Professional Documents

Culture Documents

IO01 NFZ Y RA 0001 Rev.04 1

IO01 NFZ Y RA 0001 Rev.04 1

Uploaded by

hamidrezaettelaieOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IO01 NFZ Y RA 0001 Rev.04 1

IO01 NFZ Y RA 0001 Rev.04 1

Uploaded by

hamidrezaettelaieCopyright:

Available Formats

IOOC Gas Export Pipeline System

Integrity Management System

04 31/08/2019 Issued for Approval S. Pirsiavash R. Fallahzadeh M. Hajiarab

03 25/08/2019 Issued for Review S. Pirsiavash R. Fallahzadeh M. Hajiarab

02 11/08/2019 Issued for Review S. Pirsiavash S. Pirsiavash M. Hajiarab

01 24/07/2019 Internal Document Review S. Pirsiavash R. Fallahzadeh M. Hajiarab

Revision Date Reason for issue Prepared Checked Approved

Title/Description Responsible party

NFZ/ISCO

Integrity Status of IOOC 32-inch Asaluyeh-Sirri Gas

No. of pages

Export Pipeline System

135

Document Number

Project Originator Discipline Doc type Sequence Area System

code code code code number code code

IO01 NFZ Y RA 0001 - -

IO01-NFZ-Y-RA-0001 - -

NORAN ENERGY Page 1 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC 32-inch Asaluyeh-Sirri

Gas Export Pipeline System

CONTRACT No. FG2-97-5248

CLIENT: Iranian Offshore Oil Company (IOOC)

NORAN ENERGY Page 2 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Distribution List

Soft Hard

Company Department Recipients

Copy Copy

Offshore Installation Maintenance and Repair

IOOC Ali Khavasfar ✓ ✓

head, Integrity team leader

IOOC Senior Integrity Engineer Sadegh Momeni ✓ -

Contact Details

Contractor: Client:

Norway office: Iranian Offshore Oil Company (IOOC)

Noran Energy Norge AS, Olav Brunborgsvei 6, 4 etg., No.12, Tooraj street, Vali-e-asr,

1396, Billingstad, Norway

Tehran, Iran

Tel: +47 9866 5991

Tel: +98 (21) 23942000

Iran office:

ISCO Middle East, No.29, Abbas Pour St., Vanak Sq.,

Tehran

Tel: +98 (21) 88771289

Email: Email:

info@pipeline-technologies.com akhavasfar@iooc.co.ir

r.fallahzadeh@iscogroup-ir.com

mh@noranenergy.com

NORAN ENERGY Page 3 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

This page is intentionally left blank

NORAN ENERGY Page 4 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Table of Contents:

LIST OF REPORT ACRONYMS AND DEFINITIONS ............................................................................. 11

1 INTRODUCTION (FIELD/ASSET OVERVIEW) ............................................................................... 13

1.5.1 Landfall Coordinates ............................................................................................................. 17

2 PROJECT ASSUMPTIONS .............................................................................................................. 22

3 EXECUTIVE SUMMARY .................................................................................................................. 23

4 DATA QUALITY, ACCURACY AND CONFIDENCE ....................................................................... 25

5 PIPELINE INSPECTION TECHNIQUES .......................................................................................... 26

5.1.1 Generic Inspection Techniques............................................................................................. 26

5.1.2 Inspection Categories ........................................................................................................... 26

5.2.1 Generic Pipeline Inspection Techniques ............................................................................... 27

6 THREAT IDENTIFICATION .............................................................................................................. 28

6.1.1 Generic Defect Assessment Methodologies for Subsea Pipelines ....................................... 29

7 RISK ASSESSMENTS (SEMI-QUANTITATIVE APPROACH) ....................................................... 31

7.6.1 Credible Threats .................................................................................................................... 38

7.7.1 Top of the Line Corrosion...................................................................................................... 39

7.7.2 Bottom of the Line Corrosion ................................................................................................ 39

8 FAILURE MODES ............................................................................................................................ 41

9 ASALUYEH-SIRRI PIPELINE SEGMENTATION ............................................................................ 42

10 ILI DATA ANALYSIS AND FITNESS FOR PURPOSE (FFP) ASSESSMENT ............................... 44

10.1.1 ILI Tool Tolerances ........................................................................................................... 44

NORAN ENERGY Page 5 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

10.2.1 Distribution of Features with Respect to their Types ........................................................ 46

10.2.2 Distribution of Metal Loss Features with Respect to Clock Position and Distance ........... 47

10.2.3 Summary of Anomaly Features Reported in ILI 2016 ....................................................... 49

10.2.4 Other Features .................................................................................................................. 51

10.4.1 Parameters Used in the FFP Assessments ...................................................................... 55

10.4.2 Assessment Method .......................................................................................................... 56

10.4.3 Design Factor .................................................................................................................... 56

10.4.4 Defect Assessment Results .............................................................................................. 57

10.4.5 Calculation for the Minimum Existing Wall Thickness....................................................... 58

11 ROOT CAUSE ANALYSIS ............................................................................................................... 62

11.1.1 Internal Corrosion Distribution........................................................................................... 62

11.1.2 Pitting Corrosion ................................................................................................................ 63

11.1.3 General Corrosion ............................................................................................................. 63

11.1.4 MIC .................................................................................................................................... 63

11.2.1 External Corrosion Distribution ......................................................................................... 65

11.2.2 External Corrosion Root Cause Analysis and Mechanisms ............................................. 65

11.2.3 Dents ................................................................................................................................. 65

11.2.4 Manufacturing Features .................................................................................................... 66

12 ROV................................................................................................................................................... 67

13 FACILITIES INTEGRITY STATUS ................................................................................................... 69

14 IOW ................................................................................................................................................... 70

15 ASSESSED CORROSION RATE (ACR) ......................................................................................... 73

15.3.1 Corrosion Coupons ........................................................................................................... 77

16 REMEDIAL ACTION PLAN .............................................................................................................. 79

17 OPERATIONAL PIGGING AND DEBRIS ANALYSIS ..................................................................... 84

18 LAND SURVEYS .............................................................................................................................. 85

18.2.1 Recommendation for Shore Approach Segment .............................................................. 86

19 IN-HOUSE PROCEDURES TO BE UPDATED OR DEVELOPED .................................................. 87

NORAN ENERGY Page 6 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

20 CONCLUSIONS ................................................................................................................................ 88

21 RECOMMENDATION ....................................................................................................................... 89

22 REFERENCES .................................................................................................................................. 93

23 APPENDIX A: SUPPORTIVE INFORMATION ................................................................................ 94

23.4.1 Pin-Hole Clamp ................................................................................................................. 96

23.4.2 Steel Sleeve Type B .......................................................................................................... 96

23.4.3 Bolted Repair Clamp ......................................................................................................... 97

23.4.4 Composite Repair.............................................................................................................. 97

23.4.5 Patch Clamp ...................................................................................................................... 97

23.4.6 Coupling ............................................................................................................................ 97

23.4.7 Connector .......................................................................................................................... 97

23.5.1 General Procedure ............................................................................................................ 98

23.11.1 Coating Survey ................................................................................................................ 101

23.11.2 Cathodic Protection Surveys ........................................................................................... 104

23.11.3 Trans-rectifier Settings History for Onshore Section....................................................... 106

24 APPENDIX B: LIST OF 200 MOST SIGNIFICANT ERF AND DEPTH ......................................... 107

25 APPENDIX C: DATA SHEET AND INSPECTION FORM FOR BVS ............................................ 111

26 APPENDIX D: DATA SHEET AND INSPECTION FORM FOR PIG TRAPS ................................ 117

27 APPENDIX E: PARSPIMS TM ENTERPRISE SOFTWARE SNAPSHOT FOR ASALUYEH-SIRRI

PIPELINE ................................................................................................................................................ 123

