Professional Documents

Culture Documents

Data Sheet

Data Sheet

Uploaded by

avikOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet

Data Sheet

Uploaded by

avikCopyright:

Available Formats

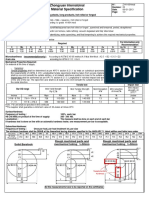

DATA SHEET 2000-06-06

500T

(ARMOX 500S C 9640X0052 THD, ARMOX 500Z TL 2350-0000, MIL-A-46100)

CHEMICAL C Si Mn P S Cr Ni Mo B

COMPOSITION max max max max max max max max

(ladle analysis) % % % % % % % % %

0,32 0,1 0,4 1,2 0,015 0,010 1,01) 1,81) 0,7 0,005

The steel is grain-refined.

1)

For plate thicknesses > 70 mm Cr £ 1,5 and Ni £ 3,5

MECHANICAL Hardness Charpy-V 40°C1) Yield strength Tensile strength Elongation

PROPERTIES HBW 10x10 test specimen2) Rp0,2 N/mm2 Rm N/mm2 A5% A50%

*480540 Min. 20 Joule Min. 1250 14501750 Min. 8 Min. 10

* Min. 490 HB can be guaranteed by special agreement.

1)

Average of three tests. Transverse to rolling direction.

Single value min 70% of specified average.

2)

For plate thicknesses under 12 mm subsize Charpy V-specimens are used. The specified

minimum value is then proportional to the specimens cross-section.

TESTING Brinell hardness test EN ISO 6506-1 Each heat treatment individual

Charpy impact test EN 10 045-1 Each heat and thickness > 4 mm

Tensile testing EN 10 002-1 Each heat and thickness < 20 mm

Ultrasonic testing SEL 072/077 CL. 3 Each plate in thickness 60150 mm

DELIVERY CONDITION Quenched and tempered.

DIMENSIONS ARMOX 500T is supplied in plate thicknesses 3150 mm. Plate thicknesses ³ 60 mm are supplied with

mill edge or by special agreement only. More detailed information on dimensions is provided in our Ge-

neral Information brochure.

TOLERANCES Dimensional tolerances according to EN 10 029 excluding thickness tolerances

Thickness tolerances:

Plate thickness Standard By special agreement

in mm Tolerances in mm Tolerances in mm

< 13 -0,0 + 0,8 0,2 +0,6

13 < 20 + 1,0 0,2 +0,8

20 < 40 + 1,2 0,2 +1,0

40 < 60 + 1,6 0,3 +1,3

60 < 80 + 2,0 0,3 +1,7

80 < 110 + 2,4 0,4 +2,0

110 150 + 3,0 0,5 +2,5

E-195, SSAB Oxelösund, ARMOX is trademark for armour plate manufactured bySSAB Oxelösund AB

Other thickness tolerances by special agreement.

Dimensional tolerances for plate with mill edge according to special agreement.

Flatness tolerances according to class N or according to special agreement.

SURFACE CONDITION According to EN 10 163-2 Class B Subclass 3.

GENERAL TECHNICAL According to EN 10 021 and EN 10 204. Unless otherwise agreed, inspection documents

DELIVERY CONDITION are issued in English with certificates of 3.1B type.

HEAT TREATMENT ARMOX 500T may not be heated above 200°C (400°F) if guaranteed hardness is to be maintained.

AND FABRICATION For further information on machining, cutting and welding, please see special

brochure or contact us.

Appropriate health and saftey precautions must be taken when welding, cutting, grinding or otherwise

working on the product. Grinding, especially of primer coated plates, may produce dust with high particle

concentration. Our Technical Customer Service Department will provide further information on request.

SSAB Oxelösund AB Phone. Fax Telex

S-613 80 Oxelösund +46 155-25 40 00 +46 155-25 40 73 50950 SSAB S

You might also like

- ASM - Specialty Handbook, Cast IronsDocument455 pagesASM - Specialty Handbook, Cast IronsMuhammad Azlan Ibrahim100% (16)

- Benteller Pipe Cataloque PDFDocument2 pagesBenteller Pipe Cataloque PDFGarry Bernard NelsonNo ratings yet

- Guided Reading 1 - Thermo Part1 - Week 1Document14 pagesGuided Reading 1 - Thermo Part1 - Week 1MarikNo ratings yet

- PCS 9705Document3 pagesPCS 9705elkhalfi50% (2)

