Professional Documents

Culture Documents

03 Framing Systems

03 Framing Systems

Uploaded by

Norris Baguio0 ratings0% found this document useful (0 votes)

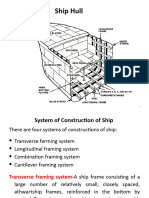

8 views22 pagesThe document discusses the longitudinal and transverse structural components of ships. The longitudinal components like the keel, longitudinals, stringers, and deck girders run parallel along the length of the ship and resist longitudinal bending stresses. The transverse components like floors, frames, and deck beams run across the ship and resist hydrostatic pressures. Long ships over 300 feet experience more longitudinal bending and typically use a longitudinal framing system with closely spaced longitudinals. Shorter ships use a transverse framing system with deeply spaced longitudinals and closely spaced frames. Many ships use a combined system.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document discusses the longitudinal and transverse structural components of ships. The longitudinal components like the keel, longitudinals, stringers, and deck girders run parallel along the length of the ship and resist longitudinal bending stresses. The transverse components like floors, frames, and deck beams run across the ship and resist hydrostatic pressures. Long ships over 300 feet experience more longitudinal bending and typically use a longitudinal framing system with closely spaced longitudinals. Shorter ships use a transverse framing system with deeply spaced longitudinals and closely spaced frames. Many ships use a combined system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

8 views22 pages03 Framing Systems

03 Framing Systems

Uploaded by

Norris BaguioThe document discusses the longitudinal and transverse structural components of ships. The longitudinal components like the keel, longitudinals, stringers, and deck girders run parallel along the length of the ship and resist longitudinal bending stresses. The transverse components like floors, frames, and deck beams run across the ship and resist hydrostatic pressures. Long ships over 300 feet experience more longitudinal bending and typically use a longitudinal framing system with closely spaced longitudinals. Shorter ships use a transverse framing system with deeply spaced longitudinals and closely spaced frames. Many ships use a combined system.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 22

Framing Systems

Compiled by Captain Sukhjit Singh

Longitudinal Structural Components

• Starting from the keel to the deck:

•Keel

-Large center-plane girder

-Runs longitudinally along the bottom of the ship

•Longitudinals

-Girders running parallel to the keel along the bottom

-It provides longitudinal strength

Compiled by Captain Sukhjit Singh

Longitudinal Structural Components (cont’d)

•Stringer

-Girders running along the sides of the ship

-Typically smaller than a longitudinal

-Provides longitudinal strength

•Deck Girder

-Longitudinal member of the deck frame (deck longitudinal)

….Primary role of longitudinal members :

Resist the longitudinal bending stress due to sagging and hogging

Compiled by Captain Sukhjit Singh

Compiled by Captain Sukhjit Singh

Transverse Structural Components

• Starting from the keel to the deck:

• Floor

-Deep frame running from the keel to the turn of the bilge

• Frame

- A transverse member running from keel to deck

- Resists hydrostatic pressure, waves, impact, etc.

- Frames may be attached to the floors (Frame would be the part

above the floor)

• Deck Beams

- Transverse member of the deck frame

Compiled by Captain Sukhjit Singh

Transverse Structural Components (cont’d)

• •Plating

-Thin pieces closing in the top, bottom and side of structure-

Contributes significantly to longitudinal hull strength

-Resists the hydrostatic pressure load (or side impact)

Primary role of transverse members : to resist the hydrostatic loads

Compiled by Captain Sukhjit Singh

Compiled by Captain Sukhjit Singh

Compiled by Captain Sukhjit Singh

Compiled by Captain Sukhjit Singh

The ship’s strength can be increased by:

-Adding more members

-increasing the size & thickness of plating and

structural pieces

BUT

All this will increase cost, reduce space utilisation, and

allow less equipment to be added Optimisation.

Compiled by Captain Sukhjit Singh

Big Question

Which framing system to choose ?

Advantages and disadvantages ?

