Professional Documents

Culture Documents

Laboratory Manual RCD 2

Laboratory Manual RCD 2

Uploaded by

Qasim TareenCopyright:

Available Formats

You might also like

- Steel Design ThesisDocument5 pagesSteel Design Thesiszuhemad0g0n3100% (2)

- CE134P ESCRUZ SyllabusDocument5 pagesCE134P ESCRUZ SyllabusAsa KaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- CTHM Lab Manual MistDocument71 pagesCTHM Lab Manual MistSyed HabeebNo ratings yet

- 15CV51 NOTES Vtu BelDocument77 pages15CV51 NOTES Vtu BelRavishankar HobannaNo ratings yet

- 18CVL38 (BMT)Document95 pages18CVL38 (BMT)AkshaynkNo ratings yet

- PSC Course File 2023-24Document35 pagesPSC Course File 2023-24raghuramreddy368No ratings yet

- Dhanalakshmi College of EngineeringDocument70 pagesDhanalakshmi College of EngineeringAkshay BhagatNo ratings yet

- Counterfort Retaining Wall PDFDocument75 pagesCounterfort Retaining Wall PDFMuralikrishna BaduruNo ratings yet

- Programme: Civil Engineering: Government College of Engineering, KaradDocument50 pagesProgramme: Civil Engineering: Government College of Engineering, KaradRohit SharmaNo ratings yet

- 18cvl38 - BMT Lab - ManualDocument79 pages18cvl38 - BMT Lab - Manualshaik saifulla lNo ratings yet

- Fitting ManualDocument72 pagesFitting Manualayush bindalNo ratings yet

- Thesis Reinforced Concrete StructureDocument5 pagesThesis Reinforced Concrete Structurejencloudcleveland100% (2)

- 17CV72 - DRSS - NotesDocument57 pages17CV72 - DRSS - Notes2BL19CV065- ROJA MUJAWAR -ANo ratings yet

- B Som and FM Lab ManualDocument101 pagesB Som and FM Lab ManualGANESH GOMATHINo ratings yet

- 06-Design Studio-II-LC-MTSE-202Document1 page06-Design Studio-II-LC-MTSE-202Vijay Baradiya IPS AcademyNo ratings yet

- Course File SOM-IDocument11 pagesCourse File SOM-IKashyap ChintuNo ratings yet

- Strength of Materials Lab (MME 2271) : Manipal Institute of Technology ManipalDocument102 pagesStrength of Materials Lab (MME 2271) : Manipal Institute of Technology ManipalOm RanjalkarNo ratings yet

- Research Papers On Steel StructuresDocument4 pagesResearch Papers On Steel Structuresjuzel0zupis3100% (1)

- Bus Stop Steel FinalDocument33 pagesBus Stop Steel FinalanuarNo ratings yet

- MottramJTStructEngr896201123 27Document15 pagesMottramJTStructEngr896201123 27jose mauricio muñoz bolivarNo ratings yet

- Thesis MetalDocument7 pagesThesis MetalWriteMyApaPaperCanada100% (2)

- DRCE NotesDocument127 pagesDRCE NotesAyush GargNo ratings yet

- Design and Drawing of Steel Steructures (15A01602) : Vemu Institute of TechnologyDocument95 pagesDesign and Drawing of Steel Steructures (15A01602) : Vemu Institute of Technologysoumyadeba04No ratings yet

- MSC Project Draft ReportDocument70 pagesMSC Project Draft ReportDavid LeeNo ratings yet

- Reinforced Concrete Structures I Course Outline 2016Document2 pagesReinforced Concrete Structures I Course Outline 2016muitefaNo ratings yet

- Steel Structure ThesisDocument8 pagesSteel Structure Thesisdeniseenriquezglendale100% (2)

- Structural Engineering Thesis PDFDocument5 pagesStructural Engineering Thesis PDFOrderPapersOnlineCanada100% (2)

- Dissertation Topics in Geotechnical EngineeringDocument4 pagesDissertation Topics in Geotechnical EngineeringPayToWritePaperCanada100% (1)

- ST4212-Structural Design Studio LaboratoryDocument78 pagesST4212-Structural Design Studio LaboratoryVICTORYSUBIKSHI100% (1)

- Proceedings 49 00166Document6 pagesProceedings 49 00166maximNo ratings yet

- 4th Sem Milling MachineDocument32 pages4th Sem Milling MachineKaran KantiNo ratings yet

- Structural Engineering Dissertation IdeasDocument7 pagesStructural Engineering Dissertation IdeasPayForAPaperKansasCity100% (1)

- 6th Sem Milling MachineDocument41 pages6th Sem Milling MachineIshan VermaNo ratings yet

- Workshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadDocument28 pagesWorkshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadECE 33 Sahil ManglaNo ratings yet

- Chapter 0 ContentDocument6 pagesChapter 0 ContentbsitlerNo ratings yet

- NotesDocument97 pagesNotesSubalakshmi PNo ratings yet

- Cad Lab Manual Mtech To B EditedDocument28 pagesCad Lab Manual Mtech To B EditedSagarNo ratings yet

- 2013 Unit Guide ENG1020 ClaytonDocument20 pages2013 Unit Guide ENG1020 ClaytonJames McCutchan100% (1)

- CTDocument28 pagesCTsainathNo ratings yet

- Steel Design HomeworkDocument6 pagesSteel Design Homeworkafnofghmameqww100% (1)

- Research Paper Topics Structural EngineeringDocument4 pagesResearch Paper Topics Structural Engineeringpntrxjwgf100% (1)

- Ce 333Document4 pagesCe 333binoNo ratings yet

- Basic Material Testing Laboratory ManualDocument33 pagesBasic Material Testing Laboratory Manualradhe shyamNo ratings yet

- Steel ThesisDocument7 pagesSteel Thesisnibaditapalmerpaterson100% (2)

- 1st & 2nd Sem Manual 2022Document33 pages1st & 2nd Sem Manual 2022Dipanshu KumarNo ratings yet

