Professional Documents

Culture Documents

Issue 11 Inspectors Newsletter

Issue 11 Inspectors Newsletter

Uploaded by

Anil yucebasCopyright:

Available Formats

You might also like

- Ballast Water Arrangement 31.07.2022Document1 pageBallast Water Arrangement 31.07.2022Anil yucebasNo ratings yet

- MSC.1-Circ.1318-Rev.1 - PDF (IMO Circular 1318 CO2 Maintenance) 4Document9 pagesMSC.1-Circ.1318-Rev.1 - PDF (IMO Circular 1318 CO2 Maintenance) 4AbuBakarSiddiqueNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- GROW Assignment - RITIKA SHARMADocument3 pagesGROW Assignment - RITIKA SHARMARitika SharmaNo ratings yet

- Inspector Bulletin: Issue 11Document2 pagesInspector Bulletin: Issue 11DeepakNo ratings yet

- Issue 31 Inspectors Newsletter 2Document2 pagesIssue 31 Inspectors Newsletter 2capt.deniztasNo ratings yet

- Inspector Bulletin: Issue 14Document3 pagesInspector Bulletin: Issue 14DeepakNo ratings yet

- Issue 19 Inspectors NewsletterDocument2 pagesIssue 19 Inspectors NewslettermihaiNo ratings yet

- Issue 7 Inspectors NewsletterDocument3 pagesIssue 7 Inspectors Newsletter..No ratings yet

- Technical InformationDocument70 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Technical InformationDocument81 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Inspector Bulletin: Interesting ObservationsDocument2 pagesInspector Bulletin: Interesting ObservationsDavid DurhamNo ratings yet

- Checklist For Planned Maintenance Focused Inspection CampaignDocument4 pagesChecklist For Planned Maintenance Focused Inspection Campaignnaing kyawNo ratings yet

- NKDocument10 pagesNKGie BastNo ratings yet

- Ci Fi BahamaDocument10 pagesCi Fi BahamaSuraj Kumar ChauhanNo ratings yet

- 20 Guidelines For The Maintenance and Inspections of Fixed CarbonDocument8 pages20 Guidelines For The Maintenance and Inspections of Fixed CarbonBatuhan SürerNo ratings yet

- Code of Practice For The Design, Installation and Operation of Underground Petroleum Storage SystemsDocument64 pagesCode of Practice For The Design, Installation and Operation of Underground Petroleum Storage SystemsSetiawanNo ratings yet

- 281 FFE MaintenaceDocument11 pages281 FFE MaintenaceNeelakantan SankaranarayananNo ratings yet

- Microsoft Word - Rec.114 - NEW June 2010 - Zoe WrightDocument2 pagesMicrosoft Word - Rec.114 - NEW June 2010 - Zoe WrightJony DarkoNo ratings yet

- Nom-Em-003-Asea-2016 Urv enDocument4 pagesNom-Em-003-Asea-2016 Urv engerman PMNo ratings yet

- Port State Control Guidance For Examination of Fixed CO2 Firefighting SystemsDocument6 pagesPort State Control Guidance For Examination of Fixed CO2 Firefighting Systemsvdeviv0% (1)

- Ci Fi Tuvalu Mc-7-2011Document20 pagesCi Fi Tuvalu Mc-7-2011franklindavid14No ratings yet

- Pumproom SafetyDocument7 pagesPumproom Safetysergiytitov100% (2)

- Bahamas CircularDocument8 pagesBahamas CircularPrasad BangaruNo ratings yet

- Issue 6 Inspectors NewsletterDocument2 pagesIssue 6 Inspectors NewsletterDeepakNo ratings yet

- Maintenance and Inspection of Fire Protection Systems and AppliancesDocument32 pagesMaintenance and Inspection of Fire Protection Systems and Appliancesdiegocely700615100% (1)

- Ci Fi Bermuda2022-021Document17 pagesCi Fi Bermuda2022-021hanyNo ratings yet

- 15-Saip-50 (Ins. For Conduit - Cable Seals)Document5 pages15-Saip-50 (Ins. For Conduit - Cable Seals)sathish KumarNo ratings yet

- MGN 389 (M+F) : Operating Instructions and Signage For Fixed Gas Fire-Extinguishing SystemsDocument3 pagesMGN 389 (M+F) : Operating Instructions and Signage For Fixed Gas Fire-Extinguishing Systemsaolaya14No ratings yet