Compiled by Captain Sukhjit Singh

•Longitudinal Framing System

•Transverse Framing System

•Combination of Framing System

Compiled by Captain Sukhjit Singh

Longitudinal Framing System

Primary role of longitudinal members :

to resist the longitudinal bending stress due to sagging and hogging

•A typical wave length in the ocean is 300 ft. Ships of this lengthor

greater are likely to experience considerable longitudinalbending

stress

•Ship that are longer than 300ft (long ship) tend to have a greater

number of longitudinal members than transverse members

Longitudinal Framing System:

-Longitudinals spaced frequently but shallower

-Frames are spaced widely

Compiled by Captain Sukhjit Singh

Transverse Framing System

•Primary role of transverse members :

to resist the hydrostatic loads

• Ships shorter than 300ft and submersibles

• Transverse Framing System:

- Longitudinals are spaced widely but deep.

- Frames are spaced closely and continuously

•Transverse members:

frame, floor, deck beam, platings

Compiled by Captain Sukhjit Singh

Combined Framing System

Optimization of the structural arrangement for the

expected loading to minimize the cost

•Combination of longitudinal and transverse framing

system

•Typical combination :

-Longitudinals and stringers with shallow frame

-Deep frame every 3rd or 4th frame

Compiled by Captain Sukhjit Singh

Compiled by Captain Sukhjit Singh

Longitudinal framing system

In this system, all the secondary supporting

members are fitted in the longitudinal

direction and are known as longitudinals.

Major structural members Some of them

are:

1. Bottom longitudinals

2. Side longitudinals

3. Deck longitudinals

The system consist of many small,

closely spaced longitudinals supporting

the plating directly and being

supported in between by large ,widely

spaced longitudinals

Compiled by Captain Sukhjit Singh

Longitudinal framing system

Compiled by Captain Sukhjit Singh

Longitudinal framing system

Compiled by Captain Sukhjit Singh

Advantages of longitudinal framing system

The advantages of longitudinal framing system are as follows:

Longitudinally stiffened plating is more resistant to buckling

especially prevalent in ship’s upper deck. When the deck or bottom is

subjected to compressive stresses as it bends in a seaway than it

would be if stiffened transversely.

Longitudinal stiffeners supporting side shell and bulkhead plating are

subjected to variable pressures from the sea or from liquid cargo. The

hydrostatic pressure on each successive longitudinal and its

associated plating increases with its depth below the waterline or

below the surface of the liquid in the tank.

Compiled by Captain Sukhjit Singh

Advantages of longitudinal framing system

Each longitudinal can be sized to withstand the maximum pressure

associated with its depth in the ship, thus achieving an efficient use of

structural material.

Graduated size cannot be done effectively with transverse frames,

which as a result are only heavy at their upper ends.

Compiled by Captain Sukhjit Singh

Disadvantages of longitudinal framing system

Though the longitudinal framing system has a lot of

advantages, it also has some disadvantages.

The intrusion of deep webs into prime cargo spaces for ships carrying

packaged cargo is an disadvantage.

Difficulty arises in the structural arrangements near the ends of the

ship.

As the hull narrows towards the bow and stem, however, the girth

necessarily reduces and the longitudinals becomes closer together

Difficulties in construction arise when they converge so closely that

some longitudinals have to be eliminated

Compiled by Captain Sukhjit Singh

You might also like

- ABS CBN vs. HilarioDocument3 pagesABS CBN vs. HilarioAnneNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Analyses of Ship ElementDocument21 pagesAnalyses of Ship Elementsaassaassaas100% (1)

- CDR Jeffrey W. Stettler, Usn, PHD: Assistant Professor, Permanent Military ProfessorDocument14 pagesCDR Jeffrey W. Stettler, Usn, PHD: Assistant Professor, Permanent Military Professormarquiname60% (5)

- Ship Construction Bow and Stern RegionDocument15 pagesShip Construction Bow and Stern RegionPranjyoti Saikia100% (1)

- Aircraft Fuselage ConfigurationDocument7 pagesAircraft Fuselage ConfigurationRajesh KumarNo ratings yet

- Traverse TablesDocument9 pagesTraverse TablesNorris BaguioNo ratings yet

- Legal System in SingaporeDocument28 pagesLegal System in SingaporeLatest Laws TeamNo ratings yet

