Professional Documents

Culture Documents

Body Repair: Section

Body Repair: Section

Uploaded by

nyanhtunlimOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Body Repair: Section

Body Repair: Section

Uploaded by

nyanhtunlimCopyright:

Available Formats

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

SECTION BRM BODY REPAIR

B

E

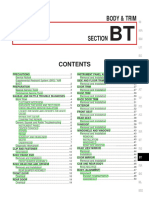

CONTENTS

KING CAB FOR THAILAND .........................................................32 F

FOR THAILAND : Undercoating ..............................32

VEHICLE INFORMATION ............................. 6 FOR THAILAND : Stone Guard Coat ......................33

FOR THAILAND : Body Sealing ..............................35 G

BODY EXTERIOR PAINT COLOR ..................... 6

Body Exterior Paint Color ....................................... 6 FOR AUSTRALIA AND NEW ZEALAND ..................40

FOR AUSTRALIA AND NEW ZEALAND : Under-

PRECAUTION ............................................... 8 coating .....................................................................41 H

FOR AUSTRALIA AND NEW ZEALAND : Stone

PRECAUTIONS ................................................... 8 Guard Coat ..............................................................41

Precautions for Removing Battery Terminal ............. 8 FOR AUSTRALIA AND NEW ZEALAND : Body I

REPAIRING HIGH STRENGTH STEEL .............. 9 Sealing .....................................................................43

High Strength Steel (HSS) ........................................ 9 BODY CONSTRUCTION .................................. 49

J

PREPARATION ........................................... 13 FOR THAILAND .........................................................49

FOR THAILAND : Body Construction ......................49

REPAIRING MATERIAL ....................................13

Foam Repair ........................................................... 13 FOR AUSTRALIA AND NEW ZEALAND ..................50 BRM

FOR AUSTRALIA AND NEW ZEALAND : Body

BODY COMPONENT PARTS ............................15 Construction ............................................................51

FOR THAILAND ........................................................ 15 L

REPLACEMENT OPERATIONS ....................... 53

FOR THAILAND : Underbody Component Parts .... 15 Description ...............................................................53

FOR THAILAND : Body Component Parts .............. 16

FOR THAILAND : Rear Body Component Parts .... 18 FOR THAILAND .........................................................54 M

FOR THAILAND : Frame Component Parts ........... 20 FOR THAILAND : Radiator Core Support ...............55

FOR THAILAND : Hoodledge ..................................55

FOR AUSTRALIA AND NEW ZEALAND .................. 23

FOR THAILAND : Hoodledge (Partial Replace- N

FOR AUSTRALIA AND NEW ZEALAND : Under-

ment) .......................................................................56

body Component Parts ........................................... 23

FOR THAILAND : Front Pillar ..................................57

FOR AUSTRALIA AND NEW ZEALAND : Body

FOR THAILAND : Outer Sill (Partial Replacement)

Component Parts .................................................... 24 O

....61

FOR AUSTRALIA AND NEW ZEALAND : Rear

FOR THAILAND : Outer Sill ....................................62

Body Component Parts ........................................... 26

FOR THAILAND : Rear Cab Pillar ...........................62

FOR AUSTRALIA AND NEW ZEALAND : Frame P

FOR THAILAND : Back Panel .................................65

Component Parts .................................................... 28

FOR THAILAND : Rear Body Fender ......................66

REMOVAL AND INSTALLATION ............... 32 FOR THAILAND : Rear Crossmember ....................67

FOR THAILAND : Crush Horn .................................68

CORROSION PROTECTION .............................32 FOR THAILAND : Roof ............................................70

Description .............................................................. 32

FOR AUSTRALIA AND NEW ZEALAND ..................70

Revision: August 2015 BRM-1 D23

FOR AUSTRALIA AND NEW ZEALAND : Radia- DOUBLE CAB

tor Core Support ..................................................... 71

FOR AUSTRALIA AND NEW ZEALAND : Hoo- VEHICLE INFORMATION ......................... 113

dledge ..................................................................... 71

FOR AUSTRALIA AND NEW ZEALAND : Hoo- BODY EXTERIOR PAINT COLOR ................... 113

dledge (Partial Replacement) ................................. 72 Body Exterior Paint Color ................................... 113

FOR AUSTRALIA AND NEW ZEALAND : Front

Pillar ........................................................................ 73

PRECAUTION ........................................... 115

FOR AUSTRALIA AND NEW ZEALAND : Outer PRECAUTIONS ................................................ 115

Sill (Partial Replacement) ....................................... 77 Precautions for Removing Battery Terminal ......... 115

FOR AUSTRALIA AND NEW ZEALAND :

Outer Sill ................................................................ 78 REPAIRING HIGH STRENGTH STEEL ........... 116

FOR AUSTRALIA AND NEW ZEALAND : Rear High Strength Steel (HSS) .................................... 116

Cab Pillar ................................................................ 78

FOR AUSTRALIA AND NEW ZEALAND : Back PREPARATION ......................................... 120

Panel ...................................................................... 81

FOR AUSTRALIA AND NEW ZEALAND : Rear REPAIRING MATERIAL ................................... 120

Body Fender ........................................................... 82 Foam Repair ......................................................... 120

FOR AUSTRALIA AND NEW ZEALAND : Rear BODY COMPONENT PARTS .......................... 122

Crossmember ......................................................... 83

FOR AUSTRALIA AND NEW ZEALAND : Crush LHD .......................................................................... 122

Horn ........................................................................ 84 LHD : Underbody Component Parts ..................... 122

FOR AUSTRALIA AND NEW ZEALAND : Roof ..... 86 LHD : Body Component Parts ............................... 123

LHD : Rear Body Component Parts ...................... 125

SERVICE DATA AND SPECIFICATIONS LHD : Frame Component Parts ............................ 127

(SDS) ........................................................... 87

FOR THAILAND ...................................................... 132

BODY ALIGNMENT ........................................... 87 FOR THAILAND : Underbody Component Parts . 132

FOR THAILAND : Body Component Parts ........... 134

FOR THAILAND ........................................................ 87 FOR THAILAND : Rear Body Component Parts ... 136

FOR THAILAND : Body Center Marks .................... 87 FOR THAILAND : Frame Component Parts ......... 138

FOR THAILAND : Description ................................ 88

FOR THAILAND : Engine Compartment ................ 88 EXCEPT FOR THAILAND ....................................... 141

FOR THAILAND : Underbody ................................. 90 EXCEPT FOR THAILAND : Underbody Compo-

FOR THAILAND : Passenger Compartment nent Parts .............................................................. 141

(Windshield and Door Opening) ............................. 93 EXCEPT FOR THAILAND : Body Component

FOR THAILAND : Passenger Compartment (Rear Parts ...................................................................... 142

Window Opening) ................................................... 94 EXCEPT FOR THAILAND : Rear Body Compo-

FOR THAILAND : Rear Body ................................. 96 nent Parts .............................................................. 144

EXCEPT FOR THAILAND : Frame Component

FOR AUSTRALIA AND NEW ZEALAND ................. 98 Parts ...................................................................... 146

FOR AUSTRALIA AND NEW ZEALAND : Body

Center Marks .......................................................... 98 REMOVAL AND INSTALLATION ............. 152

FOR AUSTRALIA AND NEW ZEALAND : De-

scription .................................................................. 99 CORROSION PROTECTION ........................... 152

FOR AUSTRALIA AND NEW ZEALAND : Engine Description ............................................................ 152

Compartment .........................................................100

LHD .......................................................................... 152

FOR AUSTRALIA AND NEW ZEALAND : Under-

LHD : Undercoating .............................................. 152

body .......................................................................101

LHD : Stone Guard Coat ....................................... 153

FOR AUSTRALIA AND NEW ZEALAND : Pas-

LHD : Body Sealing ............................................... 155

senger Compartment (Windshield and Door

Opening) ................................................................103 FOR THAILAND ...................................................... 160

FOR AUSTRALIA AND NEW ZEALAND : Pas- FOR THAILAND : Undercoating ........................... 161

senger Compartment (Rear Window Opening) .....105 FOR THAILAND : Stone Guard Coat .................... 161

