Professional Documents

Culture Documents

Teste N

Teste N

Uploaded by

Amine BoudourOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Teste N

Teste N

Uploaded by

Amine BoudourCopyright:

Available Formats

Teste N° 2:

INTRODUCTION :

All the operations involved in the production of a product, from reception to

delivery to the customer.

Depending on the technique used, the intended medium, the deadline, the number of copies to be

printed and the budget, the final document to be produced will have a different look and feel.

number of copies to be printed, and the budget, the final document will have a different

structure.

In fact, depending on whether it's a leaflet, brochure, poster, label,

a box, a newspaper, an advertisement, a novel, the problem will have to be studied differently, and

the solution will necessarily be complex.

Three key words:

Communication:

To communicate is to understand and be understood.

Organization:

Action of implementing, preparing and establishing the distribution of tasks,

to ensure the best working conditions.

Control:

Being in control of the situation until it reaches the customer;

the commitments given for the realization of the product

are very important for the future.

Translated with www.DeepL.com/Translator (free version)

2- Printing processes with printing forms

Letterpress printing

This is a direct printing process using a raised printing form.

The principle goes back a long way: the first known prints, based on engraved wood blocks

(xylography) date back to the 8th century.

So, in 1450, Gutenberg did not "invent" typography or printing, but he did perfect the first industrial

process for multiplying type by casting metal in identical molds

made from a single die. This standardization improved the quality of typefaces and enabled

considerable savings on their manufacture.

Flexography

Like letterpress, flexography is a direct printing process using a relief printing form,

but in this process, the form is "flexible", made of vulcanized rubber or soft plastic.

plastic. This process, which is particularly well-suited to printing on plastic film for packaging, enables

quality color prints to be produced using web presses, provided that the original documents have

been designed and produced in accordance with the customer's specifications.

the original documents have been designed for this process.

For a long time reserved for coarse printing on cardboard or Kraft paper, flexography owes its rise to

the combined technological developments of rotary presses, photopolymer plates,

and inks that chemists adapted as new synthetic packaging substrates were invented.

Rotogravure

Derived from intaglio and etching, this direct intaglio printing process, perfected

developed in 1878, was first applied to artistic printing on sheet paper,

It then became the printing process for paper in large widths (over 2 m). The high

of the printing form limits its use to large print runs, such as those for catalogues

catalogs, magazines and brochures (several hundred thousand copies, several million if the

several million if the roll width is smaller.

This process is also used for printing various types of packaging. Because it avoids the disadvantages

of

the disadvantages of fount solution and sticky inks inherent to offset printing, heliogravure can

produce

high color intensity on less elaborate, and therefore less expensive, paper.

Screen printing

This direct printing process, using a porous printing form, exploits the stencil principle:

The printing form is a fabric stretched over a frame. The printing parts allow the ink to pass through

the fabric weave. A special feature of screen printing is that the ink is deposited in a thickness

comparable to a coat of paint.

This process is unique when a full-coverage print is required.

Offset printing

Created around 1910 in the United States, this indirect printing process uses a planographic printing

form. Lithography (Senefelder, 1798), from which it derives, also uses a planographic printing form.

but prints by direct contact between stone and paper.

Offset is suitable for a wide range of applications.

It's the most economical process to use, thanks to the simplicity and speed of the printing form.

printing form.

http://perso.wanadoo.fr/elisabeth.fays/cours/ - 4

The Di-litho process

Also known as direct lithography, this direct offset printing process is used exclusively for

daily newspapers on letterpress presses adapted to offset printing by adding a dampening device.

fount solution.

This is a transitional process, allowing the last investments in letterpress equipment to be amortized

before the installation of offset presses.

before installing offset presses.

Indirect letterpress.

Also known as "dry offset" or "letterset", this process combines the indirect printing principle of

offset with the printing form of letterset.

with the raised printing form of letterpress. An offset press is used, without its fount solution, and

the letterpress relief printing form is replaced.

is glued to the plate cylinder. When the press is equipped

a magnetic cylinder, a photopolymer plate glued to a steel base can be used.