- DebateDocument2 pagesDebatekumiko sakamotoNo ratings yet

- 5th Grade LoteriaDocument4 pages5th Grade Loteriaapi-505705800No ratings yet

- Letter To Joe Biden On Antisemitism and IsraelDocument4 pagesLetter To Joe Biden On Antisemitism and IsraelJacob Kornbluh0% (1)

- 6.3 Ship Framing SystemDocument19 pages6.3 Ship Framing Systemfais hamzahNo ratings yet

- FramingDocument8 pagesFramingpramod.bNo ratings yet

- Ship Framing SystemDocument1 pageShip Framing SystemAndrei Bogdan BustiucNo ratings yet

- Ship Framing SystemDocument10 pagesShip Framing SystemgksahaNo ratings yet

- Longitudinal and Transverse Framing PDFDocument62 pagesLongitudinal and Transverse Framing PDFShivam Kumar100% (2)

- Shipco TermsDocument2 pagesShipco Termspramod.bNo ratings yet

- Lecture Notes Framing SystemDocument8 pagesLecture Notes Framing Systembswalimbe0% (1)

- Hull Framing SystemsDocument11 pagesHull Framing Systemsmecete8514No ratings yet

- Framing System: Frames, Deck Beams EtcDocument2 pagesFraming System: Frames, Deck Beams EtcMir Tareque AliNo ratings yet

- Sistem Konstruksi KapalDocument5 pagesSistem Konstruksi KapalNabil AyyasyNo ratings yet

- Ship Construction 2020Document108 pagesShip Construction 2020Cap Karim ElSherbini100% (3)

- Hull Structure - HandoutDocument15 pagesHull Structure - HandoutSamNo ratings yet

- Ship Construction Final Sept 2019 (Autosaved)Document108 pagesShip Construction Final Sept 2019 (Autosaved)Mohammed EhabNo ratings yet

- Ship Construction Structure NotesDocument106 pagesShip Construction Structure NotesBiplabananda Talukdar100% (2)

- Principl of Ship Construction - Lecture 3 - DR - Eng. Hussien M. HassanDocument46 pagesPrincipl of Ship Construction - Lecture 3 - DR - Eng. Hussien M. Hassanموبليات حسين المصريNo ratings yet

- Aft End StructureDocument70 pagesAft End Structurevishal giri50% (4)

- Ship Structural StrengthDocument13 pagesShip Structural StrengthZhihao LiNo ratings yet

- 02 Basic DefinitionsDocument22 pages02 Basic DefinitionsNorris BaguioNo ratings yet

- 4.system of ConstructionDocument7 pages4.system of ConstructionarmanimamsNo ratings yet

- Understanding Watertight Bulkheads in Ships Construction and SOLAS RegulationsDocument10 pagesUnderstanding Watertight Bulkheads in Ships Construction and SOLAS RegulationsGiorgi KandelakiNo ratings yet

- NAME-248 (Ship Construction)Document47 pagesNAME-248 (Ship Construction)iamtawhidhassanNo ratings yet

- Na-II Ship ConstructionDocument16 pagesNa-II Ship ConstructionmichaelrithishNo ratings yet

- Hull StructuresDocument20 pagesHull StructuresJuris PasionNo ratings yet

- Week 2Document6 pagesWeek 2Roger TerminatorNo ratings yet

- 12.8 Ship Structure-Aft End StructureDocument20 pages12.8 Ship Structure-Aft End StructureT VigneshwarNo ratings yet

- Decks, Hatches, Superstructures, Shell Plating & Pillars - UpdatedDocument28 pagesDecks, Hatches, Superstructures, Shell Plating & Pillars - UpdatedASIT DAS100% (1)

- Arrangements To Compensate PoundingDocument2 pagesArrangements To Compensate Poundingpramod_kb100% (1)

- SUBMARINEDocument9 pagesSUBMARINEKareem ElbrembalyNo ratings yet

- Ship Basic Hull DesignDocument2 pagesShip Basic Hull DesignrajishrrrNo ratings yet

- Teja's Presentation NewDocument22 pagesTeja's Presentation Newkorada gayatriNo ratings yet