NORAN ENERGY Page 7 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

List of Figures:

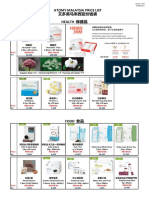

Figure 1.2-1, 32-inch Asaluyeh-Sirri pipeline overview ............................................................................. 13

Figure 1.5-1, Zone 39N (Asaluyeh landfall) & 40N (Sirri landfall), Asaluyeh-Sirri Pipeline ...................... 16

Figure 1.5-2, UTM Grid zones on Iran ...................................................................................................... 17

Figure 9.1-1, Schematic view of segmentations in 32-inch Asaluyeh-Sirri pipeline ................................. 43

Figure 10.2-1, Distribution of features with respect to their types............................................................. 46

Figure 10.2-2, Distribution of metal loss features Vs Orientation from km 0 to 4.5 .................................. 47

Figure 10.2-3, Distribution of metal loss Vs. Orientation for km 7.9 to 11 ................................................ 47

Figure 10.2-4, Distribution of defects for Depth>=40% ............................................................................. 48

Figure 10.2-5, Distribution of defects for Depth>=30%............................................................................. 49

Figure 10.4-1, Location class in 32-inch Asaluyeh-Sirri pipeline .............................................................. 56

Figure 10.4-2, Defects Graphical Plot based on DNVGL RP-F101 Part B with ILI tolerances................. 57

Figure 10.4-3, Defects Graphical Plot based on DNVGL RP-F101 Part B without ILI tolerances............ 57

Figure 10.4-4, FFP assessment results for corrosion features located at pipe joints with wall thickness <

19.5mm ..................................................................................................................................................... 58

Figure 10.5-1, RBA curve of 32-inch Asaluyeh-Sirri pipeline.................................................................... 59

Figure 10.6-1, Verified location (by DP2) .................................................................................................. 60

Figure 11.1-1, Internal corrosion distribution along the pipeline length .................................................... 62

Figure 11.1-2, Clock position of internal defects from top to bottom of pipeline ....................................... 62

Figure 11.1-3, Asaluyeh-Sirri Pipeline Elevation Profile (Offshore) .......................................................... 63

Figure 11.2-1, Distribution of External defects along the pipeline length ................................................. 65

Figure 12.1-1, Pipeline crossing with other pipeline(s) ............................................................................. 68

Figure 14.2-1, Asaluyeh-Sirri pipeline pressure gradient at Asaluyeh ...................................................... 71

Figure 14.2-2, Asaluyeh-Sirri pipeline pressure gradient at Sirri .............................................................. 71

Figure 14.3-1, Asaluyeh-Sirri Temperature gradient ................................................................................ 72

Figure 14.4-1, Asaluyeh-Sirri flow data ..................................................................................................... 72

Figure 15.3-1, Corrosion Coupon weight loss plot .................................................................................... 78

Figure 18.2-1, Landfall segment Sirri (segment #210) with predicted Geotextile protection .................... 85

Figure 18.2-2, Segment #210 profile with protection cover ...................................................................... 86

Figure 23.5-1, Above-Water Repair Procedure a) Side View, b) Top View .............................................. 99

Figure 23.11-1, Available methods for coating survey in subsea segment ............................................ 103

Figure 23.11-2, CP value of sacrificial anodes, ROV 2010 .................................................................... 105

NORAN ENERGY Page 8 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

List of Tables:

Table 1.5-1, UTM system for Zone 39 & 40 .............................................................................................. 16

Table 1.5-2, Asaluyeh and Sirri Landfall Location .................................................................................... 17

Table 1.6-1, In-scope pipeline design and operational data*.................................................................... 18

Table 1.7-1, Sea State Parameters- Shore Approach segment ............................................................... 19

Table 1.7-2, Sea States Parameters- Offshore segments ........................................................................ 19

Table 1.8-1, Coating in 32-inch Asaluyeh-Sirri pipeline (Based on As-Built)............................................ 20

Table 1.9-1, Concrete coat thickness details for offshore section ............................................................ 20

Table 1.10-1, Summary of the past working fluid composition of 32-inch Asaluyeh-Sirri pipeline ........... 21

Table 1.10-2, Summary of the future working fluid composition of 32-inch Asaluyeh-Sirri pipeline ......... 21

Table 3.1-1, Proposed summary of the pipeline integrity status ............................................................... 23

Table 5.1-1, Inspection Techniques (DNV, 2009) ..................................................................................... 26

Table 6.1-1, Typical codified Subsea Pipelines Threats ........................................................................... 28

Table 6.1-2, Overview of Subsea Pipelines Assessment Codes/Guidelines............................................ 29

Table 7.1-1, 5x5 Risk Assessment Matrix (Semi-Quantitative Approach) with Work Selection Inspection

Intervals (years) ........................................................................................................................................ 32

Table 7.1-2, Risk Categories..................................................................................................................... 32

Table 7.2-1, Semi-Quantitative risk assessment of the shore approach section...................................... 33

Table 7.3-1, Semi-Quantitative risk assessment of the subsea section ................................................... 35

Table 7.4-1, Onshore Section threat identification (Risk Based) .............................................................. 37

Table 7.5-1, Summary of Risk ranking...................................................................................................... 37

Table 7.5-2, Summary of risk ranking in 32-inch Asaluyeh-Sirri pipeline ................................................. 38

Table 9.1-1, Pipeline Segmentation .......................................................................................................... 42

Table 9.1-2, Segmentation colour codes .................................................................................................. 43

Table 10.1-1, Detection and Sizing Accuracy of ILI tool ........................................................................... 44

Table 10.1-2, Detection and sizing accuracy for anomalies ..................................................................... 45

Table 10.2-1, Summary of detected manufacturing related features and anomalies ............................... 49

Table 10.2-2, Metal loss feature distribution with respect to their depth and ERF ................................... 50

Table 10.2-3, Generic list of features in ILI-2016 ...................................................................................... 50

Table 10.3-1, The most 30 significant defects based on highest ERF* .................................................... 52

Table 10.3-2, List of 20 deepest features ................................................................................................. 53

Table 10.4-1, Offshore Pipeline Input data sheet for DNVGL RP-F101 calculations module .................. 54

Table 10.4-2, Input data used for the immediate FFP assessments ........................................................ 55

Table 10.4-3, The pipeline safety factors .................................................................................................. 56

Table 10.6-1, Wall thickness readings for subsea verification .................................................................. 60

Table 10.7-1, Summary of Pipeline Structural Integrity Assessment........................................................ 61

Table 11.1-1 Chemical and Microbial Analyzed Results of Sediments Sample ....................................... 64

Table 11.2-1, List of dents......................................................................................................................... 66

Table 12.1-1, Observed Crossings - 32-inch Asaluyeh-Sirri Pipeline ....................................................... 67

Table 12.2-1, The most severe Free Spans (ROV- 2010) ........................................................................ 68

Table 14.1-1, Integrity Operating Window ................................................................................................ 70

Table 15.2-1, ECE Corrosion calculation for Past Super Dry Sour Gas Working Fluid Composition ...... 74

Table 15.2-2, ECE Corrosion calculation for Future Dry Sweet Gas Working Fluid Composition ........... 74

Table 15.3-1, Assessed Corrosion Rate (ACR), [mm/yr] for Past Super Dry Sour Gas Working Fluid

Composition .............................................................................................................................................. 75

Table 15.3-2, Assessed Corrosion Rate (ACR), [mm/yr] for Future Dry Sweet Gas Working Fluid

Composition .............................................................................................................................................. 76

Table 15.3-3, Corrosion Coupon retrieval report period Sep. 2016 to Jan. 2019 ..................................... 77

Table 16.1-1, Immediate 1-year Action Plan............................................................................................. 79

Table 16.2-1, Medium Term 3-Years Action Plan ..................................................................................... 81

Table 16.3-1, Long-term 5-year Action Plan ............................................................................................. 83

Table 23.4-1, Possible Generic Repair Methods ...................................................................................... 96

Table 23.11-1, 32-inch Asaluyeh – Sirri pipeline Max. & min. CP potential Value ................................. 105

NORAN ENERGY Page 9 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Disclaimer

This document is issued in accordance with an agreement between ISCO-Noran Energy consortium

(Contractor) and Iranian Offshore Oil Company (Client), which sets out the rights, obligations and liabilities

of the parties with respect to the content and use of this report.