- Prediction of Time-Dependent Deformations in Post-Tensioned Concrete Suspended Beams and Slabs in Tall Buildings (T.jayaSINGHE (2011) )Document304 pagesPrediction of Time-Dependent Deformations in Post-Tensioned Concrete Suspended Beams and Slabs in Tall Buildings (T.jayaSINGHE (2011) )Micheline CousinNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityParesh NimodiyaNo ratings yet

- Part 3Document5 pagesPart 3bernardNo ratings yet

- ENG2032-N ICA 2023-24 FinalDocument7 pagesENG2032-N ICA 2023-24 FinalSajid MehmoodNo ratings yet

- Mtech Stru 19 20Document37 pagesMtech Stru 19 20Dhirendra YadavNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3Guvhvjv uguugNo ratings yet

- A Laboratory For Non Destructive Evaluation of Civil StructuresDocument13 pagesA Laboratory For Non Destructive Evaluation of Civil StructuresAfric WareNo ratings yet

- Design of Steel StructuresDocument8 pagesDesign of Steel StructuresNandana RajeevNo ratings yet

- SCIA1203Document392 pagesSCIA1203Issac Jasmin100% (1)

- Durability Design of Concrete Structures - Part 2: Modelling and Structural AssessmentDocument22 pagesDurability Design of Concrete Structures - Part 2: Modelling and Structural AssessmentnemanjakokoNo ratings yet

- Dokumen - Tips - Tince2016 Steel Concrete Modules in Civil Work Design of Future Nuclear PowerDocument12 pagesDokumen - Tips - Tince2016 Steel Concrete Modules in Civil Work Design of Future Nuclear Power김현우No ratings yet

- Arp 502 BMCDocument26 pagesArp 502 BMCAditi GuptaNo ratings yet

- Structural Design and Reliability Benchmark Study: Milan Holicky Joerg SchneiderDocument10 pagesStructural Design and Reliability Benchmark Study: Milan Holicky Joerg SchneiderPrecise Material Testing LtdNo ratings yet

- 3D Relieving EffectDocument2 pages3D Relieving Effectbad guy100% (1)

- Manual Leakage CostDocument1 pageManual Leakage CostakitainupufNo ratings yet

- Sumande - Field Work No.2 - Taping On Level and On Uneven Ground (Revised)Document12 pagesSumande - Field Work No.2 - Taping On Level and On Uneven Ground (Revised)Cedrix SumandeNo ratings yet

- Stress-Strain Response of Wood Under Radial Compression. Part Test Method and Influences of Cellular PropertiesDocument9 pagesStress-Strain Response of Wood Under Radial Compression. Part Test Method and Influences of Cellular PropertiesKerby Brylle GawanNo ratings yet

- Vulnerability Assessment of Lifelines and Essential Facilities (WP06) : Methodological HandbookDocument35 pagesVulnerability Assessment of Lifelines and Essential Facilities (WP06) : Methodological HandbookJuan Carlos Jiménez PachecoNo ratings yet

- Mow VC Huiskes RBasic Orthopaedic Biomechanics and PDFDocument1 pageMow VC Huiskes RBasic Orthopaedic Biomechanics and PDFMada MihaelaNo ratings yet

- Legal Medicine: K.-S. Saternus, H. Maxeiner, G. Kernbach-Wighton, J. KoebkeDocument6 pagesLegal Medicine: K.-S. Saternus, H. Maxeiner, G. Kernbach-Wighton, J. KoebkeEolia EffendiNo ratings yet

- Fundamentals OF Movement Skills V Fundamental Movement SkillsDocument6 pagesFundamentals OF Movement Skills V Fundamental Movement SkillsCharmaine JanorasNo ratings yet

- Design and Analysis of Air Conditioning System For An IT Office BuildingDocument6 pagesDesign and Analysis of Air Conditioning System For An IT Office BuildingVIVA-TECH IJRINo ratings yet

- Physics of Holography: Plane WavefrontsDocument2 pagesPhysics of Holography: Plane WavefrontsRemya R. KumarNo ratings yet

- Hardened Concrete and Methods of Testing NhangaDocument8 pagesHardened Concrete and Methods of Testing NhangaShepherd NhangaNo ratings yet

- Electrical Engineering QuestionsDocument3 pagesElectrical Engineering QuestionsPrem Sunder GNo ratings yet

- Production of Aluminum-Silicon Carbide Composites Using Powder Metallurgy at Sintering Temperatures Above The Aluminum Melting PointDocument13 pagesProduction of Aluminum-Silicon Carbide Composites Using Powder Metallurgy at Sintering Temperatures Above The Aluminum Melting PointMustafa Levent SipahiNo ratings yet

- Solar Energy Potential in Nepal and Global Context: Tuta/Ioe/PcuDocument12 pagesSolar Energy Potential in Nepal and Global Context: Tuta/Ioe/PcuJuju R ShakyaNo ratings yet

- Cac Bai Bao Khoa Hoc 2007-2012 (Phan II CUNG CAP DIEN)Document120 pagesCac Bai Bao Khoa Hoc 2007-2012 (Phan II CUNG CAP DIEN)EngineeringNo ratings yet

- Amaerule 1988Document37 pagesAmaerule 1988Andres CaNo ratings yet

- Optocouplers Hand Book 2006Document26 pagesOptocouplers Hand Book 2006onurinciNo ratings yet

- Chapter 6 - Tutorial 11Document11 pagesChapter 6 - Tutorial 11kwong hkNo ratings yet

- Design of PID Controller For The Modified Quadruple-Tank Process Using Inverted Decoupling TechniqueDocument5 pagesDesign of PID Controller For The Modified Quadruple-Tank Process Using Inverted Decoupling TechniqueMAURY SEBASTIAN MACIAS SANCHEZNo ratings yet

- Questioned DocumentsDocument7 pagesQuestioned Documentsjoy LoretoNo ratings yet

- Principles of Structural Analysis and DesignDocument1 pagePrinciples of Structural Analysis and DesigngellianforniasNo ratings yet

- Z TransformDocument15 pagesZ TransformSureshKumarNo ratings yet

- Detector History Rev3Document6 pagesDetector History Rev3Byu PutraNo ratings yet

