Professional Documents

Culture Documents

0 ratings0% found this document useful (0 votes)

15 views1050a Rolled Products

1050a Rolled Products

Uploaded by

BPP-Tech PythonThis data sheet provides information on alloy 1050A, an aluminum alloy composed of 99.5% pure aluminum. Some key points:

1) Alloy 1050A has very good corrosion resistance and workability and is commonly used in constructions, cabinets, and deep-drawn parts.

2) It has good thermal and electrical conductivity, is easy to weld and machine, and can be anodized for decorative purposes.

3) The alloy has low mechanical properties but good formability when cold worked or hot rolled. Sheets between 0.5-6mm and other products are available from Alumeco.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You might also like

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- BIR Form 2306Document4 pagesBIR Form 2306sedanzam80% (15)

- GstarCAD 2017 USER GUIDE ภาษาไทยDocument269 pagesGstarCAD 2017 USER GUIDE ภาษาไทยPhannachet RungsrikeawNo ratings yet

- Manual de Usuario Ups 10-20kva Ul - InglesDocument59 pagesManual de Usuario Ups 10-20kva Ul - Ingleswiiliam buitragpNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- 6005 ProfilesDocument1 page6005 ProfilesBPP-Tech PythonNo ratings yet

- Nedal Alloy DataDocument1 pageNedal Alloy DataMurali KrishnaNo ratings yet

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADocument2 pagesAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- AH MergedDocument6 pagesAH MergedReginaldo SantosNo ratings yet

- 1.4841 Aisi 314Document1 page1.4841 Aisi 314Josevi Jiménez MerinoNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- GapenDocument5 pagesGapenasyifafredasalsabNo ratings yet

- CHP 1 ProjectDocument11 pagesCHP 1 ProjectDhyey KalariyaNo ratings yet

- Copper Alloy C67500Document10 pagesCopper Alloy C67500Kapil HarchekarNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- 1050 Data Sheet: Chemical CompositionDocument1 page1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Shell Naturelle Transformer Fluid S4 IDocument2 pagesShell Naturelle Transformer Fluid S4 IEdgar Leonel CortésNo ratings yet

- EN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel TubesDocument5 pagesEN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel TubesGonzalo MazaNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- C53 Technical CardDocument1 pageC53 Technical CardAnonymous umabEI6No ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- 17 4 PHDocument2 pages17 4 PHParag NaikNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- 5083 en MarineDocument1 page5083 en MarineBPP-Tech PythonNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- Metalcor 1.4571 Aisi 316 TiDocument1 pageMetalcor 1.4571 Aisi 316 TirezaNo ratings yet

- CORUS Celsius 355 Hollow SectionsDocument24 pagesCORUS Celsius 355 Hollow SectionsPaul HardingNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- BronzeLG2LeadedGunmetalBronze PDFDocument2 pagesBronzeLG2LeadedGunmetalBronze PDFAnthonyNo ratings yet

- 4 Lincoln 7018-1Document2 pages4 Lincoln 7018-1cesar rodriguezNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Nedal Alloy Datasheet EN AW 7108ADocument1 pageNedal Alloy Datasheet EN AW 7108ANico VazquezNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFDocument2 pagesAalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFOvidiu ChertesNo ratings yet

- BS1400 HTB1Document2 pagesBS1400 HTB1Atul KulkarniNo ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- En40b PDFDocument3 pagesEn40b PDFjeyakumarNo ratings yet

- Aero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200Document2 pagesAero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200erikaNo ratings yet

- Metalcor 2.4375 Alloy K500Document1 pageMetalcor 2.4375 Alloy K500Gourav SharmaNo ratings yet

- Primacorelw 81ni1h enDocument2 pagesPrimacorelw 81ni1h enedwinNo ratings yet

- IRCE Salflex180Document1 pageIRCE Salflex180grasia77No ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelDhanu goswamiNo ratings yet

- Aluminium Alloy 5083 - '0' - H111 Sheet and PlateDocument2 pagesAluminium Alloy 5083 - '0' - H111 Sheet and PlateOmarNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Nedal Alloy Datasheet en AW 6060Document1 pageNedal Alloy Datasheet en AW 6060ankur panwarNo ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- Elerep® 310: ClassificationDocument2 pagesElerep® 310: ClassificationSerhii MishchenkoNo ratings yet