FOR AUSTRALIA AND NEW ZEALAND : Rear FOR THAILAND : Body Sealing ........................... 163

Body ......................................................................107

FOR AUSTRALIA AND NEW ZEALAND ............... 168

LOCATION OF PLASTIC PARTS ................... 110 FOR AUSTRALIA AND NEW ZEALAND : Under-

Precautions for Plastics .........................................110 coating .................................................................. 169

Location of Plastic Parts ........................................111

Revision: August 2015 BRM-2 D23

FOR AUSTRALIA AND NEW ZEALAND : Stone FOR THAILAND : Rear Crossmember .................. 229

Guard Coat ............................................................ 169 FOR THAILAND : Crush Horn ............................... 230 A

FOR AUSTRALIA AND NEW ZEALAND : Body FOR THAILAND : Roof (Normal Roof Models) ..... 232

Sealing .................................................................. 171

FOR AUSTRALIA AND NEW ZEALAND ................ 233

EXCEPT FOR THAILAND, AUSTRALIA AND FOR AUSTRALIA AND NEW ZEALAND : Radia- B

NEW ZEALAND ....................................................... 176 tor Core Support .................................................... 233

EXCEPT FOR THAILAND, AUSTRALIA AND FOR AUSTRALIA AND NEW ZEALAND : Hoo-

NEW ZEALAND : Undercoating ............................ 177 dledge .................................................................... 234 C

EXCEPT FOR THAILAND, AUSTRALIA AND FOR AUSTRALIA AND NEW ZEALAND : Hoo-

NEW ZEALAND : Stone Guard Coat .................... 177 dledge (Partial Replacement) ................................ 235

EXCEPT FOR THAILAND, AUSTRALIA AND FOR AUSTRALIA AND NEW ZEALAND : Front D

NEW ZEALAND : Body Sealing ............................ 179 Pillar ....................................................................... 235

FOR AUSTRALIA AND NEW ZEALAND : Center

BODY CONSTRUCTION .................................. 185 Pillar ....................................................................... 239

FOR AUSTRALIA AND NEW ZEALAND : Outer E

LHD .......................................................................... 185

Sill (Partial Replacement) ...................................... 241

LHD : Body Construction ....................................... 185

FOR AUSTRALIA AND NEW ZEALAND :

FOR THAILAND ...................................................... 186 Outer Sill ............................................................... 242 F

FOR THAILAND : Body Construction ................... 187 FOR AUSTRALIA AND NEW ZEALAND : Rear

Cab Pillar ............................................................... 243

FOR AUSTRALIA AND NEW ZEALAND ................ 188 FOR AUSTRALIA AND NEW ZEALAND : Back G

FOR AUSTRALIA AND NEW ZEALAND : Body Panel ..................................................................... 246

Construction .......................................................... 189 FOR AUSTRALIA AND NEW ZEALAND : Rear

Body Fender .......................................................... 247

EXCEPT FOR THAILAND, AUSTRALIA AND H

FOR AUSTRALIA AND NEW ZEALAND : Rear

NEW ZEALAND ....................................................... 190

Crossmember ........................................................ 248

EXCEPT FOR THAILAND, AUSTRALIA AND

FOR AUSTRALIA AND NEW ZEALAND : Crush

NEW ZEALAND : Body Construction .................... 191

Horn ....................................................................... 249 I

REPLACEMENT OPERATIONS ...................... 193 FOR AUSTRALIA AND NEW ZEALAND : Roof

Description ............................................................ 193 (Normal Roof Models) ........................................... 251

FOR AUSTRALIA AND NEW ZEALAND : Roof J

LHD .......................................................................... 194 (Sunroof Models) ................................................... 252

LHD : Radiator Core Support ................................ 195

LHD : Hoodledge ................................................... 195 EXCEPT FOR THAILAND AND AUSTRALIA

LHD : Hoodledge (Partial Replacement) ............... 196 (RHD) ....................................................................... 252 BRM

LHD : Front Pillar ................................................... 197 EXCEPT FOR THAILAND AND AUSTRALIA

LHD : Center Pillar ................................................ 201 (RHD) : Radiator Core Support ............................. 253

LHD : Outer Sill (Partial Replacement) ................. 203 EXCEPT FOR THAILAND AND AUSTRALIA L

LHD : Outer Sill .................................................... 204 (RHD) : Hoodledge ................................................ 253

LHD : Rear Cab Pillar ............................................ 205 EXCEPT FOR THAILAND AND AUSTRALIA

LHD : Back Panel .................................................. 208 (RHD) : Hoodledge (Partial Replacement) ............ 254

M

LHD : Rear Body Fender ....................................... 209 EXCEPT FOR THAILAND AND AUSTRALIA

LHD : Rear Crossmember ..................................... 210 (RHD) : Front Pillar ................................................ 255

LHD : Crush Horn .................................................. 211 EXCEPT FOR THAILAND AND AUSTRALIA

(RHD) : Center Pillar .............................................. 259 N

LHD : Roof (Normal Roof Models) ........................ 213

EXCEPT FOR THAILAND AND AUSTRALIA

FOR THAILAND ...................................................... 214 (RHD) : Outer Sill (Partial Replacement) ............... 261

FOR THAILAND : Radiator Core Support ............. 214 EXCEPT FOR THAILAND AND AUSTRALIA O

FOR THAILAND : Hoodledge ............................... 215 (RHD) : Outer Sill .................................................. 262

FOR THAILAND : Hoodledge (Partial Replace- EXCEPT FOR THAILAND AND AUSTRALIA

ment) ..................................................................... 216 (RHD) : Rear Cab Pillar ......................................... 263 P

FOR THAILAND : Front Pillar ............................... 216 EXCEPT FOR THAILAND AND AUSTRALIA

FOR THAILAND : Center Pillar ............................. 220 (RHD) : Back Panel ............................................... 266

FOR THAILAND : Outer Sill (Partial Replacement) EXCEPT FOR THAILAND AND AUSTRALIA

.. 222 (RHD) : Rear Body Fender .................................... 267

FOR THAILAND : Outer Sill ................................. 223 EXCEPT FOR THAILAND AND AUSTRALIA

FOR THAILAND : Rear Cab Pillar ........................ 224 (RHD) : Rear Crossmember .................................. 268

FOR THAILAND : Back Panel ............................... 227

FOR THAILAND : Rear Body Fender ................... 228

Revision: August 2015 BRM-3 D23

EXCEPT FOR THAILAND AND AUSTRALIA FOR THAILAND ...................................................... 311

(RHD) : Crush Horn ...............................................269 FOR THAILAND : Underbody Component Parts . 311

EXCEPT FOR THAILAND AND AUSTRALIA FOR THAILAND : Body Component Parts ........... 312

(RHD) : Roof (Normal Roof Models) ......................271 FOR THAILAND : Rear Body Component Parts ... 314

FOR THAILAND : Frame Component Parts ......... 316

SERVICE DATA AND SPECIFICATIONS

(SDS) .......................................................... 272 EXCEPT FOR THAILAND ....................................... 319

EXCEPT FOR THAILAND : Underbody Compo-

BODY ALIGNMENT ......................................... 272 nent Parts .............................................................. 319

EXCEPT FOR THAILAND : Body Component

LHD ..........................................................................272 Parts ...................................................................... 320

LHD : Body Center Marks ......................................272 EXCEPT FOR THAILAND : Rear Body Compo-

LHD : Description ..................................................273 nent Parts .............................................................. 322

LHD : Engine Compartment ..................................273 EXCEPT FOR THAILAND : Frame Component

LHD : Underbody ...................................................275 Parts ...................................................................... 324

LHD : Passenger Compartment (Windshield and

Door Opening) .......................................................277 REMOVAL AND INSTALLATION ............. 328

LHD : Passenger Compartment (Rear Window

Opening) ................................................................281 CORROSION PROTECTION ........................... 328

LHD : Rear Body ...................................................282 Description ............................................................ 328

RHD ..........................................................................284 FOR THAILAND ...................................................... 328

RHD : Body Center Marks .....................................284 FOR THAILAND : Undercoating ........................... 328

RHD : Description ..................................................285 FOR THAILAND : Stone Guard Coat .................... 329

