheet enQuy HoangNo ratings yet

- Using Reclosers As Sectionalizers A Conceptual Overview T&D WorldDocument10 pagesUsing Reclosers As Sectionalizers A Conceptual Overview T&D WorldE PenaNo ratings yet

- Nilai Gizi Bakso & Dimsum ProposalDocument2 pagesNilai Gizi Bakso & Dimsum ProposalRumona PutriNo ratings yet

- WEG w22 Three Phase Electric Motor 50029265 Brochure EngliDocument44 pagesWEG w22 Three Phase Electric Motor 50029265 Brochure EngliAmir SafdarNo ratings yet

- Nonisolated Multiport Converters Based On Integration of PWM Converter and Phase-Shift Switched Capacitor ConverterDocument15 pagesNonisolated Multiport Converters Based On Integration of PWM Converter and Phase-Shift Switched Capacitor Converteramala081998No ratings yet

- Hurricane Boosters: Air or NitrogenDocument2 pagesHurricane Boosters: Air or NitrogenRas-Sherwin A. JalaniNo ratings yet

- Transformer - Practice Sheet 01Document6 pagesTransformer - Practice Sheet 01Anant VermaNo ratings yet

- Apm1514 TL 101 Assignment04 2024Document3 pagesApm1514 TL 101 Assignment04 2024Rodney MahlanguNo ratings yet

- Industry Manual On Acceptance of Product by Marketing CompanDocument39 pagesIndustry Manual On Acceptance of Product by Marketing CompanGate PadipaliNo ratings yet

- Logbook Djj50193 Project 2 Sesi 2 LuqmanDocument8 pagesLogbook Djj50193 Project 2 Sesi 2 Luqmanshaik ahmad 1044No ratings yet

- Lab Report Impact Testing - FinalDocument17 pagesLab Report Impact Testing - FinalSabin KarakhetiNo ratings yet

- Taking Temperature Measurements With RTDS: How-To Guide: 1. RTD OverviewDocument3 pagesTaking Temperature Measurements With RTDS: How-To Guide: 1. RTD OverviewRandy SihombingNo ratings yet

- Binder 1Document24 pagesBinder 1NISKANA SAMSUDEENNo ratings yet

- 2013 MMTA-44A S-22013 Review PermanentMagneticMaterialsDocument20 pages2013 MMTA-44A S-22013 Review PermanentMagneticMaterialsrasoolNo ratings yet

- 303-12 Intake Air Distribution and Filtering - General Procedures - Charge Air Cooler CAC CleaningDocument2 pages303-12 Intake Air Distribution and Filtering - General Procedures - Charge Air Cooler CAC CleaningCARLOS LIMADANo ratings yet

- Compressible Flow1Document28 pagesCompressible Flow1hs sNo ratings yet

- Bearing-Conn Rod Kit IR COMPDocument1 pageBearing-Conn Rod Kit IR COMPmohamed Helal0% (1)

- Compact Guide Cylinder: SeriesDocument127 pagesCompact Guide Cylinder: Seriesdiazpolanco13No ratings yet

- 3406, 3406C & 3456 Generator Set Electrical System With EMCP IIDocument4 pages3406, 3406C & 3456 Generator Set Electrical System With EMCP IIKhalifaNo ratings yet

- Derillion Energy Corporate BrochureDocument14 pagesDerillion Energy Corporate BrochureKwadwo AkotoNo ratings yet

- TD - 201808 - Crystal - Error 010 Islanding - V1.1Document3 pagesTD - 201808 - Crystal - Error 010 Islanding - V1.1Goodbird vocational schoolNo ratings yet

- USFULLDocument4 pagesUSFULLwaleed skaf33% (3)

- Gas Detection & Alarm Device 17100-101-22 Ozone O3Document2 pagesGas Detection & Alarm Device 17100-101-22 Ozone O3Sahar AnwaarNo ratings yet

- CUBE-160-10 - SubmittalDocument3 pagesCUBE-160-10 - SubmittalElmer Ramón Murillo MejiaNo ratings yet

- Final Project Report.3Document54 pagesFinal Project Report.3mail trashNo ratings yet

- Illustrated Spare Part List FOR: Kirloskar Oil Engines LimitedDocument88 pagesIllustrated Spare Part List FOR: Kirloskar Oil Engines LimitedAlfiya AnamNo ratings yet

- V80-2.0 MW - VestasDocument16 pagesV80-2.0 MW - Vestasjamesr277272No ratings yet

- AMP (MIN572) Lecture 1 NTMDocument242 pagesAMP (MIN572) Lecture 1 NTMNAMAN AGARWALLANo ratings yet

- Kinetic TheoryDocument21 pagesKinetic TheoryDebayanbasu.juNo ratings yet

- C Cross Sectional Area (A)Document14 pagesC Cross Sectional Area (A)Jitheesh SahadevanNo ratings yet