- Stabilizing or Tertiary Winding PurposeDocument3 pagesStabilizing or Tertiary Winding Purposeమాచర్ల రవీంద్ర నాథ్No ratings yet

- UBC Guide To BearingsDocument44 pagesUBC Guide To BearingsVirgilioNo ratings yet

- Cat OptoNCDT en UsDocument40 pagesCat OptoNCDT en UsDaniel FredianiNo ratings yet

- Surge Arrester General (IN) English PDFDocument16 pagesSurge Arrester General (IN) English PDFBalan PalaniappanNo ratings yet

- Daftar PustakaDocument4 pagesDaftar Pustakapuja gladwellNo ratings yet

- Ion Exghange PDFDocument306 pagesIon Exghange PDFAhoud AlhaimliNo ratings yet

- Semaphore Contact IndicatorsDocument2 pagesSemaphore Contact IndicatorsAshish JainNo ratings yet

Laboratory Manual RCD 2

Laboratory Manual RCD 2

Uploaded by

Qasim TareenOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laboratory Manual RCD 2

Laboratory Manual RCD 2

Uploaded by

Qasim TareenCopyright:

Available Formats

Laboratory Manual

Reinforced Concrete Design 2

(CIVILE-403L)

FALL 2023

Department of Civil Engineering

Balochistan University of Information Technology Engineering

& Management Sciences, Quetta

Reinforced Concrete Design-2 Lab Fall-23

Laboratory Certificate

This is Certified that Mr./Mrs. …………………….…… of Civil Engineering department having

CMS ID ……………… has carried out the necessary lab experiments during the year 20__ .

Name of Instructor. _____________________________

Signature of Instructor. _____________________________

Department of Civil Engineering, BUITEMS Page 2

Reinforced Concrete Design-2 Lab Fall-23

DEPARTMENT MISSION

To produce highly competent professionals of high ethical values, enabling them for executive

positions in civil engineering, higher studies in prestigious universities, life-long learning, and

societal leadership. Also, to provide a dynamic learning environment that emphasizes openended

design, problem-solving skills, teamwork, communication, promote cutting edge research and

leadership skills.

PROGRAM EDUCATIONAL OBJECTIVES

PEO-1: Graduates will have the essential knowledge and possess adequate civil engineering

skills.

PEO-2: Graduates will be able to establish/build themselves as civil engineering professionals

and develop expertise through lifelong learning.

PEO-3: Graduates will be able to pursue research and higher studies at prestigious universities.

PEO-4: Graduates will be able to work effectively as responsible professionals of high ethical

values independently or in teams.

PROGRAM LEARNING OBJECTIVES

PLO-01: Engineering Knowledge: Ability to apply knowledge of mathematics, science and

engineering fundamentals and an engineering specialization to the solution of complex

engineering problems.

PLO-02: Problem Analysis: Ability to identify, formulate, research literature, and analyze

complex engineering problems reaching substantiated conclusions using first principles

of mathematics, natural sciences and engineering sciences.

PLO-03: Design/Development of Solutions: Ability to design solutions for complex engineering

problems and design systems, components, or processes that meet specified needs with

appropriate consideration for public health and safety, cultural, societal, and

environmental considerations.

Department of Civil Engineering, BUITEMS Page 3

Reinforced Concrete Design-2 Lab Fall-23

PLO-04: Investigation: Ability to investigate complex engineering problems in a methodical

way including literature survey, design and conduct of experiments, analysis and

interpretation of experimental data, and synthesis of information to derive valid

conclusions.

PLO-05: Modern Tool Usage: Ability to create, select and apply appropriate techniques,

resources, and modern engineering and IT tools, including prediction and modeling, to

complex engineering activities, with an understanding of the limitations.

PLO-06: The Engineer and Society: Ability to apply reasoning informed by contextual

knowledge to assess societal, health, safety, legal and cultural issues and the consequent

responsibilities relevant to professional engineering practice and solution to complex

engineering problems.

PLO-07: Environment and Sustainability: Ability to understand the impact of professional

engineering solutions in societal and environmental contexts, demonstrate knowledge

of, and need for sustainable development.17

PLO-08: Ethics: Apply ethical principles and commit to professional ethics and responsibilities

and norms of engineering practice.

PLO-09: Individual and Team Work: Ability to work effectively, as an individual or in a team,

on multifaceted and/or multidisciplinary settings.

PLO-10: Communication: Ability to communicate effectively, orally as well as in writing on

complex engineering activities with the engineering community and with society at

large, such as being able to comprehend and write effective reports and design

documentations, make effective presentations, and give and receive clear instructions.

PLO-11: Project Management: Ability to demonstrate management skills and apply engineering

principles to one’s own work, as a member and/or leader in a team to manage projects

in a multidisciplinary environment.

PLO-12: Lifelong Learning: Ability to recognize importance of and pursue lifelong learning in

the broader context of innovation and technological developments.

Department of Civil Engineering, BUITEMS Page 4

Reinforced Concrete Design-2 Lab Fall-23

PROGRAM SPECIFIC OUTCOMES

PLO-09: Individual and Team Work: Ability to work effectively, as an individual or in a team,

on multifaceted and/or multidisciplinary settings.

PLO-10: Communication: Ability to communicate effectively, orally as well as in writing on

complex engineering activities with the engineering community and with society at

large, such as being able to comprehend and write effective reports and design

documentations, make effective presentations, and give and receive clear instructions.

COURSE LEARNING OUTCOMES

CLO-01: PERFORM and PRACTISE the experiments related to the subject (Domain:

Psychomotor and Taxonomy Level 3).

CLO-02: FORMULATE and ORGANIZE experimental data (Domain: Affective and

Taxonomy Level 4).

CLO-03: PARTICIPATE in lab activities and COMPLY with the instructions (Domain:

Affective and Taxonomy Level 2).

Department of Civil Engineering, BUITEMS Page 5

Reinforced Concrete Design-2 Lab Fall-23

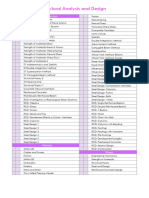

CONTENTS

S.no Name of Experiments Date Marks

To determine the tensile strength of steel

1.