RHD : Engine Compartment ..................................286 FOR THAILAND : Body Sealing ........................... 331

RHD : Underbody ..................................................287

FOR AUSTRALIA AND NEW ZEALAND ............... 336

RHD : Passenger Compartment (Windshield and

FOR AUSTRALIA AND NEW ZEALAND : Under-

Door Opening) .......................................................289

coating .................................................................. 337

RHD : Passenger Compartment (Rear Window

FOR AUSTRALIA AND NEW ZEALAND : Stone

Opening) ................................................................293

Guard Coat ........................................................... 337

RHD : Rear Body ...................................................294

FOR AUSTRALIA AND NEW ZEALAND : Body

LOCATION OF PLASTIC PARTS ................... 297 Sealing .................................................................. 339

Precautions for Plastics .........................................297

EXCEPT FOR THAILAND, AUSTRALIA AND

LHD ..........................................................................297 NEW ZEALAND ...................................................... 344

LHD : Location of Plastic Parts ..............................298 EXCEPT FOR THAILAND, AUSTRALIA AND

NEW ZEALAND : Undercoating ............................ 345

RHD ..........................................................................299 EXCEPT FOR THAILAND, AUSTRALIA AND

RHD : Location of Plastic Parts .............................300 NEW ZEALAND : Stone Guard Coat .................... 345

SINGLE CAB EXCEPT FOR THAILAND, AUSTRALIA AND

NEW ZEALAND : Body Sealing ............................ 347

VEHICLE INFORMATION .......................... 302

BODY CONSTRUCTION .................................. 353

BODY EXTERIOR PAINT COLOR .................. 302

Body Exterior Paint Color ....................................302 FOR THAILAND ...................................................... 353

FOR THAILAND : Body Construction ................... 353

PRECAUTION ............................................ 304

EXCEPT FOR THAILAND ....................................... 354

PRECAUTIONS ............................................... 304 EXCEPT FOR THAILAND : Body Construction .... 355

Precautions for Removing Battery Terminal ..........304

REPLACEMENT OPERATIONS ...................... 357

REPAIRING HIGH STRENGTH STEEL .......... 305 Description ............................................................ 357

High Strength Steel (HSS) .....................................305

FOR THAILAND ...................................................... 358

PREPARATION .......................................... 309 FOR THAILAND : Radiator Core Support ............. 359

FOR THAILAND : Hoodledge ............................... 359

REPAIRING MATERIAL .................................. 309 FOR THAILAND : Hoodledge (Partial Replace-

Foam Repair ..........................................................309 ment) ..................................................................... 360

FOR THAILAND : Front Pillar ............................... 361

BODY COMPONENT PARTS ......................... 311 FOR THAILAND : Outer Sill (Partial Replacement)

. 365

Revision: August 2015 BRM-4 D23

FOR THAILAND : Outer Sill ................................. 366 EXCEPT FOR THAILAND AND AUSTRALIA

FOR THAILAND : Rear Cab Pillar ........................ 367 (RHD) : Hoodledge (Partial Replacement) ............ 395 A

FOR THAILAND : Back Panel ............................... 370 EXCEPT FOR THAILAND AND AUSTRALIA

FOR THAILAND : Rear Body Fender ................... 371 (RHD) : Front Pillar ................................................ 396

FOR THAILAND : Rear Crossmember ................. 373 EXCEPT FOR THAILAND AND AUSTRALIA B

FOR THAILAND : Crush Horn .............................. 374 (RHD) : Outer Sill (Partial Replacement) ............... 399

FOR THAILAND : Roof ......................................... 375 EXCEPT FOR THAILAND AND AUSTRALIA

(RHD) : Outer Sill .................................................. 400

FOR AUSTRALIA AND NEW ZEALAND ................ 376 EXCEPT FOR THAILAND AND AUSTRALIA C

FOR AUSTRALIA AND NEW ZEALAND : Radia- (RHD) : Rear Cab Pillar ......................................... 401

tor Core Support .................................................... 376 EXCEPT FOR THAILAND AND AUSTRALIA

FOR AUSTRALIA AND NEW ZEALAND : Hoo- (RHD) : Back Panel ............................................... 404 D

dledge ................................................................... 377 EXCEPT FOR THAILAND AND AUSTRALIA

FOR AUSTRALIA AND NEW ZEALAND : Hoo- (RHD) : Rear Body Fender .................................... 405

dledge (Partial Replacement) ................................ 378 EXCEPT FOR THAILAND AND AUSTRALIA

FOR AUSTRALIA AND NEW ZEALAND : Front E

(RHD) : Rear Crossmember .................................. 407

Pillar ...................................................................... 378 EXCEPT FOR THAILAND AND AUSTRALIA

FOR AUSTRALIA AND NEW ZEALAND : Outer (RHD) : Crush Horn ............................................... 408

Sill (Partial Replacement) ...................................... 382 EXCEPT FOR THAILAND AND AUSTRALIA F

FOR AUSTRALIA AND NEW ZEALAND : (RHD) : Roof .......................................................... 409

Outer Sill ............................................................... 383

FOR AUSTRALIA AND NEW ZEALAND : Rear SERVICE DATA AND SPECIFICATIONS G

Cab Pillar ............................................................... 384 (SDS) .......................................................... 411

FOR AUSTRALIA AND NEW ZEALAND : Back

Panel ..................................................................... 387 BODY ALIGNMENT ........................................ 411

H

FOR AUSTRALIA AND NEW ZEALAND : Rear Body Center Marks ................................................ 411

Body Fender .......................................................... 388 Description ............................................................. 412

FOR AUSTRALIA AND NEW ZEALAND : Rear Engine Compartment ............................................. 412

Crossmember ........................................................ 390 Underbody ............................................................. 414 I

FOR AUSTRALIA AND NEW ZEALAND : Crush Passenger Compartment (Windshield and Door

Horn ...................................................................... 391 Opening) ................................................................ 416

FOR AUSTRALIA AND NEW ZEALAND : Roof .. 392 Passenger Compartment (Rear Window Opening) J

.. 418

EXCEPT FOR THAILAND AND AUSTRALIA

Rear Body .............................................................. 420

(RHD) ....................................................................... 393

EXCEPT FOR THAILAND AND AUSTRALIA LOCATION OF PLASTIC PARTS .................. 423 BRM

(RHD) : Radiator Core Support ............................. 393 Precautions for Plastics ......................................... 423

EXCEPT FOR THAILAND AND AUSTRALIA Location of Plastic Parts ........................................ 424

(RHD) : Hoodledge ................................................ 394 L

Revision: August 2015 BRM-5 D23

BODY EXTERIOR PAINT COLOR

< VEHICLE INFORMATION > [KING CAB]

VEHICLE INFORMATION

BODY EXTERIOR PAINT COLOR

Body Exterior Paint Color INFOID:0000000011680921

FOR THAILAND

JSKIA5724ZZ

Color code BCAQ BEAU BG42 BK21 BK23 BQX1 BRAA BQM1

Dark Dark

Description Orange Black Gray Silver White White

Brown Blue

Component

Paint type note 2PM 2PM 2S 2FPM 2M 3P 2P S

Standard

× × × × × × × –

clear coat

Chromium

Cr Cr Cr Cr Cr Cr Cr Cr

Door mirror plate

Material color – – – – – – – –

Chromium

Cr Cr Cr Cr Cr Cr Cr Cr

Front grille plate

Silver K23 K23 K23 K23 K23 K23 K23 K23

Front bumper fascia Body color BCAQ BEAU BG42 BK21 BK23 BQX1 BRAA BQM1

Tail gate handle Material color – – – – – – – –

Chromium

Cr Cr Cr Cr Cr Cr Cr Cr

Door outside handle plate

Material color – – – – – – – –

Upper and

Lower fin- Material color – – – – – – – –

isher

Rear

bumper Rear

bumper Chromium

Cr Cr Cr Cr Cr Cr Cr Cr

reinforce- plate

ment

NOTE:

• S: 1-Coat solid

• 2M: 2-Coat Metallic

• 2P: 2-Coat pearl

• 2S: 2-Coat solid

• 3P: 3-Coat pearl

Revision: August 2015 BRM-6 D23

BODY EXTERIOR PAINT COLOR

< VEHICLE INFORMATION > [KING CAB]