This report is prepared for the Client only and Contractor accepts no liability for any loss or damage

suffered by any third party who may rely on the contents of this report. In this respect, third party means

any entity whom has no legal status towards National Iranian Oil Company and Contractor.

This report may contain material or information obtained from third party sources. In this regard Contractor

accepts no liability for any loss or damage suffered by any person, including the Client, as a result of any

error or inaccuracy in third party material or information which is included in this report.

Further, this report is prepared by Contractor based on documented information provided by Client. This

input information is evaluated and verified to Contractor’s best knowledge and any input assumption is

clearly outlined in the report. Hence, validity of this report is based on the stated inputs and assumptions.

This document is the property of Client and any information contained herein shall not be reproduced,

used, transmitted nor in any way made public without permission of the Client. No part of this document

shall be reproduced, stored in a retrieval system or transmitted in any form or by any means electronic,

mechanical, photocopying, recording or otherwise, without the prior written permission of the Client.

NORAN ENERGY Page 10 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

List of Report Acronyms and definitions

% IR drop Percentage of potential drop due to solution resistance

3LPE Three Layer Polyethylene

4WD Four-wheel drive, also called 4×4

Abs Absolute Distance

AC Alternative Current

ACR Assessed Corrosion Rate (mm/yr)

AGM Above Ground Marker

ALARP As Low as Reasonably Practical

Amb. Temp Ambient Temperature

APB Acid-Producing Bacteria

API American Petroleum Institute

ASA-SIR Asaluyeh-Sirri pipeline

ASAP As soon as possible

ASME The American Society of Mechanical Engineers

AUT Automatic Ultrasonic testing

AUV Autonomous Underwater Vehicles

BOD Barrels of Oil per Day

BS&W Basic Sediment and Water

BVS Block Valve Station

CA Corrosion Allowance

CI Corrosion Inhibitor

CIPS Close interval potential survey

CoF Consequence of Failure

CRA Corrosion-Resistant Alloy

CVI Close Visual Inspection

CWC Concrete Weight Coating for offshore pipelines

DC Direct Current

DCVG Direct Current Voltage Gradient

DFI Design/Fabrication/Installation

DNV Det Norske Veritas

DP Dynamic Positioning like DP2

EC Eddy Current (NDT method)

ECDA External Corrosion Direct Assessment

ECE Electronic Corrosion Engineer software for quantitative estimation of corrosion

rates

EPRS Emergency Pipeline Repair Scheme

ERF Estimated Repair Factor

ERP Enterprise Resource Planning

FAT Factory Acceptance Test

FFP Fitness For Purpose (See FFS as well)

FFS Fitness For Service

FLRA Field Level Risk Assessment

GIS Geographical Information System

GVI General Visual Inspection

GVI XTD Extended Visual Pipeline survey/Inspection

GWT Guided Wave Testing

GWUT Guided Wave Ultrasonic Testing

HAT Highest Astronomical Tides

HIC Hydrogen Induced Cracking

HPS High Precision Survey

HR-MFL High Resolution Magnetic Flux Leakage

HSE Health, Safety and Environment

HVL Highly Volatile Liquids

HWM High Water Mark

ICCP Impressed Current Cathodic Protection

NORAN ENERGY Page 11 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

ICDA Internal Corrosion Direct Assessment

ILI In-Line Inspection

IM Integrity Management

IOOC Iranian Offshore Oil Company

IOW Integrity Operating Window

IRB Iron Reducing Bacteria

IVMS In Vehicle Monitoring System

LARS Logistics And Resource System

LECC Local Emergency Control Centre

Long. Seam Longitudinal seam weld of line pipe

LRUT Long Range Ultrasonic Testing (See GWT)

MAOP Maximum Allowable Operating Pressure

Metocean Meteorology and (physical) Oceanography data

MFL Magnetic Flux Leakage

MIC Microbiologically-Influenced Corrosion

MMSCFD Million Standard Cubic Feet per Day

MoC Management of Change

MOP Maximum Operating Pressure

N/A Not Available

NDE Non-Destructive Examination

NDT Non-Destructive Testing, see NDE

OD Outside Diameter

PCC Repair of Pressure Equipment ASME standard

PDAM Pipeline Defect Assessment Manual

PIMS Pipeline Integrity Management Systems

POD Probability of Detection

POF Pipeline Operators Forum

PoF Probability of Failure

PRCI Pipeline Research Council International

PTD Permanent Total Disability (insurance term)

PTT Pull Through Test (for ILI tool)

QRA Quantitative Risk Assessment

RAP Remedial Action Plan

RBA Risk Based Assessment

RBI Risk Based Inspection

RCA Root Cause Analysis

ROV Remotely Operated Vehicle

ROW Right Of Way

RTTM Real Time Transient Model

SCADA Supervisory Control and Data Acquisition

SDV Shutdown Valve

Section Means either Onshore or Offshore sections

Segment A segment is defined as a sub-section of pipeline system within the pipeline

SMLS Seamless pipe

SMTS Specified Minimum Tensile Strength

SMYS Specified Minimum Yield Strength

SOL Safe Operating Limits

SOW or SoW Scope of Work

SRB Sulphate Reducing Bacteria

SSC Sulphide Stress Cracking

SW Seam welded pipe

TBA To Be Added

UT Ultrasonic Test

UTM Universal Transverse Mercator

VIV Vortex Induced Vibration

w/o Without

w.r.t with regards to

NORAN ENERGY Page 12 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

1 Introduction (Field/Asset Overview)

The Company

Iranian Offshore Oil Company (IOOC), is one of the world's largest offshore oil producing

companies with over a half century of experience. The Company shares one third of Iranian oil

export, operating in Iranian side of the Persian Gulf and Oman Sea.

The main operation area of Iranian Offshore Oil Company is the Persian Gulf where four other

oil producing countries are located in the other side (Iraq, Saudi Arabia, Qatar, and United Arab

Emirates). These Five countries totally possess 63 percent of oil reserves and 40 percent of

natural gas reserves of the world.

Gas Field and Asaluyeh-Sirri Pipeline

The subject IOOC Gas Field is an existing oil and gas producing complex in Iranian waters of

the Persian Gulf. This Gas Field Integrated development project is conceived for expansion of

current gas production and exploitation reservoir located in the Dalan Complex. This field is

capable of increasing the oil production by 50,000 BOD and producing and transporting 500

MMSCFD of export quality gas to Mubarak Platform via a compression facility in Sirri Island.

The vicinity of existing Complex is congested with many existing gas gathering and gas lift

pipelines. List of in-scope pipelines including gas gathering and gas export pipeline network is

provided in Chapter 1.4 of this report.

As depicted in Figure 1.2-1 the schematic of project area and pipeline route, Asaluyeh-Sirri gas

pipeline project is aimed at transferring produced gas from Asaluyeh in southern Iran to Sirri

island located 70 km in the Persian Gulf with total length of approximately 305 km.

