Professional Documents

Culture Documents

Appd 3

Appd 3

Uploaded by

Med CHCopyright:

Available Formats

You might also like

- Electronic Principles and Circuits Lab Manual - BEC303 - 18-11-2023Document69 pagesElectronic Principles and Circuits Lab Manual - BEC303 - 18-11-2023Maithira H0% (1)

- Wind Power Plant Testing and CommissioningDocument4 pagesWind Power Plant Testing and CommissioningaNo ratings yet

- T&C ManualDocument65 pagesT&C ManualKarthikeyan S100% (2)

- Exquis Engineering - Electrical Power System Audit Sample Report PDFDocument22 pagesExquis Engineering - Electrical Power System Audit Sample Report PDFR Jay FranNo ratings yet

- 400-200 KV Substation DesignDocument62 pages400-200 KV Substation DesignMousum91% (22)

- PV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesDocument16 pagesPV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesSiddhartha SenguptaNo ratings yet

- LIC LAB Manual PDFDocument86 pagesLIC LAB Manual PDFSandeep SNo ratings yet

- Low-Cost Instrument For Tracing Current-Voltage Characteristics of Photovoltaic ModulesDocument6 pagesLow-Cost Instrument For Tracing Current-Voltage Characteristics of Photovoltaic Modulesa durgadeviNo ratings yet

- DccharaopampDocument11 pagesDccharaopampAvinash NandakumarNo ratings yet

- Verifying PV Array Performance: With TheDocument61 pagesVerifying PV Array Performance: With TheNiken Puspita SariNo ratings yet

- Testing and Commissioning Forms Hybrid or Off Grid FINALDocument3 pagesTesting and Commissioning Forms Hybrid or Off Grid FINALJohn Rafael R. CanoosNo ratings yet

- Site Visit Worksheet: InstructionsDocument12 pagesSite Visit Worksheet: InstructionsTankut YolsalNo ratings yet

- Kec - 452 - Analog - Circuit - Lab Manual - FinalDocument40 pagesKec - 452 - Analog - Circuit - Lab Manual - FinalAnurag siwachNo ratings yet

- Test and Commisioning PTADocument27 pagesTest and Commisioning PTASuryaNo ratings yet

- General Instruction of Energy Meter Instalation - UpdatedDocument9 pagesGeneral Instruction of Energy Meter Instalation - Updatedgurinder sandhuNo ratings yet

- Analog Circuits Lab manual18ECL48Document29 pagesAnalog Circuits Lab manual18ECL48Dintle PhofuNo ratings yet

- Thesis Proposal2Document8 pagesThesis Proposal2RynNo ratings yet

- Step-Size: ImplementationDocument4 pagesStep-Size: Implementationyousaf hameedNo ratings yet

- Ec8311 Experiment QuestionsDocument2 pagesEc8311 Experiment QuestionsBalamurugan SMNo ratings yet

- Experiment 5 - Inverter CharacteristicsDocument7 pagesExperiment 5 - Inverter CharacteristicsGowtham SpNo ratings yet

- Power Quality Improvement With SVC in A Power System of 220kVDocument5 pagesPower Quality Improvement With SVC in A Power System of 220kVSalah SaalhNo ratings yet

- Ece02 Laboratory ManualDocument18 pagesEce02 Laboratory ManualChloe Felice Aguila PaelNo ratings yet

- Analog & Digital Student Lab ManualDocument150 pagesAnalog & Digital Student Lab ManualMaheshwaran Mahi100% (1)

- Center of Advanced in Engineering, Islamabad: Studies Communication Systems LabDocument6 pagesCenter of Advanced in Engineering, Islamabad: Studies Communication Systems LabMuhammad ShayanNo ratings yet

- Selecting Arrester MCOV-UcDocument9 pagesSelecting Arrester MCOV-Ucjose GonzalezNo ratings yet

- Question Bank: RNS Institute of TechnologyDocument15 pagesQuestion Bank: RNS Institute of TechnologyManohar PNo ratings yet

- Valliammai Engineering College: (A Member of SRM Group of Institutions)Document7 pagesValliammai Engineering College: (A Member of SRM Group of Institutions)Jayasuriya PalaniNo ratings yet

- Common Emitter AmplifierDocument3 pagesCommon Emitter AmplifierDaniel Tamisen100% (1)

- Sri Lanka Institute of Information Technology: EN16544246 W.A.M.Ranasinghe Group - 05Document13 pagesSri Lanka Institute of Information Technology: EN16544246 W.A.M.Ranasinghe Group - 05Shashini MaldeniyaNo ratings yet

- Assessment Procedure for Generator (Ele) 发电机评估程序电气部分Document7 pagesAssessment Procedure for Generator (Ele) 发电机评估程序电气部分Kishore KumarNo ratings yet