• 2PM: 2-Coat Pearl metallic

• 2FPM: 2-Coat Iron pearl metallic A

FOR AUSTRALIA

B

F

JSKIA5724ZZ

Color code BAX6 BCAQ BEAU BG42 BK21 BK23 BQX1 BRAA BQM1 G

Dark Dark

Description Red Orange Black Gray Silver White White

Brown Blue

Component H

Paint type note 2S 2PM 2PM 2S 2FPM 2M 3P 2P S

Standard

× × × × × × × × –

clear coat

I

Chromium

Cr Cr Cr Cr Cr Cr Cr Cr Cr

Door mirror plate

Material color – – – – – – – – –

J

Chromium

Cr Cr Cr Cr Cr Cr Cr Cr Cr

Front grille plate

Silver K23 K23 K23 K23 K23 K23 K23 K23 K23

BRM

Front bumper fascia Body color BAX6 BCAQ BEAU BG42 BK21 BK23 BQX1 BRAA BQM1

Tail gate handle Material color – – – – – – – – –

L

Chromium

Cr Cr Cr Cr Cr Cr Cr Cr Cr

Door outside handle plate

Material color – – – – – – – – –

M

Upper and

Lower fin- Material color – – – – – – – – –

isher

Rear N

bumper Rear

bumper Chromium

Cr Cr Cr Cr Cr Cr Cr Cr Cr

reinforce- plate

ment

O

NOTE:

• S: 1-Coat solid

• 2M: 2-Coat Metallic P

• 2P: 2-Coat pearl

• 2S: 2-Coat solid

• 3P: 3-Coat pearl

• 2PM: 2-Coat Pearl metallic

• 2FPM: 2-Coat Iron pearl metallic

Revision: August 2015 BRM-7 D23

PRECAUTIONS

< PRECAUTION > [KING CAB]

PRECAUTION

PRECAUTIONS

Precautions for Removing Battery Terminal INFOID:0000000011667139

• With the adoption of Auto ACC function, ACC power is automatically supplied by operating the Intelligent

Key or remote keyless entry or by opening/closing the driver side door. In addition, ACC power is supplied

even after the ignition switch is turned to the OFF position, i.e. ACC power is supplied for a certain fixed

time.

• When disconnecting the 12V battery terminal, turn off the ACC

power before disconnecting the 12V battery terminal, observing

“How to disconnect 12V battery terminal” described below.

NOTE:

Some ECUs operate for a certain fixed time even after ignition

switch is turned OFF and ignition power supply is stopped. If the

battery terminal is disconnected before ECU stops, accidental DTC

detection or ECU data damage may occur.

• For vehicles with the 2-batteries, be sure to connect the main bat-

tery and the sub battery before turning ON the ignition switch.

NOTE:

SEF289H

If the ignition switch is turned ON with any one of the terminals of

main battery and sub battery disconnected, then DTC may be detected.

• After installing the 12V battery, always check "Self Diagnosis Result" of all ECUs and erase DTC.

NOTE:

The removal of 12V battery may cause a DTC detection error.

HOW TO DISCONNECT 12V BATTERY TERMINAL

Disconnect 12V battery terminal according to instruction described below.

1. Open the hood.

2. Turn ignition switch to the ON position.

3. Turn ignition switch to the OFF position with the driver side door opened.

4. Get out of the vehicle and close the driver side door.

5. Wait at least 3 minutes. For vehicle with the engine listed below, remove the battery terminal after a lapse

of the specified time.

D4D engine : 20 minutes YS23DDT : 4 minutes

HRA2DDT : 12 minutes YS23DDTT : 4 minutes

K9K engine : 4 minutes ZD30DDTi : 60 seconds

M9R engine : 4 minutes ZD30DDTT : 60 seconds

R9M engine : 4 minutes

V9X engine : 4 minutes

YD25DDTi : 2 minutes

CAUTION:

While waiting, never operate the vehicle such as locking, opening, and closing doors. Violation of

this caution results in the activation of ACC power supply according to the Auto ACC function.

6. Remove 12V battery terminal.

CAUTION:

After installing 12V battery, always check self-diagnosis results of all ECUs and erase DTC.

Revision: August 2015 BRM-8 D23

REPAIRING HIGH STRENGTH STEEL

< PRECAUTION > [KING CAB]

REPAIRING HIGH STRENGTH STEEL

A

High Strength Steel (HSS) INFOID:0000000011667140

High strength steel is used for body panels in order to reduce vehicle weight. B

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

Tensile strength Major applicable parts

C

• 4th cab mounting crossmember

(Rear floor assembly component part)

• Rear floor side reinforcement

(Rear floor assembly component part) D

• Inner sill wheelhouse

(Inner sill extension assembly component part)

• Front seat mounting rear crossmember

(Front floor assembly component part) E

• Center pillar crossmember

(Front floor assembly component part)

• Side member outrigger

(Front floor assembly component part) F

• 2nd body mounting member

(Front floor assembly component part)

• Inner sill

G

(Inner front sill assembly component part)

• Lower dash reinforcement

(Lower dash complete component part)

• Upper hoodledge H

(Hoodledge assembly component part)

• Lower hoodledge

(Lower hoodledge component part)

• Hoodledge reinforcement extension I

(Lower hoodledge component part)

• Lower battery support bracket

440 - 780 MPa (Lower hoodledge component part)

• Lower battery bracket J

(Lower hoodledge component part)

• Side radiator core stay

(Side radiator core support component part)

• Front roof rail

BRM

(Front roof rail component part)

• Upper inner front pillar

• Inner lock pillar assembly L

• Upper front pillar hinge brace

(Outer front pillar reinforcement component part)

• Outer sill reinforcement

• Outer side roof rail reinforcement M

• Outer lock pillar reinforcement

• Lower rear panel reinforcement

(Back panel assembly component part)

• Upper front door hinge reinforcement N

(Front door assembly component part)

• Lower front door hinge reinforcement

(Front door assembly component part)

• Outer rear door seat belt reinforcement O

(Rear door assembly component part)

• 4th floor bolster

(4th floor bolster assembly component part)

• 3rd floor bolster

P

(3rd floor bolster assembly component part)

Revision: August 2015 BRM-9 D23

REPAIRING HIGH STRENGTH STEEL

< PRECAUTION > [KING CAB]

Tensile strength Major applicable parts

• Inner front side member

(Frame assembly component part)

• Outer front side member

(Frame assembly component part)

• Outer rear side member

(Frame assembly component part)

• Inner center side member

(Frame assembly component part)

• Front bumper crossmember assembly

• Front suspension rear crossmember assembly

• 4th crossmember

440 - 780 MPa

• Diagonal member complete

• Upper rear engine mounting crossmember

(Rear engine mounting crossmember complete component part)

• Rear fuel tank crossmember

(7th crossmember component part)

• Spare wheel cross reinforcement

(Spare wheel crossmember assembly component part)

• Outer front side member extension

(Front side member extension assembly component part)

• Inner front side member extension

(Front side member extension assembly component part)

Read the following precautions when repairing HSS:

1. Additional points to consider

• The repair of reinforcements (such as side members) by heat-

ing is not recommended, because it may weaken the compo-

nent. When heating is unavoidable, never heat HSS parts

above 550°C (1,022°F).

Verify heating temperature with a thermometer.

(Crayon-type and other similar type thermometer are appropri-

ate.)

PIIA0115E

• When straightening body panels, use caution in pulling any HSS panel. Because HSS is very strong,

pulling may cause deformation in adjacent sections of the body. In this case, increase the number of

measuring points, and carefully pull the HSS panel.

• When cutting HSS panels, avoid gas (torch) cutting if possible.

Instead, use a saw to avoid weakening surrounding areas due

to heat. If gas (torch) cutting is unavoidable, allow a minimum

margin of 50 mm (1.97 in).

PIIA0117E

Revision: August 2015 BRM-10 D23

REPAIRING HIGH STRENGTH STEEL

< PRECAUTION > [KING CAB]

• When welding HSS panels, use spot welding whenever possi-

ble in order to minimize weakening surrounding areas due to A

heat.