- Technical InformationDocument81 pagesTechnical Informationoki121No ratings yet

- MSC Circ.1318Document8 pagesMSC Circ.1318Ashish SinghNo ratings yet

- DG Circular For Maintenance of Fire Ext PDFDocument15 pagesDG Circular For Maintenance of Fire Ext PDFNishanth DevddigaNo ratings yet

- 850Document5 pages850Syed Shariq AhmedNo ratings yet

- Top 10 Cargo Vessel (Subchapter I) DeficienciesDocument3 pagesTop 10 Cargo Vessel (Subchapter I) DeficienciesislimaNo ratings yet

- Sprinkler SYstems BriefDocument2 pagesSprinkler SYstems BriefCameronNo ratings yet

- MSC 1-Circ 1370Document7 pagesMSC 1-Circ 1370Renato RiveraNo ratings yet

- Fire Fighting (PANAMA)Document10 pagesFire Fighting (PANAMA)Erick GomezNo ratings yet

- Class NK Technical Information TEC 0869Document9 pagesClass NK Technical Information TEC 0869consaldNo ratings yet

- Enhanced Survey ProgrammeDocument3 pagesEnhanced Survey Programmevirendra302No ratings yet

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210Document4 pages4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210guyueyue100% (2)

- SF 27 23Document6 pagesSF 27 23Shivkumar JadhavNo ratings yet

- Chemical Section 9 - Inerting and Gasfreeing of Cargo Tanks1Document14 pagesChemical Section 9 - Inerting and Gasfreeing of Cargo Tanks1ZIAUL KARIMNo ratings yet

- MSC 1-Circ 1432Document12 pagesMSC 1-Circ 1432waliagauravNo ratings yet

- Fixed Co2 Fire Fighting Systems PDFDocument1 pageFixed Co2 Fire Fighting Systems PDFAli TekinNo ratings yet

- Inspector Bulletin: Issue 4Document2 pagesInspector Bulletin: Issue 4Deepak100% (1)

- Residential Fire Protection ProposalDocument24 pagesResidential Fire Protection ProposalAidan YepsonNo ratings yet

- Cisn 01.14 Maintenance and Inspection of Fire Protection SystemsDocument20 pagesCisn 01.14 Maintenance and Inspection of Fire Protection SystemsJimmy ChinaNo ratings yet

- Ogaom Chapter 9 PDFDocument44 pagesOgaom Chapter 9 PDFjohanaristoNo ratings yet

- Eddy Current SpecificationsDocument7 pagesEddy Current SpecificationsBhavani PrasadNo ratings yet

- Clock Ticks Down To Mandatory BNWAS: Navigation and SafetyDocument4 pagesClock Ticks Down To Mandatory BNWAS: Navigation and SafetyGuilherme ChiminelliNo ratings yet

- Confined Space Monitoring With Ventis: Global Gas Detection & Monitoring SolutionsDocument1 pageConfined Space Monitoring With Ventis: Global Gas Detection & Monitoring SolutionsagbnetNo ratings yet

- Epirb DocsDocument4 pagesEpirb DocsmiguelNo ratings yet

- Technical InformationDocument19 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Inspector Bulletin: Issue 2Document2 pagesInspector Bulletin: Issue 2DeepakNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationFrom EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationNo ratings yet

- Methodologies for Assessing Pipe Failure Rates in Advanced Water Cooled ReactorsFrom EverandMethodologies for Assessing Pipe Failure Rates in Advanced Water Cooled ReactorsNo ratings yet

- Use of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsFrom EverandUse of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- Fleet Invoice DetailsDocument1 pageFleet Invoice DetailsAnil yucebasNo ratings yet

- ABS PSC Annual Report - 2022Document33 pagesABS PSC Annual Report - 2022Anil yucebasNo ratings yet

- Narcotic ListDocument1 pageNarcotic ListAnil yucebasNo ratings yet

- 03 2018 Inoperable BWTS PDFDocument3 pages03 2018 Inoperable BWTS PDFAnil yucebas100% (1)

- DN 125 - Airvent - Certificate 00574CHN19Document1 pageDN 125 - Airvent - Certificate 00574CHN19Anil yucebasNo ratings yet

- PSC Deficiency CardsDocument22 pagesPSC Deficiency CardsAnil yucebasNo ratings yet