- PH 411 Physics Laboratory I (Electronics) : Instruction Manual IndexDocument28 pagesPH 411 Physics Laboratory I (Electronics) : Instruction Manual IndexReddyvari VenugopalNo ratings yet

- EEL 3304C - Design and Experiment Project Lab # 4 Common-Emitter AmplifierDocument4 pagesEEL 3304C - Design and Experiment Project Lab # 4 Common-Emitter AmplifierHarshaNo ratings yet

- New IEC Standard 61439Document31 pagesNew IEC Standard 61439osama100% (1)

- Pess Li 1310Document96 pagesPess Li 1310Sarmad KhanNo ratings yet

- Guide To The Measurements On - Electrical InstallationsDocument24 pagesGuide To The Measurements On - Electrical InstallationsVennila RangithNo ratings yet

- Optical Current & Voltage Sensors: Eric Langford, Langford & Associates John Swindlehurst, P.Eng, Nxtphase T&D CorpDocument38 pagesOptical Current & Voltage Sensors: Eric Langford, Langford & Associates John Swindlehurst, P.Eng, Nxtphase T&D CorpKrishna Venkataraman100% (1)

- EE-252-Electronic Devices & Digital Electronics Laboratory Manual/ RecordDocument85 pagesEE-252-Electronic Devices & Digital Electronics Laboratory Manual/ RecordkishorebabNo ratings yet

- F8941 - PRV Commissioning Check SheetDocument26 pagesF8941 - PRV Commissioning Check SheetRANJINI02VNo ratings yet

- Reno 15KDocument27 pagesReno 15KLuciano LemosNo ratings yet

- A MEMS Based Microelectrode Sensor With Integrated Signal Processing CircuitryDocument4 pagesA MEMS Based Microelectrode Sensor With Integrated Signal Processing CircuitrySrivardhan ReddyNo ratings yet

- Impulse Voltage Test System For Interturn and Main Insulation TestingDocument32 pagesImpulse Voltage Test System For Interturn and Main Insulation TestingSubhajit BasakNo ratings yet

- Mi 3108Document2 pagesMi 3108ivanNo ratings yet

- ADDAD-5 Preliminary DatasheetDocument16 pagesADDAD-5 Preliminary Datasheetbhuvan16No ratings yet

- Microwave New Bench ManualDocument51 pagesMicrowave New Bench Manual039 MeghaEceNo ratings yet

- EC2 Exp2 F09Document17 pagesEC2 Exp2 F09Nurul Hanim HashimNo ratings yet

- Pv900 IV TracerDocument4 pagesPv900 IV TracerHermes PolancoNo ratings yet

- Parameter Testing and Modeling of Excitation System For No.1 Unit in Hanpingzui Hydropower StationDocument4 pagesParameter Testing and Modeling of Excitation System For No.1 Unit in Hanpingzui Hydropower StationSanthosh Kumar PendyalaNo ratings yet

- The New IEEE-1584 Guide For Performing Arc-Flash CalculationsDocument51 pagesThe New IEEE-1584 Guide For Performing Arc-Flash CalculationsLuiz Philippe Milioni Dos Santos100% (1)

- A Study On The Effects of Solar PowerDocument34 pagesA Study On The Effects of Solar PowerTosin AbiolaNo ratings yet

- A Study On The Effects of Solar PowerDocument34 pagesA Study On The Effects of Solar PowerJasten TabayoyongNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (2)

- Potentiometric Error DectectorDocument20 pagesPotentiometric Error DectectorBalraj SinghNo ratings yet

- Execution of Hydro Power Plant - PLANNING AND OPERATIONDocument49 pagesExecution of Hydro Power Plant - PLANNING AND OPERATIONkapolaNo ratings yet

- 5896864Document53 pages5896864Sharath AlugandulaNo ratings yet

- EX-602 Control SystemDocument27 pagesEX-602 Control SystemdeepaknayanNo ratings yet

- Optical Instrument Transformers For EHV SubstationsS 0910Document28 pagesOptical Instrument Transformers For EHV SubstationsS 0910vijaykrishnatennetiNo ratings yet

- KN61000 4 2정전기방전내성시험방법Document36 pagesKN61000 4 2정전기방전내성시험방법조성철No ratings yet

- Electrical Spectrum and Network Analyzers: A Practical ApproachFrom EverandElectrical Spectrum and Network Analyzers: A Practical ApproachNo ratings yet

- Electronic Systems: Study Topics in Physics Book 8From EverandElectronic Systems: Study Topics in Physics Book 8Rating: 5 out of 5 stars5/5 (1)

- FiberFamily 4095077 6500 ENG A WDocument3 pagesFiberFamily 4095077 6500 ENG A WMed CHNo ratings yet

- Visual and Optical TestingDocument11 pagesVisual and Optical TestingMed CHNo ratings yet

- Quick Start Guide: Wi-Fi IP CameraDocument60 pagesQuick Start Guide: Wi-Fi IP CameraMed CHNo ratings yet