If spot welding is impossible, use MIG. welding. Do not use

gas (torch) for welding because it is inferior in welding

B

strength.

PIIA0144E

D

• Spot welding on HSS panels is harder than that of an ordinary

steel panel.

Therefore, when cutting spot welds on a HSS panel, use a low E

speed high torque drill (1,000 to 1,200 rpm) to increase drill bit

durability and facilitate the operation.

F

G

PIIA0145E

2. Precautions in spot welding HSS H

This work should be performed under standard working condi-

tions. Always note the following when spot welding HSS:

• The electrode tip diameter must be sized properly according to

I

the metal thickness.

PIIA0146E BRM

• The panel surfaces must fit flush to each other, leaving no

gaps. L

PIIA0147E

Revision: August 2015 BRM-11 D23

REPAIRING HIGH STRENGTH STEEL

< PRECAUTION > [KING CAB]

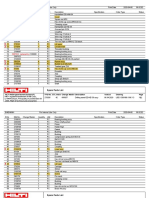

• Follow the specifications for the proper welding pitch.

Unit: mm (in)

Thickness (T) Minimum pitch (L)

0.6 (0.024) 10 (0.39) or more

0.8 (0.031) 12 (0.47) or more

1.0 (0.039) 18 (0.71) or more

1.2 (0.047) 20 (0.79) or more

1.6 (0.063) 27 (1.06) or more

1.8 (0.071) 31 (1.22) or more

JSKIA0781ZZ

Revision: August 2015 BRM-12 D23

REPAIRING MATERIAL

< PREPARATION > [KING CAB]

PREPARATION A

REPAIRING MATERIAL

Foam Repair INFOID:0000000011667141

B

During factory body assembly, foam insulators are installed in certain body panels and locations around the

vehicle. Use the following procedure(s) to replace any factory-installed foam insulators.

C

URETHANE FOAM APPLICATIONS

Use commercially available Urethane foam for sealant (foam material) repair of material used on vehicle.

D

<Urethane foam for foaming agent> 3M™ Automix™ Flexible Foam 08463 or equiva-

lent

Read instructions on product for fill procedures. E

Example of foaming agent filling operation procedure

1. Fill procedures after installation of service part.

a. Eliminate foam material remaining on vehicle side. F

b. Clean area after eliminating form insulator and foam material.

c. Install service part.

G

d. Insert nozzle into hole near fill area and fill foam material or fill enough to close gap with the service part.

BRM

L

JSKIA0129GB

Urethane foam

M

Nozzle insert hole

: Vehicle front

2. Fill procedures before installation of service part. N

a. Eliminate foam material remaining on vehicle side.

b. Clean area after eliminating foam insulator and foam material.

O

c. Fill foam material on wheelhouse outer side.

Revision: August 2015 BRM-13 D23

REPAIRING MATERIAL

< PREPARATION > [KING CAB]

Urethane foam

Fill while avoiding flange area

: Vehicle front

NOTE:

Fill enough to close gap with service part while avoiding flange

area.

d. Install service part.

NOTE: JSKIA0130GB

Refer to label for information on working times.

Revision: August 2015 BRM-14 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BODY COMPONENT PARTS

A

FOR THAILAND

FOR THAILAND : Underbody Component Parts INFOID:0000000011667143

B

Refer to parts catalogue for the replacement parts.

BRM

JSKIA5725ZZ

Revision: August 2015 BRM-15 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

AT models MT models

: Both sided anti-corrosive precoated steel sections

: High strength steel (HSS) sections

: Both sided anti-corrosive steel and HSS sections

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Rear floor assembly 440 —

Inner sill extension assembly (RH & LH) 440 ×

Front floor assembly 590 —

Inner front sill assembly (RH & LH) 590 ×

Cowl top assembly Under 440 ×

Upper dash assembly Under 440 ×

Side dash (RH & LH) under 440 —

Lower dash complete 440 —

Upper rear hoodledge (RH & LH) Under 440 ×

Hoodledge assembly (RH & LH) 440 ×

Lower hoodledge (RH & LH) 440 ×

Side radiator core support (RH & LH) 440 ×

NOTE:

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part.

FOR THAILAND : Body Component Parts INFOID:0000000011667144

Refer to parts catalogue for the replacement parts.

Revision: August 2015 BRM-16 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BRM

JSKIA5726ZZ

P

: Both sided anti-corrosive precoated steel sections

: High strength steel (HSS) sections

: Both sided anti-corrosive steel and HSS sections

Revision: August 2015 BRM-17 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Roof Under 440 —

Front roof rail 590 —

Roof bow No.1 Under 440 —

Roof bow No.2 Under 440 —

Rear roof rail Under 440 —

Hood Under 440 ×

Front fender (RH & LH) Under 440 ×

Upper inner front pillar (RH & LH) 590 —

Inner lock pillar assembly (RH & LH) 440 —

Outer front pillar reinforcement (RH & LH) 590 —

Outer sill reinforcement (RH & LH) 590 ×

Front fender bracket assembly (RH & LH) Under 440 ×

Outer side roof rail reinforcement (RH & LH) 590 —

Outer lock pillar reinforcement (RH & LH) 590 —

Outer front side body (RH & LH) Under 440 ×

Back panel assembly Under 440 ×

Front door assembly (RH & LH) 590 ×

Outer front door panel (RH & LH) Under 440 ×

Rear door assembly (RH & LH) 590 ×

Outer rear door panel (RH & LH) Under 440 ×

NOTE:

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part.

FOR THAILAND : Rear Body Component Parts INFOID:0000000011848201

Refer to parts catalogue for the replacement parts.

Revision: August 2015 BRM-18 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BRM

JSKIA5727ZZ

P

: Both sided anti-corrosive precoated steel sections

: Both sided anti-corrosive steel and HSS sections

Revision: August 2015 BRM-19 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Rear gate assembly Under 440 ×

Fuel filler lid assembly Under 440 ×

Rear body assembly Refer to No. −

Center floor panel Under 440 ×

Side panel assembly (RH & LH) Under 440 ×

Rear body tail floor bolster assembly Under 440 ×

4th floor bolster assembly 440 ×

3rd floor bolster assembly 440 ×

Floor bolster assembly Under 440 ×

1st floor bolster assembly Under 440 ×

Header panel frame assembly Under 440 ×

Header panel assembly Under 440 ×

NOTE:

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part.

FOR THAILAND : Frame Component Parts INFOID:0000000011680922

Refer to parts catalogue for the replacement parts.

Revision: August 2015 BRM-20 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BRM

JSKIA5728ZZ

P

4WD models 2WD models

: High strength steel (HSS) sections

Revision: August 2015 BRM-21 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Frame assembly Refer to No. −

Front bumper crossmember assembly 540 —

2nd crossmember Under 440 —

Front suspension rear crossmember assembly 440 —

4th crossmember 540 —

Diagonal member complete 540 —

Rear engine mounting crossmember complete 440 —

Fuel tank crossmember assembly Under 440 —

Fuel tank cover bracket assembly (RH) Under 440 —

Fuel tank cover bracket assembly (LH) Under 440 —

7th crossmember 440 —

Torsion crossmember assembly Under 440 —

Spare wheel crossmember assembly 440 —

Front side member extension assembly (RH & LH) 540 —

1st cab mounting bracket (RH & LH) Under 440 —

Front suspension cross reinforcement (RH & LH) Under 440 —

Front suspension bracket assembly (RH & LH) Under 440 —

Front brake hose bracket (RH & LH) Under 440 —

Front bound bumper bracket assembly (RH & LH) Under 440 —

2nd cab mounting bracket (RH & LH) Under 440 —

Lower front link mounting bracket assembly (RH & LH) Under 440 —

Engine mounting bracket assembly (RH & LH) Under 440 —

4th crossmember gusset (RH & LH) Under 440 —

Rear spring front bracket assembly (RH & LH) Under 440 —

3rd cab mounting bracket (RH & LH) Under 440 —

1st rear body mounting bracket (RH & LH) Under 440 —

2nd rear body mounting bracket (RH & LH) Under 440 —

Rear bound bumper bracket assembly (RH & LH) Under 440 —

Rear shock absorber bracket assembly (RH & LH) Under 440 —

ABS sensor bracket (RH & LH) Under 440 —

Crossmember collar (RH & LH) Under 440 —

Rear spring rear bracket assembly (RH & LH) Under 440 —

Rear brake hose bracket Under 440 —

4th rear body mounting bracket (RH & LH) Under 440 —

Crossmember gusset (RH & LH) Under 440 —

5th rear body mounting bracket (RH & LH) Under 440 —

NOTE:

Revision: August 2015 BRM-22 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part. A

FOR AUSTRALIA AND NEW ZEALAND

FOR AUSTRALIA AND NEW ZEALAND : Underbody Component Parts INFOID:0000000011853122

B

Refer to parts catalogue for the replacement parts.