(ASTM A 615-04)

2.

Bend test of steel bar

(ASTM A 615-04)

3.

Vickers hardness of metallic materials

(ASTM E92-82)

4.

Rebound number of hardened concretes

(ASTM C805-02)

5.

Pulse velocity through concrete

(ASTM C597 – 09)

6.

Penetration resistance of hardened concrete

ASTM C 803/C 803M

Department of Civil Engineering, BUITEMS Page 6

Reinforced Concrete Design-2 Lab Fall-23

TO DETERMINE THE TENSILE STRENGTH OF STEEL

(ASTM A 615-04)

Objective:

The objective of this lab experiments is to incrementally load a steel bar till failure, while recording

the value of the load and the change in length of the steel bar at each stage. Then based on the

collected data, determine:

1. Modulus of Elasticity of Steel & Compare it to the theoretical value.

2. Yield strength of Steel, σ yield

3. Ultimate strength of steel, σ Ultimate

4. Plot Stress Vs Strain Curve for steel

Apparatus:

1. Universal testing machine with accessories

2. Vernier calipers.

3. Scale.

4. Weight balance

Theory:

The most common material in construction besides concrete is steel. Concrete, though it has a high

compressive strength, its tensile strength is usually much lower and mounts up to 8 – 12 % of its

compressive strength. Steel, therefore, is used in concrete structural elements to bare tensile loads

and bending moments.

The major components of steel are Iron and carbon which ranges between 0.01 and 1 percent.

Sulfur, phosphorus, manganese, silicon and as much as 20 other alloys are present in steel and are

added in various quantities to steel during its manufacturing process depending on the desired

hardness, toughness, and tensile strength of steel. Reinforcing steel bars are usually manufactured

in 3 different forms:

• Plain bars

• Deformed bars

• Plain & deformed wires

Figure 1: Plain Bars Figure 2: Deformed Bars Figure 3: Plain & Deformed wires

Department of Civil Engineering, BUITEMS Page 7

Reinforced Concrete Design-2 Lab Fall-23

The deformation in deformed steel bars is intended to increase the bonding between steel and

concrete and to prevent slippage of the steel reinforcement bars Steel reinforcement bars are

produced mainly with three different yield strengths, shown in the table below. The grade of steel

indicates its yield strength in Ksi.

Reinforcement Steel Strength

Table 1: Grades of steel.

Grade σ yield (psi) σ yield (MPa)

40 40,000 300

60 60,000 400

75 75,000 500

Procedure:

1. Load a Steel bar into the Universal testing machine, with 18” length of steel between the

testing machine clamps.

2. Start the machine and apply load at constant rate.

3. At failure notice the tip & cone failure mode of the steel bar.

Note: Possible source of error; Slipping of the steel at the testing machine grips.

Department of Civil Engineering, BUITEMS Page 8

Reinforced Concrete Design-2 Lab Fall-23

Graph:

Observations and Calculations:

Department of Civil Engineering, BUITEMS Page 9

Reinforced Concrete Design-2 Lab Fall-23

BEND TEST OF STEEL BAR

(ASTM A 615-04)

Objective:

1. The bending test of reinforcement steel is performed to verify that steel ductility and to

ensure that no fracture or cracks will occur during the bending.

2. The steel bars are bent to form a specific shape such as shear stirrups, L-bars, and other

shapes. therefore, steel should have sufficient ductility to enable the bending of

reinforcement bars without affecting the steel strength

Apparatus:

1. Universal testing machine with accessories

2. Weight balance

3. Scale

Theory:

Bending Requirements:

The bend-test specimen shall withstand being bent around a pin without cracking on the outside

radius of the bent portion. When material is furnished in coils, the test sample shall be straightened

prior to placing it in the bend tester.

The bend test shall be made on specimens of sufficient length to ensure free bending and with

apparatus which provides:

• Continuous and uniform application of force throughout the duration of the bending

operation.

• Unrestricted movement of the specimen at points of contact with the apparatus and bending

around a pin free to rotate.

• Close wrapping of the specimen around the pin during the bending operation.

• It is permissible to use more severe methods of bend testing, such as placing a specimen

across two pins free to rotate and applying the bending force with a fixed pin.

Figure 4: Bend test assembly.

Department of Civil Engineering, BUITEMS Page 10

Reinforced Concrete Design-2 Lab Fall-23

The reinforcing steel may fracture or crack due to the following reasons:

• The ribs of steel are a location of concentrated stress, and it is considered as a weak point.

these locations may fracture if steel bends.

• The steel possesses high strength. Therefore, a larger force is required to bend steel, and

this could cause steel to crack.

• Also, the radius of bending the reinforcement, smaller radius of bending will have a greater

adverse effect on reinforcement steel.

• The low temperature playing an important role in reducing the steel bar’s toughness, and

this may result in bars cracking or fracture if bent.

Procedure:

1. Fix the third point loading assembly on UTM for bending

2. Place the specimen of steel correctly.

3. Start the test with continuous and uniform application of force.

4. Bend the steel bar till the desired deformation.

5. After performing the bending test, the convex surface of the tested bar should be checked

by the unaided eye to identify any cracks or fractures.

Observations and Calculations:

Department of Civil Engineering, BUITEMS Page 11

Reinforced Concrete Design-2 Lab Fall-23

VICKERS HARDNESS OF METALLIC MATERIALS

(ASTM E92-82)

Objective:

This test method covers the determination of the Vickers hardness of metallic materials, using

applied loads of 1 kgf to 120 kgf.

Apparatus:

1. Testing Machine

2. Indenter

3. Measuring Microscope

Theory:

An indentation hardness test using calibrated machines to force a square-based pyramidal diamond

indenter having specified face angles, under a predetermined load, into the surface of the material

under test and to measure the diagonals of the resulting impression after removal of the load.

Vickers hardness tests are made at test loads of 1 kgf to 120 kgf.

Vickers hardness number HV:

A number related to the applied load and the surface area of the permanent impression made by a

square-based pyramidal diamond indenter having included face angles of 136*.