The main component of the project is a 32-inch export pipeline of 500 MMSCFD capacity, that

is used to transport gas from compression facilities in Sirri to Asaluyeh (currently). The basis of

design of this pipeline (Document No. SA-000-4200-PL-DB-1001-D0) is for sour gas and flow

direction from Sirri island to Asaluyeh which in practice it is supposed (in near future) to be

reversed.

Figure 1.2-1, 32-inch Asaluyeh-Sirri pipeline overview

NORAN ENERGY Page 13 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Project Scope

IOOC is in process of setting up Pipeline Integrity Management System (PIMS) for its

organisation. In this regard a PIMS committee is established to coordinate and manage this

effort.

Noting the above and as an initial step in setting up PIMS in IOOC organisation, ISCO-Noran

Energy consortium (Contractor) is appointed by IOOC (Client) for the pipeline integrity status

study outlined in this report and implementation of PIMS platform in IOOC. However, this report

only covers the former.

To avoid any confusion in data entry and also for practical interpretations in ParsPiMS TM

platform (linked pipeline integrity viewer software), KP 0 is set in launcher Asaluyeh and KP

305 in Receiver Sirri island, therefore all inspection data and reports are projected in this

direction.

This report is prepared to give the latest integrity status of in-scope pipeline(s) system in IOOC

gas field. A course of remedial actions next to remnant lifetime of these pipelines is also

recommended.

IOOC intends to assess pipeline integrity status and to improve safety and reliability of in-scope

pipeline. This would be achieved in a phased manner. Below is detail of scope of work for this

study:

- Review of existing pipeline condition

- ILI data assessment

- Corrosion Rate Assessment

- Remaining life Assessment

- Risk Assessment and prioritization

- Recommendation of repair strategies

- Recommendation of long-Term integrity plans

- Integrity status report

- PIMS software and platform

A supplementary software (ParsPiMS TM) is prepared for this report. It is a platform to project

the GIS spatial and descriptive data for in-scope pipeline(s) and to present integrity status of

this pipeline system.

The scope of this report is to summarize the key findings and recommendations from the series

of detailed technical reviews carried out on the pipeline.

In-scope Pipelines

The Client is operator of two main pipelines under review in this project, namely:

I. 1x 32-inch Asaluyeh-Sirri, 305 km in length (onshore and offshore)

II. 1x 30-inch Sirri-Mubarak, 68.5 km in length (onshore and offshore)

This study covers the 32-inch Asaluyeh-Sirri pipeline from in-scope pipelines. Assessment of

other pipelines is covered in separate report for each pipeline.

The 32-inch export pipeline with 500 MMSCFD capacity, transports the refined offshore

product from onshore gas treatment facilities in Asaluyeh which branched from phase 9 and 10

south pars pipelines (Fifth Refinery) to Sirri (with 3 compressor stations in Sirri Island).

IOOC plans to export sour gas from South Pars Refinery to customers as part of a long-term

contract and is intending to utilize the existing 32-inch Asaluyeh-Sirri pipeline which is currently

NORAN ENERGY Page 14 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

operated by IOOC to transport sour gas from Siri Island to Asaluyeh as gas export line. Hence

the integrity of the 32-inch pipeline needs to be assessed to provide an indication of the

remaining life and required mitigation to demonstrate safe continued operation of the pipeline.

In order to ensure integrity of subject pipeline system, IOOC has requested ISCO-Noran

Energy consortium to perform a Risk Based Assessment (RBA) on the 32-inch pipeline based

on all available data at the time of writing this report.

This RBA study covers essential parts of structural integrity and supportive mechanisms such

as CP, etc. to conclude integrity status of the subject pipeline system.

See pipeline basis of design document No. SA-000-4200-PL-DB-1001-D0 for more information.

NORAN ENERGY Page 15 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Gas Fields Layout and System Diagram

Figure 1.5-1, Zone 39N (Asaluyeh landfall) & 40N (Sirri landfall), Asaluyeh-Sirri Pipeline

32-inch Asaluyeh-Sirri pipeline is starting from Asaluyeh landfall in zone 39 (see Universal

Transverse Mercator – UTM- system) and ends in Sirri landfall and receiver in Zone 40 (UTM).

For more information about in-scope pipeline coordinates and relevant Grid zones, See Table

1.5-1, UTM system for Zone 39 & 40 and Figure 1.5-2 (in Datum Transformation WGS-84).

Table 1.5-1, UTM system for Zone 39 & 40

Zone Central Meridian Longitude

39N 51E 48E-54E

40N 57E 54E-60E

NORAN ENERGY Page 16 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Figure 1.5-2, UTM Grid zones on Iran

This report summarizes the pipeline integrity status, remaining lifetime and action plan for both

offshore and onshore section from the pig launcher in Asaluyeh to the pig receiver station in

Sirri island.

1.5.1 Landfall Coordinates

The two (2), Asaluyeh and Sirri island landfall point locations are presented in Table 1.5-2.

Table 1.5-2, Asaluyeh and Sirri Landfall Location

Asaluyeh Landfall Point Location

Geographical Coordinates Grid Coordinates Expected Water

Location

Latitude (N) Longitude (E) Easting (m) Northing (m) Depth (m)

Asaluyeh 27° 27’ 52.578” 052° 36’ 58.449” 659 709.90 3 038 977.78 0.0

Spheroid: Hayford International 1924, Datum: ED77, UTM Zone: 39N, CM: 51° E

Sirri Landfall Point Location

Geographical Coordinates Grid Coordinates Expected Water

Location

Latitude (N) Longitude (E) Easting (m) Northing (m) Depth (m)

Sirri 25° 53’ 39.081” 054° 32’ 42.876” 254 046.80 2 866 306.89 0.0

Spheroid: Hayford International 1924, Datum: ED77, UTM Zone: 40N, CM: 57° E

NORAN ENERGY Page 17 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Pipeline Information

Table 1.6-1 shows a summary of design and operating information regarding the in-scope

pipeline.

Table 1.6-1, In-scope pipeline design and operational data*

W.t

W.t

for Shore

MAOP for offshore

Design Design approach

Size Pipeline Length Original/ section and

Pressure Capacity Material Section (partially)

(inch) Name (km) derated Onshore

(barg) (MMSCFD) and 3 pieces

(barg) section

subsea 5D bends

(mm)

(mm)

290 km Carbon

Subsea Steel

Asaluyeh-

32 and 15 114 114/93 500 SAWL 28.8 20.6

Sirri

km 450 I SF

Onshore (X65)

Max Year of min/Max availability availability

Coating Corrosion

Depth of Lining Fluid Construction/ design of of

type Allowance

water Operation Temp. As Builts ROV/ILI

6mm

Hot Super

-29 °C

Bitumen Dry 2008 /

1.5 mm 96 m No / Yes Yes/Yes

and Sour 2016

65 °C

90mm Gas***

CWC**

* This table is based on received information from IOOC and the operational data shall be checked and confirmed by

user of this report.

**Coating in onshore section is 3LPE and CWC varies along the pipeline length. (See Table 1.9-1).

***Working fluid is super dry sour gas (from Sirri island to Asaluyeh), however at the time of writing this report, it is

known that IOOC is intending to change the flow direction from Asaluyeh to Sirri island (MoC document is needed upon

this change noting that MoC document with authorized signature is essential for any change in operational

parameters).

Notes:

1: Wall thickness in onshore section including 8 pieces 5D bends is 28.8 mm in Asaluyeh and 20.6 mm in Sirri island.

2: Maximum operating temperature for entire pipeline is 50 °C.

3: Pipeline and cathodic protection design lifetime is 25 years.