- Mars Draft SurveyDocument721 pagesMars Draft SurveyAnil yucebasNo ratings yet

- Wind FinderDocument1 pageWind FinderAnil yucebasNo ratings yet

- Sire InspectionDocument8 pagesSire InspectionAnil yucebasNo ratings yet

- JCDRGuidebook WEBfinal 1Document76 pagesJCDRGuidebook WEBfinal 1Anil yucebasNo ratings yet

- Yasa Mars Draft SurveyDocument22 pagesYasa Mars Draft SurveyAnil yucebasNo ratings yet

- Draft Survey FormDocument39 pagesDraft Survey FormAnil yucebasNo ratings yet

- Eve-Calc2 0Document6 pagesEve-Calc2 0Anonymous NIkO5EI6No ratings yet

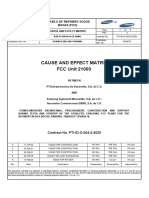

- R2B-P3-206-02-A-CE-00001 - Rev.3 - Cause and Effect Matrix-EngDocument8 pagesR2B-P3-206-02-A-CE-00001 - Rev.3 - Cause and Effect Matrix-Engdaniel contrerasNo ratings yet

- Impact of Social Media On YouthDocument2 pagesImpact of Social Media On Youthliza enriquezNo ratings yet

- NodeMCU TutorialDocument49 pagesNodeMCU Tutorialv_ananthuNo ratings yet

- Toyocool Chiller Controller Manufacturer Instruction ManualDocument17 pagesToyocool Chiller Controller Manufacturer Instruction ManualLucinei ManoelNo ratings yet

- ALU Huawei LTE RAN AnalysisDocument65 pagesALU Huawei LTE RAN AnalysisEdwilAlberts100% (4)

- Chandrika CVDocument2 pagesChandrika CVM Madan GopalNo ratings yet

- Infosphere Information Server (Datastage) - Installation ProcessDocument12 pagesInfosphere Information Server (Datastage) - Installation ProcesssrimkbNo ratings yet

- WSN 1Document16 pagesWSN 1Abhi ShahNo ratings yet

- Budgeting For SuccessDocument4 pagesBudgeting For Successbhatiasanjay89No ratings yet

- DBMS Course OutlineDocument14 pagesDBMS Course OutlineMohammed NouhNo ratings yet

- CJFFHVHMVKBJ JBLKN.NDocument3 pagesCJFFHVHMVKBJ JBLKN.NSabyasachi ChandraNo ratings yet

- What Is DataDocument2 pagesWhat Is DataabduNo ratings yet

- Company DetailsDocument3 pagesCompany DetailsanilrajakodgNo ratings yet

- Meter To CashDocument3 pagesMeter To CashAjay GuptaNo ratings yet

- Export Service Bulletin: Rear Wheel Bearing NoiseDocument2 pagesExport Service Bulletin: Rear Wheel Bearing NoiseJavier DíazNo ratings yet

- Generate MS Word Document Files With Codeigniter and Phpword LibraryDocument3 pagesGenerate MS Word Document Files With Codeigniter and Phpword LibraryNobertus ErikNo ratings yet

- Ieee Oceans 2013 Kevin Demarco Dr. Ayanna M. Howard Dr. Michael E. WestDocument29 pagesIeee Oceans 2013 Kevin Demarco Dr. Ayanna M. Howard Dr. Michael E. WestSyllogismRXSNo ratings yet

- Japanese Management Theories - The Hard Fit of It's Core Concepts Into Sri Lankan Business CultureDocument6 pagesJapanese Management Theories - The Hard Fit of It's Core Concepts Into Sri Lankan Business Cultureert3535No ratings yet

- ZXDF10 Diesel Generator User Manual-20200104Document8 pagesZXDF10 Diesel Generator User Manual-20200104David Tombe Rumi100% (1)

- The Performance EquationDocument4 pagesThe Performance Equationvamshi krishnaNo ratings yet

- SCCM Resume - BharathDocument4 pagesSCCM Resume - BharathraamanNo ratings yet

- 11 Is 0353 PS Techlog Petrophysics-LrDocument2 pages11 Is 0353 PS Techlog Petrophysics-Lredison Contreras50% (2)

- Bus Duct - Al-AhleiaDocument7 pagesBus Duct - Al-AhleiasedianpoNo ratings yet

- How To Integrate ICloud Sync in Your AppDocument26 pagesHow To Integrate ICloud Sync in Your AppAnkeet PNo ratings yet