- DS Mold 2311 1Document4 pagesDS Mold 2311 1marjan banooNo ratings yet

- En1a PDFDocument1 pageEn1a PDFRavindra ErabattiNo ratings yet

- Din en 10149-2Document12 pagesDin en 10149-2Just In TimeNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Ponente: Carpio-Morales, JDocument15 pagesPonente: Carpio-Morales, JCristelle Elaine ColleraNo ratings yet

- ZomatoDocument3 pagesZomato2305112130010No ratings yet

- Akbayan Vs Thomas G. AquinoDocument14 pagesAkbayan Vs Thomas G. AquinoNicole IbayNo ratings yet

- ZVI - ITR 2022 DraftDocument4 pagesZVI - ITR 2022 DraftMike SyNo ratings yet

- POS 205 GroupDocument5 pagesPOS 205 GroupnathanharyehrinNo ratings yet

- 2 - Skip - Nonlinear RegressionDocument41 pages2 - Skip - Nonlinear RegressionEmdad HossainNo ratings yet

- Law of Contracts II Lecture Notes 1 13Document56 pagesLaw of Contracts II Lecture Notes 1 13Mohit MalhotraNo ratings yet

- Literature Review On Motivation TheoriesDocument9 pagesLiterature Review On Motivation Theoriesafdtslawm100% (1)

- Acrysol rm-8w 3Document4 pagesAcrysol rm-8w 3Forever0% (1)

- Master of Information Technology and Systems (973AA)Document4 pagesMaster of Information Technology and Systems (973AA)kira_suziniNo ratings yet

- S3b QSG WEB EU 19022019 2.4 PDocument100 pagesS3b QSG WEB EU 19022019 2.4 PSERVICE TESTNo ratings yet

- Design of Iot Blockchain Based Smart Agriculture For Enlightening Safety and SecurityDocument14 pagesDesign of Iot Blockchain Based Smart Agriculture For Enlightening Safety and Securitysumit kaushikNo ratings yet

- Oracle: 1Z0-819 ExamDocument9 pagesOracle: 1Z0-819 ExamdspNo ratings yet

- FINAL - Presentations in Your OfficeDocument2 pagesFINAL - Presentations in Your OfficeSyed Mohammed AzharuddinNo ratings yet

- Fowler - The New MethodologyDocument18 pagesFowler - The New MethodologypglezNo ratings yet

- Indian Institute of Materials Management: Graduate Diploma in Public Procurement Paper No.5Document3 pagesIndian Institute of Materials Management: Graduate Diploma in Public Procurement Paper No.5shivamdubey12No ratings yet

- World Health OrganizationDocument13 pagesWorld Health OrganizationVincent Ranara Sabornido100% (1)

- Lab - 7 - Common Emitter AmplifiersDocument6 pagesLab - 7 - Common Emitter AmplifiersAhmed ChNo ratings yet

- Job Knowledge 65Document5 pagesJob Knowledge 65Mehmet SoysalNo ratings yet

- Exercise Chapters 1-5 No SolutionDocument7 pagesExercise Chapters 1-5 No SolutionTrâm Lê Ngọc BảoNo ratings yet

- Map of Colorado - Federal Lands and Indian ReservationsDocument1 pageMap of Colorado - Federal Lands and Indian ReservationsHistoricalMapsNo ratings yet

- TG0014en Ed03-IP PhoneDocument92 pagesTG0014en Ed03-IP PhoneEduardo Pereira da SilvaNo ratings yet

- Ethics in Engineering Profession - IES General StudiesDocument16 pagesEthics in Engineering Profession - IES General StudiesSandeep PrajapatiNo ratings yet

- Effect of Road Expansion To The Local Household Lalitpur DistrictDocument8 pagesEffect of Road Expansion To The Local Household Lalitpur DistrictJoshua CenizaNo ratings yet

- The Coming of The British WorksheetDocument5 pagesThe Coming of The British Worksheetlavender2x2No ratings yet

- Fin 604 AssignmentDocument3 pagesFin 604 AssignmentSiyao HuNo ratings yet

- ChloroplastDocument4 pagesChloroplastEmmanuel DagdagNo ratings yet

1050a Rolled Products

1050a Rolled Products

Uploaded by

BPP-Tech Python0 ratings0% found this document useful (0 votes)

15 views1 pageThis data sheet provides information on alloy 1050A, an aluminum alloy composed of 99.5% pure aluminum. Some key points:

1) Alloy 1050A has very good corrosion resistance and workability and is commonly used in constructions, cabinets, and deep-drawn parts.