- QAQC Mechanical Piping EngineerDocument2 pagesQAQC Mechanical Piping EngineerMed CHNo ratings yet

- Catalogue CryogenieDocument20 pagesCatalogue CryogenieMed CHNo ratings yet

- CV Canadien Traduction-InterprétariatDocument3 pagesCV Canadien Traduction-InterprétariatMed CHNo ratings yet

- Meedad Tech Refill Equipment Price ListDocument1 pageMeedad Tech Refill Equipment Price ListMed CHNo ratings yet

- Kiefel Medical KFU enDocument4 pagesKiefel Medical KFU enMed CHNo ratings yet

- Autoclave: Partial Waste Hospital Treatment byDocument2 pagesAutoclave: Partial Waste Hospital Treatment byMed CHNo ratings yet

- CV Canadien Management-DistributionDocument2 pagesCV Canadien Management-DistributionMed CHNo ratings yet

- Data Communications 2 ReviewerDocument6 pagesData Communications 2 ReviewerRechie VallenteNo ratings yet

- P-Q Controls, Inc.: Operations Manual Model 504 / 514 / 524 / 534Document5 pagesP-Q Controls, Inc.: Operations Manual Model 504 / 514 / 524 / 534eng_hamada_4uNo ratings yet

- Unit 3 Fourier Transforms Questions and Answers - Sanfoundry PDFDocument3 pagesUnit 3 Fourier Transforms Questions and Answers - Sanfoundry PDFzohaibNo ratings yet

- UHF Channels 435 MHZ - WWWDocument14 pagesUHF Channels 435 MHZ - WWWedosviracNo ratings yet

- Experiment No: 3 Interfacing Temperature Sensor LM35Document4 pagesExperiment No: 3 Interfacing Temperature Sensor LM35WAGHULE SHUBHAMNo ratings yet

- WCDMA OverviewDocument101 pagesWCDMA OverviewVarsanNo ratings yet

- K - PowerDocument37 pagesK - PowerRadio PartsNo ratings yet

- Single Phase Mid MetersDocument1 pageSingle Phase Mid Metersezse1No ratings yet

- As 62271.202-2008 High-Voltage Switchgear and Controlgear High-Voltage Low-Voltage Prefabricated SubstationDocument10 pagesAs 62271.202-2008 High-Voltage Switchgear and Controlgear High-Voltage Low-Voltage Prefabricated SubstationSAI Global - APAC100% (1)

- An Industrial Training Presentation: All India Radio (Prasar Bharati)Document21 pagesAn Industrial Training Presentation: All India Radio (Prasar Bharati)Anup ShawNo ratings yet

- Fdms7698: N-Channel Powertrench MosfetDocument7 pagesFdms7698: N-Channel Powertrench MosfetAdrian Kim BabelaNo ratings yet

- Use Source Transformation To Find I in The Circuit of Fig. 4.100Document16 pagesUse Source Transformation To Find I in The Circuit of Fig. 4.100Syam SundarNo ratings yet

- Student'S Syllabus: Marine Electricity and Electrical MaintenanceDocument9 pagesStudent'S Syllabus: Marine Electricity and Electrical MaintenancemarpelNo ratings yet

- CSPF Malaysia PDFDocument9 pagesCSPF Malaysia PDFlabNo ratings yet

- 2014 Jaycar AU CatalogueDocument548 pages2014 Jaycar AU Cataloguetroy8weight0% (2)

- Ajr 315-24 (B) - TR PDFDocument3 pagesAjr 315-24 (B) - TR PDFRajasekhar WenigNo ratings yet

- Generator Diesel Chicago Pneumatic CPSG 40Document2 pagesGenerator Diesel Chicago Pneumatic CPSG 40diconNo ratings yet

- Sidha Anayalasys 4.7.2022Document37 pagesSidha Anayalasys 4.7.2022S.SHANMUGA SABAREESANNo ratings yet

- E14-B LV Switchboard and MCCDocument3 pagesE14-B LV Switchboard and MCCAmyNo ratings yet

- C Ste Ftrs PDFDocument8 pagesC Ste Ftrs PDFali amhazNo ratings yet

- Tab 2 - Instruments OEMDocument111 pagesTab 2 - Instruments OEMJocelyn Ambar Gallardo ArismendiNo ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Bridges_1993compressed.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Cache-Control: max-age=0 Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 32c7217e2e3c7d2ff8dfc8507de87c3a2f52331e User-Agent: Mozilla/5.0 (Windows NT 6.0) AppleWebKit/537.22 (KHTML, like Gecko) Chrome/25.0.1364.97 Safari/537.22 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document AccDocument166 pages<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Bridges_1993compressed.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Cache-Control: max-age=0 Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 32c7217e2e3c7d2ff8dfc8507de87c3a2f52331e User-Agent: Mozilla/5.0 (Windows NT 6.0) AppleWebKit/537.22 (KHTML, like Gecko) Chrome/25.0.1364.97 Safari/537.22 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document Acceverest2007No ratings yet