- Stadium FailureDocument1 pageStadium Failurerao_gsv7598No ratings yet

- 20480B Programming in HTML5 With JavaScript and CSS3Document11 pages20480B Programming in HTML5 With JavaScript and CSS3zolodjoNo ratings yet

- Test Engine Specifications: IVECO F1C Euro 4 / 105 KW at 3500 RPMDocument3 pagesTest Engine Specifications: IVECO F1C Euro 4 / 105 KW at 3500 RPMFazalNo ratings yet

Issue 11 Inspectors Newsletter

Issue 11 Inspectors Newsletter

Uploaded by

Anil yucebasOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Issue 11 Inspectors Newsletter

Issue 11 Inspectors Newsletter

Uploaded by

Anil yucebasCopyright:

Available Formats

Please keep up to date on the latest news and the high quality services that AWP marine provided:

http://awpmarine.com/

Issue 11

Inspector Bulletin Latest updates & News feeds for Inspectors. 06th Dec 2019

Experience Transfer Advice and Guidance Regulation Updates

VIQ 5.39 Are officers aware of the requirements for

testing fixed fire detection and alarm systems and are

the systems in good order and tested regularly?

Inspector Observation: The vessel was not provided with the correct equipment

Spaces not covered by a fire detection system should be

covered by regular fire patrols. for testing of the flame and heat detectors onboard. A non-approved heat gun

was reported to have been used for such testing rather than the correct flame

and heat testers as recommended by the makers instruction booklet.

Approved Test Equipment

Approved Test Equipment

Inspector Observation: There was no fire detection sensor in Exhaust Gas Cleaning System Failures

the Navigation Bridge which was a control station,

therefore bridge was not protected by fire detection during

cargo operations when bridge was unmanned. The nearest

sensor was located outside the bridge behind the internal

bridge entrance fire door.

Initial Operator Comments: Ship was constructed on 2011

(vessel’s keel laid on 09 Sept 2011) and delivered to her

owners on 17th Feb 2012 being fully compliant with

applicable rules & regulations at the time of construction.

However, following the observation we are in contact with

Classification Society in order to ascertain if further actions

are required. Effect of Failure of EGCS

SOLAS Reg II/2 Reg 7 5.5 Cargo ships (Unless expressly With the 2020 sulphur cap deadline approaching

provided otherwise, the requirements of this chapter shall and the numerous installations of exhaust gas

apply to ships constructed on or after 1 July 2012) cleaning systems on vessels the IMO have

introduced guidance on actions in the event of

Accommodation and service spaces and control stations of failure of such systems.

cargo ships shall be protected by a fixed fire detection and

fire alarm system and/or an automatic sprinkler, fire This Guidance letter https://www.mardep.gov.hk/en/msnote/pdf/msin1917anx3.pdf

detection and fire alarm system as follows, depending on a specifies that a short-term temporary emission exceedance due to the system failure

protection method adopted in accordance with regulation should not be considered as a breach, and the system malfunction that cannot be rectified

9.2.3.1. within one hour is regarded as a breakdown and should be reported to flag States and

port State's Administration. The Guidance also specifies the procedures to show the

In this case here there is no requirement for the fitting of ongoing compliance, in case of the failure of a single monitoring instrument, with other

sensors, however the VIQ guidance does require regular fire parameters continuing at the normal levels.

rounds during periods of the bridge being unmanned. In (Refer to MEPC.1/Circ.883 as attachment 14).

this case, inspectors should verify that a regular fire round

covers the bridge during these unmanned periods. This also This is just to inform inspectors in advance what actions operators will be expected to

applies to other areas that are not protected with fixed fire follow.

detection equipment.

AWP Marine Consultancy Ltd

EMAIL: admin@awpmarine.com TELEPHONE: +44 (0) 151 792 4882

Please keep up to date on the latest news and the high quality services that AWP marine provided: http://awpmarine.com/

Issue 11

Inspector Bulletin

Latest updates & News feeds for Inspectors. 06th Dec 2019

Experience Transfer Advice and Guidance Regulation Updates

Interesting Observation Shared

VIQ 8.46 Is the pump room gas monitoring system ECDIS Annual Inspection Test

in good order, regularly checked and are officers Following on from the Concentrated Inspection Campaign (CIC) on Safety of

aware of the alarm settings? Navigation including ECDIS jointly with the Tokyo MOU between 1 September

2017 and 30 November 2017 it was noted in 3.8% of the inspections, Q2 of the

Sampling points or detector heads shall be located in

suitable positions in order that potentially dangerous questionnaire “Does the ECDIS have the appropriate up-to-date electronic charts

leakages are readily detected. for the intended voyage and is there a suitable back-up arrangement?” raised a

deficiency.