2) It has good thermal and electrical conductivity, is easy to weld and machine, and can be anodized for decorative purposes.

3) The alloy has low mechanical properties but good formability when cold worked or hot rolled. Sheets between 0.5-6mm and other products are available from Alumeco.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis data sheet provides information on alloy 1050A, an aluminum alloy composed of 99.5% pure aluminum. Some key points:

1) Alloy 1050A has very good corrosion resistance and workability and is commonly used in constructions, cabinets, and deep-drawn parts.

2) It has good thermal and electrical conductivity, is easy to weld and machine, and can be anodized for decorative purposes.

3) The alloy has low mechanical properties but good formability when cold worked or hot rolled. Sheets between 0.5-6mm and other products are available from Alumeco.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

0 ratings0% found this document useful (0 votes)

15 views1 page1050a Rolled Products

1050a Rolled Products

Uploaded by

BPP-Tech PythonThis data sheet provides information on alloy 1050A, an aluminum alloy composed of 99.5% pure aluminum. Some key points:

1) Alloy 1050A has very good corrosion resistance and workability and is commonly used in constructions, cabinets, and deep-drawn parts.

2) It has good thermal and electrical conductivity, is easy to weld and machine, and can be anodized for decorative purposes.

3) The alloy has low mechanical properties but good formability when cold worked or hot rolled. Sheets between 0.5-6mm and other products are available from Alumeco.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

Download as pdf or txt

You are on page 1of 1

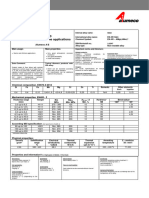

Data Sheet

Internal alloy name: 1050A

EN AW 1050A – Rolled products International alloy name: EN AW 1050A

99.50% pure aluminium Chemical Symbol: EN AW - Al 99.5

DIN-Werkstoff no.: 3.0255

Alumeco A/S Alloy type: Non heat treatable alloy

Main usage Main properties Important norms and literature

Cold rolled products: Deep-drawn parts:

• Constructions • Very good atmospheric corrosion EN 1669: Earing test for sheet and strip

EN 485-1: Technical conditions for

• Cabinets resistance

inspection and delivery

• Deep-drawn parts • Very good workability Usages:

EN 485-2: Mechanical properties

• Strips for heat exchanger • High thermal and electrical EN 485-4: Tolerances on dimensions and EN 602: Usage in the food industry

• Light reflectors conductivity (preferred alloy 1350) form cold rolled products

• Attractive appearance

• High reflectivity

• Suitable for decorative anodizing* Chemical composition:

• Very good weld ability EN 573-3: Chemical composition

• Low mechanical properties

• Plates are available in deep drawing

quality (DDQ)

*Not for continuously cast (CC) materials

Chemical composition (%) EN 573-3

Si Fe Cu Mn Mg Cr Zn Ti Remarks Other elements

Each together

0.25 0.40 0.05 0.05 0.05 - 0.07 0.05 Min 99.5% Al 0.03 -

Typical mechanical properties EN 485 - 2

Thickness range Temper Rm Rp0,2 A% Hardness* Bend radius**

(mm) MPa MPa HB 180⁰ 90⁰

0.5 up to 1.5 H111 65 - 95 Min. 20 22 20 0t 0t

1.5 up to 3.0 H111 65 – 95 Min. 20 26 20 0t 0t

0.5 up to 1.5 H14 105 - 145 Min. 85 2 34 1.0t 0.5t

1.5 up to 3.0 H14 105 – 145 Min. 85 4 34 1.0t 1.0t

3.0 up to 6.0 H14 105 – 145 Min. 85 5 34 - 1.5t

** Information values only

Physical properties

Density Solidification Electrical Thermal Thermal Annealing E - modulus

g/cm³ range conductivity conductivity expansion temperature ⁰C (N / mm²)