C

BRM

JSKIA5729ZZ

Revision: August 2015 BRM-23 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

AT models MT models

: Both sided anti-corrosive precoated steel sections

: High strength steel (HSS) sections

: Both sided anti-corrosive steel and HSS sections

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Rear floor assembly 440 —

Inner sill extension assembly (RH & LH) 440 ×

Front floor assembly 590 —

Inner front sill assembly (RH & LH) 590 ×

Cowl top assembly Under 440 ×

Upper dash assembly Under 440 ×

Side dash (RH & LH) under 440 —

Lower dash complete 440 —

Upper rear hoodledge (RH & LH) Under 440 ×

Hoodledge assembly (RH & LH) 440 ×

Lower hoodledge (RH & LH) 440 ×

Side radiator core support (RH & LH) 440 ×

NOTE:

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part.

FOR AUSTRALIA AND NEW ZEALAND : Body Component Parts INFOID:0000000011853123

Refer to parts catalogue for the replacement parts.

Revision: August 2015 BRM-24 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BRM

JSKIA5730ZZ

P

: Both sided anti-corrosive precoated steel sections

: High strength steel (HSS) sections

: Both sided anti-corrosive steel and HSS sections

Revision: August 2015 BRM-25 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Roof Under 440 —

Front roof rail 590 —

Roof bow No.1 Under 440 —

Roof bow No.2 Under 440 —

Rear roof rail Under 440 —

Hood Under 440 ×

Front fender (RH & LH) Under 440 ×

Upper inner front pillar (RH & LH) 590 —

Inner lock pillar assembly (RH & LH) 440 —

Outer front pillar reinforcement (RH & LH) 590 —

Outer sill reinforcement (RH & LH) 590 ×

Front fender bracket assembly (RH & LH) Under 440 ×

Outer side roof rail reinforcement (RH & LH) 590 —

Outer lock pillar reinforcement (RH & LH) 590 —

Outer front side body (RH & LH) Under 440 ×

Back panel assembly Under 440 ×

Front door assembly (RH & LH) 590 ×

Outer front door panel (RH & LH) Under 440 ×

Rear door assembly (RH & LH) 590 ×

Outer rear door panel (RH & LH) Under 440 ×

NOTE:

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part.

FOR AUSTRALIA AND NEW ZEALAND : Rear Body Component Parts INFOID:0000000011863868

Refer to parts catalogue for the replacement parts.

Revision: August 2015 BRM-26 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BRM

JSKIA5727ZZ

P

: Both sided anti-corrosive precoated steel sections

: Both sided anti-corrosive steel and HSS sections

Revision: August 2015 BRM-27 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Rear gate assembly Under 440 ×

Fuel filler lid assembly Under 440 ×

Rear body assembly Refer to No. −

Center floor panel Under 440 ×

Side panel assembly (RH & LH) Under 440 ×

Rear body tail floor bolster assembly Under 440 ×

4th floor bolster assembly 440 ×

3rd floor bolster assembly 440 ×

Floor bolster assembly Under 440 ×

1st floor bolster assembly Under 440 ×

Header panel frame assembly Under 440 ×

Header panel assembly Under 440 ×

NOTE:

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part.

FOR AUSTRALIA AND NEW ZEALAND : Frame Component Parts INFOID:0000000011863869

Refer to parts catalogue for the replacement parts.

Revision: August 2015 BRM-28 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

BRM

JSKIA5728ZZ

P

4WD models 2WD models

: High strength steel (HSS) sections

Revision: August 2015 BRM-29 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

Both sided

Tensile strength anti-corrosive

No. Parts name

(MPa) precoated

steel sections

Frame assembly Refer to No. −

Front bumper crossmember assembly 540 —

2nd crossmember Under 440 —

Front suspension rear crossmember assembly 440 —

4th crossmember 540 —

Diagonal member complete 540 —

Rear engine mounting crossmember complete 440 —

Fuel tank crossmember assembly Under 440 —

Fuel tank cover bracket assembly (RH) Under 440 —

Fuel tank cover bracket assembly (LH) Under 440 —

7th crossmember 440 —

Torsion crossmember assembly Under 440 —

Spare wheel crossmember assembly 440 —

Front side member extension assembly (RH & LH) 540 —

1st cab mounting bracket (RH & LH) Under 440 —

Front suspension cross reinforcement (RH & LH) Under 440 —

Front suspension bracket assembly (RH & LH) Under 440 —

Front brake hose bracket (RH & LH) Under 440 —

Front bound bumper bracket assembly (RH & LH) Under 440 —

2nd cab mounting bracket (RH & LH) Under 440 —

Lower front link mounting bracket assembly (RH & LH) Under 440 —

Engine mounting bracket assembly (RH & LH) Under 440 —

4th crossmember gusset (RH & LH) Under 440 —

Rear spring front bracket assembly (RH & LH) Under 440 —

3rd cab mounting bracket (RH & LH) Under 440 —

1st rear body mounting bracket (RH & LH) Under 440 —

2nd rear body mounting bracket (RH & LH) Under 440 —

Rear bound bumper bracket assembly (RH & LH) Under 440 —

Rear shock absorber bracket assembly (RH & LH) Under 440 —

ABS sensor bracket (RH & LH) Under 440 —

Crossmember collar (RH & LH) Under 440 —

Rear spring rear bracket assembly (RH & LH) Under 440 —

Rear brake hose bracket Under 440 —

4th rear body mounting bracket (RH & LH) Under 440 —

Crossmember gusset (RH & LH) Under 440 —

5th rear body mounting bracket (RH & LH) Under 440 —

NOTE:

Revision: August 2015 BRM-30 D23

BODY COMPONENT PARTS

< PREPARATION > [KING CAB]

• For the parts without a number described in the figure, it is supplied only with the assembly part that the part is included with.

• Tensile strength column shows the largest strength value of a part in the component part. A

BRM

Revision: August 2015 BRM-31 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

REMOVAL AND INSTALLATION

CORROSION PROTECTION

Description INFOID:0000000011680946

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

To improve repairability and corrosion resistance, a new type of anti-

corrosive precoated steel sheet has been adopted replacing conven-

tional zinc-coated steel sheet.

Galvannealed steel is electroplated and heated to form Zinc-iron

alloy, which provides excellent and long term corrosion resistance

with cationic electrodeposition primer.

SIIA2294E

Nissan Genuine Service Parts are fabricated from galvannealed steel. Therefore, it is recommended that

GENUINE NISSAN PARTS or equivalent be used for panel replacement to maintain the anti-corrosive perfor-

mance built into the vehicle at the factory.

PHOSPHATE COATING TREATMENT AND CATIONIC ELECTRODEPOSITION PRIMER

A phosphate coating treatment and a cationic electrodeposition

primer, which provide excellent corrosion protection, are employed

on all body components.

CAUTION:

Confine paint removal during welding operations to an absolute

minimum.

PIIA0095E

Nissan Genuine Service Parts are also treated in the same manner. Therefore, it is recommended that GENU-

INE NISSAN PARTS or an equivalent be used for panel replacement to maintain anti-corrosive performance

built into the vehicle at the factory.

FOR THAILAND

FOR THAILAND : Undercoating INFOID:0000000011680948

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoat-

ing which is rust resistant, soundproof, vibration-proof, shock-resistant, adhesive, and durable.

PRECAUTIONS IN UNDERCOATING

1. Never apply undercoating to any place unless specified (such as the areas above the muffler and three

way catalyst that are subjected to heat).