- Data Sheet: Chemical CompositionDocument1 pageData Sheet: Chemical CompositionavikNo ratings yet

- Ae 370 TDocument1 pageAe 370 TavikNo ratings yet

- Data SheetDocument1 pageData SheetavikNo ratings yet

- Strenx 700MC Plus: General Product DescriptionDocument1 pageStrenx 700MC Plus: General Product DescriptionMircea FloreaNo ratings yet

- Data Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFDocument2 pagesData Sheet 2008 Strenx#174 700MC D E 2017-04-20 PDFangelokyoNo ratings yet

- Strenx 700MC D e 2017-04-20Document2 pagesStrenx 700MC D e 2017-04-20Amandeep SinghNo ratings yet

- TDC 09 - R1 - S690 QL & Weldox 700Document2 pagesTDC 09 - R1 - S690 QL & Weldox 700Thennarasu VelloreNo ratings yet

- Data Sheet 2008 Strenx 700 MC 20170420 254 371857150 enDocument2 pagesData Sheet 2008 Strenx 700 MC 20170420 254 371857150 enmarkoNo ratings yet

- Data Sheet Strenx 650 MCDocument3 pagesData Sheet Strenx 650 MCRoger BandeiraNo ratings yet

- Data Sheet Strenx 700 MCDocument3 pagesData Sheet Strenx 700 MCRoger BandeiraNo ratings yet

- Domex 355 MC: High Strength Cold Forming SteelDocument2 pagesDomex 355 MC: High Strength Cold Forming SteelKhantoNo ratings yet

- Data Sheet 2006 Strenx 700 20170420 121 371857150 enDocument2 pagesData Sheet 2006 Strenx 700 20170420 121 371857150 enRodrigoNo ratings yet

- Steel X20Cr13: EN 10250-4:1999, Number: 1.4021Document4 pagesSteel X20Cr13: EN 10250-4:1999, Number: 1.4021AdamNo ratings yet

- 107 - WELDOX - 700 - UK - Data SheetDocument2 pages107 - WELDOX - 700 - UK - Data SheetLuis AguilarNo ratings yet

- Ew 700Document2 pagesEw 700Stefano BarbieriNo ratings yet

- SSAB Domex 420MC: General Product DescriptionDocument2 pagesSSAB Domex 420MC: General Product DescriptionpeterNo ratings yet

- Strenx 960: General Product DescriptionDocument2 pagesStrenx 960: General Product DescriptionJean Paulo SalvatiNo ratings yet

- Ficha Técnica - XABO 500 - ThyssenkruppDocument3 pagesFicha Técnica - XABO 500 - ThyssenkruppDiego Ramírez ParraNo ratings yet

- Datasheet Strenx 700E - en - 2016Document3 pagesDatasheet Strenx 700E - en - 2016peterNo ratings yet

- Data Sheet 2007en Strenx® 700 CR 2021-05-04Document2 pagesData Sheet 2007en Strenx® 700 CR 2021-05-04Idan FriedbergNo ratings yet

- Strenx 700 MC: Advanced High Strength SteelDocument2 pagesStrenx 700 MC: Advanced High Strength SteeldbaNo ratings yet

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNo ratings yet

- 1 4571 PDFDocument7 pages1 4571 PDFSiis IngenieriaNo ratings yet

- Stainless Steel 1.4401 316Document3 pagesStainless Steel 1.4401 316Luis LoayzaNo ratings yet

- Tata Steel HR & CR SteelDocument2 pagesTata Steel HR & CR SteelSaravanan KNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- Data Sheet Raex 450Document3 pagesData Sheet Raex 450Amit GauravNo ratings yet

- Strenx 700: General Product DescriptionDocument2 pagesStrenx 700: General Product DescriptionpeterNo ratings yet

- Domex 700 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocument2 pagesDomex 700 MC Hot Rolled, Extra High Strength, Cold Forming Steelflorin_iacob2001No ratings yet

- Data Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enDocument2 pagesData Sheet 2007 Strenx 700 CR 2017-04-20 52 371857150 enThainã NavarroNo ratings yet

- High-Strength Steels For Cold-Forming, Thermomechanically-RolledDocument2 pagesHigh-Strength Steels For Cold-Forming, Thermomechanically-RolledAshishkekreNo ratings yet