You might also like

- Hybrid Printing PresentationDocument53 pagesHybrid Printing PresentationSumit kr100% (2)

- Offset Printing PDFDocument89 pagesOffset Printing PDFdance100% (2)

- Chapter 2 FLEXOGRAPHY PRINTINGDocument26 pagesChapter 2 FLEXOGRAPHY PRINTINGGiha Tardan100% (2)

- By Shrikant Athavale SPA Technical Advisor Pune Cell: +91 7588288204Document80 pagesBy Shrikant Athavale SPA Technical Advisor Pune Cell: +91 7588288204Avi Yusri100% (1)

- Heat Transfer PrintingDocument24 pagesHeat Transfer Printingshreya bhagat100% (1)

- Safavid Ceramics and Chinese InspirationDocument4 pagesSafavid Ceramics and Chinese InspirationGermanikNo ratings yet

- Unit 3 Fabric PrintingDocument57 pagesUnit 3 Fabric PrintingCarlo Gojo Cruz HalasanNo ratings yet

- Flexo and PackagingDocument28 pagesFlexo and PackagingFlorencia Tinta100% (4)

- Stencil CuttingDocument10 pagesStencil Cuttingapi-237537981No ratings yet

- Lecture 1 PDFDocument20 pagesLecture 1 PDFKe WalNo ratings yet

- Rotogravure Printing Learn MoreDocument15 pagesRotogravure Printing Learn Moreumangashling100% (1)

- Gravure Vs FlexographyDocument31 pagesGravure Vs FlexographyAkhilesh Kumar50% (2)

- Flat Screen Printing - O ECOTEXTILESDocument3 pagesFlat Screen Printing - O ECOTEXTILESluisricardosantosNo ratings yet

- Uttara University: AssignmentDocument11 pagesUttara University: AssignmentMOJAHID HASAN Fall 19No ratings yet

- IDJ - Volume 6 - Issue 1 - Pages 151-157Document7 pagesIDJ - Volume 6 - Issue 1 - Pages 151-1574smarttechnologyNo ratings yet

- Printing TechnologyDocument10 pagesPrinting TechnologyfarortasyoNo ratings yet

- Different Types of Printing Techniques On FabricDocument51 pagesDifferent Types of Printing Techniques On FabricRikta IslamNo ratings yet

- 9 Flexographic-InksDocument52 pages9 Flexographic-Inksrenditasyr 2No ratings yet

- Offset Lithography (A3)Document1 pageOffset Lithography (A3)Choco Apple100% (1)

- Flexo vs. Other Printing MethodsDocument12 pagesFlexo vs. Other Printing MethodsMaster Puskyn100% (1)

- Lec Notes1Document10 pagesLec Notes1Mesfin BettNo ratings yet

- Dyeing Dyes: PrintingDocument16 pagesDyeing Dyes: Printingjack omeNo ratings yet

- CHAPTER 3.0 - GravureDocument10 pagesCHAPTER 3.0 - GravureGiha Tardan100% (1)

- Rottery Printing PressDocument4 pagesRottery Printing PressSALONI JAINNo ratings yet

- Computer Aided Packaging DesignDocument3 pagesComputer Aided Packaging DesignVinod NairNo ratings yet

- History About Screen PrintingDocument14 pagesHistory About Screen Printingbluffy1No ratings yet

- Dyeing, Printing 2Document15 pagesDyeing, Printing 2Sahadat Hossen100% (1)

- History of Printing Press: First Stage: Woodblock PrintingDocument7 pagesHistory of Printing Press: First Stage: Woodblock PrintingAnjali GuptaNo ratings yet

- Screen PintingDocument40 pagesScreen PintingAllen CardonaNo ratings yet

- Unit 1 PDFDocument42 pagesUnit 1 PDFLalit SinghaLNo ratings yet

- Offset Printing - WikipediaDocument48 pagesOffset Printing - WikipediaLKMs HUBNo ratings yet