°C %IACS W/m K (µm m-1 K-1)

2.70 645-658 59.5 210-220 23.5 350-400 69,000

Typical Alumeco products with this alloy

• Sheets in the size of 0.5 – 6 mm in three different sizes (1000x2000; 1250x2500; 1500x3000) and temper H14

• 1 – 3 mm warehouse materials (Continuously Cast)

• Deep-drawn sheets in the size of 1 – 2 mm - Temper H111

• Sheets with stucco pattern

• Strips/Coils

Properties and information (3 high/good; 2 medium; 1 poor/bad)

Resistance Cold formability Tips regarding machining General information

Corrosion index, general: 3 Cold formability general: 3 (Soft Tools for aluminum processing: Decorative anodizing cannot be

Marine atm. corr. index: 3 tempers and hot rolled only) High-usable cutting speeds, recommended for continuously

Deep drawing: 3* (Deep drawing possibly> 2000 m / min. cast (CC) materials.

Hot workability quality/DDQ)

Extrusion: 3 Bending: 3 (Soft tempers and hot *We stock special produced plates

Forging: 3 rolled only) Anodizing that are especially suited for deep

Decorative anodizing surface drawing – deep drawing quality

Solderability treatment: 3 (CC cast materials 1) (DDQ).

Weldability 3 Protective anodizing index: 3

TIG welding: 3 Hard anodizing: 3

MIG welding: 3 Machinability Color anodizing: 3 (CC materials 1)

Machinability index: 1

You might also like

- Cu ZN 15 TombacDocument2 pagesCu ZN 15 TombacPetrus UngureanuNo ratings yet

- BIR Form 2306Document4 pagesBIR Form 2306sedanzam80% (15)

- GstarCAD 2017 USER GUIDE ภาษาไทยDocument269 pagesGstarCAD 2017 USER GUIDE ภาษาไทยPhannachet RungsrikeawNo ratings yet

- Manual de Usuario Ups 10-20kva Ul - InglesDocument59 pagesManual de Usuario Ups 10-20kva Ul - Ingleswiiliam buitragpNo ratings yet

- 6063 ProfilesDocument1 page6063 ProfilesBPP-Tech PythonNo ratings yet

- 6005 ProfilesDocument1 page6005 ProfilesBPP-Tech PythonNo ratings yet

- Nedal Alloy DataDocument1 pageNedal Alloy DataMurali KrishnaNo ratings yet

- Al 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSADocument2 pagesAl 99.5 AW 10-50 Aluminium A 1050 Technical Data Sheet RLSAAlex GăuruşNo ratings yet

- Alloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)Document1 pageAlloy Data Sheet En-Aw 7020 (Alzn4.5Mg1) : Type: High Strength Structural Alloy)rahul vermaNo ratings yet

- AH MergedDocument6 pagesAH MergedReginaldo SantosNo ratings yet

- 1.4841 Aisi 314Document1 page1.4841 Aisi 314Josevi Jiménez MerinoNo ratings yet

- En 10305 1 Sunny SteelDocument6 pagesEn 10305 1 Sunny Steelmohamed belkadiNo ratings yet

- GapenDocument5 pagesGapenasyifafredasalsabNo ratings yet

- CHP 1 ProjectDocument11 pagesCHP 1 ProjectDhyey KalariyaNo ratings yet

- Copper Alloy C67500Document10 pagesCopper Alloy C67500Kapil HarchekarNo ratings yet

- Cw008a Cu-Of Version1Document1 pageCw008a Cu-Of Version1Gaka RtaNo ratings yet

- 1050 Data Sheet: Chemical CompositionDocument1 page1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- 29102015000000B - Boehler DCMS-IG - SWDocument1 page29102015000000B - Boehler DCMS-IG - SWErdinc BayatNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF Standard Grade - Luvata Alloy Cu-OFMuhammad Asif IqbalNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T3 Rod and Bar 3Agung SulisNo ratings yet

- Shell Naturelle Transformer Fluid S4 IDocument2 pagesShell Naturelle Transformer Fluid S4 IEdgar Leonel CortésNo ratings yet

- EN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel TubesDocument5 pagesEN 10305-2 E195 E235 E355 Welded Cold Drawn Precision Steel TubesGonzalo MazaNo ratings yet