- Ship StructureDocument170 pagesShip Structuresasikumarmarine92% (12)

- NASC TheoryDocument20 pagesNASC Theoryannie rawatNo ratings yet

- Trelleborg Fender GuideDocument8 pagesTrelleborg Fender GuideFranciscoPedroNo ratings yet

- SMSC-1400-01 - Answer KeysDocument5 pagesSMSC-1400-01 - Answer KeysAmir SoleimanyNo ratings yet

- Dreams Aviation TechnicalDocument11 pagesDreams Aviation Technicalmonkey playNo ratings yet

- ShipCo Notes - Phase 1 MMDDocument52 pagesShipCo Notes - Phase 1 MMDGurjit Singh100% (1)

- Ship Construction For MarinersDocument32 pagesShip Construction For Marinerskyaw100% (1)

- V07a Mooring 1206Document48 pagesV07a Mooring 1206Htin Lin Aung100% (1)

- Ship Construction SystemDocument2 pagesShip Construction SystemNabil AyyasyNo ratings yet

- Longitudinal Vs Transversal Frame in Ship ConstructionDocument17 pagesLongitudinal Vs Transversal Frame in Ship Constructionistinpoli100% (4)

- Framing Systems Double BottomsDocument29 pagesFraming Systems Double Bottomssugam singh PahwaNo ratings yet

- Numerical Modelling of Strength For Hull Form Components of A 700 Tonne Self-Propelled Barge Under Moment and Operational LoadingDocument11 pagesNumerical Modelling of Strength For Hull Form Components of A 700 Tonne Self-Propelled Barge Under Moment and Operational LoadingIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Framing Systems of Ships (1) (Rahul)Document6 pagesFraming Systems of Ships (1) (Rahul)kashyapyash6524No ratings yet

- Field Development ConceptsDocument54 pagesField Development ConceptsMarc Raphael ParrikalNo ratings yet

- 3.3 Berth Structures: - PurposeDocument30 pages3.3 Berth Structures: - Purposelance carterNo ratings yet

- 02-Offshore Production SystemDocument24 pages02-Offshore Production SystemChirag KatariyaNo ratings yet

- Basics of Ship Hull DesignDocument3 pagesBasics of Ship Hull Designalp_alpNo ratings yet

- Ship History of Naval Architecture EngineersDocument3 pagesShip History of Naval Architecture EngineerspothirajkalyanNo ratings yet

- Ship History of Naval Architecture EngineersDocument3 pagesShip History of Naval Architecture EngineerssnvijayanNo ratings yet

- Ship History of Naval Architecture EngineersDocument3 pagesShip History of Naval Architecture EngineerssnvijayanNo ratings yet

- Ship History of Naval Architecture EngineersDocument3 pagesShip History of Naval Architecture EngineerspothirajkalyanNo ratings yet

- Hull StructureDocument94 pagesHull StructureAktarojjaman MiltonNo ratings yet

- Ass in SEAM 1Document19 pagesAss in SEAM 1dyanlacasaNo ratings yet

- Shell and Deck PlatingDocument22 pagesShell and Deck PlatingVijay DamleyNo ratings yet

- 02 Basic DefinitionsDocument22 pages02 Basic DefinitionsNorris BaguioNo ratings yet

- 01 NAVAL ARCHITECTURE Ship Construction Part 1Document10 pages01 NAVAL ARCHITECTURE Ship Construction Part 1Norris BaguioNo ratings yet

- The Use of Horizontal and Vertical Angles in Terrestrial NavigationDocument10 pagesThe Use of Horizontal and Vertical Angles in Terrestrial NavigationNorris BaguioNo ratings yet

- Elementary First Aid Course (EFA) STCW-95 PDFDocument1 pageElementary First Aid Course (EFA) STCW-95 PDFNorris BaguioNo ratings yet

- Asset-V1 RICE+46 6 4010+2021 Q1+type@asset+block@MCQs For HO SDH New WBCS 2nd SM 2nd Class Constitution QDocument5 pagesAsset-V1 RICE+46 6 4010+2021 Q1+type@asset+block@MCQs For HO SDH New WBCS 2nd SM 2nd Class Constitution QSourin bisalNo ratings yet