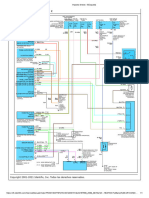

- Sistema Ac JeepDocument1 pageSistema Ac Jeepjorge P, SanchezNo ratings yet

- Antenna Analysis and Design Chapter 3Document7 pagesAntenna Analysis and Design Chapter 3SisayNo ratings yet

- Adobe Scan Sep 20, 2020Document25 pagesAdobe Scan Sep 20, 2020SaibabuNo ratings yet

- MEP Services: WIR EDocument25 pagesMEP Services: WIR EAakanksha VijayNo ratings yet

- Laboratory Exercise 11: Implementing Algorithms in HardwareDocument3 pagesLaboratory Exercise 11: Implementing Algorithms in HardwareTuân PhạmNo ratings yet

- Sales Sheet Agile Airlink 1537518930Document2 pagesSales Sheet Agile Airlink 1537518930გიორგი მოდებაძეNo ratings yet

- ABB GroundingDocument56 pagesABB GroundingAbdullah Kul100% (1)

Appd 3

Appd 3

Uploaded by

Med CHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appd 3

Appd 3

Uploaded by

Med CHCopyright:

Available Formats

Appendix 3

Testing & Commissioning Procedures

HKU PV Research Group

March 2002

Test & Commissioning Procedures for BIPV Systems

1. Introduction

The HKUPV research group is conducting research into Building Integrated

Photovoltaic (BIPV) projects. Initial funds from the Government’s Environment and

Conservation Fund began the thin-film technology monitoring research in 1997. Recent

funding has allowed the group to carry out building integration demonstration projects

with funds mainly from the Hongkong Electric Co. Ltd. (HEC), the Innovation &

Technology Fund (ITF), CLP Research Institute (CLP RI) and a donation in kind from

Flourcity Architectural Metals Asia.

The object of the HKUPV research group is to promote the application of photovoltaic

(PV) technology and the sophisticated integration of PV in Hong Kong’s buildings. To

fulfill this and other activities, e.g. the setting up of demonstration PV projects, the

group now publishes the document Testing and Commissioning Procedures for BIPV

systems, hereinafter referred as the ‘T&C Procedures’.

The purpose of publishing this T&C Procedures is to set up recommended practice to

guarantee quality installation of photovoltaic systems in Hong Kong. It discusses the

following issues:

• Design stage considerations,

• Detail testing and commissioning procedures

• Checklist examples (3 sections)

2. Design stage considerations

Testing and commissioning of a PV system should be seriously addressed and

planned during the design stage to ensure that appropriate provision is made. It is

recommended to identify the commissioning engineer at an early stage of the design

phase. Sufficient time should be allowed in the construction schedule for testing and

commissioning to be adequately carried out and to ensure that any faults or equipment

defects are identified and rectified. Testing cannot be properly carried out under low

levels of sunlight so extra time should be allowed for testing during rainy seasons.

Testing and commissioning requirements should be clearly stated in the contract

specification. These should include parameters to be tested, test conditions, test

points, values expected and acceptable tolerances. If specialist commissioning is

required, it should also be outlined in the specification.

HKU PV Research :August 2001/revised 19 March 2002 1

Test & Commissioning Procedures for BIPV Systems

3. Detail testing and commissioning procedures

Visual checks will be the most simple and effective way to check the PV system

components prior to and after installation. Special attention has to be paid for:

• cracked or broken glass

• signs of delamination or water infiltration

• broken, damaged or discoloured cells

• loose electrical connections to the junction boxes and leads

After examining the components, electrical tests can then be carried out according to

IEE Wiring Regulations, or Code of Practice for Electricity (Wiring) Regulations – 1997

Edition:

1. Continuity of circuit, protective conductors, equi-potential bonding

2. Earth electrode impedance

3. Insulation resistance

4. Polarity

5. Earth loop impedance

6. Functions of protective devices

For a sensible recording of the PV performance, the array commissioning tests should

be carried out under a reasonable sunlight condition of global irradiance of higher than

400W/m2 onto the plane of PV panels. The tests should be checked against the

system specification and detail design taking into account any change made during

installation as follow:

1. string open circuit voltage

2. string short circuit current

3. string maximum power point voltage

4. string maximum power point current

5. array open circuit voltage

6. array short circuit current

7. array maximum power point voltage

8. array maximum power point current

9. array rated power

10. physical installation including mounting details, orientation, and tilt angle

HKU PV Research :August 2001/revised 19 March 2002 2

Test & Commissioning Procedures for BIPV Systems

3. Detail testing and commissioning procedures/continued

For most of the applications there will be a power conversion unit (PCU) for converting

the power to proper form for usage. A series of power conversion unit functional tests

will then be essential:

1. anti-islanding tests (for grid-connecting inverters)

2. disconnection capability for voltage and frequency disturbances (for grid-

connecting inverters)

3. THD and individual harmonics measurement (for grid-connecting inverters)

4. isolation between dc and ac side (for grid-connecting inverters)

5. power factor recording (for PCU with AC output only)

6. EMI measurement

7. acoustic noise recording

8. visual check on markings

Under certain circumstances, specialist commissioning tests of IV curve measuring,

detail tests of inverter performance and data acquisition system tests may be required.