Test Specimen

The Vickers hardness test is adaptable to a wide variety of test specimens ranging from large bars

and rolled sections to minute pieces in metallographic mounts

• Thickness

The thickness of the test specimen shall be such

that no bulge or marking showing the effect of

the force appears on the side of the specimen

opposite the impression. In any event, the

thickness of the specimen shall be at least one-

and one-half times the length of the diagonal.

• Finish

The surface of the specimen should be so

prepared that the ends of the diagonals are

clearly defined and can be read with the

precision of ± 0.0005 mm or ± 0.5 % of the

length of the diagonals, whichever is larger.

Care should be taken in specimen preparation to

avoid tempering during grinding, or work-

hardening the surface during polishing. Figure 5: Vickers hardness indenter.

Department of Civil Engineering, BUITEMS Page 12

Reinforced Concrete Design-2 Lab Fall-23

Procedure:

1. Magnitude of Test Force

Test forces of 1 kgf to 120 kgf may be used, depending on the requirements of the test.

Although tests on homogeneous materials indicate that the Vickers hardness number is

nearly independent of the test force, this condition will not be present in cases where there

is a hardness gradient from the specimen surface to the interior of the specimen. The

magnitude of the test force should therefore be stated in the test report.

2. Application of Test Force

Apply the test force and release smoothly without shock or vibration. The time of

application of the full test force shall be 10 to 15 sec unless otherwise specified.

3. Spacing of Indentations

The center of the impression shall not be closer to any edge of the test specimen or to

another impression than a distance equal to two- and one-half times the length of the

diagonal of the impression. When laminated material is tested, a bond surface shall be

considered as an edge for spacing of indentation calculation.

Calculation:

HV = 1.854 (F/D2)

F = Applied load (kilograms-force).

D = Mean diagonal of impression, mm.

Department of Civil Engineering, BUITEMS Page 13

Reinforced Concrete Design-2 Lab Fall-23

Observations and Calculations:

Department of Civil Engineering, BUITEMS Page 14

Reinforced Concrete Design-2 Lab Fall-23

REBOUND NUMBER OF HARDENED CONCRETE

(ASTM C805-02)

Objective:

This test method covers the determination of a rebound number of hardened concretes using a

spring-driven steel hammer.

Apparatus:

1. Rebound hammer.

2. Abrasive stone: consisting of medium-grain texture silicon carbide or equivalent material.

Theory:

This test is also known as the Schmidt hammer or impact hammer and is a non-destructive method

of testing concrete. The test is based on the principle that the rebound of an elastic mass depends

on the hardness of the surface against which the mass strikes. This test method is applicable to

assess the in-place uniformity of concrete, to delineate regions in a structure of poor quality or

deteriorated concrete, and to estimate in-place strength development.

For a given concrete mixture, the rebound number is affected by factors such as the moisture

content of the test surface, the method used to obtain the test surface (type of form material or type

of finishing), and the depth of carbonation. These factors need to be considered in preparing the

strength relationship and interpreting test results.

If more than one hammer is to be used, perform tests on a range of typical concrete surfaces to

determine the magnitude of the differences to be expected.

Figure 6: Spring-driven steel hammer.

Department of Civil Engineering, BUITEMS Page 15

Reinforced Concrete Design-2 Lab Fall-23

Selection of Test Surface:

Concrete members to be tested shall be at least 100 mm (4 in.) thick and fixed within a structure.

Smaller specimens must be rigidly supported. Avoid areas exhibiting honeycombing, scaling, or

high porosity. Do not compare test results if the form material against which the concrete was

placed is not similar. Troweled surfaces generally exhibit higher rebound numbers than screeded

or formed finishes. If possible, test structural slabs from the underside to avoid finished surfaces.

Concretes should be approximately the same age and moisture condition to be compared. Dry

concretes give higher rebound numbers than wet concrete, and the surface layer of concrete may

be carbonated, yielding higher rebound numbers.

Preparation of test surface:

A test area shall be at least150 mm (6 in.) in diameter. Heavily textured, soft, or surfaces with

loose mortar shall be ground flat with the abrasive stone. Smooth-formed or troweled surfaces do

not have to be ground prior to testing. Do not compare results from ground and unground surfaces.

In cases of a thick layer of carbonated concrete, it may be necessary to remove the carbonated

layer in the test area, using a power grinder, to obtain rebound numbers that are representative of

the interior concrete. Data are not available on the relationship between rebound number and

thickness of carbonated concrete. The user must exercise professional judgment when testing

carbonated concrete. Do not test frozen concrete.

Procedure:

1- Firmly hold the instrument in a position that allows the plunger to strike perpendicularly

to the surface tested. Gradually increase the pressure on the plunger until the hammer

impacts.

2- After impact, record the rebound number to two significant figures.

3- Take ten readings from each test area. No two impact tests shall be closer together than 25

mm.

Calculation:

Discard readings differing from the average of 10 readings by more than 6 units and determine the

average of the remaining readings. If more than 2 readings differ from the average by 6 units,

discard the entire set of readings.

Table 2: Quality of concrete based on rebound number.

Department of Civil Engineering, BUITEMS Page 16

Reinforced Concrete Design-2 Lab Fall-23

Observations and Calculations:

Department of Civil Engineering, BUITEMS Page 17

Reinforced Concrete Design-2 Lab Fall-23

PULSE VELOCITY THROUGH CONCRETE

(ASTM C597 – 09)

Objective:

This test method covers the determination of the propagation velocity of longitudinal stress wave

pulses through concrete.

Apparatus:

1. The testing apparatus consists of a pulse generator, a pair of transducers (transmitter and

receiver), an amplifier, a time measuring circuit, a time display unit, and connecting cables.

2. Scale

3. Coupling agent

Theory:

This test is done to assess the quality of concrete by ultrasonic pulse velocity method.

The method consists of measuring the time of travel of an ultrasonic pulse passing through the

concrete being tested. Comparatively higher velocity is obtained when concrete quality is good in

terms of density, uniformity, homogeneity etc.