- P I P: A M ': Ostponement OF Ssue OF Rocess Agistrate S DiscretionDocument22 pagesP I P: A M ': Ostponement OF Ssue OF Rocess Agistrate S DiscretionRadhika SharmaNo ratings yet

- The B61 Family of BombsDocument3 pagesThe B61 Family of BombsMermaczNo ratings yet

- War by Luigi PirandelloDocument3 pagesWar by Luigi PirandelloAlfredo Colombos LuluNo ratings yet

- Spanish Colonial Literature: Survey of Philippine Lit. Reviewer - MidtermDocument3 pagesSpanish Colonial Literature: Survey of Philippine Lit. Reviewer - MidtermHazel GeronimoNo ratings yet

- Modesty, Body Image & Why I'm Joining NYC Bodypainting DayDocument3 pagesModesty, Body Image & Why I'm Joining NYC Bodypainting DayNashFloyd00No ratings yet

- Brazeal (2014) - History of Emerald Mining in ColombiaDocument11 pagesBrazeal (2014) - History of Emerald Mining in ColombiaMaicolBravoNo ratings yet

- English4U: Adjective or Adverb 1Document4 pagesEnglish4U: Adjective or Adverb 1Chandra GunawanNo ratings yet

- Online Safeguarding GuidelinesDocument6 pagesOnline Safeguarding GuidelineshodmezevasarheljNo ratings yet

- Philip Agee & Louis Wolf - Dirty Work (1978)Document316 pagesPhilip Agee & Louis Wolf - Dirty Work (1978)Henry HallNo ratings yet

- Macalintal vs. Teh DigestDocument5 pagesMacalintal vs. Teh DigestAdrianne BenignoNo ratings yet

- Uy vs. Puzon GR No. L-19819, October 26, 1977Document1 pageUy vs. Puzon GR No. L-19819, October 26, 1977SHARIEF ABBAS ABANTASNo ratings yet

- Summary of Arguments StarDocument2 pagesSummary of Arguments StarSuhani ChanchlaniNo ratings yet

- Ansari v. Pahlavi, 4th Cir. (1997)Document11 pagesAnsari v. Pahlavi, 4th Cir. (1997)Scribd Government DocsNo ratings yet

- United States v. Gonzalez-Bartolo, 10th Cir. (2005)Document4 pagesUnited States v. Gonzalez-Bartolo, 10th Cir. (2005)Scribd Government DocsNo ratings yet

- Biography of His Excellency President HIFIKEPUNYE POHAMBADocument2 pagesBiography of His Excellency President HIFIKEPUNYE POHAMBAMilton Louw100% (1)

- San Pablo Manufacturing Corp V CirDocument2 pagesSan Pablo Manufacturing Corp V CirCai CarpioNo ratings yet

- When I'm With My Baby, YeahDocument6 pagesWhen I'm With My Baby, YeahMary Carmen Ruiz ReyesNo ratings yet

- Fraud and MisrepresentationDocument32 pagesFraud and MisrepresentationFreya Mehmeen0% (1)

- Boarding PassDocument1 pageBoarding PassKavitha K ReddyNo ratings yet

- Akira 033Document69 pagesAkira 033Ocre OcreNo ratings yet

- Arbitration Case Between The Philippines and China Under The United Nations Convention On The Law of The Sea (UNCLOS)Document29 pagesArbitration Case Between The Philippines and China Under The United Nations Convention On The Law of The Sea (UNCLOS)Anthia Aille BolagaoNo ratings yet

- Project 4ed - Level 4 - Photocopiable Activities - Unit 4Document8 pagesProject 4ed - Level 4 - Photocopiable Activities - Unit 4Lu NaNo ratings yet

- 06-25-14 Speaker Memo To House Members On Separation of PowersDocument2 pages06-25-14 Speaker Memo To House Members On Separation of PowersfrankthorpNo ratings yet

- Stacon Case DigestDocument5 pagesStacon Case DigestRICKY ALEGARBESNo ratings yet