4: Pig receiver barrel has 31.4 mm wall thickness (including design CA).

5: Shore approach segments was supposed to be with 28.8 mm wall thickness in design documents, but in practice

there are wall thicknesses less than this thickness. See Table 9.1-1, Pipeline Segmentation for more details.

6: Hydrotest pressure (at reference height), offshore and onshore Sec. is 125.7 and 159.6 barg respectively.

7: Design Code for Offshore section and onshore section is DNV-OS-F101 and ASME B31.8 respectively.

8: Delivery condition in Normal operating pressure shall be 76 bar min at the Asaluyeh

9: Pipeline tag in ParsPiMS TM GIS platform is “ASA-SIR”.

10: It is noted that working fluid in this pipeline is super dry with no water (from well, upstream, downstream, refinery or

any condensate water. Ref.: Signed Minutes of Meeting 10th July 2019 with Client’s focal point of this project.

11: Max. working pressure in last 12 months (2018-2019) was 80.5 barg.

12: For more information about Asaluyeh-Sirri pipeline pressure gradient, temperature profile and flow data in last 12

months please see Chapter 13.

Source: Pipeline basis of design document No. SA-000-4200-PL-DB-1001-D0.

NORAN ENERGY Page 18 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Metocean Data

Table 1.7-1 and Table 1.7-2 show sea state parameters for shore approach and offshore

segments of this pipeline.

Table 1.7-1, Sea State Parameters- Shore Approach segment

Environmental Condition

Sl No. Description

1 year 100 years

1 Highest Astronomical Tide (HAT), m 1.52 1.52

2 Lowest Astronomical Tide (LAT), m 0.00 0.00

3 Storm Tide, m 0.18 0.30

4 Total Tide, m 1.70 1.82

5 Current (Surface), m/s 1.036 1.310

6 Current (Bottom), m/s 0.366 0.400

7 Significant Wave Height, m Ref.: Glenn Report, Fig 10

8 Significant Wave Period, sec Ref.: Glenn Report, Fig 12

9 Maximum Wave Height, m Ref.: Glenn Report, Fig 9

10 Maximum Wave Period, sec Ref.: Glenn Report, Fig 11

11 Sea Water Kinematic Viscosity, m2/s 1.51 E-06 1.51 E-06

12 Sea Water Density, kg/m3 1027 1027

Variation of wave parameters with water depth is indicated in the Environmental report

(metrological-Oceanographic conditions affecting Design of Offshore petroleum facilities:

Approximately 250 31’07” N, 530 08’ 45” E, 67-foot chart depth, Persian Gulf by A.H. GLENN

and Associates) shall be considered for more details.

Table 1.7-2, Sea States Parameters- Offshore segments

Environmental Condition

Sl No Description

1 year 100 years

1 Highest Astronomical Tide (HAT), m 2.1 2.1

2 Lowest Astronomical Tide (LAT), m - -

3 Storm Tide, m 0.2 0.3

4 Total Tide, m 2.3 2.4

5 Current (Surface), m/s 0.8 1.1

6 Current (Bottom), m/s 0.3 0.5

7 Significant Wave Height, m 3.2 5.9

8 Significant Wave Period, sec 7.6 10.0

9 Maximum Wave Height, m 6.0 11.0

10 Maximum Wave Period, sec 8.5 11.0

11 Sea Water Kinematic Viscosity, m2/s 1.51 E-06 1.51 E-06

12 Sea Water Density, kg/m3 1027 1027

The shore approach wave and current data used for this report and analysis are extracted from

Salman project design basis (AH. GLENN and Associates report for Mubarak Field). These

data are fully applicable to this project owing to the small distance of approach location of

pipeline to Sirri Island.

NORAN ENERGY Page 19 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Pipeline Coating

Table 1.8-1 summarizes external Coating detail of the 32-inch Asaluyeh-Sirri pipeline.

Table 1.8-1, Coating in 32-inch Asaluyeh-Sirri pipeline (Based on As-Built)

Onshore section (Underground)

Type Three Layer Polyethylene

Density 980 kg/m3

Thickness 3.5 mm

Onshore section (Aboveground)

Type Paint

Offshore section (Straight concrete coated spool piece section)

Type Hot Bitumen Enamel

Density 1400 kg/m3

Thickness 6 mm

All bended spools

Type Three Layer Polyethylene

Density 980 kg/m3

Thickness 3.5 mm

Offshore Section Concrete Coating Thickness (Per Segment)

Table 1.9-1 presents CWC in the subject pipeline.

Table 1.9-1, Concrete coat thickness details for offshore section

Concrete

Pipeline Section

Thickness

KP 0 to KP 12 90 mm

KP 12 to KP 22 68 mm

KP 22 to KP 42 55 mm

KP 42 to KP 270 51 mm

KP 270 to KP 286 55 mm

KP 286 to KP 288 68 mm

KP 288 to KP 290 90 mm

Spool piece 51 mm

Density of concrete in all segments is assumed to be 3,040 kg/m3.

NORAN ENERGY Page 20 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Working Fluid

Characteristics of the pipeline working fluid composition during its operation lifetime since start-

up is received from IOOC and outlined in Table 1.10-1. This data is from latest monitoring

activity in Asaluyeh and are used as the basis for tabulating this report.

Table 1.10-1, Summary of the past working fluid composition of 32-inch Asaluyeh-Sirri pipeline

Mole fractions

Component Early Life Early Life End Years End Years

Min Amb. Temp. Max Amb. Temp. Min Amb. Temp. Max Amb. Temp.

N2 0.0322 0.0320 0.0321 0.0321

CO2 0.0316 0.0315 0.0316 0.0316

H2S 0.0154 0.0155 0.0155 0.0155

C1 0.8376 0.8343 0.8354 0.8350

C2 0.0508 0.0509 0.0508 0.0509

C3 0.0181 0.0187 0.0185 0.0186

iC4 0.0040 0.0043 0.0042 0.0043

nC4 0.0044 0.0047 0.0047 0.0047

iC5 0.0019 0.0022 0.0021 0.0022

nC5 0.0015 0.0017 0.0017 0.0017

nC6 0.0013 0.0016 0.0016 0.0017

C7+ (*) 0.0012 0.0024 0.0016 0.0016

H2O 0.0000 0.0002 0.0002 0.0002

Total 1.0000 1.0000 1.0000 1.0001

(*) Properties of C7+ Molecular Weight = 128.3 and Specific Gravity = 0.776

It is noted that IOOC is in preparation to use the subject pipeline for transportation of dry sweet

gas in the future with fluid composition outlined in Table 1.10-2. Upon implementation of such

change, this assessment shall be revisited including new ILI data.

Table 1.10-2, Summary of the future working fluid composition of 32-inch Asaluyeh-Sirri pipeline

Mole fractions

Component Assaluye Phase 9 & 10

Export Gas

N2 3.601

CO2 0.909

H2S 0

C1 92.978

C2 2.429

C3 0.079

iC4 0.002

nC4 0.002

Total 1.0000

NORAN ENERGY Page 21 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

2 Project Assumptions

- The working fluid in this pipeline is super dry sour gas from Asaluyeh to Sirri. For

working fluid composition see Table 1.10-1 for assumed composition of inlet. The

current assessment is performed based on this assumption and the results of this report

are pending this confirmation.

- MAOP equals 93 barg.

- Maximum operating temperature for entire pipeline is 50 °C.

- ILI 2016 is validated by IOOC and the existing ILI data is applicable for this study.

- Design life of pipeline is 25 years.

- Installation was started in 2008 and operation start-up year was in 2016.

- For the purpose of this assessment, the ILI tool accuracy for length, width and depth of

anomalies is as per Table 10.1-1.