- Data Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKDocument2 pagesData Sheet: Oxygen-Free Copper Cu-OF - Luvata Alloy OF-OKMuhammad Asif IqbalNo ratings yet

- C53 Technical CardDocument1 pageC53 Technical CardAnonymous umabEI6No ratings yet

- L1 34264 en T Thermanit MTS 3 Se en v2Document1 pageL1 34264 en T Thermanit MTS 3 Se en v2Enrique MurgiaNo ratings yet

- Copper Cu-Dhp / Sf-Cu: Page 1/2Document2 pagesCopper Cu-Dhp / Sf-Cu: Page 1/2gemilanglpNo ratings yet

- 17 4 PHDocument2 pages17 4 PHParag NaikNo ratings yet

- Utp 34 NDocument1 pageUtp 34 NbrayanNo ratings yet

- 5083 en MarineDocument1 page5083 en MarineBPP-Tech PythonNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesMellierNo ratings yet

- Aluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesDocument3 pagesAluminium Alloy 2014A T651 Sheet and Plate: Specifications Temper TypesBeni hidayatullahNo ratings yet

- Metalcor 1.4571 Aisi 316 TiDocument1 pageMetalcor 1.4571 Aisi 316 TirezaNo ratings yet

- CORUS Celsius 355 Hollow SectionsDocument24 pagesCORUS Celsius 355 Hollow SectionsPaul HardingNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- En Aw 6082 Rev 2 Final PDFDocument3 pagesEn Aw 6082 Rev 2 Final PDFtechspawNo ratings yet

- BronzeLG2LeadedGunmetalBronze PDFDocument2 pagesBronzeLG2LeadedGunmetalBronze PDFAnthonyNo ratings yet

- 4 Lincoln 7018-1Document2 pages4 Lincoln 7018-1cesar rodriguezNo ratings yet

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 pagesTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UNo ratings yet

- Nedal Alloy Datasheet EN AW 7108ADocument1 pageNedal Alloy Datasheet EN AW 7108ANico VazquezNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- OK Weartrode 62 (84.84)Document2 pagesOK Weartrode 62 (84.84)Dieng MessatsuNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFDocument2 pagesAalco Metals LTD - Aluminium Alloy 5083 0 H111 Sheet and Plate - 149 PDFOvidiu ChertesNo ratings yet

- BS1400 HTB1Document2 pagesBS1400 HTB1Atul KulkarniNo ratings yet

- Elimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79Document5 pagesElimination of Crack Formation in Stainless Steel After Tig Welding - 2-427-151816990575-79arjun prajapatiNo ratings yet

- En40b PDFDocument3 pagesEn40b PDFjeyakumarNo ratings yet

- Aero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200Document2 pagesAero Metal Alliance - Aluminium Alloy QQ A 25011 T6 Sheet - 200erikaNo ratings yet

- Metalcor 2.4375 Alloy K500Document1 pageMetalcor 2.4375 Alloy K500Gourav SharmaNo ratings yet

- Primacorelw 81ni1h enDocument2 pagesPrimacorelw 81ni1h enedwinNo ratings yet

- IRCE Salflex180Document1 pageIRCE Salflex180grasia77No ratings yet

- Technical Datasheet: Engineering SteelDocument1 pageTechnical Datasheet: Engineering SteelDhanu goswamiNo ratings yet

- Aluminium Alloy 5083 - '0' - H111 Sheet and PlateDocument2 pagesAluminium Alloy 5083 - '0' - H111 Sheet and PlateOmarNo ratings yet

- 11042016000000T - Thermanit 22 - 09 - Tig RodDocument1 page11042016000000T - Thermanit 22 - 09 - Tig RodKonrad MatuszkiewiczNo ratings yet

- Nedal Alloy Datasheet en AW 6060Document1 pageNedal Alloy Datasheet en AW 6060ankur panwarNo ratings yet

- Tenacito 70Document1 pageTenacito 70Luis Angel Unocc FernandezNo ratings yet

- Elerep® 310: ClassificationDocument2 pagesElerep® 310: ClassificationSerhii MishchenkoNo ratings yet