Inspectors Observation;

The Consilium fixed Gas As a result of the CIC and in response to concerns raised by stakeholders across

Sensor Cabinet fitted in the

the maritime industry about the condition of in-service ECDIS, frequently found to

CCR had lost its gas

containment function for have operational issues. Problems typically encountered included inadequate

an eventual system gas power supply arrangements, outdated software versions, disabled audio signal

leak, as 2 approx. 8 cm for alerts, and the incorrect functioning of interfaces to connected equipment.

Diam. Holes had been The purpose of the Guideline is to ensure that an in-service ECDIS is functioning

perforated on the side, properly, in the interests of safety of navigation and of course to meet ISM and

reportedly for better pump SOLAS requirements.

ventilation/cooling.

MSC.1/Circ.1370 GUIDELINES FOR THE DESIGN,

CONSTRUCTION AND TESTING OF FIXED

HYDROCARBON GAS DETECTION SYSTEMS

2.1.7 " The system should be designed, constructed

and installed to prevent the leakage of hydrocarbon

gases into any accommodation and service spaces,

control stations or machinery spaces."

Though the test is NOT mandatory it is recommended and inspectors should

3.2.3 " The gas concentration inside the control verify that there is a process in place for verifying the performance of the

panel enclosure should be monitored. Upon equipment annually. Makers maintenance instructions for ECDIS should also be

detection of gas concentrations above the alarm included within the vessels planned maintenance program.

setpoint within the enclosure, in addition to the

alarm, the gas analysis unit should be automatically Ballast Tanks and Flame Screens - Clarification

isolated from all sampling pipes and shut down.

Appropriate measures should be taken to vent VIQ 11.7 Are fuel, ballast and other space vents and air pipes in good

flammable gas inside the enclosure to an open order and does visual evidence indicate regular maintenance?

NOTE There is no requirement for ballast tank vents to be fitted with flame

space away from ignition sources." screens.

Class have no requirement for installing flame screens on ballast tanks

Basis the above guidance the inspector has rightly though if there are screens fitted then they should of course be in

identified a compromise of the cabinet integrity good order.

which may have an impact on the gas detection 46 CFR 56.50-85 states “Vent outlets from all tanks which may emit

capability of the sensor detecting a leak within the flammable or combustible vapors must be fitted with either :

1) A single screen of corrosion resistant wire of at least 30 by 30 mesh;

space. Refers to enclosure and as you say this is now

or

broached with a larger hole hence integrity is 2) Two screens of corrosion resistant wire of at least 20 by 20 mesh

compromised and system no longer approved or an spaced not less than 1/2 inch nor more than 1 1/2 inches apart. The

"enclosure" clear area through the mesh must not be less than the internal

unobstructed area of the required pipe.”

Hence again no requirement for fitting flame screens in ballast tanks.

AWP Marine Consultancy Ltd

EMAIL: admin@awpmarine.com TELEPHONE: +44 (0) 151 792 4882

You might also like

- Ballast Water Arrangement 31.07.2022Document1 pageBallast Water Arrangement 31.07.2022Anil yucebasNo ratings yet

- MSC.1-Circ.1318-Rev.1 - PDF (IMO Circular 1318 CO2 Maintenance) 4Document9 pagesMSC.1-Circ.1318-Rev.1 - PDF (IMO Circular 1318 CO2 Maintenance) 4AbuBakarSiddiqueNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- GROW Assignment - RITIKA SHARMADocument3 pagesGROW Assignment - RITIKA SHARMARitika SharmaNo ratings yet

- Inspector Bulletin: Issue 11Document2 pagesInspector Bulletin: Issue 11DeepakNo ratings yet

- Issue 31 Inspectors Newsletter 2Document2 pagesIssue 31 Inspectors Newsletter 2capt.deniztasNo ratings yet

- Inspector Bulletin: Issue 14Document3 pagesInspector Bulletin: Issue 14DeepakNo ratings yet

