Professional Documents

Culture Documents

Ik Siemens-7MF4233

Ik Siemens-7MF4233

Uploaded by

hoapro537817Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ik Siemens-7MF4233

Ik Siemens-7MF4233

Uploaded by

hoapro537817Copyright:

Available Formats

9.

2 MODEL 7MF4233, ABSOLUTE PRESSURE

This section contains a dimension drawing of the transmitter, a model designation table and performance

specifications.

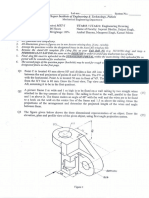

1 Process connection, ½ -14NPT, connection shank 4 Connector side

G1/2A or oval flange 5 Electronics side, digital display (greater length for

2 Blanking plug cover with window)

3 Electrical connection: 6 Access cover over magnetic pushbuttons

Screwed gland Pg 13.5 (adapter) 7 Mounting bracket (optional)

Screwed gland M20 x 1.5 or

Screwed gland ½ -14NPT or This Figure is for Models 7MF4033 and 7MF4233.

Han 7D/Han 8 U-plug

FIGURE 9-2 Model 7MF4233, Dimensions

November 2010 9-7

Model Designations and Specifications UMSITRPDS3-1

TABLE 9-3 Model 7MF4233, Model Designation

Absolute pressure, gauge construction, two-wire, series DSIII, 7MF4233- -

Measuring cell filling Measuring cell cleaning

Silicone oil Standard 1

Inert liquid Grease-free 3

Span

8.3 to 250 mbar a (0.12 to 3.63 psi a) D

43 to 1300 mbar a (0.62 to 18.9 psi a) F

0.16 to 5 bar a (2.32 to 72.5 psi a) G

1 to 30 bar a (14.5 to 435 psi a) H

Wetted parts materials

Seal diaphragm Process Connection

Stainless Steel Stainless steel A

Hastelloy Stainless steel B

Hastelloy Hastelloy C

Version for diaphragm seal Y

Process connection

• Connection shank G1/2A to EN 837-1 0

• Female thread 1/2-14 NPT 1

• Oval flange stainless steel

- Mounting thread 7/16-20 UNF to EN 61518 2

- Mounting thread M10 to DIN 19213 3

• Male thread M20 x 1.5 5

• Male thread 1/2-14 NPT 6

Non-wetted parts material

• Housing die-cast aluminum 0

• Housing stainless steel precision casting 3

Version

• Standard version 1

• International version, English label inscriptions; documentation in 5 languages on CD 2

Explosion protection

• Without A

• With ATEX; type of protection:

- Intrinsic safety (EEx ia) B

- Explosion proof (EEx d) D

- Intrinsic safety and explosion-proof enclosure (EEx ia + EEx d) P

- Ex nA/nL (Zone 2) E

- Intrinsic safety, explosion-proof enclosure and dust explosion protection (EEx ia +

R

EEx d + Zone 1D/2D)

• With FM + CSA, type of protection: intrinsic safety and explosion proof (is + xp) N C

Electrical connection / cable entry

• Screwed gland Pg 13.5; Adapter A

• Screwed gland M20 x 1.5 B

• Screwed gland 1/2-14 NPT C

• Han 7D plug (plastic housing) includes mating connector D

• Plug M12 (metal) F

Display

• Without (digital indicator hidden, setting: mA) 1

• With visible digital indicator, setting: mA 6

• With customer specified digital indicator and setting, order code Y21 or Y22 required) 7

Additional selections and data on next page.

9-8 November 2010

UMSITRAPDS3-1 Model Designations and Specifications

Additional Model 7MF4233 Selections and Data* Order Code

Transmitter with mounting bracket of:

- steel A01

- stainless steel A02

Plug: Han 7D (metal, gray) A30

Plug: Han 8U (instead of Han 7D) A31

Cable sockets for M12 connectors (metal) A50

Inscribing of rating plate (instead of German):

- English B11

- French B12

- Spanish B13

- Italian B14

- English, pressure units in inH2O or psi B21

Manufacturer’s test/calibration certificate M to DIN 55350, part 18, and ISO 8402 C11