- Lesson 1 Print Production History of PrintingDocument42 pagesLesson 1 Print Production History of PrintingneildomNo ratings yet

- Offset Printing - EditedDocument6 pagesOffset Printing - EditedLeornard MukuruNo ratings yet

- Printing ProcessesDocument8 pagesPrinting ProcessesPriyanka ChaudharyNo ratings yet

- Different Types of Printing Method Block PrintingDocument2 pagesDifferent Types of Printing Method Block PrintingPrabhu RichardNo ratings yet

- Printing Types: The Main Industrial Printing Processes AreDocument29 pagesPrinting Types: The Main Industrial Printing Processes ArerasajatiNo ratings yet

- Printing DesindDocument29 pagesPrinting DesindGIHA BINTI TARDAN (KKSA)No ratings yet

- CHAPTER 2.1 - FlexographyDocument8 pagesCHAPTER 2.1 - FlexographyGiha TardanNo ratings yet

- Printing ProcessDocument22 pagesPrinting ProcessPrashant SarfareNo ratings yet

- Hybrid PrintingDocument32 pagesHybrid PrintingSumit krNo ratings yet

- Dye Sublimation PrinterDocument5 pagesDye Sublimation PrinterPaula ZorziNo ratings yet

- History of Print MakingDocument6 pagesHistory of Print MakingBen BabuNo ratings yet

- How Offset Printing Work1Document2 pagesHow Offset Printing Work1pavan4samudralaNo ratings yet

- New Microsoft Word Document (1) .Docx FDocument8 pagesNew Microsoft Word Document (1) .Docx FYogesh SharmaNo ratings yet

- Carton Board Detail With OffsetDocument7 pagesCarton Board Detail With OffsetIzhar ShaikhNo ratings yet

- Final Textile PrintingDocument26 pagesFinal Textile PrintingRamsha Mubeen100% (1)

- History of PrintingDocument10 pagesHistory of Printingapi-284248147100% (1)

- Muskaan Naeem (1269-2022) Print Design-II THYDocument21 pagesMuskaan Naeem (1269-2022) Print Design-II THYOsama JawedNo ratings yet

- Digital Printing in Textiles: Prepared byDocument10 pagesDigital Printing in Textiles: Prepared byAbi Nikil100% (2)

- Digital, Hand and Mechanical PrintingDocument16 pagesDigital, Hand and Mechanical PrintingJessicaa1994No ratings yet

- SqueegeeDocument49 pagesSqueegeeKeerthanaNo ratings yet

- Glasnik-Stampa Proslosst Sadasnjost BuducnostDocument12 pagesGlasnik-Stampa Proslosst Sadasnjost BuducnostDjordjeNo ratings yet

- Michaels Mechanical PrintingDocument4 pagesMichaels Mechanical PrintingCHIGGERZNo ratings yet

- History of Printing MethodsDocument10 pagesHistory of Printing Methodsapi-332761631No ratings yet

- Introdusction To Flexographic PrintDocument77 pagesIntrodusction To Flexographic PrintTamas RaduNo ratings yet

- 2016 02 04 Specialist Printing Sublimation TransferDocument2 pages2016 02 04 Specialist Printing Sublimation Transferwat everNo ratings yet

- Digital PrintingDocument18 pagesDigital PrintingPradip PatelNo ratings yet

- Lithographic PrintingDocument34 pagesLithographic PrintingSirfMujjuNo ratings yet

- Extrusion Dies for Plastics and Rubber: Design and Engineering ComputationsFrom EverandExtrusion Dies for Plastics and Rubber: Design and Engineering ComputationsNo ratings yet

- Physica A: Bilal Saoud, Abdelouahab MoussaouiDocument9 pagesPhysica A: Bilal Saoud, Abdelouahab MoussaouiHaroonRashidNo ratings yet

- 0810 Operation Manual250708Document117 pages0810 Operation Manual250708isaacaiyacNo ratings yet