- Issue 19 Inspectors NewsletterDocument2 pagesIssue 19 Inspectors NewslettermihaiNo ratings yet

- Issue 7 Inspectors NewsletterDocument3 pagesIssue 7 Inspectors Newsletter..No ratings yet

- Technical InformationDocument70 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Technical InformationDocument81 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Inspector Bulletin: Interesting ObservationsDocument2 pagesInspector Bulletin: Interesting ObservationsDavid DurhamNo ratings yet

- Checklist For Planned Maintenance Focused Inspection CampaignDocument4 pagesChecklist For Planned Maintenance Focused Inspection Campaignnaing kyawNo ratings yet

- NKDocument10 pagesNKGie BastNo ratings yet

- Ci Fi BahamaDocument10 pagesCi Fi BahamaSuraj Kumar ChauhanNo ratings yet

- 20 Guidelines For The Maintenance and Inspections of Fixed CarbonDocument8 pages20 Guidelines For The Maintenance and Inspections of Fixed CarbonBatuhan SürerNo ratings yet

- Code of Practice For The Design, Installation and Operation of Underground Petroleum Storage SystemsDocument64 pagesCode of Practice For The Design, Installation and Operation of Underground Petroleum Storage SystemsSetiawanNo ratings yet

- 281 FFE MaintenaceDocument11 pages281 FFE MaintenaceNeelakantan SankaranarayananNo ratings yet

- Microsoft Word - Rec.114 - NEW June 2010 - Zoe WrightDocument2 pagesMicrosoft Word - Rec.114 - NEW June 2010 - Zoe WrightJony DarkoNo ratings yet

- Nom-Em-003-Asea-2016 Urv enDocument4 pagesNom-Em-003-Asea-2016 Urv engerman PMNo ratings yet

- Port State Control Guidance For Examination of Fixed CO2 Firefighting SystemsDocument6 pagesPort State Control Guidance For Examination of Fixed CO2 Firefighting Systemsvdeviv0% (1)

- Ci Fi Tuvalu Mc-7-2011Document20 pagesCi Fi Tuvalu Mc-7-2011franklindavid14No ratings yet

- Pumproom SafetyDocument7 pagesPumproom Safetysergiytitov100% (2)

- Bahamas CircularDocument8 pagesBahamas CircularPrasad BangaruNo ratings yet

- Issue 6 Inspectors NewsletterDocument2 pagesIssue 6 Inspectors NewsletterDeepakNo ratings yet

- Maintenance and Inspection of Fire Protection Systems and AppliancesDocument32 pagesMaintenance and Inspection of Fire Protection Systems and Appliancesdiegocely700615100% (1)

- Ci Fi Bermuda2022-021Document17 pagesCi Fi Bermuda2022-021hanyNo ratings yet

- 15-Saip-50 (Ins. For Conduit - Cable Seals)Document5 pages15-Saip-50 (Ins. For Conduit - Cable Seals)sathish KumarNo ratings yet

- MGN 389 (M+F) : Operating Instructions and Signage For Fixed Gas Fire-Extinguishing SystemsDocument3 pagesMGN 389 (M+F) : Operating Instructions and Signage For Fixed Gas Fire-Extinguishing Systemsaolaya14No ratings yet

- Technical InformationDocument81 pagesTechnical Informationoki121No ratings yet

- MSC Circ.1318Document8 pagesMSC Circ.1318Ashish SinghNo ratings yet

- DG Circular For Maintenance of Fire Ext PDFDocument15 pagesDG Circular For Maintenance of Fire Ext PDFNishanth DevddigaNo ratings yet

- 850Document5 pages850Syed Shariq AhmedNo ratings yet

- Top 10 Cargo Vessel (Subchapter I) DeficienciesDocument3 pagesTop 10 Cargo Vessel (Subchapter I) DeficienciesislimaNo ratings yet

- Sprinkler SYstems BriefDocument2 pagesSprinkler SYstems BriefCameronNo ratings yet

- MSC 1-Circ 1370Document7 pagesMSC 1-Circ 1370Renato RiveraNo ratings yet

- Fire Fighting (PANAMA)Document10 pagesFire Fighting (PANAMA)Erick GomezNo ratings yet

- Class NK Technical Information TEC 0869Document9 pagesClass NK Technical Information TEC 0869consaldNo ratings yet