Acceptance test certificate to EN 10204-3.1 C12

Factory certificate to EN 10204-2.2 C14

“Functional Safety (SIL)” certificate C20

Setting upper limit of output signal limit to 22.0 mA D05

Manufacturer’s declaration according to NACE D07

Type of protection IP68 D12

Digital indicator alongside the input keys D27

Supplied with oval flange D37

Use in or on Zone 1D/2D E01

Use in Zone 0 E02

Oxygen cleaning application, 160 bar g (2320 psi g) maximum, for oxygen

measurement and inert liquid) E10

Explosion proof, intrinsic safety to INMETRO (Brazil) E25

Explosion proof, intrinsic safety to NEPSI (China) E55

Explosion protection, explosion proof to NEPSI (China) E56

Explosion proof, Zone 2 to NEPSI (China) E57

Measuring range to be set, specify in plane text (5 characters maximum):

Y01: ... to ... mbar, bar, psi, kPa, MPa, Y01

Tag number/descriptor, 16 characters maximum, specify in plain text: Y15

Tag message, 27 characters maximum, specify in plain text Y16

Entry of HART address (Tag): 8 characters maximum, specify in plain text Y17

Setting of pressure indication in pressure units, specify in clear text: mbar, psi,

Y21

kPa, MPa...

3

Setting of pressure indication in non-pressure units, specify in plain text: l/min, m /h,

Y22+Y01

m, USgpm... (5 characters maximum)

Only Y01, Y21, Y22, Y25 and D05 can be factory preset.

* Add “-Z” to model number and specify Order Code(s).

November 2010 9-9

Model Designations and Specifications UMSITRPDS3-1

TABLE 9-4 Model 7MF4233, Specifications

Input

Measured variable Absolute pressure (gage construction)

Span (infinitely adjustable) Span Max. permissible test pressure

8.3 to 250 mbar a (0.12 to 3.6 psi a) see Note 6 bar a (87 psi a)

43 to 1300 mbar a (0.62 to 18.9 psi a) 10 bar a (145 psi a)

160 to 5000 mbar a (2.32 to 72.5 psi a) 30 bar a (435 psi a)

1 to 30 bar a (14.5 to 435 psi a) 100 bar a (1450 psi a)

Lower measuring limit

• Measuring cell, silicone oil filling 0 mbar a (0 psi a)

Upper measuring limit 100% of maximum span

Output

Output signal 4 to 20 mA

• Lower limit (infinitely adjustable) 3.55 mA, factory preset to 3.84 mA

• Upper limit (infinitely adjustable) 23 mA, factory preset to 20.5 mA or optionally set to 22.0 mA

Load

• Without HART communication RB ≤ (UH – 10.5 V)/0.023 A in Ω; UH: power supply in V

• With Hart communication RB = 230 to 500 Ω (SIMATIC PDM) or

RB = 230 to 1100 Ω (HART Communicator)

Accuracy To EN 60770-1

Reference Conditions Increasing characteristic, start of scale value 0 bar, stainless steel seal diaphragm,

silicon oil filling, temperature 25°C (77°F) r: span ratio (r = max. span/set span)

Error in measurement and fixed-point

setting (including hysteresis and

repeatability)

• Linear characteristic

- r ≤ 10 ≤ 0.1%

- 10 ≤ r < 30 ≤ 0.2%

Long-term drift (temperature change ≤ (0.1 * r)%/year

+/-30°C (+/-54°F))

Influence of ambient temperature

• at -10 to +60°C (14 to +140°F) ≤ (0.1 * r + 0.2)%

• at -40 to -10°C and +60 to +85°C (-40 ≤ (0.1 * r + 0.15)%/10K

to +14°F and 140 to +185°F)

Rated operating conditions

Degree of protection (to EN 60529) IP65

Process temperature

• Measuring cell, silicon oil filling -40 to +100°C (-40 to +212°F)

• Measuring cell, inert filling liquid -20 to +100°C (-4 to +212°F)

• In conjunction with dust explosion -20 to +60°C (-4 to +140°F)

protection

Ambient conditions

• Ambient temperature, digital indicators -30 to +85°C (-22 to +185°F)

• Storage temperature -50 to +85°C (-58 to +185°F)

• Climatic class, condensation Permissible

• Electromagnet compatibility To EN 61326 and NAMUR NE 21

Design

Weight, approximate, without options 1.5 kg (3.3 lb)

Housing material Low copper die-cast aluminum, GD-AISi 12 or stainless steel precision casing, mat.