- Since the shore approach segment in Sirri island is with the same wall thickness of

subsea section (20.8 mm), hence it is impossible to identify the Abs. distances of shore

approach segment now, therefore same length of 547 meter for shore approach section

of Asaluyeh has been assumed same for Sirri shore approach.

- Although the overall pipeline integrity is evaluated here, noting the available

information, corrosion defects are noted to be the most credible threat and this study

remains focused on assessment of corrosion defects in the form of metal loss caused

by exposure of the pipeline internal surface to seawater during commissioning and

produced gas during operation.

- It is noted that material of construction of the existing pipeline as specified in the Basis

of Design is compliant with NACE MR 0175/ISO 15156 for H2S cracking resistant

materials.

- All the defects reported in the 2016 ILI inspection were assessed except the

manufacturing anomalies which have been reported without any depth value. However,

these features are considered to have been introduced during the manufacturing and

construction phases. Consequently, they will have survived the pre-service hydrotest

and in the absence of a growth mechanism or additional axial loading, they are not

considered a threat to the integrity of the pipeline and assumed fit for service.

- All ERFs greater than or equal to 1 (one) in this report, are based on ILI company

calculation and might be different based on the DNVGL-RP-F101.

- For the onshore section of the pipeline, the same anomalies of existing ILI report for

offshore section is also assumed for the onshore section.

- Wall thickness in onshore section including 8 pieces 5D bends is noted to be 28.8 mm

in Asaluyeh and 20.6 mm in Sirri island. An erroneous record (wall thickness

measurement) is noted in the preliminary tabulated data available form 2016 ILI report

and is excluded in this study.

- Dent calculation is based on pipe ID.

- In the absence of any external coating survey, it was not possible to identify the

condition of the external coating on the onshore section of the pipeline. Similarly, no

information about the external coating for the offshore section of the pipeline can be

established as the pipeline is fully concrete coated.

NORAN ENERGY Page 22 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

3 Executive Summary

Pipeline Integrity Status Summary

Noting that internal and external corrosion is the most credible threat to this pipeline, this

review has confirmed that Asaluyeh-Sirri pipeline system is operating with no risk of failure with

current MAOP. This conclusion is based on the assumptions outlined in Chapter 2 of this report

and is only valid based on these assumed parameters.

The Asaluyeh-Sirri pipeline system is therefore confirmed as fit for service at the time of writing

this report. Moreover, it is highly recommended to monitor the most significant defects

(reported in ILI 2016) in the next ILI (which is ongoing at time of writing this report) and to

conduct and update other inspection and maintenance activities as planned in the Integrity

Management Plan (IMP) of this pipeline followed by repeating this RBA study afterwards. This

is due to:

• The time gap between construction and operation and possibility of water ingress in this

period

• Medium level of confidence with 2016 ILI report

• The criticality of subject pipeline (exporting)

It is noted that IOOC is intending to run the next ILI (HR-MFL) at the time of writing this report

and pre-cleaning preparations before MFL run was in process with pipeline integrity team in

IOOC.

It is further noted that IOOC integrity team has routine PIMS meeting (monthly) in a separate

committee in the presence of asset owner, inspection team, operation team and Integrity team

and to update integrity status of this pipeline.

Table 3.1-1, Proposed summary of the pipeline integrity status

Pipeline name: 32-inch Asaluyeh-Sirri

Asset owner: IOOC

Pipeline tag in IOOC ParsPiMS TM GIS platform: ASA-SIR

Overall Integrity Status Green

Length: 305 km Service type: Super Dry Sour Gas*

Nominal Diameter: 32-inch Last intelligent pigging: Jan 2016

20.6 mm & Replacement costs for

Wall thickness (design): Estimated $ 1,281 million**

28.8 mm entire pipeline:

Internal

Material: 5L X65 (inhibited External

Status: scenario)

Date in service: 2016 Green Green

0.44 0.23

Design Pressure: 114 barg ACR:

mm/year mm/year

MAOP: 93 barg Remaining life (Yr): 2031

MOP It was in process at the time of

80.5 barg ILI Due Date:

(period of last 12 months): writing this report.

NORAN ENERGY Page 23 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

*It is understood that working fluid in this pipeline is super dry with no water (from well, upstream, downstream,

refinery or any condensate water.

** US AID bulletin for offshore pipeline construction (Local cost factor is included). A proper and project specific cost

estimate to be performed to confirm this estimated value.

NORAN ENERGY Page 24 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

4 Data Quality, Accuracy and Confidence

Contractor is provided with following data which were analysed and assessed as part of this

report:

- ROV 2010

- Anodes potential readings by ROV 2010

- Route for Asaluyeh to Sirri Island (design documents)

- Shore approach drawings for both Asaluyeh and Sirri Island (design documents)

- Engineering drawings and material selection

- ILI 2016 reports

- Sonar reports

- Corrosion coupons for Sirri onshore section

- CP reports of onshore section (only On-potential)

- Fluid composition data

- AUT inspection of hot spot location in onshore section

- Inspection of all BVSs in this pipeline

- Inspection of pig traps (launcher and receiver)

At the time of writing this report below action was in progress:

- CP survey of onshore section in Asaluyeh and Sirri island (DCVG and CIPS)

- ILI (HR-MFL)

Noting the above, this integrity status report is established on the basis of medium confidence

rating on the data available. The confidence rating is critical to determine the Assessed

Corrosion Rate, the Remnant Life and the next ILI inspection date for this pipeline. These

parameters can be improved by provision of some missing data and more accurate inspections

practices.

For ILI, the compliance check to API-1163 (ver. 2013 - Qualification standards for In-line

Inspection Systems) and Pipeline Operators Forum (POF ver. 2009-Specifications and

requirements for intelligent pig inspections of pipelines) shows that last ILI run in 2016 lack

attention to following areas :

- Clustering criteria (interaction criteria) is not followed (reference made to ASME B31G).

- Cluster reporting is not in accordance to POF.

- ILI raw data is not reported therefore, detailed analysis of defects is not possible.

- No software viewer provided to IOOC for ILI 2016.

- Dig-up Verification of ILI run in 2016 is not available and not adequate to determine the

Probability of Identification (POI) and Probability of Detection (POD). However, IOOC

integrity team has conducted a direct examination in chainage 16758.55 of this pipeline

to inspect and size the defect with depth of 38.6% (at the time of inspection) and it is

found 18% in July 2019. See 10.6.

- Version management of the ILI data from the vendor (marking on the CD) for latest

report is missing.

For the purpose of this assessment and considering the above limitations, the accuracy for

depth of defects is assumed 0.5 mm and for the length of defects 50 mm based on information

received from IOOC.

NORAN ENERGY Page 25 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

5 Pipeline Inspection Techniques

As part of Pipeline Integrity Management Systems (PIMS), in-service pipelines shall be

inspected either planned (regularly) or unplanned in case of an emergency.

Offshore Pipeline Inspection Techniques

5.1.1 Generic Inspection Techniques

Inspection of subsea pipelines can be carried out with a wide range of inspection tools having

different capabilities and areas of applications. Capability of each technique should be known

at the time of selecting the most applicable technique. All these details will be considered by

the inspection professional and will be included in the inspection test procedures.

A summary of inspection techniques for detecting typical damages in subsea pipelines is given

in DNVGL-RP-F116 and re-produced in Table 5.1-1.

5.1.2 Inspection Categories

A description of typical inspection categories often used in connection with inspection planning

for subsea pipelines is given in Table 5.1-1.

Table 5.1-1, Inspection Techniques (DNV, 2009)

What can be measured/detected by this

Inspection Method Description

technique in IOOC?