This test method is applicable to assess the uniformity and relative quality of concrete, to indicate

the presence of voids and cracks, and to evaluate the effectiveness of crack repairs. It is also

applicable to indicate changes in the properties of concrete, and in the survey of structures, to

estimate the severity of deterioration or cracking.

Figure 7: Illustration of UPV test setup.

Department of Civil Engineering, BUITEMS Page 18

Reinforced Concrete Design-2 Lab Fall-23

Procedure:

1. Verify that the equipment is operating properly and perform a zero-time adjustment.

2. Apply the coupling agent to the transducer faces and press the faces together. The

instrument uses a microprocessor to record this delay time, which is subtracted

automatically from subsequent transit time measurements.

3. For testing existing construction, select test locations

4. For best results, locate the transducers directly opposite each other. Because the beam

width of the vibrational pulses emitted by the transducers is large, it is permissible to

measure transit times across corners of a structure but with some loss of sensitivity and

accuracy. Measurements along the same surface shall not be used unless only one face of

the structure is accessible.

5. Apply an appropriate coupling agent (such as water, oil, petroleum jelly, grease, moldable

rubber, or other viscous materials) to the transducer faces or the test surface, or both. Press

the faces of the transducers firmly against the surfaces of the concrete until a stable transit

time is displayed and measure the transit time. Determine the straight-line distance between

centers of transducer faces.

Calculations:

Calculate the pulse velocity as follows:

V=L/T

Where:

V= pulse velocity, km/s

L= distance between transducers, mm

T= transit time, µs

Table 3: Quality of concrete based on Pulse velocity.

PULSE

CONCRETE QUALITY

VELOCITY

>4.0 km/s Very good to excellent

Good to very good, slight porosity may

3.5 – 4.0 km/s

exist

Satisfactory but loss of integrity is

3.0 – 3.5 km/s

suspected

<3.0 km/s Poor and los of integrity exist.

Department of Civil Engineering, BUITEMS Page 19

Reinforced Concrete Design-2 Lab Fall-23

Observations and Calculations:

Department of Civil Engineering, BUITEMS Page 20

Reinforced Concrete Design-2 Lab Fall-23

PENETRATION RESISTANCE OF HARDENED CONCRETE

ASTM C 803/C 803M

Objective:

This test method covers the determination of the resistance of hardened concrete to penetration by

either a steel probe or pin.

Apparatus:

1. Driver unit (Windsor pin system)

2. Steel probe/ pin

3. Measuring instrument (caliper, gauge)

Theory:

A driver delivers a known amount of energy to either a steel probe or pin. The penetration

resistance of the concrete is determined by measuring either the exposed lengths of probes that

have been driven into the concrete or by measuring the depth of the holes created by the penetration

of the pins into the concrete.

This test method is applicable to estimate in-place strength, provided that a relationship has been

experimentally established between penetration resistance and concrete strength. A spring-

actuated driver unit with a spring stiffness of 49.7 kN/m [284 lb/in.] has been successfully used to

test concrete with strength in the range of 3 to 28 MPa [450 to 4000 psi].

Figure 8: Windsor pin system.

Department of Civil Engineering, BUITEMS Page 21

Reinforced Concrete Design-2 Lab Fall-23

Procedure:

1. Insert a new pin into the chuck.

2. Tighten the loading nut until the trigger mechanism latch closes to hold the spring in place.

3. It is very important to back off the loading nut completely to the top of the load screw

before pulling trigger. Failure to do so will result in damage to the threads of both nut and

spindle.

4. Place the instrument on a smooth flat surface of the material to be tested (2-3 square

inches). If necessary, use a grindstone to prepare the surface.

5. Place the instrument perpendicular to the test surface and pull the trigger. The instrument

should be held firmly against the surface, particularly when testing vertical walls and

ceilings.

6. With the chuck removed, the V-shaped barrel can be inserted directly into the mortar joint

ensuring pin penetration at its center.

7. Remove the instrument, then using the rubber bulb-type blower, clean out the small hole

made in the material surface.

8. Place the micrometer over the hole, making sure that the reference surface of the

micrometer is flat on the material (For measuring mortar joints, the micrometer utilizes a

V-shaped barrel similar to the pin driver.)

9. Insert micrometer probe to the bottom of the hole using the knurled thimble on the head of

the micrometer.

10. Read and note the micrometer reading. Remove chuck to expose V-Shaped barrel if

measuring in a mortar joint.

11. After each strike, check the steel pin in the go/no-go gauge provided - located in the plastic

box containing 40 steel pins. If the pin can easily pass through the slot in the gauge, or it

appears too blunt, it should be discarded and a new one selected. (Note) When checking

the length of a used pin, make sure that it is parallel to the surface of the gauge.

12. Repeat the above procedure seven times and reject the two readings farthest from the mean.

13. Average the five best remaining point readings and, using the charts provided, look up the

corresponding compressive strength. If the pin is too blunt or too short, the strength of the

material can be considerably overstated.

Department of Civil Engineering, BUITEMS Page 22

Reinforced Concrete Design-2 Lab Fall-23

Observations and Calculations:

Department of Civil Engineering, BUITEMS Page 23

You might also like

- Steel Design ThesisDocument5 pagesSteel Design Thesiszuhemad0g0n3100% (2)

- CE134P ESCRUZ SyllabusDocument5 pagesCE134P ESCRUZ SyllabusAsa KaNo ratings yet

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- CTHM Lab Manual MistDocument71 pagesCTHM Lab Manual MistSyed HabeebNo ratings yet

- 15CV51 NOTES Vtu BelDocument77 pages15CV51 NOTES Vtu BelRavishankar HobannaNo ratings yet

- 18CVL38 (BMT)Document95 pages18CVL38 (BMT)AkshaynkNo ratings yet

- PSC Course File 2023-24Document35 pagesPSC Course File 2023-24raghuramreddy368No ratings yet

- Dhanalakshmi College of EngineeringDocument70 pagesDhanalakshmi College of EngineeringAkshay BhagatNo ratings yet

- Counterfort Retaining Wall PDFDocument75 pagesCounterfort Retaining Wall PDFMuralikrishna BaduruNo ratings yet