These circumstances include but are not limited to:

1. requirement for the supplier to provide modules with a specified actual power output

rather than a total nominal power output;

2. guaranteed system performance to deliver a specified number of kWh over a given

period;

3. system requirement for modelling or research purposes requiring an accurate

knowledge of the performance;

4. reference data is required for use in subsequent tests, data analysis, computer

modelling or in devising plant management strategies;

5.it has been specified by the system designer;

6. a problem is suspected within the array and further tests are required to confirm the

nature of the fault and pin-point its location.

HKU PV Research :August 2001/revised 19 March 2002 3

Test & Commissioning Procedures for BIPV Systems

4. Check-list example

The following serves only as an example and detail testing procedures shall be

submitted for approval prior to commence tests.

Project Title:

Client:

Commissioning Engineer:

Date of Tests:

Signature:

Witnessed by:

PV ARRAY PERFORMANCE RESULTS

Parameter Measurement Comments

PV system with n strings

Measured Voc V

Measured Isc A

String 1

Measured Voc V

Measured Isc A

String 2

Measured Voc V

Measured Isc A

String n-1

Measured Voc V

Measured Isc A

String n

Measured Voc V

Measured Isc A

Sun of I for all strings A

=∑ Isc

Specified Isc for system A Not for string PCUs

Specified Isc for each string A For string PCU systems

Lowest measured for Isc strings 1 to n A For string PCU system

Lowest measured for Voc strings 1 to n V

Specified string Voc V

INVERTER PERFORMANCE RESULTS

Parameter Symbol Measurements

Inverter serial number

d.c. array power PA kW

d.c. inverter input PII kW

a.c. inverter output PIO kW

Rated inverter efficiency at %

measured d.c. input power

(from supplier’s information)

Measured Inverter efficiency (PIO / PII ) x 100 %

Symbol Description Units

PA Array output power (d.c.) kW

PII Inverter input power (d.c.) kW

PIO Inverter output power (a.c.) kW

end

HKU PV Research :August 2001/revised 19 March 2002 4

You might also like

- Electronic Principles and Circuits Lab Manual - BEC303 - 18-11-2023Document69 pagesElectronic Principles and Circuits Lab Manual - BEC303 - 18-11-2023Maithira H0% (1)

- Wind Power Plant Testing and CommissioningDocument4 pagesWind Power Plant Testing and CommissioningaNo ratings yet

- T&C ManualDocument65 pagesT&C ManualKarthikeyan S100% (2)

- Exquis Engineering - Electrical Power System Audit Sample Report PDFDocument22 pagesExquis Engineering - Electrical Power System Audit Sample Report PDFR Jay FranNo ratings yet

- 400-200 KV Substation DesignDocument62 pages400-200 KV Substation DesignMousum91% (22)

- PV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesDocument16 pagesPV Doctor: For The Inspection and Fault Location of The Photovoltaic ModulesSiddhartha SenguptaNo ratings yet

- LIC LAB Manual PDFDocument86 pagesLIC LAB Manual PDFSandeep SNo ratings yet

- Low-Cost Instrument For Tracing Current-Voltage Characteristics of Photovoltaic ModulesDocument6 pagesLow-Cost Instrument For Tracing Current-Voltage Characteristics of Photovoltaic Modulesa durgadeviNo ratings yet

- DccharaopampDocument11 pagesDccharaopampAvinash NandakumarNo ratings yet

- Verifying PV Array Performance: With TheDocument61 pagesVerifying PV Array Performance: With TheNiken Puspita SariNo ratings yet

- Testing and Commissioning Forms Hybrid or Off Grid FINALDocument3 pagesTesting and Commissioning Forms Hybrid or Off Grid FINALJohn Rafael R. CanoosNo ratings yet

- Site Visit Worksheet: InstructionsDocument12 pagesSite Visit Worksheet: InstructionsTankut YolsalNo ratings yet

- Kec - 452 - Analog - Circuit - Lab Manual - FinalDocument40 pagesKec - 452 - Analog - Circuit - Lab Manual - FinalAnurag siwachNo ratings yet

- Test and Commisioning PTADocument27 pagesTest and Commisioning PTASuryaNo ratings yet