2. Never undercoat the exhaust pipe or other parts that become hot.

3. Never undercoat rotating parts.

4. Apply bitumen wax after applying undercoating.

5. After putting seal on the vehicle, put undercoating on it.

Revision: August 2015 BRM-32 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5733ZZ F

: Undercoated areas

: Sealed portions G

FOR THAILAND : Stone Guard Coat INFOID:0000000011680950

To prevent damage caused by stones, the lower outer body panel (fender, door, etc.) have an additional layer H

of Stone Guard Coating over the ED primer coating. When replacing or repairing these panels, apply Stone

Guard coating to the same portions as before. Use a coating which is rust preventive, durable, shock-resistant

and has a long shelf life. I

CAB

BRM

Revision: August 2015 BRM-33 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5735ZZ

: Stone guard coated portions

REAR BODY

Revision: August 2015 BRM-34 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5736ZZ

BRM

: Stone guard coated portions

L

FOR THAILAND : Body Sealing INFOID:0000000011680952

The following figure shows the areas that are sealed at the factory. Sealant that is applied to these areas M

should be smooth and free from cuts or gaps. Care should be taken not to apply an excess amount of sealant

and not to allow other unaffected parts to come into contact with the sealant.

CAB N

Revision: August 2015 BRM-35 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5737ZZ

: Vehicle front

: Sealed portions

Revision: August 2015 BRM-36 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

JSKIA7248ZZ

P

: Vehicle front

: Sealed portions

Revision: August 2015 BRM-37 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5739ZZ

: Sealed portions

REAR BODY

Revision: August 2015 BRM-38 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5741ZZ

: Vehicle front O

: Sealed portions

Revision: August 2015 BRM-39 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5742ZZ

Without rear skirt panel models With rear skirt panel models

: Vehicle front

: Sealed portions

FOR AUSTRALIA AND NEW ZEALAND

Revision: August 2015 BRM-40 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

FOR AUSTRALIA AND NEW ZEALAND : Undercoating INFOID:0000000011863884

A

The underside of the floor and wheelhouse are undercoated to prevent rust, vibration, noise and stone chip-

ping. Therefore, when such a panel is replaced or repaired, apply undercoating to that part. Use an undercoat-

ing which is rust resistant, soundproof, vibration-proof, shock-resistant, adhesive, and durable. B

PRECAUTIONS IN UNDERCOATING

1. Never apply undercoating to any place unless specified (such as the areas above the muffler and three

way catalyst that are subjected to heat). C

2. Never undercoat the exhaust pipe or other parts that become hot.

3. Never undercoat rotating parts.

4. Apply bitumen wax after applying undercoating. D

5. After putting seal on the vehicle, put undercoating on it.

E

J

JSKIA5733ZZ

: Undercoated areas

: Sealed portions BRM

FOR AUSTRALIA AND NEW ZEALAND : Stone Guard Coat INFOID:0000000011863885

L

To prevent damage caused by stones, the lower outer body panel (fender, door, etc.) have an additional layer

of Stone Guard Coating over the ED primer coating. When replacing or repairing these panels, apply Stone

Guard coating to the same portions as before. Use a coating which is rust preventive, durable, shock-resistant

and has a long shelf life. M

CAB

N

Revision: August 2015 BRM-41 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5735ZZ

: Stone guard coated portions

REAR BODY

Revision: August 2015 BRM-42 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5736ZZ

BRM

: Stone guard coated portions

L

FOR AUSTRALIA AND NEW ZEALAND : Body Sealing INFOID:0000000011688026

The following figure shows the areas that are sealed at the factory. Sealant that is applied to these areas M

should be smooth and free from cuts or gaps. Care should be taken not to apply an excess amount of sealant

and not to allow other unaffected parts to come into contact with the sealant.

CAB N

Revision: August 2015 BRM-43 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5749ZZ

: Vehicle front

: Sealed portions

Revision: August 2015 BRM-44 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

JSKIA7249ZZ

P

: Vehicle front

: Sealed portions

Revision: August 2015 BRM-45 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5739ZZ

: Sealed portions

REAR BODY

Revision: August 2015 BRM-46 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5741ZZ

: Vehicle front O

: Sealed portions

Revision: August 2015 BRM-47 D23

CORROSION PROTECTION

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5742ZZ

Without rear skirt panel models With rear skirt panel models

: Vehicle front

: Sealed portions

Revision: August 2015 BRM-48 D23

BODY CONSTRUCTION

< REMOVAL AND INSTALLATION > [KING CAB]

BODY CONSTRUCTION

A

FOR THAILAND

FOR THAILAND : Body Construction INFOID:0000000011681252

B

BRM

JSKIA5755ZZ

Outer side body Upper front pillar hinge brace Upper inner front pillar

Weld nut Side dash Upper dash

Revision: August 2015 BRM-49 D23

BODY CONSTRUCTION

< REMOVAL AND INSTALLATION > [KING CAB]

Upper rear hoodledge Lower front pillar reinforcement Lower dash

Front fender bracket Lower front pillar bulkhead Front floor

Inner sill Outer sill reinforcement Front seat mounting front cross-

member

Outer front seat mounting front 2nd crossmember extension Outer side roof rail reinforcement

bracket

Roof 1st roof bow Inner front side roof rail

Inner lock pillar Upper outer lock pillar reinforcement 4th cab mounting crossmember

Inner sill wheelhouse Rear seat mounting bracket Outer rear seat mounting bracket

Rear floor Hinge brace Lower outer lock pillar reinforcement

FOR AUSTRALIA AND NEW ZEALAND

Revision: August 2015 BRM-50 D23

BODY CONSTRUCTION

< REMOVAL AND INSTALLATION > [KING CAB]

FOR AUSTRALIA AND NEW ZEALAND : Body Construction INFOID:0000000011853121

BRM

P

JSKIA5756ZZ

Outer side body Upper front pillar hinge brace Upper outer front pillar

Upper inner front pillar Weld nut Inner front pillar reinforcement

Side dash Upper dash Upper rear hoodledge

Lower front pillar reinforcement Lower dash Front fender bracket

Revision: August 2015 BRM-51 D23

BODY CONSTRUCTION

< REMOVAL AND INSTALLATION > [KING CAB]

Lower front pillar bulkhead Front floor Inner sill

Outer sill reinforcement Front seat mounting front cross- Outer front seat mounting front

member bracket

2nd crossmember extension Outer side roof rail reinforcement Roof

1st roof bow Inner front side roof rail Inner lock pillar

Seat belt anchor bracket Inner rear pillar reinforcement Upper outer lock pillar reinforcement

4th cab mounting crossmember Inner sill wheelhouse Rear seat mounting bracket

Outer rear seat mounting bracket Rear floor Hinge brace

Lower outer lock pillar reinforcement

Revision: August 2015 BRM-52 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

REPLACEMENT OPERATIONS

A

Description INFOID:0000000011667153

• This section is prepared for technicians who have attained a high level of skill and experience in repairing B

collision-damaged vehicles and also use modern service tools and equipment. Persons unfamiliar with body

repair techniques should not attempt to repair collision-damaged vehicles by using this section.

• Technicians are also encouraged to read the Body Repair Manual (Fundamentals) in order to ensure that the

original functions and quality of the vehicle are maintained. The Body Repair Manual (Fundamentals) con- C

tains additional information, including cautions and warnings, that are not including in this manual. Techni-

cians should refer to both manuals to ensure proper repair.

• Please note that this information is prepared for worldwide usage, and as such, certain procedures might not D

apply in some regions or countries.

The symbols used in this section for welding operations are shown below.

Symbol marks Description

E

F

2-spot welds

G

JSKIA0049ZZ

H

JSKIA0053ZZ

3-spot welds

I

JSKIA0050ZZ

BRM

JSKIA0054ZZ L

MIG plug weld

For 3 panels plug weld method

M

JSKIA0051ZZ

N

JSKIA0055ZZ

MIG seam weld / Point weld

P

JSKIA0052ZZ JSKIA0056ZZ

Revision: August 2015 BRM-53 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

• Front pillar butt joint can be determined anywhere within shaded

area as shown in the figure. The best location for the butt joint is at

position A due to the construction of the vehicle.