No. 1.4408

Wetted parts materials

• Connection shank Stainless steel, mat. No. 1.4404/316L or Hastelloy C4, mat. No. 2.4610

• Oval flange Stainless steel, mat. No. 1.4404/316L

• Seal diaphragm Stainless steel, mat. No. 1.4404/316L or Hastelloy C276, mat. No. 2.4819

9-10 November 2010

UMSITRAPDS3-1 Model Designations and Specifications

Measuring cell filling Silicone oil or inert filling liquid; max. 160 bar a (2320 psia) with oxygen

measurement

Process connection Connection shank G1/2A to DIN EN837-1, female thread 1/2-14 NPT or oval flange

to DIN 19213 with mounting thread M10 or 7/16-20 UNF to EN 16518

Power Supply UH

Terminal voltage at transmitter 10.5 to 45 Vdc

10.5 to 30 Vdc in intrinsically-safe mode

Certificate and approvals See Table 9-20

HART communication

HART communication 230 to 1100 Ω

Protocol HART Version 5.x

Software for computer SIMATIC PDM

Note: 3.6 psi absolute (250 mbar a) Capsule

This measuring cell is designed for operation within the measuring limits of 0 to 3.63 psi

(absolute). When stored in the normal ambient pressure of about of about 14.7 psi

(absolute), the measuring cell is in the overload state. An overload error of up to 0.03 psi

may occur. The overload disappears in normal operation within the measuring limits and

the transmitter operates within specifications.

When performing accurate continuous pressure measurements within the measuring

limits, a readjustment of the transmitter zero for absolute pressure must be performed

after approximately one day (refer to Section 6.2.5).

If pressure measurements exceed the measuring limits repeatedly (e.g. batch processes

with transitions between vacuum and ventilation), a measuring cell with a maximum

range of 18.9 psi should be selected to avoid overloading.

November 2010 9-11

You might also like

- How To Bulk Upload WAV Files To Avaya Aura Media Server (AAMS) For Use As Communication Manager 7 AnnouncementsDocument8 pagesHow To Bulk Upload WAV Files To Avaya Aura Media Server (AAMS) For Use As Communication Manager 7 AnnouncementspawarsanjuNo ratings yet

- Gnexcp7-Bg Break Glass Manual Call PointDocument3 pagesGnexcp7-Bg Break Glass Manual Call PointbondsivamaniNo ratings yet

- Schmersal Safety Switch Datasheet Az 16 02zvk 1426622599 PDFDocument9 pagesSchmersal Safety Switch Datasheet Az 16 02zvk 1426622599 PDFDoninho LimaNo ratings yet

- Gs01f06a00 50eDocument8 pagesGs01f06a00 50eDaniloNo ratings yet

- Datasheet m12 4 PiinesDocument2 pagesDatasheet m12 4 PiinesLuis Yefferson Tica QuispeNo ratings yet

- 783 y AdaptorDocument1 page783 y AdaptorDavide GuerreiroNo ratings yet

- Mb-0301-4e DX07 PlugDocument4 pagesMb-0301-4e DX07 PlugSHYAM THILLAINATHANNo ratings yet

- Crane CablesDocument2 pagesCrane CablesTimuçin KARABULUTLARNo ratings yet

- IE PI RJ45 FH - enDocument4 pagesIE PI RJ45 FH - enklkkmklf fejkrfNo ratings yet

- DCU SeriesDocument4 pagesDCU SeriesSupakanit LimsowanNo ratings yet

- WDU 2.5 enDocument15 pagesWDU 2.5 enAsad NaeemNo ratings yet

- Servo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionDocument10 pagesServo-Assisted 2/2 Way Valve Diaphragm Valve: Standard EX VersionYacineNo ratings yet

- MIL-DTL-5015 Style Circular Connectors: D/MS A/B SeriesDocument18 pagesMIL-DTL-5015 Style Circular Connectors: D/MS A/B Seriespratik septaNo ratings yet