- CT Burden Calculation ReportDocument6 pagesCT Burden Calculation ReportMd Mahbubur RahmanNo ratings yet

- Steel: Nisco Wear Plate NM400Document2 pagesSteel: Nisco Wear Plate NM400Paolo Sebastián Bernal GómezNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Stainless Steel 1.4404 316lDocument3 pagesStainless Steel 1.4404 316lDilipSinghNo ratings yet

- Data Sheet 1996-06-01: Applications DesignationDocument2 pagesData Sheet 1996-06-01: Applications DesignationEnoc AndradeNo ratings yet

- Aaepl: TDC No. AAEPL/RM/lDocument2 pagesAaepl: TDC No. AAEPL/RM/lSandip PandeNo ratings yet

- T300 Technical Data Sheet 1 PDFDocument2 pagesT300 Technical Data Sheet 1 PDFmaraNo ratings yet

- CRCA (Cold Rolled Close Annealed Coils) Specifications: As Per IsDocument2 pagesCRCA (Cold Rolled Close Annealed Coils) Specifications: As Per Isray_k_917790% (10)

- T300 R6 - 04132018Document2 pagesT300 R6 - 04132018Suraj_73No ratings yet

- Data Sheet: Applications Designation Chemical CompositionDocument2 pagesData Sheet: Applications Designation Chemical CompositionManankNo ratings yet

- Tornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartDocument1 pageTornillos Hexagonales Grados de Resistencia - Bolt Grade Markings and Strength ChartGabriel Cabezas NaranjoNo ratings yet

- S275JR PDFDocument1 pageS275JR PDFEmrahCayboylu100% (1)

- 9SMNPB28K-14.00 Hex Tc.Document1 page9SMNPB28K-14.00 Hex Tc.Mechtek LabNo ratings yet

- Armox 370T Class 2Document2 pagesArmox 370T Class 2ShuvamNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- z3T - Maraging Steel 1-2709 (EOS MS1)Document1 pagez3T - Maraging Steel 1-2709 (EOS MS1)martinm3tNo ratings yet

- Material Data Sheet: DescriptionDocument7 pagesMaterial Data Sheet: DescriptionCharles SedilloNo ratings yet

- Quenched and Tempered Steels: Mechanical PropertiesDocument2 pagesQuenched and Tempered Steels: Mechanical Propertiesarjun prajapatiNo ratings yet

- 168 Hardox 450 Uk Data SheetDocument2 pages168 Hardox 450 Uk Data SheetBambang WibisonoNo ratings yet

- S355J2+N Steel PlateDocument2 pagesS355J2+N Steel PlateAmanNo ratings yet

- Zhongyuan Internatoinal Material Specification: ZyicoDocument2 pagesZhongyuan Internatoinal Material Specification: ZyicoAbozar BilanNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- Non-Alloy Structural Steels: Mechanical Properties Available DimensionsDocument1 pageNon-Alloy Structural Steels: Mechanical Properties Available Dimensionssorin robertNo ratings yet

- Data Sheet 2067uk Hardox 500 Sheet 2016-03-02 50 371857150 enDocument3 pagesData Sheet 2067uk Hardox 500 Sheet 2016-03-02 50 371857150 enPtbbi TubanNo ratings yet

- Bolt Depot - Bolt Grade Markings and Strength ChartDocument2 pagesBolt Depot - Bolt Grade Markings and Strength ChartSundar KumarNo ratings yet

- Data Sheet: Chemical CompositionDocument1 pageData Sheet: Chemical CompositionavikNo ratings yet

- PR VESSEL FABRICATION - Awareness Session - 16.11.19Document50 pagesPR VESSEL FABRICATION - Awareness Session - 16.11.19avik100% (1)

- When You Go in Search of Honey, You Must Expect To Be Stung by Bees. Joseph JoubertDocument24 pagesWhen You Go in Search of Honey, You Must Expect To Be Stung by Bees. Joseph JoubertavikNo ratings yet

- Gas Cutting - JKPDocument19 pagesGas Cutting - JKPavikNo ratings yet

- Micom P130C: Feeder Management and Frequency Protection P130C/En M/B53Document580 pagesMicom P130C: Feeder Management and Frequency Protection P130C/En M/B53MarcNo ratings yet

- E Gasspring PDFDocument148 pagesE Gasspring PDFSing Industrial Gas VietnamNo ratings yet