- Enhanced Survey ProgrammeDocument3 pagesEnhanced Survey Programmevirendra302No ratings yet

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210Document4 pages4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210guyueyue100% (2)

- SF 27 23Document6 pagesSF 27 23Shivkumar JadhavNo ratings yet

- Chemical Section 9 - Inerting and Gasfreeing of Cargo Tanks1Document14 pagesChemical Section 9 - Inerting and Gasfreeing of Cargo Tanks1ZIAUL KARIMNo ratings yet

- MSC 1-Circ 1432Document12 pagesMSC 1-Circ 1432waliagauravNo ratings yet

- Fixed Co2 Fire Fighting Systems PDFDocument1 pageFixed Co2 Fire Fighting Systems PDFAli TekinNo ratings yet

- Inspector Bulletin: Issue 4Document2 pagesInspector Bulletin: Issue 4Deepak100% (1)

- Residential Fire Protection ProposalDocument24 pagesResidential Fire Protection ProposalAidan YepsonNo ratings yet

- Cisn 01.14 Maintenance and Inspection of Fire Protection SystemsDocument20 pagesCisn 01.14 Maintenance and Inspection of Fire Protection SystemsJimmy ChinaNo ratings yet

- Ogaom Chapter 9 PDFDocument44 pagesOgaom Chapter 9 PDFjohanaristoNo ratings yet

- Eddy Current SpecificationsDocument7 pagesEddy Current SpecificationsBhavani PrasadNo ratings yet

- Clock Ticks Down To Mandatory BNWAS: Navigation and SafetyDocument4 pagesClock Ticks Down To Mandatory BNWAS: Navigation and SafetyGuilherme ChiminelliNo ratings yet

- Confined Space Monitoring With Ventis: Global Gas Detection & Monitoring SolutionsDocument1 pageConfined Space Monitoring With Ventis: Global Gas Detection & Monitoring SolutionsagbnetNo ratings yet

- Epirb DocsDocument4 pagesEpirb DocsmiguelNo ratings yet

- Technical InformationDocument19 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Inspector Bulletin: Issue 2Document2 pagesInspector Bulletin: Issue 2DeepakNo ratings yet

- Technical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationFrom EverandTechnical Aspects Related to the Design and Construction of Engineered Containment Barriers for Environmental RemediationNo ratings yet

- Regulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsFrom EverandRegulatory Oversight of Ageing Management and Long Term Operation Programme of Nuclear Power PlantsNo ratings yet

- Ageing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationFrom EverandAgeing Management and Long Term Operation of Nuclear Power Plants: Data Management, Scope Setting, Plant Programmes and DocumentationNo ratings yet

- Methodologies for Assessing Pipe Failure Rates in Advanced Water Cooled ReactorsFrom EverandMethodologies for Assessing Pipe Failure Rates in Advanced Water Cooled ReactorsNo ratings yet

- Use of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsFrom EverandUse of Periodic Safety Review for Long Term Operation of Nuclear Power PlantsNo ratings yet

- Summary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignFrom EverandSummary Review on the Application of Computational Fluid Dynamics in Nuclear Power Plant DesignNo ratings yet

- Fleet Invoice DetailsDocument1 pageFleet Invoice DetailsAnil yucebasNo ratings yet

- ABS PSC Annual Report - 2022Document33 pagesABS PSC Annual Report - 2022Anil yucebasNo ratings yet

- Narcotic ListDocument1 pageNarcotic ListAnil yucebasNo ratings yet

- 03 2018 Inoperable BWTS PDFDocument3 pages03 2018 Inoperable BWTS PDFAnil yucebas100% (1)

- DN 125 - Airvent - Certificate 00574CHN19Document1 pageDN 125 - Airvent - Certificate 00574CHN19Anil yucebasNo ratings yet

- PSC Deficiency CardsDocument22 pagesPSC Deficiency CardsAnil yucebasNo ratings yet

- Mars Draft SurveyDocument721 pagesMars Draft SurveyAnil yucebasNo ratings yet

- Wind FinderDocument1 pageWind FinderAnil yucebasNo ratings yet

- Sire InspectionDocument8 pagesSire InspectionAnil yucebasNo ratings yet

- JCDRGuidebook WEBfinal 1Document76 pagesJCDRGuidebook WEBfinal 1Anil yucebasNo ratings yet