- Micro-USB ConnectorsDocument4 pagesMicro-USB ConnectorsTonpitonpi Ton PiNo ratings yet

- 51 PAPD-PAPDR enDocument2 pages51 PAPD-PAPDR enGulf Trans PowerNo ratings yet

- Catalogo Tecnico PresostatoDocument32 pagesCatalogo Tecnico PresostatoRonulfo GutierrezNo ratings yet

- ZDU 2.5-2 PTDocument14 pagesZDU 2.5-2 PTMarcelo de PaulaNo ratings yet

- 0109 H05VV-F EngDocument2 pages0109 H05VV-F EngNermin MustafiNo ratings yet

- 02122020-Gen - Cat - EuropeDocument32 pages02122020-Gen - Cat - EuropeABDULSALAMNo ratings yet

- Datasheet: AZ 16 ZVK-M16Document6 pagesDatasheet: AZ 16 ZVK-M16zuda.ahamdNo ratings yet

- 1 27 130 Stexcp8 PT M - DatasheetDocument3 pages1 27 130 Stexcp8 PT M - DatasheetRoberto Martin NavarroNo ratings yet

- JST NV ConnectorDocument2 pagesJST NV ConnectorRicky CapascoNo ratings yet

- Westlock 316 Silver BulletDocument3 pagesWestlock 316 Silver BulletSunil RajNo ratings yet

- JVC gr-d750 gr-d770 gr-d771 gr-d775 gr-d790 gr-d796 Uc Us SM PDFDocument64 pagesJVC gr-d750 gr-d770 gr-d771 gr-d775 gr-d790 gr-d796 Uc Us SM PDFguanteNo ratings yet

- Cordsets and Field Attachables: Technical DataDocument126 pagesCordsets and Field Attachables: Technical Datayoquins22No ratings yet

- JVC Gr-D720ex, D725eg, D740ex, D760ex, D770exDocument64 pagesJVC Gr-D720ex, D725eg, D740ex, D760ex, D770exOleg OlegerNo ratings yet

- Flexidrum TD 210 C TPDocument2 pagesFlexidrum TD 210 C TPBruno TumbacoNo ratings yet

- 1101 - LiYCY - ENG-TIM Kabel HrvatskaDocument4 pages1101 - LiYCY - ENG-TIM Kabel Hrvatskaanon_684099349No ratings yet

- b1x b2x Ds PDFDocument2 pagesb1x b2x Ds PDFscibduser001No ratings yet

- CELLFLEX® Factory-Fit Jumper Assembly, 7-16 DIN Male / 7-16 DIN MaleDocument2 pagesCELLFLEX® Factory-Fit Jumper Assembly, 7-16 DIN Male / 7-16 DIN MaleLuciano Silvério LeiteNo ratings yet

- Series: Clamp Filters (Ferrite Core With Case)Document13 pagesSeries: Clamp Filters (Ferrite Core With Case)Алексей АндрияшNo ratings yet

- CELLFLEX® Factory-Fit Jumper Assembly, Weatherproof Boot 7-16 DIN Male/7-16 DIN Male, 1/2" Low Loss Foam, 2 MDocument2 pagesCELLFLEX® Factory-Fit Jumper Assembly, Weatherproof Boot 7-16 DIN Male/7-16 DIN Male, 1/2" Low Loss Foam, 2 MnguyentraihdNo ratings yet

- Yf 200Document25 pagesYf 200dottodotNo ratings yet

- Data Sheet: W-Series Wdu 6Document5 pagesData Sheet: W-Series Wdu 6nisha_khanNo ratings yet

- Schmersal - Finecorsa Alza Abbassa - Datasheet - Z1R 236-11zDocument6 pagesSchmersal - Finecorsa Alza Abbassa - Datasheet - Z1R 236-11zLiliana ZamoraNo ratings yet

- 0900766b8123d204 WDU2.5Document5 pages0900766b8123d204 WDU2.5Samdan NamhaisurenNo ratings yet

- Data Sheet: W-Series WSI 6/LD 10-36V DC/ACDocument12 pagesData Sheet: W-Series WSI 6/LD 10-36V DC/ACLUIS FELIPE LIZCANO MARINNo ratings yet