- Programme: Civil Engineering: Government College of Engineering, KaradDocument50 pagesProgramme: Civil Engineering: Government College of Engineering, KaradRohit SharmaNo ratings yet

- 18cvl38 - BMT Lab - ManualDocument79 pages18cvl38 - BMT Lab - Manualshaik saifulla lNo ratings yet

- Fitting ManualDocument72 pagesFitting Manualayush bindalNo ratings yet

- Thesis Reinforced Concrete StructureDocument5 pagesThesis Reinforced Concrete Structurejencloudcleveland100% (2)

- 17CV72 - DRSS - NotesDocument57 pages17CV72 - DRSS - Notes2BL19CV065- ROJA MUJAWAR -ANo ratings yet

- B Som and FM Lab ManualDocument101 pagesB Som and FM Lab ManualGANESH GOMATHINo ratings yet

- 06-Design Studio-II-LC-MTSE-202Document1 page06-Design Studio-II-LC-MTSE-202Vijay Baradiya IPS AcademyNo ratings yet

- Course File SOM-IDocument11 pagesCourse File SOM-IKashyap ChintuNo ratings yet

- Strength of Materials Lab (MME 2271) : Manipal Institute of Technology ManipalDocument102 pagesStrength of Materials Lab (MME 2271) : Manipal Institute of Technology ManipalOm RanjalkarNo ratings yet

- Research Papers On Steel StructuresDocument4 pagesResearch Papers On Steel Structuresjuzel0zupis3100% (1)

- Bus Stop Steel FinalDocument33 pagesBus Stop Steel FinalanuarNo ratings yet

- MottramJTStructEngr896201123 27Document15 pagesMottramJTStructEngr896201123 27jose mauricio muñoz bolivarNo ratings yet

- Thesis MetalDocument7 pagesThesis MetalWriteMyApaPaperCanada100% (2)

- DRCE NotesDocument127 pagesDRCE NotesAyush GargNo ratings yet

- Design and Drawing of Steel Steructures (15A01602) : Vemu Institute of TechnologyDocument95 pagesDesign and Drawing of Steel Steructures (15A01602) : Vemu Institute of Technologysoumyadeba04No ratings yet

- MSC Project Draft ReportDocument70 pagesMSC Project Draft ReportDavid LeeNo ratings yet

- Reinforced Concrete Structures I Course Outline 2016Document2 pagesReinforced Concrete Structures I Course Outline 2016muitefaNo ratings yet

- Steel Structure ThesisDocument8 pagesSteel Structure Thesisdeniseenriquezglendale100% (2)

- Structural Engineering Thesis PDFDocument5 pagesStructural Engineering Thesis PDFOrderPapersOnlineCanada100% (2)

- Dissertation Topics in Geotechnical EngineeringDocument4 pagesDissertation Topics in Geotechnical EngineeringPayToWritePaperCanada100% (1)

- ST4212-Structural Design Studio LaboratoryDocument78 pagesST4212-Structural Design Studio LaboratoryVICTORYSUBIKSHI100% (1)

- Proceedings 49 00166Document6 pagesProceedings 49 00166maximNo ratings yet

- 4th Sem Milling MachineDocument32 pages4th Sem Milling MachineKaran KantiNo ratings yet

- Structural Engineering Dissertation IdeasDocument7 pagesStructural Engineering Dissertation IdeasPayForAPaperKansasCity100% (1)

- 6th Sem Milling MachineDocument41 pages6th Sem Milling MachineIshan VermaNo ratings yet

- Workshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadDocument28 pagesWorkshop Manual: J.C. Bose University of Science and Technology, Ymca, FaridabadECE 33 Sahil ManglaNo ratings yet

- Chapter 0 ContentDocument6 pagesChapter 0 ContentbsitlerNo ratings yet

- NotesDocument97 pagesNotesSubalakshmi PNo ratings yet

- Cad Lab Manual Mtech To B EditedDocument28 pagesCad Lab Manual Mtech To B EditedSagarNo ratings yet

- 2013 Unit Guide ENG1020 ClaytonDocument20 pages2013 Unit Guide ENG1020 ClaytonJames McCutchan100% (1)

- CTDocument28 pagesCTsainathNo ratings yet

- Steel Design HomeworkDocument6 pagesSteel Design Homeworkafnofghmameqww100% (1)

- Research Paper Topics Structural EngineeringDocument4 pagesResearch Paper Topics Structural Engineeringpntrxjwgf100% (1)

- Ce 333Document4 pagesCe 333binoNo ratings yet

- Basic Material Testing Laboratory ManualDocument33 pagesBasic Material Testing Laboratory Manualradhe shyamNo ratings yet

- Steel ThesisDocument7 pagesSteel Thesisnibaditapalmerpaterson100% (2)

- 1st & 2nd Sem Manual 2022Document33 pages1st & 2nd Sem Manual 2022Dipanshu KumarNo ratings yet

- Prediction of Time-Dependent Deformations in Post-Tensioned Concrete Suspended Beams and Slabs in Tall Buildings (T.jayaSINGHE (2011) )Document304 pagesPrediction of Time-Dependent Deformations in Post-Tensioned Concrete Suspended Beams and Slabs in Tall Buildings (T.jayaSINGHE (2011) )Micheline CousinNo ratings yet

- Gujarat Technological UniversityDocument3 pagesGujarat Technological UniversityParesh NimodiyaNo ratings yet

- Part 3Document5 pagesPart 3bernardNo ratings yet

- ENG2032-N ICA 2023-24 FinalDocument7 pagesENG2032-N ICA 2023-24 FinalSajid MehmoodNo ratings yet

- Mtech Stru 19 20Document37 pagesMtech Stru 19 20Dhirendra YadavNo ratings yet

- Gujarat Technological University: Page 1 of 3Document3 pagesGujarat Technological University: Page 1 of 3Guvhvjv uguugNo ratings yet

- A Laboratory For Non Destructive Evaluation of Civil StructuresDocument13 pagesA Laboratory For Non Destructive Evaluation of Civil StructuresAfric WareNo ratings yet