- HVAC Solution Help FileDocument291 pagesHVAC Solution Help FileInventor SolidworksNo ratings yet

- Factors Affecting Potential and Kinetic Energy - 012431Document26 pagesFactors Affecting Potential and Kinetic Energy - 012431kathlene Mae TrinidadNo ratings yet

- (L5) - (JLD 4.0) - Solutions - 12th MayDocument35 pages(L5) - (JLD 4.0) - Solutions - 12th MayVidhan jainNo ratings yet

- Minima Timing of Eclipsing Binaries: Lubo S BR At, Zden Ek Mikul A Sek and Ond Rej PejchaDocument7 pagesMinima Timing of Eclipsing Binaries: Lubo S BR At, Zden Ek Mikul A Sek and Ond Rej Pejcha14Nguyễn Đăng khoaNo ratings yet

- Induction MotDocument15 pagesInduction Motsuresh krishnanNo ratings yet

- EE6512-Electrical Machines LaboratoryDocument82 pagesEE6512-Electrical Machines LaboratoryGopinath B L NaiduNo ratings yet

- Chapter - 15 A Level Physics WB MSDocument4 pagesChapter - 15 A Level Physics WB MSmichelle winataNo ratings yet

- Landmark Graphics Corporation Petroworks ParametersDocument216 pagesLandmark Graphics Corporation Petroworks Parametersahmed_497959294No ratings yet

- Service Manual of CS-T180 CS-T240Plus Auto-Chemistry Analyzer REV.2021-08Document248 pagesService Manual of CS-T180 CS-T240Plus Auto-Chemistry Analyzer REV.2021-08Albeiro PiraquiveNo ratings yet

- Physics 2 (A) KifungiloDocument6 pagesPhysics 2 (A) KifungiloDaniel MapogoNo ratings yet

- 220 KV Grid Substation AlwarDocument62 pages220 KV Grid Substation AlwarSunnyjai Kukreja50% (2)

- C9 Engines For Motor Graders CaterpillarDocument7 pagesC9 Engines For Motor Graders Caterpillarspelz 1No ratings yet

- F. Trigonometric Leveling1Document6 pagesF. Trigonometric Leveling1Russell AyaquilNo ratings yet

- Polyfuse: Seminar Report OnDocument24 pagesPolyfuse: Seminar Report OnPranjal JalanNo ratings yet

- Waste Glass: Table 5.1 Types of Glass and Their Main UsesDocument2 pagesWaste Glass: Table 5.1 Types of Glass and Their Main UsesGowri J BabuNo ratings yet

- High Voltage With Flexible Termination System (HV FT-CAP) X7R Dielectric, 500VDC-3000VDC (Commercial Grade)Document18 pagesHigh Voltage With Flexible Termination System (HV FT-CAP) X7R Dielectric, 500VDC-3000VDC (Commercial Grade)dovesnest_inNo ratings yet

- A Review On A Gear Tooth Failure AnalysisDocument13 pagesA Review On A Gear Tooth Failure AnalysisKKDhNo ratings yet

- YLSK-3D-3100 Wire Bending MachineDocument4 pagesYLSK-3D-3100 Wire Bending MachineMiroslav Djuric KratNo ratings yet

- Chapter Two: Synthesis, Characterization of Semicarbazide and Thiosemicarbazide Based Ligands and Their ComplexesDocument38 pagesChapter Two: Synthesis, Characterization of Semicarbazide and Thiosemicarbazide Based Ligands and Their ComplexesJallow KowlyNo ratings yet

- Gotham CablesDocument52 pagesGotham CablesAdams3232No ratings yet

- (35621) F. Cabo 12 Fibras Autosust As120m-12f G652D SMDocument5 pages(35621) F. Cabo 12 Fibras Autosust As120m-12f G652D SMAbelMouraNo ratings yet

- Keele (1983-10 AES Preprint) - Horn Covers Flat Rectangular AreaDocument22 pagesKeele (1983-10 AES Preprint) - Horn Covers Flat Rectangular AreaBob BeduneauNo ratings yet

- Caledonian Railway Cables PDFDocument251 pagesCaledonian Railway Cables PDFamitvaishnav1No ratings yet

- Gujarat Technological UniversityDocument1 pageGujarat Technological UniversityBhagirath sinh ZalaNo ratings yet

- Wet BondingDocument3 pagesWet Bondingvrana23No ratings yet