- General Instruction of Energy Meter Instalation - UpdatedDocument9 pagesGeneral Instruction of Energy Meter Instalation - Updatedgurinder sandhuNo ratings yet

- Analog Circuits Lab manual18ECL48Document29 pagesAnalog Circuits Lab manual18ECL48Dintle PhofuNo ratings yet

- Thesis Proposal2Document8 pagesThesis Proposal2RynNo ratings yet

- Step-Size: ImplementationDocument4 pagesStep-Size: Implementationyousaf hameedNo ratings yet

- Ec8311 Experiment QuestionsDocument2 pagesEc8311 Experiment QuestionsBalamurugan SMNo ratings yet

- Experiment 5 - Inverter CharacteristicsDocument7 pagesExperiment 5 - Inverter CharacteristicsGowtham SpNo ratings yet

- Power Quality Improvement With SVC in A Power System of 220kVDocument5 pagesPower Quality Improvement With SVC in A Power System of 220kVSalah SaalhNo ratings yet

- Ece02 Laboratory ManualDocument18 pagesEce02 Laboratory ManualChloe Felice Aguila PaelNo ratings yet

- Analog & Digital Student Lab ManualDocument150 pagesAnalog & Digital Student Lab ManualMaheshwaran Mahi100% (1)

- Center of Advanced in Engineering, Islamabad: Studies Communication Systems LabDocument6 pagesCenter of Advanced in Engineering, Islamabad: Studies Communication Systems LabMuhammad ShayanNo ratings yet

- Selecting Arrester MCOV-UcDocument9 pagesSelecting Arrester MCOV-Ucjose GonzalezNo ratings yet

- Question Bank: RNS Institute of TechnologyDocument15 pagesQuestion Bank: RNS Institute of TechnologyManohar PNo ratings yet

- Valliammai Engineering College: (A Member of SRM Group of Institutions)Document7 pagesValliammai Engineering College: (A Member of SRM Group of Institutions)Jayasuriya PalaniNo ratings yet

- Common Emitter AmplifierDocument3 pagesCommon Emitter AmplifierDaniel Tamisen100% (1)

- Sri Lanka Institute of Information Technology: EN16544246 W.A.M.Ranasinghe Group - 05Document13 pagesSri Lanka Institute of Information Technology: EN16544246 W.A.M.Ranasinghe Group - 05Shashini MaldeniyaNo ratings yet

- Assessment Procedure for Generator (Ele) 发电机评估程序电气部分Document7 pagesAssessment Procedure for Generator (Ele) 发电机评估程序电气部分Kishore KumarNo ratings yet

- PH 411 Physics Laboratory I (Electronics) : Instruction Manual IndexDocument28 pagesPH 411 Physics Laboratory I (Electronics) : Instruction Manual IndexReddyvari VenugopalNo ratings yet

- EEL 3304C - Design and Experiment Project Lab # 4 Common-Emitter AmplifierDocument4 pagesEEL 3304C - Design and Experiment Project Lab # 4 Common-Emitter AmplifierHarshaNo ratings yet

- New IEC Standard 61439Document31 pagesNew IEC Standard 61439osama100% (1)

- Pess Li 1310Document96 pagesPess Li 1310Sarmad KhanNo ratings yet

- Guide To The Measurements On - Electrical InstallationsDocument24 pagesGuide To The Measurements On - Electrical InstallationsVennila RangithNo ratings yet

- Optical Current & Voltage Sensors: Eric Langford, Langford & Associates John Swindlehurst, P.Eng, Nxtphase T&D CorpDocument38 pagesOptical Current & Voltage Sensors: Eric Langford, Langford & Associates John Swindlehurst, P.Eng, Nxtphase T&D CorpKrishna Venkataraman100% (1)

- EE-252-Electronic Devices & Digital Electronics Laboratory Manual/ RecordDocument85 pagesEE-252-Electronic Devices & Digital Electronics Laboratory Manual/ RecordkishorebabNo ratings yet

- F8941 - PRV Commissioning Check SheetDocument26 pagesF8941 - PRV Commissioning Check SheetRANJINI02VNo ratings yet

- Reno 15KDocument27 pagesReno 15KLuciano LemosNo ratings yet

- A MEMS Based Microelectrode Sensor With Integrated Signal Processing CircuitryDocument4 pagesA MEMS Based Microelectrode Sensor With Integrated Signal Processing CircuitrySrivardhan ReddyNo ratings yet

- Impulse Voltage Test System For Interturn and Main Insulation TestingDocument32 pagesImpulse Voltage Test System For Interturn and Main Insulation TestingSubhajit BasakNo ratings yet

- Mi 3108Document2 pagesMi 3108ivanNo ratings yet

- ADDAD-5 Preliminary DatasheetDocument16 pagesADDAD-5 Preliminary Datasheetbhuvan16No ratings yet

- Microwave New Bench ManualDocument51 pagesMicrowave New Bench Manual039 MeghaEceNo ratings yet