PIIA0150E

• Determine cutting position and record distance from the locating

indent. Use this distance when cutting the service part. Cut outer

front pillar over 60 mm (2.36 in) above the inner front pillar cut

position.

JSKIA0104GB

• Prepare a cutting jig to make outer pillar easier to cut. Also, this will

permit the service part to be accurately cut at the joint position.

JSKIA0105GB

• An example of cutting operation using a cutting jig is as per the fol-

lowing.

1. Mark cutting lines.

A: Cut position of outer pillar

B: Cut position of inner pillar

2. Align cutting line with notch on jig. Clamp jig to pillar.

3. Cut outer pillar along groove of jig (at position A).

4. Remove jig and cut remaining portions.

5. Cut inner pillar at position B in same manner.

PIIA0153E

FOR THAILAND

Revision: August 2015 BRM-54 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR THAILAND : Radiator Core Support INFOID:0000000011667155

BRM

JSKIA5626ZZ O

: Vehicle front

: Weld the parts onto the back of the component part. P

Replacement part

z Side radiator core support

FOR THAILAND : Hoodledge INFOID:0000000011667156

Work after radiator core support is removed.

Revision: August 2015 BRM-55 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5627ZZ

: Vehicle front

: Weld the parts onto the back of the component part.

Replacement part

z Hoodledge assembly z Upper rear hoodledge

View D: Before installing upper rear hoodledge

FOR THAILAND : Hoodledge (Partial Replacement) INFOID:0000000011667157

Work after radiator core support is removed.

Revision: August 2015 BRM-56 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5628GB

Unit: mm (in) O

Replacement part

z Lower hoodledge

P

FOR THAILAND : Front Pillar INFOID:0000000011667160

Work after upper rear hoodledge is removed.

Revision: August 2015 BRM-57 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5633GB

Body sealing Urethane foam

Unit: mm (in)

: Vehicle front

Replacement part

z Outer front side body z Outer front pillar reinforcement z Side dash

z Upper inner front pillar z Front fender bracket assembly

Revision: August 2015 BRM-58 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5634GB

Urethane foam O

Unit: mm (in)

: Vehicle front

P

: N·m (kg-m, ft-lb)

View B: Before installing outer front side body and outer front pillar reinforcement

Revision: August 2015 BRM-59 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5635GB

Body sealing

Unit: mm (in)

: Vehicle front

Revision: August 2015 BRM-60 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR THAILAND : Outer Sill (Partial Replacement) INFOID:0000000011667162

BRM

JSKIA5644GB O

Unit: mm (in)

: Vehicle front P

Replacement part

z Outer front side body

Revision: August 2015 BRM-61 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR THAILAND : Outer Sill INFOID:0000000011667163

JSKIA5647GB

Urethane foam

Unit: mm (in)

: Vehicle front

Replacement part

z Outer front side body z Front fender bracket assembly

FOR THAILAND : Rear Cab Pillar INFOID:0000000011667164

Work after back panel is removed.

Revision: August 2015 BRM-62 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5652GB

Urethane foam O

Unit: mm (in)

: Vehicle front

Replacement part P

z Outer front side body

Revision: August 2015 BRM-63 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5653GB

Urethane foam

Unit: mm (in)

: Vehicle front

Revision: August 2015 BRM-64 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR THAILAND : Back Panel INFOID:0000000011667165

BRM

JSKIA5658GB O

Body sealing

Unit: mm (in) P

: Vehicle front

: Welding method, the number of welding points, and the tightening torque apply to both side of the vehicle.

: Sealing portion apply to both side of the vehicle.

: N·m (kg-m, in-lb)

Replacement part

z Back panel assembly

Revision: August 2015 BRM-65 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR THAILAND : Rear Body Fender INFOID:0000000011667166

JSKIA5661GB

: Vehicle front

: Weld the parts onto the back of the component part.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

Replacement part

z Side panel assembly

Revision: August 2015 BRM-66 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5662GB

: Vehicle front O

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

P

FOR THAILAND : Rear Crossmember INFOID:0000000011667167

Work after rear body fender is removed.

Revision: August 2015 BRM-67 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5667GB

: Vehicle front

: Welding method and the number of welding points apply to both side of the vehicle.

: N·m (kg-m, ft-lb)

: N·m (kg-m, in-lb)

Replacement part

z Rear body tail floor bolster assembly

FOR THAILAND : Crush Horn INFOID:0000000011667168

CAUTION:

Revision: August 2015 BRM-68 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

Create the reinforcing sheet from the redundant area of service parts for butt welding area.

Weld the reinforcing sheet on the back of butt welding area, and then perform butt welding. A

After welding, apply anti-corrosive wax on the reinforcing sheet-welded area.

BRM

O

JSKIA5669GB

Front side member closing bracket Reinforcing sheet

P

Unit: mm (in)

: Vehicle front

Replacement part

z Front side member extension as-

sembly

View A: Before installing front side member closing bracket and outer front side member extension

Revision: August 2015 BRM-69 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

View B: Before installing front side member closing bracket

FOR THAILAND : Roof INFOID:0000000011667371

JSKIA5670ZZ

Body sealing

: Vehicle front

: Welding method and the number of welding points apply to both side of the vehicle.

Replacement part

z Roof z Roof bow No.1 z Roof bow No.2

FOR AUSTRALIA AND NEW ZEALAND

Revision: August 2015 BRM-70 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR AUSTRALIA AND NEW ZEALAND : Radiator Core Support INFOID:0000000011854129

BRM

JSKIA5626ZZ O

: Vehicle front

: Weld the parts onto the back of the component part. P

Replacement part

z Side radiator core support

FOR AUSTRALIA AND NEW ZEALAND : Hoodledge INFOID:0000000011854130

Work after radiator core support is removed.

Revision: August 2015 BRM-71 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5627ZZ

: Vehicle front

: Weld the parts onto the back of the component part.

Replacement part

z Hoodledge assembly z Upper rear hoodledge

View D: Before installing upper rear hoodledge

FOR AUSTRALIA AND NEW ZEALAND : Hoodledge (Partial Replacement)

INFOID:0000000011854131

Work after radiator core support is removed.

Revision: August 2015 BRM-72 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5628GB

Unit: mm (in) O

Replacement part

z Lower hoodledge

P

FOR AUSTRALIA AND NEW ZEALAND : Front Pillar INFOID:0000000011854132

Work after upper rear hoodledge is removed.

Revision: August 2015 BRM-73 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA7376GB

Body sealing Urethane foam

Unit: mm (in)

: Vehicle front

Replacement part

z Outer front side body z Outer front pillar reinforcement z Side dash

z Upper inner front pillar z Front fender bracket assembly

View B: Before installing outer front side body and outer front pillar reinforcement

Revision: August 2015 BRM-74 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA7377GB

Urethane foam O

Unit: mm (in)

: Vehicle front

P

: N·m (kg-m, ft-lb)

Revision: August 2015 BRM-75 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

JSKIA5632GB

Body sealing Urethane foam

Unit: mm (in)

: Vehicle front

View J: Before installing upper inner front pillar, outer front side body and outer front pillar reinforcement

View N: Before installing outer front side body

Revision: August 2015 BRM-76 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR AUSTRALIA AND NEW ZEALAND : Outer Sill (Partial Replacement) INFOID:0000000011854133

BRM

JSKIA5644GB O

Unit: mm (in)

: Vehicle front P

Replacement part

z Outer front side body

Revision: August 2015 BRM-77 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

FOR AUSTRALIA AND NEW ZEALAND : Outer Sill INFOID:0000000011854134

JSKIA7379GB

Urethane foam

Unit: mm (in)

: Vehicle front

Replacement part

z Outer front side body z Front fender bracket assembly

FOR AUSTRALIA AND NEW ZEALAND : Rear Cab Pillar INFOID:0000000011854135

Work after back panel is removed.

Revision: August 2015 BRM-78 D23

REPLACEMENT OPERATIONS

< REMOVAL AND INSTALLATION > [KING CAB]

BRM

N

JSKIA5652GB

Urethane foam O

Unit: mm (in)

: Vehicle front

Replacement part P

z Outer front side body

Revision: August 2015 BRM-79 D23

REPLACEMENT OPERATIONS