- Tronic - Cy PDFDocument2 pagesTronic - Cy PDFEugenioNo ratings yet

- YF219Document22 pagesYF219acselectronicaNo ratings yet

- IE PI RJ45 FH - enDocument5 pagesIE PI RJ45 FH - enEdouard_CarvalhoNo ratings yet

- Dms3106a22-14p CPDocument14 pagesDms3106a22-14p CPnishank srivastavaNo ratings yet

- Service Manual: GZ-MG20EK, GZ-MG20EX, GZ-MG20EY, GZ-MG20EZ, GZ-MG30EK, GZ-MG30EX, GZ-MG30EY, GZ-MG30EZ, GZ-MG33EGDocument17 pagesService Manual: GZ-MG20EK, GZ-MG20EX, GZ-MG20EY, GZ-MG20EZ, GZ-MG30EK, GZ-MG30EX, GZ-MG30EY, GZ-MG30EZ, GZ-MG33EGbzrmiltosNo ratings yet

- MeasurIT KTek BETA Switches 0803Document32 pagesMeasurIT KTek BETA Switches 0803cwiejkowskaNo ratings yet

- Data Sheet: W-Series WDU 2.5Document5 pagesData Sheet: W-Series WDU 2.5nisha_khanNo ratings yet

- Datasheet Datasheet: AmotechDocument13 pagesDatasheet Datasheet: AmotechByron MartinezNo ratings yet

- JST - 03R JWPF Vsle SDocument2 pagesJST - 03R JWPF Vsle STrần Long VũNo ratings yet

- Phoenix Contact 3044076 enDocument6 pagesPhoenix Contact 3044076 enDGNo ratings yet

- PCB Terminal Block - MKDS 5/ 2-9,5 - 1714971: Key Commercial DataDocument8 pagesPCB Terminal Block - MKDS 5/ 2-9,5 - 1714971: Key Commercial DataSergioCandiottiNo ratings yet

- Canfield ConnectorDocument2 pagesCanfield Connectorbarry.tappNo ratings yet

- Cordsets and Field Attachables: Technical DataDocument124 pagesCordsets and Field Attachables: Technical DataJoaldo SantosNo ratings yet

- Solido 500 enDocument3 pagesSolido 500 enFariyad AnsariNo ratings yet

- Az 16 12zvrk m16 2023 05 26 02 34Document6 pagesAz 16 12zvrk m16 2023 05 26 02 34Ian RustNo ratings yet

- Datenblatt Adaptors Made of Metal CMP-737D Adaptor NB M20-NPT GBDocument2 pagesDatenblatt Adaptors Made of Metal CMP-737D Adaptor NB M20-NPT GBkedasian beijiNo ratings yet

- "ZNR" Transient/Surge Absorbers (Type D)Document4 pages"ZNR" Transient/Surge Absorbers (Type D)VeronicaGonzalezNo ratings yet

- Phoenix Contact 1859548 enDocument5 pagesPhoenix Contact 1859548 enDGNo ratings yet

- Hke Ai411 487Document1 pageHke Ai411 487YazanassiNo ratings yet

- GS32P06K10 01enDocument9 pagesGS32P06K10 01enDhirender DagarNo ratings yet

- Data Sheet - BR - CTF - Ankleshwar PDFDocument1 pageData Sheet - BR - CTF - Ankleshwar PDFASHISH GORDENo ratings yet

- Wdu 4Document8 pagesWdu 4Vinicius PereiraNo ratings yet

- Automated Optical Inspection: Advancements in Computer Vision TechnologyFrom EverandAutomated Optical Inspection: Advancements in Computer Vision TechnologyNo ratings yet

- Online FDP - Civil Engg-VIT ChennaiDocument2 pagesOnline FDP - Civil Engg-VIT ChennaiDharmesh DharmaNo ratings yet

- A6j MB - 0103 R2.2 0118Document63 pagesA6j MB - 0103 R2.2 0118Thịnh TúNo ratings yet

- Performance Curves: Centrifugal Pumps S SolidcDocument2 pagesPerformance Curves: Centrifugal Pumps S SolidcPhượng NguyễnNo ratings yet