Visual inspection (or any kind of

transmissions like Acoustic, RF, optical) Reveals most external condition threats to

General Visual carried out by ROV or divers. GVI will not the pipeline including coating/insulation

Inspection (GVI) include any cleaning. Anomalies found may anomaly, anode condition, leaks and

be subject to more detailed inspection - see gross damages to the system.

CVI below.

Inspection using a pipeline work class ROV GVI XTD will reveal the same type of

which will normally include: 3-view digital anomalies as GVI, but with the addition of

GVI Extended Visual

video (left/Centre/right), digital camera, giving detailed span profiles and depth of

Pipeline survey

seabed transverse profiles (such as side scan burial. It also has a higher degree of

(XTD)

or multi-beam sonar), CP (gradient and stab) precision with respect to positioning

and Pipe Tracker (depth of burial). pertaining to the pipeline KP system.

A high standard of cleaning is required for this

Reveals most external condition threats to

type of inspection; all hard and soft marine

the pipeline including coating/insulation

Close Visual growth should be removed. The purpose of

anomaly, anode condition, leaks and

Inspection (CVI) the inspection is to establish a detailed

gross damages to the system however

inspection of an area of specific interest.

with more details compared to GVI.

Requires either a diver or work class ROV.

A high accuracy positional survey. This is

achieved using a work class pipeline ROV (as

used for GVI), in conjunction with high

accuracy calibrated positional equipment (e.g.

high performance corrected DGPS, Absolute position and relative year to year

High Precision

transponders (USBL/ LBL systems), ROV lateral movement of the pipeline on the

Survey (HPS)

mounted survey quality gyro and motion seabed.

sensor, high frequency Doppler velocity log

etc.). Inspection rate can be expected to be

slower and will require more calibration time

than standard GVI.

Intelligent pigging inspection, of the pipeline

To measure continuous end to end

In-Line Inspection utilizing various non-destructive testing (NDT)

pipeline wall thickness loss or pipeline

(ILI) methods such as MFL, EC, tethered /

anomalies/defects.

umbilical UT tools.

NORAN ENERGY Page 26 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

The frequency of the inspection actions should be established via a risk-based program and as

part of subsea pipeline IM activities. IOOC has a planned ILI and scheduled for Q3 2019 (it was

in progress at the time of writing this report) and this document will be amended/updated after

review of the new and updated inspection results.

Onshore Pipeline Inspection Techniques

5.2.1 Generic Pipeline Inspection Techniques

As part of Pipeline Integrity Management Systems, in-service pipelines shall be inspected

either on a planned (regularly) or unplanned basis in case of an emergency.

Due to the buried and covered nature of onshore section of 32-inch Asaluyeh-Sirri pipeline, in-

line inspection technique is the most optimal solution for defect identification.

Guided Wave Testing (GWT) is another alternative method in the field of non-destructive

evaluation (just for trending not for sizing). The method employs mechanical stress waves that

propagate along an elongated structure while guided by its boundaries. This allows the waves

to travel a long distance with little loss in energy. Nowadays, GWT is widely used to inspect

and screen many engineering structures, particularly for the inspection of non-piggable

pipelines. In some cases, 30m each direction of the sensors can be inspected from a single

location.

Although GWT is also commonly known as Guided Wave Ultrasonic Testing (GWUT) or Long-

Range Ultrasonic Testing (LRUT), it is fundamentally very different from conventional ultrasonic

testing. GWT uses very low ultrasonic frequencies compared to those used in conventional UT,

typically between 10~100kHz. Higher frequencies can be used in some cases, but detection

range is significantly reduced. In addition, this procedure is one of the available inspection

techniques to inspect pipelines underneath culverts without any direct access methods.

For leak detection next to all available techniques (such as Fibre Optics Cables, SCADA,

RTTM-based systems, Mass balance methods, Laser scanners, etc.), there is another

methodology by using what is commonly called a Geophone. This is an acoustic amplifier

system that allows the operator to hear extremely faint sounds at great distances using a

geophone probe which is placed in direct contact with the pipeline. This allows the operator to

pinpoint location of a leak.

Pressure test and other Direct assessments methods such as ECDA and ICDA are alternative

options to ILI.

NORAN ENERGY Page 27 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

6 Threat Identification

Subsea section pipelines could experience various types of threats during their design life.

Threat is defined as an indication of an impending danger or harm to the system, which may

have an adverse influence on the integrity of the system. Subsea pipelines threats could result

in damages/anomalies to the pipelines some of which may result in a failure or an unsafe

defect which require mitigation, repair or replacement.

Generic Codified Threats and Expected Damage to Subsea Pipelines

DNVGL-RP-F116 identifies Seven (7) generic Threat Group (Design, Corrosion, Erosion, Third

Party, Structural, Natural Hazards and Incorrect Operations) and Twenty Six (26) Threats for

subsea pipelines as shown in Table 6.1-1. Not all these threats are relevant to in-scope

pipeline hence in next section, threats only applicable to this pipeline are discussed.

For each threat the list of expected anomalies or damages related to a threat are also given in

the same table.

Table 6.1-1, Typical codified Subsea Pipelines Threats

Threat Group Threat Anomaly/Damage

Design/Fabrication/ Design Errors Metal loss

Installation Dent

Fabrication Related

Crack

DFI threats Installation Related Gouge

Internal Corrosion

Metal loss

Corrosion/Erosion External Corrosion

Crack

Erosion

Trawling Interface Metal loss

Dent

Anchoring Crack

Gouge

Third Party Vessel Impact Local Buckle

Global Buckle

Dropped Objects Displacement

Exposure

Global Buckling - Exposed

Global Buckling - Buried Crack

Free-Span

End Expansion Local Buckle

Structural

On-Bottom Stability Global Buckle

Displacement

Static Overload Exposure

Fatigue (VIV, waves, or process vibrations)

Extreme Weather Crack

Free-Span

Earthquake

Local Buckle

Floods Global Buckle

Natural Hazards

Displacement

Lightning Exposure

Coating Anomaly

Land Slide Anode Anomaly

Incorrect Procedures

Procedures not Implemented Metal loss

Coating Anomaly

Incorrect Operation Human Errors Local Buckle

Global Buckle

Internal Protection System Related Anode Anomaly

Interface Component Related

NORAN ENERGY Page 28 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

6.1.1 Generic Defect Assessment Methodologies for Subsea Pipelines

When a potentially unacceptable anomaly or abnormality is observed or detected, a defect

(integrity) assessment shall be performed. The aim is to determine whether or not the MAOP

should be reduced. Calculations for predicating the pressure at which a pipeline may fail at the

location of the defect shall be based on worst case assumptions.

Table 6.1-2 summarizes the defect assessment techniques applicable to subsea pipelines.

Table 6.1-2, Overview of Subsea Pipelines Assessment Codes/Guidelines

Anomaly Code/Guideline Comments

For assessment of Subsea Corroded Pipelines (Grade X42 and

DNVGL-RP-F101

above). Applicable for all in-scope subsea section of IOOC pipelines

Including the modified version (RSTRENG) - Older grades such as

ASME B31G

Metal Loss Grade B, etc. – Applicable for all onshore section of IOOC pipelines.