- CPR Test - SummaryDocument2 pagesCPR Test - Summaryas0537 31No ratings yet

- Contribution of Medieval MuslimDocument16 pagesContribution of Medieval Muslimannur osmanNo ratings yet

- Cell City IntroDocument6 pagesCell City Intromayah12No ratings yet

- NBA 2K12 Ext Manual Wii FinalDocument10 pagesNBA 2K12 Ext Manual Wii FinalEthan TampusNo ratings yet

- Perforated Peptic Ulcer DiseaseDocument2 pagesPerforated Peptic Ulcer DiseaseRene John FranciscoNo ratings yet

- (REVIEW) KENDALL, Stuart - The Philosophy of Design by Glenn ParsonsDocument5 pages(REVIEW) KENDALL, Stuart - The Philosophy of Design by Glenn ParsonsOmega ZeroNo ratings yet

- Or On LineDocument10 pagesOr On LinekateNo ratings yet

- W6400 PC PDFDocument34 pagesW6400 PC PDFHùng TàiNo ratings yet

- Heat, Temperature, and Heat Transfer: Cornell Doodle Notes FREE SAMPLERDocument13 pagesHeat, Temperature, and Heat Transfer: Cornell Doodle Notes FREE SAMPLERShraddha PatelNo ratings yet

- Material ManagementDocument20 pagesMaterial Managementgkataria110100% (1)

- Join The Club: C207 - Database Systems 2012Document237 pagesJoin The Club: C207 - Database Systems 2012hamzahNo ratings yet

- Hellermann Tyton PDFDocument152 pagesHellermann Tyton PDFanon_34390801No ratings yet

- Podman Part4Document5 pagesPodman Part4anbuchennai82No ratings yet

- Smart Contracts: Functioning and Legal Enforceability in IndiaDocument14 pagesSmart Contracts: Functioning and Legal Enforceability in IndiaPrasanth Raju100% (1)

- Chapter 6 Project ManagementDocument54 pagesChapter 6 Project ManagementSHAWN TAKAONANo ratings yet

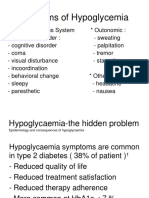

- Symptoms of HypoglycemiaDocument20 pagesSymptoms of Hypoglycemiakenny StefNo ratings yet

- Manual de Instalación - Tableros Centro de Carga - Marca GEDocument4 pagesManual de Instalación - Tableros Centro de Carga - Marca GEmariana0% (1)

- Chemical Engineering Plant Economics Questions and AnswersDocument32 pagesChemical Engineering Plant Economics Questions and AnswersLily Antonette Agustin100% (1)

- Haunted: MuseumDocument36 pagesHaunted: MuseumNgoc PhanNo ratings yet

- Database Systems, Eleventh Edition by Coronel Morris, Course Technology 2014Document5 pagesDatabase Systems, Eleventh Edition by Coronel Morris, Course Technology 2014LaluMohan KcNo ratings yet

- CHUYÊN ĐỀ CHỈ SỰ NHƯỢNG BỘDocument5 pagesCHUYÊN ĐỀ CHỈ SỰ NHƯỢNG BỘĐinh DuyênNo ratings yet

- Programa FinalDocument63 pagesPrograma Finalpatmos666No ratings yet

- PoonamDocument54 pagesPoonamCH Rajan GujjarNo ratings yet

- Comparing Low RPM Juicers by John KohlerDocument12 pagesComparing Low RPM Juicers by John Kohlerandra_panaitNo ratings yet

- शरीर में सन्निहित शक्ति-केंद्र या चक्र Inner Powers Center or Chakra in BodyDocument33 pagesशरीर में सन्निहित शक्ति-केंद्र या चक्र Inner Powers Center or Chakra in BodygujjuNo ratings yet

- SOLO TaxonomyDocument3 pagesSOLO Taxonomytini0211No ratings yet

- An 2013 1Document6 pagesAn 2013 1ashwinNo ratings yet