- Hea 4003 24 9DDocument3 pagesHea 4003 24 9Dhugo renzo chavez bernuyNo ratings yet

- CEWE Prometer: Precision MeteringDocument2 pagesCEWE Prometer: Precision MeteringEric DondebzangaNo ratings yet

- 30KW Diesel Generator Datasheet T30u (English) PDFDocument4 pages30KW Diesel Generator Datasheet T30u (English) PDFojopoderosoNo ratings yet

- EXPERIMENT 3: Single Phase Transformer: Part A: Off-Load, Loaded, Short-CircuitDocument9 pagesEXPERIMENT 3: Single Phase Transformer: Part A: Off-Load, Loaded, Short-CircuitCHERUYIOT IANNo ratings yet

- Afm A320f 05apr23Document1,306 pagesAfm A320f 05apr23HaeLyong JooNo ratings yet

- AMDVBFLASH User Guide NDADocument12 pagesAMDVBFLASH User Guide NDADanej DoberšekNo ratings yet

- Practice Problem Based On Travelling Salesman Problem Using Branch and Bound ApproachDocument13 pagesPractice Problem Based On Travelling Salesman Problem Using Branch and Bound Approachvvvcxzzz3754No ratings yet

- Year 6 Week 5 Lesson 1 Main Focus Prior Knowledge Key Vocabulary Curriculum ObjectivesDocument18 pagesYear 6 Week 5 Lesson 1 Main Focus Prior Knowledge Key Vocabulary Curriculum Objectiveslenson kinyuaNo ratings yet

- SRF34752 - Job Description and Person SpecificationDocument5 pagesSRF34752 - Job Description and Person SpecificationmahahajNo ratings yet

- IAT Paper Jan-June 22 DMBI DIV A&B SolutionDocument10 pagesIAT Paper Jan-June 22 DMBI DIV A&B SolutionAnirudh TripathiNo ratings yet

- Chapter One: Introduction To Human Computer Interaction: Software Engineering Department, Wolkite UniversityDocument39 pagesChapter One: Introduction To Human Computer Interaction: Software Engineering Department, Wolkite UniversityEstifanos0% (1)

- Digital Systems Design and PrototypingDocument633 pagesDigital Systems Design and PrototypingAshish Shrivastava50% (2)

- UTA015Document2 pagesUTA015sans cipher 435No ratings yet

- Kwitansi Visalux 2021Document23 pagesKwitansi Visalux 2021Devi SitanggangNo ratings yet

- Virtual & Augmented Reality Use Cases For Fusion Design EngineeringDocument4 pagesVirtual & Augmented Reality Use Cases For Fusion Design EngineeringXto PeregrinNo ratings yet

- AK-SC255 355 Phase OutDocument3 pagesAK-SC255 355 Phase Outsmith_raNo ratings yet

- NB 06 Cat9200 Ser Data Sheet Cte enDocument42 pagesNB 06 Cat9200 Ser Data Sheet Cte enrobin11111111No ratings yet

- A Survey On 3G Mobile Network Traffic Performance and Analysis in EthiopiaDocument13 pagesA Survey On 3G Mobile Network Traffic Performance and Analysis in EthiopiaahmedNo ratings yet

- A Secure and Verifiable Color Visual Cryptography Scheme With LSB Based Image SteganographyDocument9 pagesA Secure and Verifiable Color Visual Cryptography Scheme With LSB Based Image SteganographyWARSE JournalsNo ratings yet

- DBMS Complete NoteDocument89 pagesDBMS Complete NoteSan DipNo ratings yet

- Legazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceDocument9 pagesLegazpi Certificate of Non-Availability of Stocks: Product Code Product Description UOM PriceGamas Pura JoseNo ratings yet

- 5 6133982140783657921Document5 pages5 6133982140783657921cos thetaNo ratings yet

- Public Speaking AssignmentDocument4 pagesPublic Speaking AssignmentSiti NursyafiqahNo ratings yet

- NovartisDocument1 pageNovartismanisha_jha_11No ratings yet

- Pre-Test: Vocabulary and GrammarDocument4 pagesPre-Test: Vocabulary and GrammarMiriamNo ratings yet