Pipeline Defect

Assessment Manual Summarizes most common methods

(PDAM)

For design and assessment of subsea pipelines Acceptance criteria

DNVGL-OS-F101

and allowable dent depth are defined

DNVGL-RP-F113 Pipeline Repair Methodology for Subsea pipelines

For assessment of fatigue loading on subsea pipelines at presence

Dent DNVGL-RP-C203

of dents

Summarizes most common methods and acceptance criteria and

EPRG/PDAM

allowable dent depth

PDAM Summarizes most common methods

DNVGL-OS-F101 Detailed ECA analyses (Appendix A)

Guide to methods for assessing the acceptability of flaws in metallic

BS7910

structures

Crack

DNVGL-RP-F113 Pipeline Repair Methodology for Subsea pipelines containing cracks

PDAM Summarizes most common methods

Gouge PDAM Summarizes most common methods

For assessment of fatigue loading on subsea pipelines at presence

DNVGL-RP-C203

of free spans

Free-Span

For assessment of acceptable span size for the subsea pipelines

DNVGL-RP-F105

beyond which mitigation should be performed

For design and assessment of subsea pipelines Acceptance criteria

DNVGL-OS-F101

and allowable dent depth are defined

Local Buckle

For design and assessment of Pipeline Repair Methodology for

DNVGL-RP-F113

Subsea pipelines at presence of local buckles

For design and assessment methodology for Subsea pipelines at

Global Buckle DNVGL-RP-F110

presence of local buckles

Exposure DNVGL-RP-F107 For design and assessment of subsea pipelines exposures

For design and assessment of subsea pipelines displacements by

Displacement DNVGL-RP-F109

external sources

Coating

DNVGL-RP-F102 For repair of subsea pipelines damaged coatings

Anomaly

Anode DNVGL-RP- For design and assessment of Cathodic Protection using galvanic

Anomaly B401/F103 anodes)

NORAN ENERGY Page 29 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Generic Codified Threats and Expected Damage to Onshore Pipelines

As stated in ASME B318S, experience has indicated that the following are potential threats to

the integrity of onshore gas pipeline. The threats for gas pipelines that operators should

address can be characterized as follows:

1. External corrosion;

2. Internal corrosion;

3. Selective seam corrosion (external or internal);

4. SCC;

5. Manufacturing defects (defective pipe seams including hard heat-affected zones

and defective pipe including pipe body hard spots);

6. Construction and fabrication defects (including defective girth welds, defective

fabrication welds, wrinkle bends and buckles, and stripped threads/broken

pipe/coupling failure);

7. Equipment failure (including gasket or O-ring failure, control/relief equipment failure,

seal/pump packing failure, and miscellaneous);

8. Mechanical damage (causing an immediate failure or from vandalism);

9. Mechanical damage (previously damaged pipe causing a delayed failure or

vandalism);

10. Incorrect operations;

11. Weather and outside force (cold weather, lightning, heavy rains or floods, and earth

movement);

12. The growth of an initially non-injurious anomaly arising from any one of several of

the above causes into an injurious defect via pressure-cycle-induced fatigue

(including transit fatigue).

Threats 1, 2, 3, 4 and 12 are clearly time-dependent threats that should be addressed by

periodic assessment and monitoring. Threats 5, 6 and 9 are considered possibly time-

dependent threats because of the potential for their enlargement by pressure-cycle-induced

fatigue. For the latter threats, the pipeline operator will be called upon to judge the need for

continuing assessments or monitoring. Threats 7, 8, 10 and 11 are considered time-

independent because they involve random events for which the time of occurrence is usually

not predictable. Management of the latter class of threats involves employing preventive and

mitigative measures.

It is recognized that not all 12 may apply to the Asaluyeh-Sirri pipeline and that pipeline

credible threats are discussed in detail in the Chapter 7.

NORAN ENERGY Page 30 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

7 Risk Assessments (Semi-Quantitative Approach)

Different risk assessment approaches can be used for a specific pipeline. Risk can be

evaluated qualitatively and/or quantitatively as most feasible. Common for all the models is an

evaluation of the probability of an event and the consequences (based on impacts on Safety,

Assets, Environment and company Reputation) that this event will impose.

A levelled approach (among three options) can be used for assessing risk including:

- Assessments based on applying simple qualitative evaluations. The main objective is to

determine risk levels with minimum efforts through one or several workshops.

- Assessments that require more effort than what was outlined previously and may be

more appropriate to be done as a combination of workshops and individual efforts.

These assessments are based on applying qualitative and/or semi-quantitative

evaluations. Relevant documents and data are typically reviewed more thoroughly.

Documentation of this assessment may therefore be more comprehensive.

- Assessments that involve quantitative probabilistic calculations (w.r.t. to PoF and

possibly also w.r.t. CoF as well). Such an assessment should be considered if e.g.

serious failure has been positively identified.

Risk of the above threats to the shore approach and subsea sections of the 32-inch Asaluyeh-

Sirri pipeline is ranked based on semi-quantitative approach as per developed 5x5 risk matrix

given in Chapter 7.1 and based on the evidences from past inspections and information

gathered from the IOOC integrity team.

It is noted that IOOC has established a unique and well customized method (Developed in

collaboration with Petroleum University of Technology) for pipeline prioritization and ranking

(quantitively). It is highly recommended to use this document to prioritize the pipeline network

in future for RBA study.

NORAN ENERGY Page 31 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Risk Assessment Matrix with Work Selection

Following 5x5 Risk assessment matrix is used for risk assessment of this pipeline following

workshops with asset owner. The risk matrix is developed based on DNVGL-RP-F116 with input

from IOOC.

Threat dependent, work selection recommended inspection intervals (in years) are outlined in

the risk assessment matrix.

Table 7.1-1, 5x5 Risk Assessment Matrix (Semi-Quantitative Approach) with Work Selection Inspection

Intervals (years)

Consequences categories Increasing Likelihood (Probability)

1 2 3 4 5

Environment

Has

Severity

Reputation

Has

happened in Has

Assets

People

happened at

the happened

Never heard the location

Heard of in Organization more than

of in the or more than

the industry or more than once per

industry once per

once per year at the

year in the

year in the Location

organization

industry

More

Massive Massive Massive

E than 3

damage effect impact

3 1 NA NA NA

fatalities

PTD or

Major Major Major

D up to 3

damage effect impact

5 3 1 NA NA

fatalities

Major

injury or Moderate Moderate Moderate

C health damage effect impact

8 5 3 1 NA

effect

Minor

injury or Minor Minor Minor

B health damage effect impact

8 8 5 3 1

effect

Slight

injury or Slight Slight Slight

A health damage effect impact

8 8 8 5 3

effect

Table 7.1-2, Risk Categories

Risk Description

Very High Unacceptable risk - immediate action to be taken

High Unacceptable risk - action to be taken

Medium Acceptable risk - action to reduce the risk may be evaluated

Low Acceptable risk - Low

Very Low Acceptable risk - Insignificant

Risk rankings performed for the 32-inch Asaluyeh-Sirri pipeline are summarized in Table 7.2-1

for shore approach, Table 7.3-1 for subsea section and Table 7.4-1 for Onshore section of the

pipeline.

NORAN ENERGY Page 32 of 135 ISCO MIDDLE EAST

www.noranenergy.com www.isco-me.ir

Integrity Status of IOOC Gas Export Pipeline System Doc. No. IO01-NFZ-Y-RA-0001

Asaluyeh-Sirri

Rev.04

Shore Approach Section Risk Ranking

Table 7.2-1, Semi-Quantitative risk assessment of the shore approach section

Threat

Threat CoF PoF Risk Comments

Group

Design Errors B 3 B3

Shore Approach segment in Sirri island has same wall thickness as

Design/ Fabrication subsea section (20.8 mm), while it was supposed to be 28.8 mm as per

B 3 B3

Fabrication/ Related standards and design documents. This don’t seem to have been

Installation controlled or reported during commissioning. In any case the pipeline is

noted to have passed the hydrostatic test.

Installation

B 3 B3

Related

UT intelligent inspection of pipeline in 2016 revealed

803 defects all Internal corrosion in Asaluyeh shore approach segment

Internal