- EC2 Exp2 F09Document17 pagesEC2 Exp2 F09Nurul Hanim HashimNo ratings yet

- Pv900 IV TracerDocument4 pagesPv900 IV TracerHermes PolancoNo ratings yet

- Parameter Testing and Modeling of Excitation System For No.1 Unit in Hanpingzui Hydropower StationDocument4 pagesParameter Testing and Modeling of Excitation System For No.1 Unit in Hanpingzui Hydropower StationSanthosh Kumar PendyalaNo ratings yet

- The New IEEE-1584 Guide For Performing Arc-Flash CalculationsDocument51 pagesThe New IEEE-1584 Guide For Performing Arc-Flash CalculationsLuiz Philippe Milioni Dos Santos100% (1)

- A Study On The Effects of Solar PowerDocument34 pagesA Study On The Effects of Solar PowerTosin AbiolaNo ratings yet

- A Study On The Effects of Solar PowerDocument34 pagesA Study On The Effects of Solar PowerJasten TabayoyongNo ratings yet

- CT Testing LTDocument25 pagesCT Testing LTVijaya Kumar100% (2)

- Potentiometric Error DectectorDocument20 pagesPotentiometric Error DectectorBalraj SinghNo ratings yet

- Execution of Hydro Power Plant - PLANNING AND OPERATIONDocument49 pagesExecution of Hydro Power Plant - PLANNING AND OPERATIONkapolaNo ratings yet

- 5896864Document53 pages5896864Sharath AlugandulaNo ratings yet

- EX-602 Control SystemDocument27 pagesEX-602 Control SystemdeepaknayanNo ratings yet

- Optical Instrument Transformers For EHV SubstationsS 0910Document28 pagesOptical Instrument Transformers For EHV SubstationsS 0910vijaykrishnatennetiNo ratings yet

- KN61000 4 2정전기방전내성시험방법Document36 pagesKN61000 4 2정전기방전내성시험방법조성철No ratings yet

- Electrical Spectrum and Network Analyzers: A Practical ApproachFrom EverandElectrical Spectrum and Network Analyzers: A Practical ApproachNo ratings yet

- Electronic Systems: Study Topics in Physics Book 8From EverandElectronic Systems: Study Topics in Physics Book 8Rating: 5 out of 5 stars5/5 (1)

- FiberFamily 4095077 6500 ENG A WDocument3 pagesFiberFamily 4095077 6500 ENG A WMed CHNo ratings yet

- Visual and Optical TestingDocument11 pagesVisual and Optical TestingMed CHNo ratings yet

- Quick Start Guide: Wi-Fi IP CameraDocument60 pagesQuick Start Guide: Wi-Fi IP CameraMed CHNo ratings yet

- QAQC Mechanical Piping EngineerDocument2 pagesQAQC Mechanical Piping EngineerMed CHNo ratings yet

- Catalogue CryogenieDocument20 pagesCatalogue CryogenieMed CHNo ratings yet

- CV Canadien Traduction-InterprétariatDocument3 pagesCV Canadien Traduction-InterprétariatMed CHNo ratings yet

- Meedad Tech Refill Equipment Price ListDocument1 pageMeedad Tech Refill Equipment Price ListMed CHNo ratings yet

- Kiefel Medical KFU enDocument4 pagesKiefel Medical KFU enMed CHNo ratings yet

- Autoclave: Partial Waste Hospital Treatment byDocument2 pagesAutoclave: Partial Waste Hospital Treatment byMed CHNo ratings yet

- CV Canadien Management-DistributionDocument2 pagesCV Canadien Management-DistributionMed CHNo ratings yet

- Data Communications 2 ReviewerDocument6 pagesData Communications 2 ReviewerRechie VallenteNo ratings yet

- P-Q Controls, Inc.: Operations Manual Model 504 / 514 / 524 / 534Document5 pagesP-Q Controls, Inc.: Operations Manual Model 504 / 514 / 524 / 534eng_hamada_4uNo ratings yet

- Unit 3 Fourier Transforms Questions and Answers - Sanfoundry PDFDocument3 pagesUnit 3 Fourier Transforms Questions and Answers - Sanfoundry PDFzohaibNo ratings yet

- UHF Channels 435 MHZ - WWWDocument14 pagesUHF Channels 435 MHZ - WWWedosviracNo ratings yet

- Experiment No: 3 Interfacing Temperature Sensor LM35Document4 pagesExperiment No: 3 Interfacing Temperature Sensor LM35WAGHULE SHUBHAMNo ratings yet

- WCDMA OverviewDocument101 pagesWCDMA OverviewVarsanNo ratings yet

- K - PowerDocument37 pagesK - PowerRadio PartsNo ratings yet

- Single Phase Mid MetersDocument1 pageSingle Phase Mid Metersezse1No ratings yet