- Yasa Mars Draft SurveyDocument22 pagesYasa Mars Draft SurveyAnil yucebasNo ratings yet

- Draft Survey FormDocument39 pagesDraft Survey FormAnil yucebasNo ratings yet

- Eve-Calc2 0Document6 pagesEve-Calc2 0Anonymous NIkO5EI6No ratings yet

- R2B-P3-206-02-A-CE-00001 - Rev.3 - Cause and Effect Matrix-EngDocument8 pagesR2B-P3-206-02-A-CE-00001 - Rev.3 - Cause and Effect Matrix-Engdaniel contrerasNo ratings yet

- Impact of Social Media On YouthDocument2 pagesImpact of Social Media On Youthliza enriquezNo ratings yet

- NodeMCU TutorialDocument49 pagesNodeMCU Tutorialv_ananthuNo ratings yet

- Toyocool Chiller Controller Manufacturer Instruction ManualDocument17 pagesToyocool Chiller Controller Manufacturer Instruction ManualLucinei ManoelNo ratings yet

- ALU Huawei LTE RAN AnalysisDocument65 pagesALU Huawei LTE RAN AnalysisEdwilAlberts100% (4)

- Chandrika CVDocument2 pagesChandrika CVM Madan GopalNo ratings yet

- Infosphere Information Server (Datastage) - Installation ProcessDocument12 pagesInfosphere Information Server (Datastage) - Installation ProcesssrimkbNo ratings yet

- WSN 1Document16 pagesWSN 1Abhi ShahNo ratings yet

- Budgeting For SuccessDocument4 pagesBudgeting For Successbhatiasanjay89No ratings yet

- DBMS Course OutlineDocument14 pagesDBMS Course OutlineMohammed NouhNo ratings yet

- CJFFHVHMVKBJ JBLKN.NDocument3 pagesCJFFHVHMVKBJ JBLKN.NSabyasachi ChandraNo ratings yet

- What Is DataDocument2 pagesWhat Is DataabduNo ratings yet

- Company DetailsDocument3 pagesCompany DetailsanilrajakodgNo ratings yet

- Meter To CashDocument3 pagesMeter To CashAjay GuptaNo ratings yet

- Export Service Bulletin: Rear Wheel Bearing NoiseDocument2 pagesExport Service Bulletin: Rear Wheel Bearing NoiseJavier DíazNo ratings yet

- Generate MS Word Document Files With Codeigniter and Phpword LibraryDocument3 pagesGenerate MS Word Document Files With Codeigniter and Phpword LibraryNobertus ErikNo ratings yet

- Ieee Oceans 2013 Kevin Demarco Dr. Ayanna M. Howard Dr. Michael E. WestDocument29 pagesIeee Oceans 2013 Kevin Demarco Dr. Ayanna M. Howard Dr. Michael E. WestSyllogismRXSNo ratings yet

- Japanese Management Theories - The Hard Fit of It's Core Concepts Into Sri Lankan Business CultureDocument6 pagesJapanese Management Theories - The Hard Fit of It's Core Concepts Into Sri Lankan Business Cultureert3535No ratings yet

- ZXDF10 Diesel Generator User Manual-20200104Document8 pagesZXDF10 Diesel Generator User Manual-20200104David Tombe Rumi100% (1)

- The Performance EquationDocument4 pagesThe Performance Equationvamshi krishnaNo ratings yet

- SCCM Resume - BharathDocument4 pagesSCCM Resume - BharathraamanNo ratings yet

- 11 Is 0353 PS Techlog Petrophysics-LrDocument2 pages11 Is 0353 PS Techlog Petrophysics-Lredison Contreras50% (2)

- Bus Duct - Al-AhleiaDocument7 pagesBus Duct - Al-AhleiasedianpoNo ratings yet

- How To Integrate ICloud Sync in Your AppDocument26 pagesHow To Integrate ICloud Sync in Your AppAnkeet PNo ratings yet

- Stadium FailureDocument1 pageStadium Failurerao_gsv7598No ratings yet

- 20480B Programming in HTML5 With JavaScript and CSS3Document11 pages20480B Programming in HTML5 With JavaScript and CSS3zolodjoNo ratings yet

- Test Engine Specifications: IVECO F1C Euro 4 / 105 KW at 3500 RPMDocument3 pagesTest Engine Specifications: IVECO F1C Euro 4 / 105 KW at 3500 RPMFazalNo ratings yet