- Design of Steel StructuresDocument8 pagesDesign of Steel StructuresNandana RajeevNo ratings yet

- SCIA1203Document392 pagesSCIA1203Issac Jasmin100% (1)

- Durability Design of Concrete Structures - Part 2: Modelling and Structural AssessmentDocument22 pagesDurability Design of Concrete Structures - Part 2: Modelling and Structural AssessmentnemanjakokoNo ratings yet

- Dokumen - Tips - Tince2016 Steel Concrete Modules in Civil Work Design of Future Nuclear PowerDocument12 pagesDokumen - Tips - Tince2016 Steel Concrete Modules in Civil Work Design of Future Nuclear Power김현우No ratings yet

- Arp 502 BMCDocument26 pagesArp 502 BMCAditi GuptaNo ratings yet

- Structural Design and Reliability Benchmark Study: Milan Holicky Joerg SchneiderDocument10 pagesStructural Design and Reliability Benchmark Study: Milan Holicky Joerg SchneiderPrecise Material Testing LtdNo ratings yet

- 3D Relieving EffectDocument2 pages3D Relieving Effectbad guy100% (1)

- Manual Leakage CostDocument1 pageManual Leakage CostakitainupufNo ratings yet

- Sumande - Field Work No.2 - Taping On Level and On Uneven Ground (Revised)Document12 pagesSumande - Field Work No.2 - Taping On Level and On Uneven Ground (Revised)Cedrix SumandeNo ratings yet

- Stress-Strain Response of Wood Under Radial Compression. Part Test Method and Influences of Cellular PropertiesDocument9 pagesStress-Strain Response of Wood Under Radial Compression. Part Test Method and Influences of Cellular PropertiesKerby Brylle GawanNo ratings yet

- Vulnerability Assessment of Lifelines and Essential Facilities (WP06) : Methodological HandbookDocument35 pagesVulnerability Assessment of Lifelines and Essential Facilities (WP06) : Methodological HandbookJuan Carlos Jiménez PachecoNo ratings yet

- Mow VC Huiskes RBasic Orthopaedic Biomechanics and PDFDocument1 pageMow VC Huiskes RBasic Orthopaedic Biomechanics and PDFMada MihaelaNo ratings yet

- Legal Medicine: K.-S. Saternus, H. Maxeiner, G. Kernbach-Wighton, J. KoebkeDocument6 pagesLegal Medicine: K.-S. Saternus, H. Maxeiner, G. Kernbach-Wighton, J. KoebkeEolia EffendiNo ratings yet

- Fundamentals OF Movement Skills V Fundamental Movement SkillsDocument6 pagesFundamentals OF Movement Skills V Fundamental Movement SkillsCharmaine JanorasNo ratings yet

- Design and Analysis of Air Conditioning System For An IT Office BuildingDocument6 pagesDesign and Analysis of Air Conditioning System For An IT Office BuildingVIVA-TECH IJRINo ratings yet

- Physics of Holography: Plane WavefrontsDocument2 pagesPhysics of Holography: Plane WavefrontsRemya R. KumarNo ratings yet

- Hardened Concrete and Methods of Testing NhangaDocument8 pagesHardened Concrete and Methods of Testing NhangaShepherd NhangaNo ratings yet

- Electrical Engineering QuestionsDocument3 pagesElectrical Engineering QuestionsPrem Sunder GNo ratings yet

- Production of Aluminum-Silicon Carbide Composites Using Powder Metallurgy at Sintering Temperatures Above The Aluminum Melting PointDocument13 pagesProduction of Aluminum-Silicon Carbide Composites Using Powder Metallurgy at Sintering Temperatures Above The Aluminum Melting PointMustafa Levent SipahiNo ratings yet

- Solar Energy Potential in Nepal and Global Context: Tuta/Ioe/PcuDocument12 pagesSolar Energy Potential in Nepal and Global Context: Tuta/Ioe/PcuJuju R ShakyaNo ratings yet

- Cac Bai Bao Khoa Hoc 2007-2012 (Phan II CUNG CAP DIEN)Document120 pagesCac Bai Bao Khoa Hoc 2007-2012 (Phan II CUNG CAP DIEN)EngineeringNo ratings yet

- Amaerule 1988Document37 pagesAmaerule 1988Andres CaNo ratings yet

- Optocouplers Hand Book 2006Document26 pagesOptocouplers Hand Book 2006onurinciNo ratings yet

- Chapter 6 - Tutorial 11Document11 pagesChapter 6 - Tutorial 11kwong hkNo ratings yet

- Design of PID Controller For The Modified Quadruple-Tank Process Using Inverted Decoupling TechniqueDocument5 pagesDesign of PID Controller For The Modified Quadruple-Tank Process Using Inverted Decoupling TechniqueMAURY SEBASTIAN MACIAS SANCHEZNo ratings yet

- Questioned DocumentsDocument7 pagesQuestioned Documentsjoy LoretoNo ratings yet

- Principles of Structural Analysis and DesignDocument1 pagePrinciples of Structural Analysis and DesigngellianforniasNo ratings yet

- Z TransformDocument15 pagesZ TransformSureshKumarNo ratings yet

- Detector History Rev3Document6 pagesDetector History Rev3Byu PutraNo ratings yet

- Stabilizing or Tertiary Winding PurposeDocument3 pagesStabilizing or Tertiary Winding Purposeమాచర్ల రవీంద్ర నాథ్No ratings yet

- UBC Guide To BearingsDocument44 pagesUBC Guide To BearingsVirgilioNo ratings yet

- Cat OptoNCDT en UsDocument40 pagesCat OptoNCDT en UsDaniel FredianiNo ratings yet

- Surge Arrester General (IN) English PDFDocument16 pagesSurge Arrester General (IN) English PDFBalan PalaniappanNo ratings yet

- Daftar PustakaDocument4 pagesDaftar Pustakapuja gladwellNo ratings yet

- Ion Exghange PDFDocument306 pagesIon Exghange PDFAhoud AlhaimliNo ratings yet

- Semaphore Contact IndicatorsDocument2 pagesSemaphore Contact IndicatorsAshish JainNo ratings yet