- As 62271.202-2008 High-Voltage Switchgear and Controlgear High-Voltage Low-Voltage Prefabricated SubstationDocument10 pagesAs 62271.202-2008 High-Voltage Switchgear and Controlgear High-Voltage Low-Voltage Prefabricated SubstationSAI Global - APAC100% (1)

- An Industrial Training Presentation: All India Radio (Prasar Bharati)Document21 pagesAn Industrial Training Presentation: All India Radio (Prasar Bharati)Anup ShawNo ratings yet

- Fdms7698: N-Channel Powertrench MosfetDocument7 pagesFdms7698: N-Channel Powertrench MosfetAdrian Kim BabelaNo ratings yet

- Use Source Transformation To Find I in The Circuit of Fig. 4.100Document16 pagesUse Source Transformation To Find I in The Circuit of Fig. 4.100Syam SundarNo ratings yet

- Student'S Syllabus: Marine Electricity and Electrical MaintenanceDocument9 pagesStudent'S Syllabus: Marine Electricity and Electrical MaintenancemarpelNo ratings yet

- CSPF Malaysia PDFDocument9 pagesCSPF Malaysia PDFlabNo ratings yet

- 2014 Jaycar AU CatalogueDocument548 pages2014 Jaycar AU Cataloguetroy8weight0% (2)

- Ajr 315-24 (B) - TR PDFDocument3 pagesAjr 315-24 (B) - TR PDFRajasekhar WenigNo ratings yet

- Generator Diesel Chicago Pneumatic CPSG 40Document2 pagesGenerator Diesel Chicago Pneumatic CPSG 40diconNo ratings yet

- Sidha Anayalasys 4.7.2022Document37 pagesSidha Anayalasys 4.7.2022S.SHANMUGA SABAREESANNo ratings yet

- E14-B LV Switchboard and MCCDocument3 pagesE14-B LV Switchboard and MCCAmyNo ratings yet

- C Ste Ftrs PDFDocument8 pagesC Ste Ftrs PDFali amhazNo ratings yet

- Tab 2 - Instruments OEMDocument111 pagesTab 2 - Instruments OEMJocelyn Ambar Gallardo ArismendiNo ratings yet

- <!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Bridges_1993compressed.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Cache-Control: max-age=0 Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 32c7217e2e3c7d2ff8dfc8507de87c3a2f52331e User-Agent: Mozilla/5.0 (Windows NT 6.0) AppleWebKit/537.22 (KHTML, like Gecko) Chrome/25.0.1364.97 Safari/537.22 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document AccDocument166 pages<!DOCTYPE HTML PUBLIC "-//W3C//DTD HTML 4.01 Transitional//EN" "http://www.w3.org/TR/html4/loose.dtd"> <HTML><HEAD><META HTTP-EQUIV="Content-Type" CONTENT="text/html; charset=iso-8859-1"> <TITLE>ERROR: The requested URL could not be retrieved</TITLE> <STYLE type="text/css"><!--BODY{background-color:#ffffff;font-family:verdana,sans-serif}PRE{font-family:sans-serif}--></STYLE> </HEAD><BODY> <H1>ERROR</H1> <H2>The requested URL could not be retrieved</H2> <HR noshade size="1px"> <P> While trying to process the request: <PRE> TEXT http://www.scribd.com/titlecleaner?title=Bridges_1993compressed.pdf HTTP/1.1 Host: www.scribd.com Proxy-Connection: keep-alive Cache-Control: max-age=0 Accept: */* Origin: http://www.scribd.com X-CSRF-Token: 32c7217e2e3c7d2ff8dfc8507de87c3a2f52331e User-Agent: Mozilla/5.0 (Windows NT 6.0) AppleWebKit/537.22 (KHTML, like Gecko) Chrome/25.0.1364.97 Safari/537.22 X-Requested-With: XMLHttpRequest Referer: http://www.scribd.com/upload-document Acceverest2007No ratings yet

- Sistema Ac JeepDocument1 pageSistema Ac Jeepjorge P, SanchezNo ratings yet

- Antenna Analysis and Design Chapter 3Document7 pagesAntenna Analysis and Design Chapter 3SisayNo ratings yet

- Adobe Scan Sep 20, 2020Document25 pagesAdobe Scan Sep 20, 2020SaibabuNo ratings yet

- MEP Services: WIR EDocument25 pagesMEP Services: WIR EAakanksha VijayNo ratings yet

- Laboratory Exercise 11: Implementing Algorithms in HardwareDocument3 pagesLaboratory Exercise 11: Implementing Algorithms in HardwareTuân PhạmNo ratings yet

- Sales Sheet Agile Airlink 1537518930Document2 pagesSales Sheet Agile Airlink 1537518930გიორგი მოდებაძეNo ratings yet

- ABB GroundingDocument56 pagesABB GroundingAbdullah Kul100% (1)