- DS Mold 2311 1Document4 pagesDS Mold 2311 1marjan banooNo ratings yet

- En1a PDFDocument1 pageEn1a PDFRavindra ErabattiNo ratings yet

- Din en 10149-2Document12 pagesDin en 10149-2Just In TimeNo ratings yet

- Aalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355Document2 pagesAalco Metals LTD Aluminium Alloy 2011 T6 Extruded Rod and Bar 56 SS4355novkovic1984No ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Ponente: Carpio-Morales, JDocument15 pagesPonente: Carpio-Morales, JCristelle Elaine ColleraNo ratings yet

- ZomatoDocument3 pagesZomato2305112130010No ratings yet

- Akbayan Vs Thomas G. AquinoDocument14 pagesAkbayan Vs Thomas G. AquinoNicole IbayNo ratings yet

- ZVI - ITR 2022 DraftDocument4 pagesZVI - ITR 2022 DraftMike SyNo ratings yet

- POS 205 GroupDocument5 pagesPOS 205 GroupnathanharyehrinNo ratings yet

- 2 - Skip - Nonlinear RegressionDocument41 pages2 - Skip - Nonlinear RegressionEmdad HossainNo ratings yet

- Law of Contracts II Lecture Notes 1 13Document56 pagesLaw of Contracts II Lecture Notes 1 13Mohit MalhotraNo ratings yet

- Literature Review On Motivation TheoriesDocument9 pagesLiterature Review On Motivation Theoriesafdtslawm100% (1)

- Acrysol rm-8w 3Document4 pagesAcrysol rm-8w 3Forever0% (1)

- Master of Information Technology and Systems (973AA)Document4 pagesMaster of Information Technology and Systems (973AA)kira_suziniNo ratings yet

- S3b QSG WEB EU 19022019 2.4 PDocument100 pagesS3b QSG WEB EU 19022019 2.4 PSERVICE TESTNo ratings yet

- Design of Iot Blockchain Based Smart Agriculture For Enlightening Safety and SecurityDocument14 pagesDesign of Iot Blockchain Based Smart Agriculture For Enlightening Safety and Securitysumit kaushikNo ratings yet

- Oracle: 1Z0-819 ExamDocument9 pagesOracle: 1Z0-819 ExamdspNo ratings yet

- FINAL - Presentations in Your OfficeDocument2 pagesFINAL - Presentations in Your OfficeSyed Mohammed AzharuddinNo ratings yet

- Fowler - The New MethodologyDocument18 pagesFowler - The New MethodologypglezNo ratings yet

- Indian Institute of Materials Management: Graduate Diploma in Public Procurement Paper No.5Document3 pagesIndian Institute of Materials Management: Graduate Diploma in Public Procurement Paper No.5shivamdubey12No ratings yet

- World Health OrganizationDocument13 pagesWorld Health OrganizationVincent Ranara Sabornido100% (1)

- Lab - 7 - Common Emitter AmplifiersDocument6 pagesLab - 7 - Common Emitter AmplifiersAhmed ChNo ratings yet

- Job Knowledge 65Document5 pagesJob Knowledge 65Mehmet SoysalNo ratings yet

- Exercise Chapters 1-5 No SolutionDocument7 pagesExercise Chapters 1-5 No SolutionTrâm Lê Ngọc BảoNo ratings yet

- Map of Colorado - Federal Lands and Indian ReservationsDocument1 pageMap of Colorado - Federal Lands and Indian ReservationsHistoricalMapsNo ratings yet

- TG0014en Ed03-IP PhoneDocument92 pagesTG0014en Ed03-IP PhoneEduardo Pereira da SilvaNo ratings yet

- Ethics in Engineering Profession - IES General StudiesDocument16 pagesEthics in Engineering Profession - IES General StudiesSandeep PrajapatiNo ratings yet

- Effect of Road Expansion To The Local Household Lalitpur DistrictDocument8 pagesEffect of Road Expansion To The Local Household Lalitpur DistrictJoshua CenizaNo ratings yet

- The Coming of The British WorksheetDocument5 pagesThe Coming of The British Worksheetlavender2x2No ratings yet

- Fin 604 AssignmentDocument3 pagesFin 604 AssignmentSiyao HuNo ratings yet

- ChloroplastDocument4 pagesChloroplastEmmanuel DagdagNo ratings yet